Table of Contents

- [What Does a CNC Machinist Do?](#what-does-a-cnc-machinist-do)

- [Average CNC Machinist Salary: A Deep Dive](#average-cnc-machinist-salary-a-deep-dive)

- [Key Factors That Influence Your CNC Machinist Salary](#key-factors-that-influence-your-cnc-machinist-salary)

- [Job Outlook and Career Growth for CNC Machinists](#job-outlook-and-career-growth-for-cnc-machinists)

- [How to Become a CNC Machinist: A Step-by-Step Guide](#how-to-become-a-cnc-machinist-a-step-by-step-guide)

- [Is a Career as a CNC Machinist Right for You?](#is-a-career-as-a-cnc-machinist-right-for-you)

In a world increasingly dominated by digital abstractions, there is a profound and growing respect for those who can bridge the gap between a blueprint and a physical reality. If you are someone who finds satisfaction in precision, problem-solving, and creating tangible objects that power our world, a career as a Computer Numerical Control (CNC) machinist might be your calling. This is not just a job; it is a modern craft, blending the time-honored principles of machining with the cutting edge of computer technology. But beyond the satisfaction of the work itself, you're likely asking a critical question: What can I expect to earn, especially when I'm just starting out?

The query "CNC machinist starting salary" is one of the most common searches for a reason. You want to know if this skilled trade can provide a stable, rewarding livelihood. The answer is a resounding yes. While a starting salary can vary, entry-level CNC machinists can expect to earn between $38,000 and $55,000 per year, with the national average for all machinists hovering around $58,350 annually, according to the U.S. Bureau of Labor Statistics (BLS) as of May 2023. However, this is just the beginning. With experience, specialization, and the right skills, a six-figure income is well within reach for masters of this trade.

I once toured a high-tech facility that manufactured components for surgical robots. I held a titanium part no bigger than my thumb, impossibly complex, with tolerances so tight they were measured in microns. The lead machinist explained that a single error in the code or setup could render the $5,000 piece of raw material worthless. It was a powerful reminder that CNC machinists are the essential artisans of the modern industrial age, a role that commands respect and, deservedly, a strong salary. This guide will serve as your comprehensive roadmap, detailing not just the starting salary but the entire financial and professional trajectory of a CNC machinist.

What Does a CNC Machinist Do?

At its core, a CNC machinist is a highly skilled technician who uses computer-controlled machinery to cut, shape, and form raw materials—primarily metals and plastics—into precise parts and components. They are the translators between a digital design file, typically a CAD (Computer-Aided Design) model, and a finished, physical product. This is not a simple "press a button and walk away" job. It's a dynamic role that requires a blend of mechanical aptitude, mathematical precision, and computer literacy.

The "CNC" in the title stands for Computer Numerical Control. This means that instead of manually turning cranks and levers on traditional machines like lathes and mills, the machinist programs the machine's movements using a specific programming language, most commonly G-code and M-code. This code dictates every action: the tool's path, its speed, the coolant flow, and the sequence of operations.

Core Responsibilities and Daily Tasks:

A CNC machinist's duties can be broken down into several key phases of the production process:

1. Interpretation and Planning: The process begins with a blueprint or a 2D/3D CAD model. The machinist must analyze these plans to understand the part's dimensions, required materials, and specified tolerances (the acceptable margin of error). They plan the sequence of operations needed to create the part efficiently.

2. Programming: For simpler parts, the machinist may write the G-code directly at the machine's control panel. More commonly, especially for complex geometries, they use CAM (Computer-Aided Manufacturing) software. The machinist imports the CAD model into the CAM program, defines the toolpaths, selects the appropriate cutting tools, and sets speeds and feeds. The software then generates the G-code that the machine will run.

3. Setup (The Most Critical Phase): This is where a machinist's skill truly shines. The setup process involves:

- Securing the Workpiece: Firmly clamping the block of raw material (the "workpiece") into the machine using vises, fixtures, or chucks. It must be perfectly positioned and immovable.

- Loading the Tools: Selecting the correct cutting tools (end mills, drills, taps, etc.) and loading them into the machine's tool turret or magazine.

- Setting Offsets: Precisely measuring the location of the workpiece and the length of each tool, and inputting these "offsets" into the machine's control. This tells the machine exactly where the workpiece and tools are in 3D space. An error of a thousandth of an inch here can ruin the entire part.

