In the heart of every monumental construction project, bustling mine, or productive farm, there is a symphony of powerful machinery. Towering cranes, massive excavators, and earth-moving bulldozers are the steel-and-iron titans that shape our modern world. But these giants are not immortal. When they falter, when a hydraulic line bursts or an engine sputters to a halt, entire multi-million dollar projects can grind to a standstill. It is in this critical moment that the heavy machinery mechanic becomes the most important person on site.

This career is for the problem-solvers, the hands-on thinkers who find satisfaction in diagnostics and repair. It’s a path that offers immense stability, tangible results, and a surprisingly lucrative financial future. While the average heavy machinery mechanic salary often surprises people, ranging comfortably from $50,000 to well over $100,000 per year with experience and specialization, the true value lies in being an indispensable expert in a high-demand field. I once stood on the edge of a massive highway overpass project, watching as a single, state-of-the-art paver sat silent. The delay was costing the company tens of thousands of dollars per hour until a field service mechanic, flown in specially, diagnosed and repaired a complex electronic control module in under two hours, single-handedly getting the entire project back on track. That is the power and importance of this profession.

This guide is designed to be your comprehensive roadmap to understanding and achieving a top-tier heavy machinery mechanic salary. We will dissect every factor that influences your earnings, explore the long-term career outlook, and provide a step-by-step plan to get you started on this rewarding path.

### Table of Contents

- [What Does a Heavy Machinery Mechanic Do?](#what-does-a-heavy-machinery-mechanic-do)

- [Average Heavy Machinery Mechanic Salary: A Deep Dive](#average-heavy-machinery-mechanic-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

What Does a Heavy Machinery Mechanic Do?

A heavy machinery mechanic, often called a heavy equipment technician, is a highly skilled professional responsible for the inspection, maintenance, diagnosis, and repair of large machinery used in industries like construction, mining, agriculture, and forestry. They are the doctors for the world’s most powerful and complex vehicles. Their work goes far beyond simply turning wrenches; it's a sophisticated blend of mechanical aptitude, electronic troubleshooting, and hydraulic expertise.

The core of the role is ensuring that expensive, mission-critical equipment operates safely, efficiently, and with minimal downtime. A single large haul truck in a mine can cost over $5 million, and any unplanned downtime represents a significant financial loss for the company. The mechanic's primary objective is to prevent failures before they happen and to resolve them quickly when they do.

Core Responsibilities and Daily Tasks Include:

- Preventative Maintenance (PM): Performing routine service on equipment according to manufacturer specifications. This includes changing oil and fluids, lubricating moving parts, replacing filters, and inspecting critical components like brakes, transmissions, and hydraulic systems.

- Advanced Diagnostics: Utilizing a combination of computerized diagnostic equipment, schematics, and hands-on inspection to identify the root cause of mechanical, hydraulic, or electrical failures. Modern heavy equipment is laden with sensors, GPS (telematics), and electronic control units (ECUs) that require specialized software (like Caterpillar's ET or John Deere's Service Advisor) to diagnose.

- Complex Repairs: Disassembling, repairing, and reassembling major components such as diesel engines, transmissions, steering systems, and final drives. This can involve anything from replacing a simple hose to a complete engine or transmission rebuild.

- Hydraulic and Pneumatic Systems: A massive part of the job involves troubleshooting and repairing the hydraulic systems that power booms, buckets, and blades. This requires a deep understanding of pumps, valves, cylinders, and high-pressure fluid dynamics.

- Welding and Fabrication: Cutting and welding metal to repair cracks in frames, buckets, or other structural components. Sometimes, they must fabricate custom parts to complete a repair.

- Record Keeping: Meticulously documenting all maintenance and repair work performed. This service history is crucial for tracking equipment health, managing parts inventory, and ensuring compliance with safety regulations.

- Field Service: Many mechanics travel directly to job sites to perform emergency repairs. This requires them to be highly independent, resourceful, and capable of working in challenging environments, from muddy construction sites to remote mines.

### A Day in the Life: Field Service Technician

Let's imagine a day for "Alex," a senior field service technician for a large equipment dealership.

