So, you're drawn to the flash of the arc, the hum of the machine, and the satisfaction of joining two pieces of metal into something strong, permanent, and useful. You're considering a career as a welder, a foundational trade that literally builds the world around us. But beyond the skill and the satisfaction, you have a practical question that needs a real answer: what is the average salary for a welder? The answer is more complex and far more promising than a single number might suggest. This guide is your blueprint, designed to give you a comprehensive, no-nonsense look at what you can expect to earn and, more importantly, how you can maximize that earning potential throughout your career.

I once spoke with a veteran pipeline welder in West Texas who described his craft not as a job, but as "writing a story in steel." He said every perfect bead was a sentence, and every completed pipeline was a chapter that brought energy and resources to millions. That perspective stuck with me—this isn't just manual labor; it's a highly skilled art form with immense real-world impact. And for those who master it, the financial rewards are substantial.

This in-depth guide will take you far beyond a simple national average. We'll dissect every factor that influences a welder's salary, from the certifications in your pocket to the state you work in and the industry you serve. We will explore the job outlook, map out your career path, and give you the tools you need to build a prosperous and fulfilling career in welding.

### Table of Contents

- [What Does a Welder Do? A Look Beyond the Arc](#what-does-a-welder-do)

- [Average Welder Salary: A Deep Dive](#average-welder-salary)

- [Key Factors That Influence a Welder's Salary](#key-factors)

- [Job Outlook and Career Growth for Welders](#job-outlook)

- [How to Get Started on Your Welding Career Path](#how-to-get-started)

- [Conclusion: Forging Your High-Value Career in Welding](#conclusion)

What Does a Welder Do? A Look Beyond the Arc

At its core, a welder is a skilled professional who uses intense heat to join or cut metal parts. While this sounds straightforward, the reality of the profession is a dynamic blend of science, artistry, technical skill, and unwavering attention to detail. Welders work on everything from microscopic components in electronics to massive seafaring vessels and the structural skeletons of skyscrapers. They are the backbone of manufacturing, construction, energy, and transportation.

The primary responsibility is to create strong, clean, and durable bonds between metal pieces. This involves much more than just pulling a trigger on a welding gun. A welder's work is guided by blueprints, schematics, and technical drawings that specify the exact dimensions, materials, and processes required for a project.

Core Responsibilities and Daily Tasks:

- Interpreting Technical Plans: A welder must be proficient in reading and understanding blueprints, welding procedure specifications (WPS), and other technical documents to determine the project requirements.

- Preparing Materials: This involves cleaning, cutting, and shaping metal components using tools like grinders, saws, and plasma cutters to ensure a proper fit and a clean surface for welding. A contaminated surface results in a weak, failed weld.

- Selecting the Right Process and Equipment: There are over 100 different welding processes, but most welders specialize in a few key ones, such as Shielded Metal Arc Welding (SMAW or "Stick"), Gas Metal Arc Welding (GMAW or "MIG"), Gas Tungsten Arc Welding (GTAW or "TIG"), and Flux-Cored Arc Welding (FCAW). They must select the appropriate method, filler material, and machine settings based on the type of metal, its thickness, and the project's structural requirements.

- Executing the Weld: This is the most visible part of the job—meticulously guiding the welding tool along a seam to melt and fuse the metal. It requires exceptional hand-eye coordination, a steady hand, and a deep understanding of how heat affects different materials.

- Inspection and Quality Control: After a weld is complete, it must be inspected for defects like cracks, porosity, or lack of fusion. Welders often perform initial visual inspections and may use more advanced non-destructive testing (NDT) methods. They then clean, grind, and polish the finished weld to meet project specifications.

- Adhering to Safety Protocols: Welding is an inherently hazardous job, involving extreme heat, ultraviolet radiation, fumes, and electrical dangers. A professional welder's day is built around rigorous safety protocols, including the consistent use of Personal Protective Equipment (PPE) like helmets, gloves, and fire-resistant clothing.

### A Day in the Life of a Structural Welder

To make this more concrete, let's imagine a day for a welder working on a commercial building project:

- 6:30 AM: Arrive on site. Attend the daily safety briefing with the site supervisor. Discuss the day's tasks, potential hazards (like working at height or in a confined space), and review safety procedures.