4. Operation and Monitoring: The machinist runs a "first article" or test piece, carefully monitoring the machine's operation. They listen for unusual sounds, watch for vibrations, and check the dimensions of the initial cuts. They may need to adjust the program or offsets to perfect the process. Once satisfied, they proceed with the full production run, periodically checking parts to ensure they remain within tolerance.

5. Quality Control and Inspection: Using precision measuring instruments like digital calipers, micrometers, and height gauges, the machinist meticulously inspects the finished parts to ensure they meet all blueprint specifications. For parts with extremely tight tolerances, they may use a CMM (Coordinate Measuring Machine).

### A Day in the Life of a CNC Machinist

To make this more tangible, here's what a typical day might look like for a machinist in a mid-sized job shop:

- 7:00 AM: Arrive, grab a coffee, and head to the shop floor. Review the day's work orders. The first job is a run of 50 small aluminum brackets for an electronics company.

- 7:15 AM: Pull the blueprint and the program file. Review the G-code on the control panel to ensure it matches the plan.

- 7:45 AM: Begin the setup on a Haas VF-2 vertical milling machine. Clean the vise, secure the first block of aluminum, and load the required tools: a face mill, a half-inch end mill, and a quarter-inch drill.

- 8:30 AM: Carefully touch off each tool to set the length offsets and use an edge finder to locate the corner of the workpiece, establishing the work offset (G54). Double-check all numbers.

- 9:00 AM: Run the program in "graphics" mode to simulate the toolpaths visually. Everything looks good. Close the doors and run the first part at 50% speed, finger on the feed hold button, listening intently.

- 9:20 AM: The first part is finished. Deburr the sharp edges and take it to the inspection bench. Use calipers and a height gauge to check every dimension against the blueprint. Everything is perfectly in spec.

- 9:45 AM: Begin the production run, loading a new piece of material every 15 minutes. Between cycles, perform a quick check on a key dimension to ensure consistency.

- 12:00 PM: Lunch break.

- 12:30 PM: The bracket job is halfway done. While the machine runs, the supervisor brings a new, more complex one-off job: a prototype part for a medical device made from PEEK (a high-performance plastic).

- 1:00 PM: While the Haas machine continues the production run, begin planning the PEEK job at a separate workstation. Use Mastercam software to create the toolpaths, paying special attention to the material's unique properties (it can melt if machined too aggressively).

- 3:00 PM: The aluminum bracket job is complete. Clean the machine, break down the setup, and prepare it for the prototype job.

- 3:30 PM: Begin the setup for the PEEK part on a different, more precise machine. This requires extreme care.

- 4:30 PM: The setup is complete. Run the first few lines of code to face the material. The day is ending, so leave the machine ready to start the full program first thing in the morning.

- 4:55 PM: Clean the workstation, log the completed jobs, and clock out.

This demonstrates the constant blend of hands-on work, computer interaction, critical thinking, and meticulous attention to detail that defines the role.

Average CNC Machinist Salary: A Deep Dive

Understanding the earning potential is a fundamental part of evaluating any career path. For CNC machinists, the salary is not a single, static number but a spectrum that reflects experience, skill, location, and specialization. While the CNC machinist starting salary is a key benchmark, it's crucial to see the full picture to appreciate the long-term financial rewards of this trade.

Let's break down the compensation data from several authoritative sources.

National Averages and Ranges

First, it's important to look at the official government data. The U.S. Bureau of Labor Statistics (BLS) groups CNC Machinists with "Machinists and Tool and Die Makers" in their Occupational Outlook Handbook. As of May 2023, the most recent data available, the BLS reports:

- Median Pay: $58,350 per year, or $28.05 per hour.

- Lowest 10%: Earned less than $37,070 per year. This often represents true entry-level positions, apprentices, or machine operators in low-cost-of-living areas.

- Highest 10%: Earned more than $82,920 per year. This tier includes highly experienced, specialized machinists, programmers, and those in lead or supervisory roles.

Salary aggregator websites, which collect real-time, user-reported data, provide a more granular view and often reflect very recent market conditions. Here's a comparison:

- Payscale.com: Reports an average base salary for a CNC Machinist of $24.51 per hour, which translates to approximately $51,000 per year for a standard 40-hour week. Their reported range spans from $18.06 to $34.78 per hour.

