In the complex, interconnected machinery of our modern world, there is a class of essential professionals who work tirelessly behind the scenes. They are the individuals who keep the lights on, the water flowing, the factories producing, and the buildings standing. These are the maintenance technicians, the unsung heroes of operational continuity. If you are a natural problem-solver, enjoy working with your hands, and seek a career with stability and significant earning potential, then you've arrived at the right place. This guide is your definitive resource for understanding the maintenance technician salary, career trajectory, and the steps required to enter and excel in this vital field.

While often overlooked, the financial rewards for skilled maintenance professionals are substantial. The median salary is competitive, but with specialization, experience, and strategic career choices, top-tier technicians can command salaries well into the upper echelons of skilled trades, often exceeding $85,000 or more annually. I once managed a large commercial property where a critical HVAC chiller failed on the hottest day of the year. While panic set in among the management team, it was a senior maintenance technician who, with calm expertise, diagnosed a complex electrical fault and had the system back online in hours, single-handedly preventing tens of thousands of dollars in business disruption. That moment solidified my deep respect for the immense value and expertise this profession represents.

This article will serve as your comprehensive roadmap. We will dissect every component of a maintenance technician's compensation, explore the factors that can dramatically increase your earnings, and lay out a clear, step-by-step plan to launch your career.

### Table of Contents

- [What Does a Maintenance Technician Do?](#what-does-a-maintenance-technician-do)

- [Average Maintenance Technician Salary: A Deep Dive](#average-maintenance-technician-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

What Does a Maintenance Technician Do?

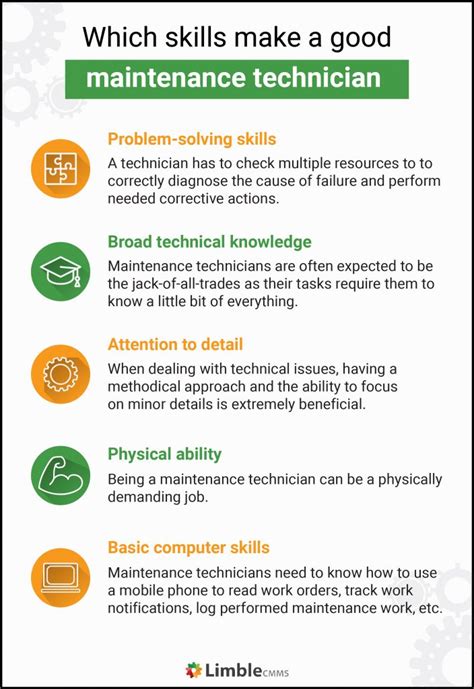

At its core, a maintenance technician is a highly skilled problem-solver responsible for ensuring that machinery, equipment, and physical facilities are operating safely, reliably, and efficiently. They are the first line of defense against costly breakdowns and operational downtime. The scope of their work is incredibly broad, ranging from a technician who maintains the HVAC and plumbing systems in a large apartment complex to one who services complex robotic arms on an automotive assembly line.

Their work can be broadly categorized into two main functions: preventive maintenance and corrective maintenance.

1. Preventive Maintenance (PM): This is the proactive side of the job. Technicians follow a scheduled maintenance plan to inspect, clean, lubricate, and perform minor adjustments on equipment to prevent failures before they happen. This could involve changing filters on an air handling unit, greasing the bearings on a conveyor belt, or testing the functionality of emergency lighting systems. Effective PM is the cornerstone of a well-run facility and a key performance indicator for maintenance departments.

2. Corrective (or Reactive) Maintenance: This is the reactive, "firefighting" side of the role. When a piece of equipment breaks down or a system fails, the maintenance technician is called upon to diagnose the root cause of the problem and perform the necessary repairs. This requires a deep understanding of mechanical, electrical, hydraulic, and pneumatic systems, as well as the ability to read blueprints, schematics, and technical manuals.

### Daily Tasks and Typical Projects

A maintenance technician's day is rarely monotonous. The demands can shift from routine tasks to high-pressure emergencies in an instant. Common responsibilities include:

- Inspecting and Diagnosing Issues: Performing regular checks on equipment and using diagnostic tools (like multimeters, vibration analyzers, or thermal cameras) to identify potential problems.

- Performing Repairs: Disassembling machinery, replacing worn or broken parts (such as motors, belts, valves, and circuit boards), and reassembling equipment to operational standards.

- Conducting Installations: Installing new machinery, equipment, or facility components according to manufacturer specifications and safety codes.

- System Maintenance: Working on various building systems, including plumbing (fixing leaks, clearing clogs), electrical (repairing outlets, troubleshooting circuits), and HVAC (servicing furnaces, air conditioners).

- Documentation: Meticulously recording all maintenance and repair work in a logbook or a Computerized Maintenance Management System (CMMS). This data is crucial for tracking equipment history, managing inventory, and planning future maintenance.

