In the world of modern manufacturing, few roles are as critical and hands-on as the Computer Numerical Control (CNC) Operator. These skilled professionals are the bridge between digital design and physical reality, operating sophisticated machinery to create precision parts for everything from medical devices to aerospace components. If you're considering a career in this dynamic field, your first question is likely about earning potential.

So, what can you expect to earn? While entry-level operators might start around $40,000 per year, experienced and specialized CNC professionals can command salaries well over $75,000. This guide will provide a comprehensive breakdown of CNC operator salaries, the factors that drive your earning potential, and the promising future of this essential career.

What Does a CNC Operator Do?

Before we dive into the numbers, let's clarify the role. A CNC Operator is a skilled technician who sets up and operates computer numerical control machines to cut, shape, and finish materials like metal, plastic, or wood. Their daily responsibilities often include:

- Reading Technical Blueprints: Interpreting engineering drawings and specifications to understand the final product's requirements.

- Machine Setup: Loading materials into the machine, installing the correct cutting tools, and calibrating the equipment for the job.

- Programming & Operation: Inputting pre-written programs (often in G-code) or performing minor programming edits directly at the machine's control panel.

- Quality Control: Monitoring the machining process and using precision measuring tools like micrometers and calipers to ensure parts meet strict quality standards.

- Maintenance: Performing routine cleaning and maintenance on the machinery to ensure optimal performance.

It is a role that perfectly blends mechanical aptitude with technological proficiency.

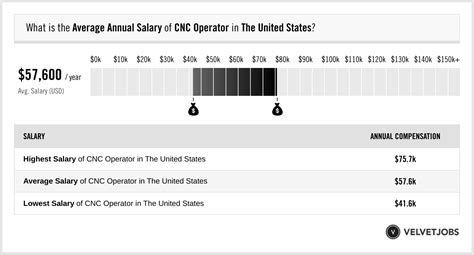

Average CNC Operator Salary

When analyzing salary data, it's important to look at medians and ranges to get a complete picture.

According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for machinists, a category that includes CNC operators, was $52,680 in May 2022, which translates to approximately $25.33 per hour.

However, this median figure is just a starting point. Data from leading salary aggregators reveals a more detailed spectrum:

- Salary.com reports that the typical salary range for a CNC Machine Operator in the United States falls between $46,081 and $61,563 as of May 2024.

- Payscale shows a similar average base salary of around $51,000 per year, with a reported range from $38,000 to $71,000.

This wide range highlights a crucial point: your specific salary as a CNC operator is not fixed. It is heavily influenced by a combination of key factors.

Key Factors That Influence Salary

Advancing your earnings in this field is directly tied to enhancing your skills, experience, and strategic career choices. Here are the primary factors that will determine your paycheck.

### Level of Education and Certification

While a four-year university degree is not required for a CNC operator role, formal training is highly valued and directly impacts starting salary and career progression.

- Baseline: A high school diploma or GED is the minimum requirement.

- Higher Earnings: Candidates with a certificate from a technical or vocational school, or an associate's degree in Machining Technology, often command higher starting salaries. These programs provide foundational knowledge in blueprint reading, shop math, and machine operation.

- Certifications: Industry-recognized credentials, such as those from the National Institute for Metalworking Skills (NIMS), are a powerful way to validate your skills and boost your value to employers.

### Years of Experience

Experience is arguably the most significant driver of salary growth for a CNC operator. Employers pay a premium for operators who are reliable, efficient, and can work with minimal supervision.

- Entry-Level (0-2 years): Expect a salary in the $40,000 to $48,000 range. The focus at this stage is on learning basic machine operation, safety protocols, and quality checks.

- Mid-Career (3-9 years): With proven experience, operators can expect to earn between $48,000 and $62,000. These professionals are proficient in machine setups, can troubleshoot minor issues, and may perform some programming edits.

- Senior/Experienced (10+ years): Highly experienced operators and CNC programmers can earn $62,000 to $75,000+. These experts handle the most complex jobs, are capable of full machine programming (G-code and M-code), can operate advanced multi-axis machines, and often take on leadership or training roles.

### Geographic Location

Where you work matters. Salaries for CNC operators vary significantly based on the state and metropolitan area, driven by local demand and cost of living. States with strong manufacturing, aerospace, or tech industries tend to offer higher wages.

For example, data suggests that CNC operators in states like Washington, Massachusetts, Alaska, and Connecticut often earn salaries above the national average. Conversely, salaries may be lower in regions with a lower cost of living and less concentrated manufacturing activity.

### Company Type and Industry

The type of company you work for and its industry can have a major impact on your earnings.

- Company Size: Large corporations, especially in high-tech sectors, often have more structured pay scales and better benefits packages compared to smaller, local job shops.

- Industry: The highest salaries are typically found in industries where precision and reliability are non-negotiable. These include:

- Aerospace and Defense: Manufacturing components for aircraft and military hardware.

- Medical Device Manufacturing: Creating surgical instruments, implants, and other medical equipment with extremely tight tolerances.

- Automotive: Especially in roles related to prototyping and high-performance parts.

### Area of Specialization

Not all CNC machines are created equal, and specializing in more complex equipment is a direct path to a higher salary.

- Basic Operation: Operators who primarily work with standard 3-axis mills and lathes will earn a solid, baseline salary.

- Advanced Specialization: A significant pay increase comes with the ability to set up, program, and operate more complex machinery. Expertise in 5-axis milling, mill-turn centers, or Swiss-style CNC lathes is highly sought after and commands a premium salary.

- Operator vs. Machinist/Programmer: The most significant pay jump occurs when you transition from a pure "operator" (loading parts and pressing a button) to a CNC Machinist or CNC Programmer who can plan a job from a blueprint, write the full program, and execute the production run.

Job Outlook

The future for skilled CNC operators is bright. The U.S. Bureau of Labor Statistics (BLS) projects that employment for machinists and tool and die makers will grow 3 percent from 2022 to 2032, which is about as fast as the average for all occupations.

While automation is a frequent topic of discussion, in this field, it increases the demand for highly skilled professionals. As machinery becomes more complex and automated, companies need fewer manual laborers but have a greater need for technicians who can program, manage, and troubleshoot these sophisticated systems. The operators who embrace continuous learning will be the most in-demand.

Conclusion

A career as a CNC operator offers a stable and rewarding path with significant potential for financial growth. While the national median salary provides a solid benchmark, your individual earnings are directly within your control.

The key takeaway is that advancement is tied to skill. By pursuing formal training, gaining hands-on experience with complex machinery, earning industry certifications, and specializing in high-demand sectors, you can build a career that is not only financially lucrative but also places you at the heart of modern innovation. For anyone with a mechanical mind and a passion for technology, the path of a CNC operator is an excellent choice for a durable and prosperous career.