7:00 AM: Alex starts the day not at a shop, but in a custom-outfitted service truck that is essentially a mobile workshop on wheels, complete with a crane, welder, air compressor, and thousands of dollars in tools. The first dispatch call comes in: a D9 bulldozer at a major highway construction site, 60 miles away, is showing a "low power" fault code and the operator reports it can't push a full load.

8:30 AM: After navigating to the site and checking in with the foreman, Alex connects a laptop running diagnostic software to the dozer's electronic control module. The software confirms the fault code relates to fuel pressure.

9:15 AM: Alex doesn't just replace parts. The diagnostic is just the starting point. Using a pressure gauge, Alex confirms the fuel pressure is indeed low. The investigation begins: is it a clogged filter? A weak lift pump? A faulty injector? A leak in the line?

11:00 AM: After methodically checking the system, Alex discovers the issue is a failing fuel transfer pump, a common wear-and-tear item. Alex has the part on the service truck, a testament to good preparation.

12:30 PM: The pump is replaced, the system is primed, and the dozer roars back to life. Alex runs another diagnostic check to ensure all parameters are normal and clears the fault codes.

2:00 PM: After completing digital paperwork and getting a sign-off from the site foreman, the next call comes in. A large excavator at a different site has a ruptured hydraulic line. Alex heads that way, knowing the afternoon will involve dealing with high-pressure oil and fabricating a new hose on-site.

5:30 PM: The excavator is repaired and operational. Alex cleans up, restocks the service truck mentally for the next day, and begins the drive back to the main shop, knowing that two multi-million dollar projects are back on schedule because of the work done today.

This "Day in the Life" illustrates the high-stakes, problem-solving nature of the job. It's not just about being a mechanic; it's about being a critical operational partner.

Average Heavy Machinery Mechanic Salary: A Deep Dive

The compensation for a heavy machinery mechanic is a compelling aspect of the career, reflecting the high level of skill and responsibility required. Unlike some trades, the earning potential has a very high ceiling, especially for those who specialize and embrace continuous learning.

Let's break down the numbers from the most reliable sources.

### National Averages and Salary Ranges

The most authoritative source for employment and wage data in the United States is the U.S. Bureau of Labor Statistics (BLS). The BLS classifies this role under "49-3042 Heavy Vehicle and Mobile Equipment Service Technicians." According to the most recent BLS data from May 2023:

- Median Annual Salary: $61,070 per year

- Median Hourly Wage: $29.36 per hour

The "median" is the midpoint—half of all mechanics earned more than this, and half earned less. However, this single number doesn't tell the whole story. The salary range is vast:

- Lowest 10% earned less than: $42,260 per year ($20.32/hour)

- Highest 10% earned more than: $83,810 per year ($40.29/hour)

It's crucial to note that the BLS data often doesn't fully capture overtime pay, which can be a significant portion of a mechanic's total income. Reputable salary aggregators, which collect self-reported data, often show a higher upper range.

- Payscale.com reports an average base salary of around $62,100 per year, with a total pay range (including bonuses and overtime) stretching from $45,000 to $98,000.

- Salary.com lists the median salary for a Heavy Equipment Mechanic II (an experienced, non-supervisory role) at $71,114, with a typical range between $63,180 and $79,933. Senior and Master Technicians are listed with median salaries well into the $80,000s and $90,000s.

- Glassdoor shows a total pay estimate of around $73,500 per year, combining a base salary of approximately $66,000 with additional pay like bonuses and profit sharing.

The consensus is clear: while a starting mechanic might be in the $45k-$55k range, an experienced, skilled technician can realistically expect to earn between $65,000 and $85,000, with master technicians in high-demand industries and locations pushing well past $100,000 when overtime is factored in.