- Salary.com: Provides a more structured view based on skill level. For a "CNC Machinist I" (entry-level), they report a median annual salary of $49,661, with a typical range falling between $44,142 and $56,233. A "CNC Machinist III" (senior level) has a median salary of $67,614, with a range of $60,256 to $75,917.

- Glassdoor.com: As of late 2023, Glassdoor reports a total pay estimate (including base and additional pay) for a CNC Machinist in the United States at $63,607 per year, with a likely range between $52,000 and $78,000.

What does this data tell us? A reasonable expectation for a CNC machinist starting salary for someone with formal training (e.g., a certificate or associate's degree) but minimal on-the-job experience would be in the $45,000 to $55,000 range. Those starting with only a high school diploma in an apprenticeship might begin closer to the $38,000 to $42,000 mark. The BLS median of over $58,000 reflects a machinist with a few years of solid experience.

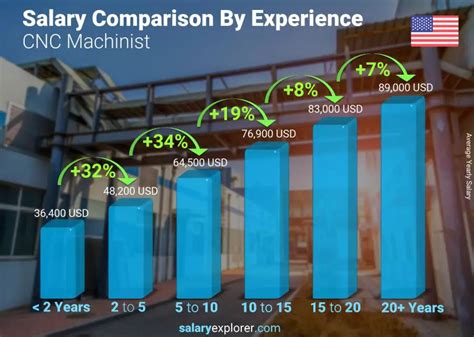

### Salary Progression by Experience Level

Your value—and therefore your salary—grows significantly as you move from simply operating a machine to setting it up, programming it, and solving complex problems. Here's a typical salary progression timeline, collating data from Payscale and Salary.com:

| Experience Level | Typical Years of Experience | Typical Annual Salary Range | Key Responsibilities |

| :--- | :--- | :--- | :--- |

| Apprentice / Operator | 0 - 1 year | $38,000 - $48,000 | Loading/unloading parts, basic quality checks, observing setups, learning machine controls. |

| Entry-Level Machinist (Machinist I) | 1 - 4 years | $48,000 - $60,000 | Performing basic setups, making tool offsets, running proven programs, inspecting parts. |

| Mid-Career Machinist (Machinist II) | 5 - 9 years | $60,000 - $75,000 | Complex multi-axis setups, basic G-code editing, CAM programming for simpler parts, troubleshooting. |

| Senior / Lead Machinist (Machinist III) | 10 - 19 years | $75,000 - $90,000+ | 5-axis programming, process optimization, fixture design, training junior machinists, prototyping. |

| Master Machinist / Programmer / Supervisor | 20+ years | $85,000 - $120,000+ | Overseeing shop floor, complex CAM programming, quoting jobs, managing a team, working with exotic materials. |

*Note: These are national averages. Your specific salary will be heavily influenced by the factors discussed in the next section.*

### Beyond the Base Salary: Understanding Total Compensation

A machinist's paycheck is often more than just their hourly wage or annual salary. The manufacturing industry relies heavily on a skilled workforce, and companies use various incentives to attract and retain talent.

- Overtime Pay: This is arguably the most significant additional compensation for many machinists. The standard workweek is 40 hours, but 50-hour weeks are common, especially in busy job shops. All hours worked over 40 are paid at "time and a half" (1.5x the hourly rate). For a machinist earning $28/hour, a 50-hour week means an extra $420 in gross pay ($28 x 10 hours x 1.5). This can add $15,000-$20,000 or more to an annual income.

- Bonuses: Many companies offer annual or quarterly performance bonuses based on company profitability, productivity metrics, or safety records. These can range from a few hundred to several thousand dollars.

- Profit Sharing: Some companies, particularly smaller, privately-owned shops, distribute a percentage of their annual profits among their employees. This directly ties the machinist's success to the company's success.

- Shift Differentials: Machinists working second or third shifts (evenings or nights) almost always receive a "shift differential," which is an additional amount per hour (e.g., an extra $1.50/hour) or a percentage of their base pay (e.g., +10%). This is to compensate for working less desirable hours.

- Benefits: A comprehensive benefits package is a crucial part of total compensation. This includes:

- Health Insurance: Medical, dental, and vision coverage.

- Retirement Savings: 401(k) plans, often with a company match.