- 7:00 AM: Gear up in full PPE. Review the blueprints for the day's objective: welding a series of I-beam support joints on the third floor.

- 7:30 AM: Ascend to the work area via a man lift. Inspect the pre-fitted beams that were put in place by the ironworkers. Use a grinder to clean the joint surfaces, ensuring they are free of rust, paint, and debris.

- 9:00 AM: Set up the welding equipment—a portable "Stick" welder. Dial in the correct amperage based on the beam thickness and the type of welding rod specified in the WPS.

- 9:30 AM - 12:00 PM: Perform the welds. This requires focus and precision, often in an awkward position, to lay down a strong, multi-pass weld that meets structural code.

- 12:00 PM: Lunch break.

- 12:30 PM: Move to the next set of joints. The process repeats: inspect, clean, weld. Another welder might be following behind, performing ultrasonic testing (a form of NDT) on the completed welds to ensure their integrity.

- 3:30 PM: Finish the final weld for the day. Clean up the work area, secure all tools and equipment, and store welding rods in a dry oven to prevent moisture contamination.

- 4:00 PM: Debrief with the supervisor, report on the day's progress, and confirm the plan for tomorrow before heading home.

This example highlights that welding is a physically and mentally demanding role that requires technical knowledge, physical stamina, and a commitment to quality and safety.

Average Welder Salary: A Deep Dive

Now, let's get to the numbers. The compensation for a welder is not a single, fixed figure but a wide spectrum influenced by numerous factors we'll explore in the next section. However, by examining data from authoritative sources, we can establish a clear and reliable baseline.

According to the most recent data from the U.S. Bureau of Labor Statistics (BLS) Occupational Outlook Handbook, the median annual wage for welders, cutters, solderers, and brazers was $50,460 in May 2022. This "median" wage means that half of all welders in the U.S. earned more than this amount, and half earned less.

However, the BLS also provides a more detailed breakdown of the salary range:

- Lowest 10% earned: Less than $36,880

- Highest 10% earned: More than $72,970

This initial range from the BLS is a solid starting point, but it's crucial to understand that it represents a broad cross-section of the entire profession, including entry-level fabrication shop welders and more routine manufacturing roles. It does *not* fully capture the immense earning potential of specialized, high-demand welders.

To get a more nuanced picture, let's turn to reputable salary aggregators that often incorporate more real-time data and user-reported figures.

- Payscale.com reports the average welder salary at approximately $23.08 per hour, with a typical annual range of $39,000 to $81,000.

- Salary.com places the median salary for a "Welder I" (entry-level) at $49,602, while a "Welder III" (experienced/senior) has a median of $67,313. Their data shows the top 10% of welders can earn $78,000 or more.

- Indeed.com, based on its extensive job postings, lists an average base salary of $24.81 per hour for welders in the United States.

What this data collectively shows is that a typical, competent welder can expect to earn a solid middle-class income. However, the path to earning in the top 10-25% of the profession—pulling in $70,000, $80,000, or even well over $100,000—is paved with experience, specialization, and strategic career choices.

### Welder Salary by Experience Level

Experience is arguably the single most powerful driver of salary growth in welding. As you progress, your speed, accuracy, and ability to handle complex projects and exotic materials increase dramatically, making you far more valuable to an employer.

Here is a typical salary progression based on a synthesis of data from BLS, Payscale, and Salary.com:

| Experience Level | Years of Experience | Typical Annual Salary Range | Key Characteristics |

| ---------------------- | ------------------- | --------------------------- | ------------------------------------------------------------------------------------------------------------------------- |

| Entry-Level Welder | 0-2 Years | $38,000 - $52,000 | Possesses basic certifications. Works under supervision on simpler fabrication and repair tasks. Focus is on building skills. |

| Mid-Career Welder | 3-9 Years | $50,000 - $68,000 | Proficient in multiple processes (e.g., TIG, MIG). Can work independently from blueprints. May have some specialized certs. |

| Senior/Master Welder | 10+ Years | $65,000 - $85,000+ | Expert in complex processes and exotic materials. May hold multiple advanced certifications (e.g., pipe, aerospace). |

| Specialized Welder | Varies (5+ Years) | $80,000 - $200,000+ | Works in high-demand, high-risk fields like underwater, nuclear, or pipeline welding. Often involves travel and overtime. |

### A Closer Look at Compensation Components

A welder's paycheck is often more than just an hourly wage. Total compensation can be significantly higher, especially in industrial or field settings.

- Overtime Pay: Welding is a project-driven field. When deadlines loom, overtime is common and lucrative. Working more than 40 hours a week means earning time-and-a-half, and sometimes double-time for holidays or weekend work. It's not uncommon for welders on major projects to work 60-70 hours a week, dramatically increasing their take-home pay.

- Per Diem: For welders who travel for work—a common requirement for pipeline, industrial shutdown, and specialized construction projects—a "per diem" is a daily allowance provided by the employer to cover living expenses like food and lodging. This allowance is typically tax-free and can add a significant amount to a welder's net income.

- Bonuses and Profit Sharing: In many manufacturing and industrial companies, welders may be eligible for performance-based bonuses, project completion bonuses, or company-wide profit-sharing plans.

- Hazard Pay: Jobs in particularly dangerous environments, such as at extreme heights, in confined spaces, or with hazardous materials, may come with additional "hazard pay" that increases the hourly rate.

- Benefits: Comprehensive benefits packages are a key part of compensation. These typically include health, dental, and vision insurance; a 401(k) or other retirement plan (often with an employer match); paid time off; and life insurance. Union welders often enjoy some of the most robust benefits packages, including pensions.

When evaluating a job offer, it's essential to look beyond the base hourly rate and consider the entire compensation package to understand your true earning potential.

Key Factors That Influence a Welder's Salary

The difference between earning $45,000 and $145,000 as a welder comes down to a specific set of factors. Mastering and strategically navigating these elements is the key to maximizing your income. This section breaks down the six most critical drivers of a welder's salary.

### 1. Education and Certifications

While a four-year university degree is not required, your level of formal training and, most importantly, your certifications are paramount.

- High School Diploma / GED: This is the minimum requirement to start. Students who take shop classes, metalworking, and advanced math (geometry, trigonometry) in high school have a distinct advantage.

- Vocational School Certificate / Diploma: This is the most common and effective entry point. A 9-18 month program at a technical college provides intensive, hands-on training in various welding processes, safety, and blueprint reading. Graduates emerge with a solid foundation and often their first basic certifications.

- Associate's Degree in Welding Technology: A two-year degree from a community college goes deeper. It covers the same hands-on skills but adds coursework in metallurgy, weld inspection, computer-aided design (CAD), and robotic welding. This higher level of theoretical knowledge can lead to roles in quality control, supervision, or as a welding technician, which often command higher salaries.

The Power of Certification:

Certifications are the true currency in the welding world. They are proof of your ability to perform a specific type of weld to a certain code or standard. The American Welding Society (AWS) is the leading authority, and its Certified Welder (CW) credential is the most recognized in the industry.

- How it Works: To become an AWS Certified Welder, you must perform a sound weld in a specified position, using a specific process, and on a specific material. The test coupon is then sent for destructive testing to ensure it meets the standard.

- Impact on Salary: A basic certification can be the difference between getting an entry-level job and not. Advanced certifications, however, are a direct ticket to higher pay. For example:

- 6G Pipe Welding Certification: This is one of the most difficult and sought-after certifications. It requires welding a pipe in a fixed, 45-degree inclined position, testing your ability to weld in all positions (flat, horizontal, vertical, overhead) on one joint. Welders with a 6G certification are in high demand for pipeline, power plant, and refinery work, often starting at wages 30-50% higher than a general fabricator.

- Specialized Certifications: Certifications for working with specific alloys (e.g., stainless steel, Inconel, titanium) or for specific industry codes (e.g., ASME for pressure vessels, API for petroleum pipelines) unlock elite, high-paying jobs.

### 2. Years of Experience

As detailed in the previous section, experience is a linear driver of pay. But *why*?

- Speed and Efficiency: An experienced welder can lay down a quality weld much faster than a novice, increasing productivity and saving the employer money.

- Problem-Solving: When a project presents unexpected challenges—a poor fit-up, a difficult material, a complex position—a senior welder has the knowledge to adapt and find a solution without costly delays.

- Versatility: A 10-year veteran has likely worked with dozens of materials, projects, and processes. They can be plugged into almost any role with minimal ramp-up time.

- Mentorship and Leadership: Experienced welders are often tasked with training apprentices and junior welders, taking on a quasi-supervisory role that adds value and warrants higher pay. They may advance to roles like Welding Foreman, Supervisor, or Certified Welding Inspector (CWI).

The Salary Trajectory:

- Years 0-2: Learning phase. Your primary value is your potential.

- Years 3-5: Journeyman phase. You are a reliable, independent contributor. This is where you see significant pay jumps as you prove your competence.

- Years 5-10: Senior phase. You are now a go-to expert for standard and moderately complex tasks. You can pursue advanced certifications.

- Years 10+: Master/Specialist phase. You are an expert. You handle the most critical, highest-paying jobs. Your income potential is now primarily limited by your specialization and willingness to take on demanding projects.

### 3. Geographic Location

Where you work matters—a lot. Welding salaries vary dramatically by state, city, and even region, largely driven by the cost of living and the concentration of key industries.

Top-Paying States for Welders:

According to BLS data, the states with the highest annual mean wages for welders often correlate with major energy, defense, and shipping industries.

| State | Annual Mean Wage (BLS, May 2022) | Key Industries Driving Wages |

| -------------- | -------------------------------- | ------------------------------------- |

| Alaska | $74,830 | Oil & Gas, Pipeline Maintenance, Marine |

| Wyoming | $69,600 | Mining, Oil & Gas, Power Generation |

| North Dakota | $66,610 | Oil & Gas (Bakken Shale), Manufacturing |

| Hawaii | $66,000 | Military Shipyards (Pearl Harbor), Construction |

| District of Columbia | $65,580 | Federal Construction, Infrastructure |

Conversely, states with lower costs of living and a focus on general manufacturing or agriculture tend to have lower average wages. It's a trade-off: your dollar may go further, but the top-end earning potential might be lower unless you're a traveling specialist.

High-Paying Metropolitan Areas:

Even within a state, cities with major industrial projects pay more. Cities like Bremerton, WA (Naval shipyard), Anchorage, AK (oil/gas hub), and Houston, TX (petrochemical industry) consistently offer higher-than-average wages.

### 4. Industry and Company Type

The industry you apply your welding skills to is arguably the most significant factor in your long-term earning potential. A welder in a small, local fabrication shop will have a vastly different salary ceiling than one working on an offshore oil rig.

- General Manufacturing: This is the largest employer of welders. Pay is typically close to the national median. Work involves creating metal products, from appliances to automotive parts. The work is steady but rarely offers the extreme high pay of other sectors.

- Construction: Welders in construction build everything from bridges to skyscrapers. Structural welders often earn above-average wages, especially those working in union roles on large-scale commercial or public infrastructure projects.

- Shipbuilding and Repair: This is a high-paying sector due to the critical nature of the work and the often-demanding conditions. Welders in Navy shipyards or private marine construction companies (e.g., working on LNG tankers) can earn excellent wages and benefits.

- Aerospace: This is an elite field. Aerospace welders work with exotic materials like titanium and aluminum alloys to build aircraft and spacecraft. The work requires extreme precision and rigorous certification, commanding very high salaries.

- Oil & Gas (Energy Sector): This sector offers some of the highest paychecks in the profession.

- Pipeline Welders: Travel across the country laying the arteries of the energy grid. They are often independent contractors and can earn well into the six figures, especially when combining their rig pay with per diem.

- Offshore Rig Welders: Work on platforms in the middle of the ocean, often in difficult conditions. The pay is exceptional to compensate for the risk and the long hitches away from home.