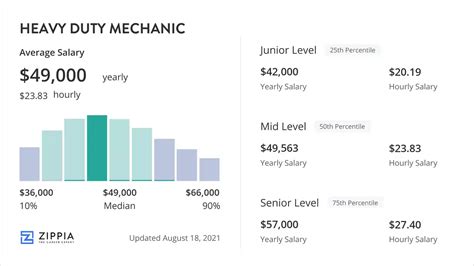

### Salary by Experience Level

Your earnings will grow substantially as you move from an apprentice to a seasoned expert. Here's a typical salary progression:

| Experience Level | Years of Experience | Typical Annual Salary Range (Base) | Key Characteristics & Roles |

| :--- | :--- | :--- | :--- |

| Entry-Level / Apprentice | 0-2 Years | $42,000 - $55,000 | Learning the trade, performing preventative maintenance, assisting senior techs, developing foundational skills. |

| Mid-Career / Technician II | 3-9 Years | $55,000 - $75,000 | Working independently, diagnosing complex issues, handling a wide range of repairs, may mentor apprentices. |

| Senior / Lead Technician | 10-15 Years | $70,000 - $90,000+ | Master of diagnostics, specializes in complex systems (e.g., hydraulics, electronics), leads repair jobs, acts as shop foreman. |

| Master / Diagnostic Specialist | 15+ Years | $85,000 - $120,000+ | The top-tier expert, often a field service technician in a high-paying industry (mining, cranes), possesses manufacturer-specific master certifications. |

### Beyond the Paycheck: A Look at Total Compensation

A heavy machinery mechanic's salary is only one piece of the puzzle. The total compensation package can add significant value and is a critical factor when comparing job offers.

- Overtime Pay: This is arguably the most significant variable. In construction and mining, long hours are common, especially during peak season or for emergency repairs. Time-and-a-half and even double-time pay can add 20-50% or more to a mechanic's annual earnings. A mechanic with a base hourly rate of $35 could see their rate jump to $52.50 for overtime hours.

- Bonuses: Many companies offer performance-based bonuses tied to efficiency (e.g., billable hours), safety records, and company profitability.

- Profit Sharing: Some employers, particularly smaller, successful independent shops or dealerships, distribute a portion of their annual profits to employees.

- Tool and Boot Allowance: The profession requires a significant personal investment in tools. Many top-tier employers offer an annual allowance (e.g., $500 - $2,000 per year) to help build and maintain your tool collection, as well as allowances for safety boots.

- Company Vehicle: For field service technicians, a fully-equipped service truck is provided. This often includes fuel, maintenance, and insurance, eliminating all commuting and work-related vehicle costs.

- Comprehensive Benefits: This is a major differentiator. Good employers offer robust packages that include:

- Health, Dental, and Vision Insurance: A valuable, non-taxable benefit.

- Retirement Plans: 401(k) or 403(b) plans, often with a generous company match (e.g., matching 50% of your contribution up to 6% of your salary).

- Paid Time Off (PTO): Including vacation, sick days, and paid holidays.

- Disability and Life Insurance: Providing a safety net for you and your family.

- Union Benefits: In many regions, heavy equipment mechanics are represented by unions like the International Union of Operating Engineers (IUOE). Union positions typically feature defined-benefit pension plans, excellent healthcare, and standardized wage scales that are often higher than non-union shops.

When evaluating a job offer, it's essential to look at the entire package. A job with a slightly lower base salary but with guaranteed overtime, a company truck, an excellent 401(k) match, and a pension plan could be far more lucrative in the long run.

Key Factors That Influence Salary

Your earning potential as a heavy machinery mechanic is not a fixed number. It's a dynamic figure influenced by a combination of your skills, choices, and environment. To maximize your salary, you need to understand and strategically leverage these key factors. This is the most critical section for anyone serious about building a high-income career in this field.

### Level of Education & Certification

While you can enter the field with just a high school diploma, formal education and, more importantly, certifications are the fastest way to increase your value and pay.

- High School Diploma / GED: This is the minimum entry requirement. Aspiring mechanics should focus on shop classes, mathematics, physics, and computer literacy.

- Vocational/Technical School Certificate: A 9-to-12-month program in Diesel Technology or Heavy Equipment Repair provides a massive head start. Employers overwhelmingly prefer candidates with this foundational training because it drastically reduces their initial training investment. Graduates can often start at a higher pay grade than someone with no formal training.

- Associate's Degree (A.A.S.): A two-year Associate of Applied Science degree goes deeper into the theory behind diesel engines, advanced hydraulics, electronic control systems, and even business management. This degree makes you a prime candidate for top-tier apprenticeship programs at major dealerships (like Caterpillar's "ThinkBIG" program) and positions you for future leadership roles like a Service Manager. An associate's degree can command a starting salary 10-15% higher than a certificate alone.