- Adhering to Safety Protocols: Following all safety procedures, including lock-out/tag-out (LOTO) when working on energized equipment, to ensure a safe work environment for themselves and others.

### A "Day in the Life" of an Industrial Maintenance Technician

To make this role more tangible, let's walk through a typical day for a technician in a manufacturing plant:

- 7:00 AM: Arrive and attend the daily team huddle. Review the work order queue in the CMMS. A high-priority task is a preventive maintenance check on the main packaging line, and a lower-priority ticket is to investigate a minor oil leak on a hydraulic press.

- 7:30 AM: Gather tools and perform the scheduled PM on the packaging line. This involves lubricating chains, inspecting sensors, checking belt tension, and cleaning photo-eyes. The work is logged in the CMMS upon completion.

- 10:00 AM: An urgent call comes over the radio: a CNC machine has stopped mid-cycle with an alarm code. The technician heads to the machine, talks to the operator, and pulls up the machine's electrical schematics on a tablet. Using a multimeter, they diagnose the problem as a faulty proximity switch.

- 11:00 AM: The technician gets the correct replacement switch from the parts storeroom, installs it, and works with the operator to test the machine, confirming it's back to full functionality.

- 12:00 PM: Lunch Break.

- 12:30 PM: Time to address the hydraulic press leak. After a thorough inspection, the technician identifies a cracked fitting as the culprit. They fabricate a replacement hydraulic hose and install it, cleaning up the spilled oil afterward.

- 3:00 PM: With the urgent tasks completed, the technician dedicates time to a small improvement project: installing a new set of LED lights over a dimly lit workspace to improve safety and visibility for operators.

- 4:00 PM: The final hour is spent updating the CMMS with detailed notes on all repairs performed, ordering any parts that were used, and tidying the maintenance workshop to prepare for the next day.

This example illustrates the dynamic blend of planned work, emergency response, and problem-solving that defines the career.

Average Maintenance Technician Salary: A Deep Dive

Understanding the earning potential is a critical step in evaluating any career path. For maintenance technicians, the compensation is competitive and offers significant room for growth. Salary figures can vary widely based on the factors we'll explore in the next section, but we can establish a solid baseline using data from authoritative sources.

It's important to distinguish between different categories of maintenance work. The U.S. Bureau of Labor Statistics (BLS) groups these roles into several classifications. The broadest is "General Maintenance and Repair Workers," while more specialized (and often higher-paying) roles include "Industrial Machinery Mechanics" and "Heating, Air Conditioning, and Refrigeration Mechanics and Installers (HVACR)."

### National Salary Averages and Ranges

Let's look at the most recent data to paint a clear picture of the national landscape.

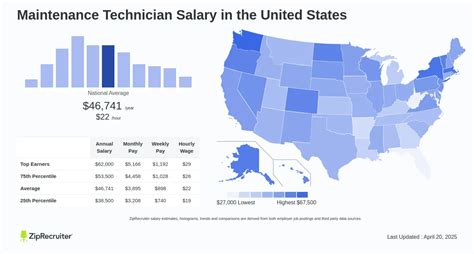

- General Maintenance and Repair Workers: According to the BLS Occupational Outlook Handbook data from May 2023, the median annual wage for this group was $46,730. This means half of the workers in this occupation earned more than that amount, and half earned less. The full range is quite broad: the lowest 10 percent earned less than $31,170, while the highest 10 percent earned more than $74,780.

- Industrial Machinery Mechanics: This specialization focuses on factory and industrial equipment and commands a higher salary. The BLS reports a median annual wage of $61,890 as of May 2023. The salary spectrum here is also wider at the top end: the lowest 10 percent earned less than $41,430, and the highest 10 percent earned more than $84,860.

- HVACR Mechanics and Installers: Another high-value specialty, HVACR technicians saw a median annual wage of $57,460 in May 2023. The top 10 percent in this field earned more than $85,600.

Reputable salary aggregators, which collect real-time, self-reported data, often show slightly different but complementary figures.

- Salary.com: As of May 2024, the site reports the median salary for a Maintenance Technician I (entry-level) in the U.S. is around $48,900, while a Maintenance Technician III (senior) has a median salary of $67,600. A Maintenance Supervisor's median salary is listed at $84,500.

- Payscale.com: This platform shows the average base salary for a Maintenance Technician is approximately $54,000 per year. They provide an excellent breakdown by experience, which we will explore below.

- Glassdoor: Reports an average total pay of around $61,000 per year for Maintenance Technicians in the United States, a figure that includes base salary and additional compensation like overtime and bonuses.

The key takeaway is that while a generalist might start in the $40,000s, a specialized, experienced technician can realistically expect to earn between $60,000 and $85,000+, even before considering overtime and other factors.