- Power Generation: Welders are critical for building and maintaining power plants, including traditional fossil fuel plants, hydroelectric dams, and nuclear facilities.

- Nuclear Welders: This is a highly specialized and lucrative field. The level of quality, documentation, and security clearance required is immense, and the compensation reflects that.

### 5. Area of Specialization

Within these industries, specializing in a particularly difficult or in-demand type of welding is the fast track to becoming a top earner.

- Underwater Welding: This is the pinnacle of high-risk, high-reward welding. Combining commercial diving with master-level welding, these professionals perform repairs on ships, offshore oil platforms, and underwater pipelines. Annual salaries can range from $100,000 to over $200,000.

- Pipe Welding: As mentioned, skilled pipe welders (especially those with 6G certification) are always in demand for energy and industrial projects. They must be able to create perfect, leak-proof welds on cylindrical surfaces.

- TIG (GTAW) Welding: TIG welding is a precise process used for thin or delicate materials like aluminum, stainless steel, and titanium. It's essential in the aerospace, motorsports, and food-grade manufacturing industries. Master TIG welders are highly sought after and well-compensated.

- Robotic Welding Technician: As automation increases, there's a growing need for professionals who can program, operate, and troubleshoot robotic welding systems. This role blends traditional welding knowledge with robotics and programming skills, creating a future-proof, high-paying career path.

- Certified Welding Inspector (CWI): An experienced welder can transition to an inspector role. A CWI from the AWS is responsible for quality control, ensuring all welds on a project meet code. It's a less physically demanding role that leverages a career's worth of knowledge and commands a salary often in the $70,000 to $100,000+ range.

### 6. In-Demand Skills

Beyond specific processes, a portfolio of supplementary skills can make you a more valuable and higher-paid employee.

- Blueprint Reading Mastery: Being able to look at a complex schematic and instantly visualize the finished product and the steps to get there is a high-value skill.

- Metallurgy Knowledge: Understanding how different metals react to heat, what filler materials to use, and how to prevent issues like distortion or cracking sets you apart from a basic "metal-joiner."

- Pipefitting: Welders who can also fit and prepare their own pipes are more efficient and valuable on a job site.

- Non-Destructive Testing (NDT): Basic knowledge or certification in NDT methods like visual testing (VT), magnetic particle testing (MT), or dye penetrant testing (PT) adds another layer to your skillset.

- Rigging: On large construction sites, the ability to safely rig and signal for crane lifts of heavy materials is a major asset.

- Bilingualism: In many parts of the country, being fluent in both English and Spanish is a significant advantage on diverse job sites.

Job Outlook and Career Growth for Welders

When considering a long-term career, salary is only one part of the equation. Job security and opportunities for advancement are equally important. The outlook for skilled welders is strong and nuanced, shaped by economic trends, technological advancements, and demographic shifts.

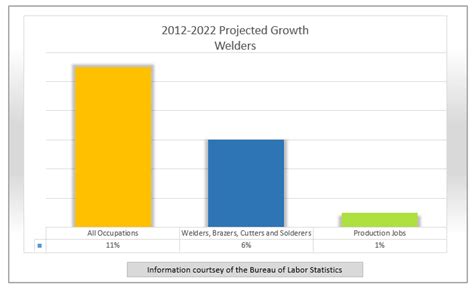

According to the U.S. Bureau of Labor Statistics (BLS), overall employment for welders, cutters, solderers, and brazers is projected to grow 2 percent from 2022 to 2032. While this is slower than the average for all occupations, this single statistic can be misleading and requires deeper analysis.

The BLS projects about 40,300 openings for welders each year, on average, over the decade. A significant portion of these openings is expected to result from the need to replace workers who are retiring or transferring to different occupations. This is a critical point: the welding workforce is aging. A large cohort of highly experienced baby boomer welders is retiring, creating a "skills gap." While automation may handle some simple, repetitive tasks, it cannot replace the problem-solving ability and adaptability of a skilled human welder on a complex construction site or in a custom fabrication shop.

### Emerging Trends and Future Opportunities

The future for welders is not in competing with robots, but in performing the high-skill tasks that robots cannot. Several key areas are poised for significant growth