The Power of Certifications:

Certifications are the gold standard in the industry. They are a verifiable testament to your expertise and are often directly tied to pay increases.

- ASE Certifications: The National Institute for Automotive Service Excellence (ASE) is the most recognized certification body. While many associate ASE with cars, they have a dedicated series for medium-heavy trucks (T-Series), school buses (S-Series), and are highly respected in the heavy equipment world. Holding multiple ASE certifications, especially achieving "Master Technician" status, can lead to immediate pay bumps and makes you a much more attractive hire.

- Manufacturer-Specific Certifications: This is where the highest salaries are often found. Major manufacturers like Caterpillar, John Deere, Komatsu, Volvo, and Cummins have their own intensive, multi-level training and certification programs. A mechanic who is a "Cat Certified Master Technician" or a "John Deere Certified Master Technician" has proven expertise on that specific brand's equipment. These certifications are often required for top-paying dealership and field service jobs. Companies invest heavily in this training and reward certified technicians with premium pay rates.

- Specialized Certifications:

- Welding Certifications (e.g., AWS): Being a certified welder in various processes (Stick, MIG) is a highly valuable ancillary skill.

- Crane Operator/Mechanic Certifications (e.g., NCCCO): The world of cranes is highly specialized and regulated. A mechanic who is also a certified crane inspector or operator is in a class of their own.

- Hydraulic Specialist Certification (IFPS): Certification from the International Fluid Power Society demonstrates elite knowledge of hydraulic systems, the lifeblood of most heavy equipment.

### Years of Experience

Experience is, without a doubt, a primary driver of salary growth. In this trade, there is no substitute for time spent troubleshooting real-world problems.

- 0-2 Years (Apprentice): You are learning and earning. Your primary value is your potential and willingness to absorb knowledge. You'll handle routine maintenance and assist senior techs, with your pay reflecting your trainee status. Expect to be in the $42k-$55k range.

- 3-5 Years (Technician): You've proven your competence. You can work independently on most common repairs and can diagnose a wide range of issues. You are a reliable, productive member of the team. Your salary will see its first significant jump, likely into the $55k-$70k range. This is where you start to see significant overtime opportunities.

- 6-10 Years (Senior Technician): You are now a go-to problem solver. You've seen hundreds of different failures and can diagnose the obscure, intermittent problems that stump junior mechanics. You may have a specialization in electronics or hydraulics. You're likely mentoring others. Your base salary should be in the $70k-$85k range, with total compensation often pushing higher with overtime and bonuses.

- 10+ Years (Lead / Master Technician): You are at the top of your technical game. You are the final authority on complex repairs in the shop or the lead technician in the field. You hold multiple master-level certifications and are trusted with the most critical and expensive equipment. Your base salary can easily be $85k-$100k+, and with overtime in a high-demand sector like mining or field service, total compensation can reach $120,000 or more.

### Geographic Location

Where you work has a dramatic impact on your paycheck. This is due to a combination of local demand for technicians and the prevailing cost of living. BLS data from May 2023 clearly highlights the highest-paying regions.

Top-Paying States for Heavy Machinery Mechanics:

| State | Annual Mean Wage | Why It Pays More |

| :--- | :--- | :--- |

| Alaska | $82,370 | Remote work, oil/gas/mining industries, harsh conditions. |

| Nevada | $77,660 | Dominated by the massive mining industry. |

| Wyoming | $74,010 | Mining, oil, and gas extraction industries. |

| Washington | $73,730 | Major construction, shipping ports, and aerospace industries. |

| California | $72,830 | Massive economy, large-scale agriculture and construction, high cost of living. |

Conversely, states in the Southeast and some parts of the Midwest tend to have lower average salaries, but this is often offset by a significantly lower cost of living. A $65,000 salary in Alabama can provide a better quality of life than a $75,000 salary in California.