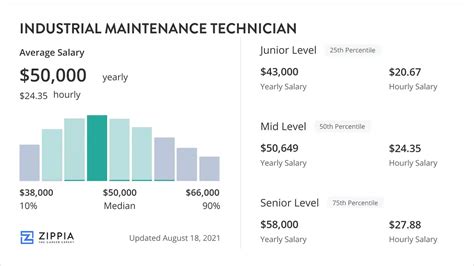

### Salary by Experience Level

Experience is arguably the single most important factor in a maintenance technician's salary progression. As you gain skills, speed, and diagnostic prowess, your value to an employer skyrockets. Here is a typical salary trajectory based on data from Payscale and industry observations:

| Experience Level | Typical Annual Salary Range | Key Responsibilities & Skills |

| :--- | :--- | :--- |

| Entry-Level (0-2 Years) | $38,000 - $52,000 | Assisting senior technicians, performing basic preventive maintenance (e.g., lubrication, filter changes), handling minor repairs (e.g., replacing light bulbs, fixing leaky faucets), and learning safety protocols. |

| Mid-Career (3-8 Years) | $52,000 - $70,000 | Working independently on complex troubleshooting and repairs, reading schematics, maintaining specific systems (HVAC, electrical, hydraulic), training junior technicians, and using CMMS software proficiently. |

| Senior/Lead (9+ Years) | $70,000 - $85,000+ | Leading complex diagnostic challenges, managing preventive maintenance programs, specifying and ordering parts, coordinating projects, leading a team of technicians, and developing maintenance procedures. May hold advanced certifications. |

| Supervisor/Manager (10+ Years)| $80,000 - $110,000+ | Managing the entire maintenance department, creating budgets, hiring and training staff, implementing maintenance strategies (e.g., predictive maintenance), ensuring regulatory compliance, and reporting to senior management. |

### Understanding Your Total Compensation Package

A maintenance technician's salary is just one part of their overall compensation. To get a true picture of your earnings, you must consider the complete package, which often includes significant additions to your base pay.

- Overtime Pay: This is a major factor. Maintenance is not always a 9-to-5 job. Emergency repairs, scheduled shutdowns, and weekend work are common, and this work is typically paid at 1.5x (time-and-a-half) or 2x (double-time) the standard hourly rate. It's not uncommon for a technician's overtime pay to add 10-25% or more to their annual income.

- Shift Differentials: Many facilities operate 24/7 and pay a premium for working second (evening), third (night), or weekend shifts. This differential can add several dollars per hour to your base rate.

- Bonuses: Annual or quarterly bonuses may be tied to individual performance, department goals (like uptime percentage or safety record), or overall company profitability.

- On-Call Pay/Stipend: Technicians who are required to be "on-call" during their off-hours often receive a stipend for their availability, plus their hourly rate (or overtime) if they are actually called in to work.

- Tool and Uniform Allowance: Many employers provide an annual allowance to help technicians purchase or replace the high-quality tools required for the job. They also typically provide and clean work uniforms.

- Benefits Package: This has significant monetary value. A strong benefits package includes comprehensive health, dental, and vision insurance; a retirement plan like a 401(k) with a company match; paid time off (vacation, sick days, holidays); and sometimes tuition reimbursement for continued education.

When evaluating a job offer, it's crucial to look beyond the hourly rate or base salary and calculate the value of this entire compensation structure.

Key Factors That Influence Salary

The national averages provide a useful starting point, but a technician's actual paycheck is determined by a potent combination of specific factors. Understanding these variables is the key to maximizing your earning potential throughout your career. Think of them as levers you can pull to strategically increase your value in the job market.

### ### Geographic Location

Where you work is one of the most powerful drivers of salary. High-paying areas often correlate with a high cost of living and a high concentration of industries that rely heavily on skilled maintenance. Conversely, salaries are typically lower in rural areas and states with a lower cost of living.

According to the BLS May 2023 data for General Maintenance and Repair Workers, the top-paying states are:

1. District of Columbia: Annual Mean Wage: $69,450

2. Alaska: Annual Mean Wage: $64,280

3. Hawaii: Annual Mean Wage: $62,560

4. Washington: Annual Mean Wage: $60,940

5. Massachusetts: Annual Mean Wage: $60,280

The top-paying metropolitan areas often offer even higher wages, reflecting intense demand:

1. San Jose-Sunnyvale-Santa Clara, CA: Annual Mean Wage: $78,890

2. San Francisco-Oakland-Hayward, CA: Annual Mean Wage: $73,310

3. Anchorage, AK: Annual Mean Wage: $68,360

4. Napa, CA: Annual Mean Wage: $67,700

5. Seattle-Tacoma-Bellevue, WA: Annual Mean Wage: $65,560

It is crucial to balance these high salaries against the cost of living. A $75,000 salary in San Jose may not afford the same lifestyle as a $65,000 salary in a city like Houston, Texas, where the cost of housing and daily expenses is significantly lower.