- Paid Time Off (PTO): Vacation days, sick leave, and paid holidays.

- Tool Allowance: Some employers provide an annual stipend to help machinists purchase their own precision tools and measurement devices.

- Tuition Reimbursement: Companies may pay for continuing education, such as advanced CAM courses or an associate's degree in manufacturing technology.

When evaluating a job offer, it's essential to look at the entire compensation package, not just the hourly wage. A job with a slightly lower base pay but excellent overtime opportunities, a generous 401(k) match, and comprehensive health insurance can be far more valuable financially.

Key Factors That Influence Your CNC Machinist Salary

The national average salary provides a useful benchmark, but your individual earning potential is determined by a combination of specific, interconnected factors. Understanding these variables is the key to strategically maximizing your income throughout your career. This is the most critical section for anyone looking to go beyond an entry-level wage and build a lucrative career in CNC machining.

### 1. Level of Education and Certification

While you can enter the field with just a high school diploma, formal education and industry-recognized certifications provide a significant boost to your starting salary and long-term earning power.

- High School Diploma / GED: This is the minimum requirement. Individuals starting at this level typically begin as machine operators or apprentices, with starting pay at the lower end of the spectrum (around $18-$22/hour). Their training is almost entirely on-the-job.

- Vocational School Certificate: A 9-to-12-month certificate program from a technical college is a powerful launching pad. These programs focus on hands-on skills: manual machining fundamentals, blueprint reading, shop math, G-code programming, and basic CAM software. Graduates can often bypass the "operator" stage and start as entry-level machinists, commanding a starting salary 5-15% higher than those without formal training.

- Associate of Applied Science (A.A.S.) in Machining Technology: A two-year degree provides a deeper theoretical foundation. It covers everything in a certificate program plus more advanced topics like Geometric Dimensioning and Tolerancing (GD&T), metallurgy, CNC programming with CAM software, and quality control methods like statistical process control (SPC). Graduates are highly sought after and can expect a CNC machinist starting salary at the higher end of the entry-level range (e.g., $50,000-$60,000), with a faster track to programming and setup roles.

- Certifications: Industry credentials validate your skills to employers. They act as proof of competency.

- NIMS (National Institute for Metalworking Skills): This is the gold standard. NIMS offers credentials in specific, performance-based skills like CNC Mill Operations, CNC Lathe Programming Setup & Operations, and Measurement, Materials & Safety. Holding multiple NIMS credentials can significantly increase your marketability and salary.

- SME (Society of Manufacturing Engineers): Offers certifications like the Certified Manufacturing Technologist (CMfgT), which is broader and demonstrates a solid understanding of manufacturing processes.

- Software-Specific Certifications: Becoming a certified user of a specific CAM software, like Mastercam (the most widely used), Fusion 360, or GibbsCAM, is extremely valuable. It proves you can efficiently program complex parts and can lead directly to higher-paying CNC Programmer roles.

### 2. Years of Experience (The Experience Premium)

In skilled trades, there is no substitute for experience. Each year on the job builds a library of knowledge about how different materials react, how to solve unexpected problems, and how to set up jobs more efficiently. This "experience premium" is directly reflected in your pay.

- 0-2 Years (Apprentice/Junior): Focus is on learning the fundamentals. Your value is in your potential. Salary growth comes from demonstrating reliability, a willingness to learn, and mastering basic tasks. Expect pay raises in the 3-5% range annually as you prove yourself.

- 3-7 Years (Mid-Career/Setup Machinist): You are now a reliable, independent machinist. You can handle complex setups, edit programs, and solve common machining issues without supervision. This is where salary growth accelerates significantly. You can command 25-40% more than your starting salary. This is the stage where you begin specializing.

- 8-15+ Years (Senior/Lead Machinist): You are a problem-solver and a mentor. You're tasked with the most difficult jobs—prototypes, complex 5-axis work, or parts made from exotic alloys. You likely have strong CAM programming skills and are looked to for process improvements. Your salary can be 50-100% higher than your starting wage. Top-tier machinists in this bracket, especially those with programming skills, frequently earn $80,000 to $100,000+.

### 3. Geographic Location

Where you work is one of the biggest drivers of your salary. The demand for skilled machinists and the local cost of living create significant wage disparities across the country.

According to the BLS (May 2023), the top-paying states for machinists are:

1. Washington: Average annual salary of $76,430

2. Alaska: Average annual salary of $72,590

3. District of Columbia: Average annual salary of $69,470

4. Massachusetts: Average annual salary of $68,260

5. Maryland: Average annual salary of $67,780

Conversely, states in the Southeast and parts of the Midwest tend to have lower average salaries, though the cost of living is also significantly lower.

The disparity is even more pronounced at the metropolitan level. High-tech manufacturing hubs pay a premium.

- High-Paying Metro Areas: Seattle-Tacoma-Bellevue, WA ($79,480); Boston-Cambridge-Nashua, MA-NH ($69,720); San Jose-Sunnyvale-Santa Clara, CA ($74,400). These areas are dense with aerospace, medical device, and tech companies.

- Lower-Paying Metro Areas: Areas in the rural South or Midwest may have average salaries in the $40,000 - $50,000 range.

It's crucial to weigh salary against the cost of living. A $75,000 salary in Seattle may not go as far as a $60,000 salary in a smaller Midwestern city with much lower housing costs.

### 4. Company Type, Size, and Industry

The type of company you work for and the industry it serves dramatically impacts compensation.

- Small "Job Shops": These are smaller, often family-owned businesses that take on custom jobs from various clients. They offer a fantastic learning environment where you'll work on a wide variety of parts. Pay can be more modest initially, but there's often more flexibility and a close-knit culture.

- Large Corporations / OEMs (Original Equipment Manufacturers): Companies like Boeing, Lockheed Martin, General Electric, or major automotive manufacturers have structured pay scales, excellent benefits, and union representation (in many cases). Salaries are often higher, and there are clear paths for advancement into management or engineering roles. The work might be more specialized and repetitive.

- Government and Defense Contractors: Working for a government entity or a prime defense contractor often comes with premium pay and top-tier benefits due to the high-security, high-precision nature of the work (e.g., manufacturing parts for military aircraft or naval ships).

- High-Margin Industries: The industry is paramount.

- Aerospace/Defense: Requires machining of tough alloys like titanium and Inconel to extreme tolerances. This is one of the highest-paying sectors.

- Medical Device Manufacturing: Similar to aerospace, this industry demands incredible precision and documentation for surgical instruments and implants. Pay is excellent.

- Semiconductor Industry: Machining components for the machines that make computer chips is another high-paying niche.

- Motorsports/Automotive (High-Performance): Shops that build engines and components for racing teams pay well for skilled machinists who can work quickly and creatively.

- General Manufacturing: A shop that makes simpler industrial hardware will generally pay less than the specialized industries above.

### 5. Area of Specialization

"CNC Machinist" is a broad term. Specializing in a high-demand area is the fastest way to increase your earnings.

- 3-Axis vs. 5-Axis Machining: A 3-axis machine moves in X, Y, and Z. A 5-axis machine can also rotate the tool and/or the part, allowing for the creation of incredibly complex shapes in a single setup. A skilled 5-axis machinist/programmer is one of the most sought-after professionals in the industry and can earn 20-30% more than a 3-axis machinist.

- Mill vs. Lathe vs. Mill-Turn: Specializing in one type of machine is common. Mills cut parts that are typically blocky, while lathes spin round parts. A mill-turn machine combines both functions into one highly complex and efficient platform. Expertise in mill-turn machining is a high-value, high-salary skill.

- CNC Programmer vs. Setup/Operator: A machinist who can only set up and operate a machine will earn less than a CNC Programmer who uses CAM software to create the programs from scratch. Many top-tier machinists are "Programmer/Machinists" who can do it all, from CAM to final inspection. Pure programming roles are often salaried and can be some of the highest-paid positions on the shop floor.

- Material Specialization: Expertise in machining difficult materials like titanium, Inconel, hardened steels, or advanced plastics (PEEK, Ultem) is a valuable niche. These materials are expensive and unforgiving, and shops will pay a premium for a machinist who won't scrap costly material.

### 6. In-Demand Technical Skills

Beyond your title, specific, demonstrable skills on your resume will get you noticed and justify a higher salary.

- GD&T Proficiency: A deep understanding of Geometric Dimensioning and Tolerancing is non-negotiable for high-level work. Being able to read and interpret complex GD&T callouts on a blueprint is a critical skill that separates entry-level from senior machinists.

- CAM Software Mastery: Being an expert in