Top-Paying Metropolitan Areas:

Cities with heavy industrial activity also command premium pay. The BLS highlights areas like:

- Anchorage, AK: $82,470

- Reno, NV: $80,180

- San Jose-Sunnyvale-Santa Clara, CA: $85,270

- Fairbanks, AK: $83,330

When considering a location, always analyze the salary in the context of housing costs, taxes, and other living expenses.

### Industry and Employer Type

The industry you serve dictates the type of equipment you work on, the working conditions, and your pay scale.

- Mining, Quarrying, and Oil & Gas Extraction: This is consistently the highest-paying industry for heavy machinery mechanics. The equipment is colossal (e.g., 400-ton haul trucks), the work is often in remote and challenging locations, and the cost of downtime is astronomical. These factors combine to create six-figure earning potential for experienced technicians.

- Federal, State, and Local Government: Working for entities like the Department of Transportation, a state parks department, or a municipal public works fleet offers incredible job security, excellent benefits, and often a pension plan. While the top-end salary might be slightly lower than in the private sector's most demanding jobs, the work-life balance and total benefits package are often superior.

- Construction: This is the largest employer of heavy equipment mechanics. Pay is strong and driven by a robust economy and infrastructure spending. Union representation is common in this sector, leading to standardized high wages and strong benefits.

- Equipment Rental and Leasing Companies: Companies like United Rentals or Sunbelt Rentals employ large numbers of mechanics to maintain their vast fleets. This provides exposure to a wide variety of equipment brands and types.

- Equipment Dealerships: Working for a Caterpillar, John Deere, or Komatsu dealer is a fantastic career path. You become a specialist on a single brand and gain access to unparalleled manufacturer training and certification programs. Top technicians at dealerships are highly paid and respected.

- Agriculture: Mechanics specializing in agricultural equipment like combines, tractors, and sprayers are in high demand, especially in the Midwest. The work can be seasonal but is extremely critical during planting and harvesting seasons, leading to significant overtime.

### Area of Specialization

Generalists are valuable, but specialists are invaluable. Developing deep expertise in a specific, complex area of heavy equipment repair is the most direct route to a higher salary.

- Field Service Technician vs. Shop Technician: While both are crucial, Field Service Technicians consistently earn more. They are the elite troubleshooters who work independently, face customers directly, and operate under immense pressure to get equipment running. Their premium pay reflects their higher skill level, autonomy, and the demands of travel and on-site problem-solving.

- Electronics and Diagnostics Specialist: As machines become "smarter," the mechanic who can master the laptop is as important as the one who can master the wrench. Technicians who can expertly navigate diagnostic software, read electronic schematics, and troubleshoot complex sensor and ECU issues are in extremely high demand and can command top dollar.

- Hydraulics Specialist: Hydraulic systems are the muscles of heavy equipment. A technician who has a profound understanding of hydraulic pumps, motors, valves, and control systems can solve problems that leave others baffled. This is a highly respected and well-compensated specialization.

- Engine and Powertrain Specialist: While many repairs involve bolt-on components, the expert who can perform a complete, in-frame engine rebuild or diagnose a complex transmission failure possesses a rare and valuable skill set.

- Crane and Rigging Specialist: The world of cranes is governed by strict safety standards (OSHA). Mechanics who specialize in crane repair and inspection are part of a niche, highly paid community.

### In-Demand Skills

Beyond broad specializations, specific, demonstrable skills on your resume will get you noticed and paid more.

- High-Value Technical Skills:

- Proficiency with OEM diagnostic software (CAT ET, John Deere Service Advisor, Cummins INSITE).

- Advanced welding and fabrication (certifications are a plus).

- Air conditioning (A/C) system diagnosis and repair (requires Section 609 certification).

- Machining and line boring.

- Experience with telematics systems and interpreting the data they provide for predictive maintenance.

- Crucial Soft Skills:

- Communication: Clearly explaining a complex technical failure to a non-technical site manager or customer is a vital skill, especially in field service roles.

- Problem-Solving: A logical, systematic approach to diagnostics is more valuable than just knowing how to replace parts.

- Attention to Detail: Meticulousness in repairs and documentation prevents comebacks and ensures safety.

- Time Management: In the field, efficiently managing your time to maximize uptime for multiple clients is key