### ### Industry of Employment

The industry in which you apply your maintenance skills has a dramatic impact on pay. A technician maintaining complex, high-stakes equipment in a specialized industry will almost always earn more than a generalist in a less demanding environment.

Here's a breakdown of median annual salaries for Industrial Machinery Mechanics across different sectors (BLS, May 2023), illustrating the pay disparity:

- Electric Power Generation, Transmission and Distribution: $82,600

- Natural Gas Distribution: $79,840

- Aerospace Product and Parts Manufacturing: $75,410

- Automobile Manufacturing: $71,150

- Plastics and Rubber Products Manufacturing: $62,720

- Food Manufacturing: $60,860

- Real Estate (Property Management): (General Maintenance Techs) ~$48,000

The lesson is clear: Targeting high-tech, capital-intensive industries like aerospace, automotive, pharmaceutical manufacturing, or energy production is a direct path to a higher salary. These industries cannot afford downtime, and they are willing to pay a premium for technicians who can keep their multi-million dollar machinery running flawlessly.

### ### Area of Specialization

General maintenance is a valuable skill, but specialization is the key to unlocking the highest salary brackets. By developing deep expertise in a specific, in-demand area, you become a more valuable and harder-to-replace asset.

- Industrial Maintenance / Mechatronics: This is arguably the most lucrative specialization. These technicians work on a combination of mechanical, electrical, and computerized systems. Expertise in Programmable Logic Controllers (PLCs)—the brains behind most modern automation—is a massive salary booster. A technician who can troubleshoot and perform minor programming on Allen-Bradley or Siemens PLCs is highly sought after. Skills in robotics, hydraulics, and pneumatics also fall under this high-paying umbrella.

- HVAC/R (Heating, Ventilation, Air Conditioning, and Refrigeration): HVACR is a perpetually in-demand field. Technicians who can install, service, and repair complex commercial and industrial HVAC systems, including chillers, boilers, and large-scale ventilation, are well-compensated. EPA 608 certification is a federal requirement for handling refrigerants and is the baseline for entry into this specialty.

- Electrical Maintenance: Technicians with strong electrical skills, including the ability to work with high-voltage systems, troubleshoot motor control centers (MCCs), and understand the National Electrical Code (NEC), can command excellent wages. A state-issued electrician's license, while not always required for a maintenance role, can significantly increase earning potential.

- CMMS Administration / Reliability Engineering: For experienced technicians with strong organizational and analytical skills, a path into reliability is a powerful next step. This involves moving beyond day-to-day repairs to a more strategic role. This includes managing the CMMS, analyzing maintenance data to identify failure trends, and developing predictive maintenance (PdM) strategies using technologies like vibration analysis, thermal imaging, and oil analysis. A Certified Maintenance & Reliability Professional (CMRP) or Certified Maintenance & Reliability Technician (CMRT) certification validates these advanced skills.

### ### Level of Education and Certifications

While a four-year university degree is not required for this career, formal education and professional certifications provide a clear and verifiable signal of your knowledge and commitment, directly impacting your starting salary and long-term growth.

- High School Diploma or GED: This is the minimum requirement for entry-level positions.

- Vocational/Trade School Certificate: A 1-2 year program in Industrial Maintenance Technology, Mechatronics, or HVACR from a community college or trade school is a powerful accelerator. Graduates enter the workforce with a solid theoretical foundation and hands-on lab experience, allowing them to bypass lower-level helper roles and command a higher starting salary.

- Associate's Degree: An Associate of Applied Science (A.A.S.) degree often provides a more in-depth curriculum than a certificate program, including more advanced coursework and general education credits, which can be beneficial for future advancement into management roles.

Certifications are the currency of the skilled trades. They are tangible proof of your expertise in a specific area. Key certifications that boost your salary include:

- Certified Maintenance & Reliability Technician (CMRT): Offered by the Society for Maintenance & Reliability Professionals (SMRP), this is a premier credential that demonstrates your competence in preventive, predictive, and corrective maintenance.

- EPA Section 608 Certification: Essential for any technician who works with refrigerants in HVACR systems.

- OSHA 10-Hour or 30-Hour Safety Certification: Demonstrates a fundamental understanding of workplace safety, which is highly valued by all employers.

- Welding Certifications (e.g., from AWS): If fabrication and welding are part of your role, formal certification proves your ability to produce strong, safe welds.

- Manufacturer-Specific Certifications: Training and certification directly from equipment manufacturers (e.g., Rockwell Automation for PLCs, FANUC for robotics) are extremely valuable in specialized industrial settings.

### ### In-Demand Skills

Beyond formal credentials, your specific skillset is what you bring to the table every day. Cultivating high-value skills is a direct investment in your income.

High-Value Hard Skills: