In the intricate, humming world of modern industry, from the robotic arms that assemble your car to the complex systems that purify your water, there is an unsung hero: the PLC Technician. These are the individuals who speak the language of machines, the digital conductors of the industrial orchestra. If you're a natural problem-solver, fascinated by how things work, and seeking a stable, lucrative, and in-demand career, then understanding the potential of a PLC technician salary is your first step into a larger, more exciting world.

This career isn't just about turning a wrench; it's about programming the brains behind the brawn of automation. The financial rewards reflect this high level of skill, with typical salaries ranging from a solid starting wage of around $55,000 to well over $100,000 for experienced specialists. I once toured a massive food and beverage packaging facility that ran with breathtaking efficiency, a whirlwind of conveyors, fillers, and robotic packers. When a critical sorting machine went down, it wasn't a team of mechanics that swarmed it; it was a single, focused technician with a laptop who, after a few minutes of digital diagnostics and coding, brought the entire line back to life. That moment crystalized for me the immense value and power held by a skilled PLC technician—they are the critical link between potential and production.

This comprehensive guide will serve as your blueprint for navigating this career path. We will dissect every component of a PLC technician's salary, explore the factors that can maximize your earning potential, and lay out a clear, step-by-step plan to get you started.

### Table of Contents

- [What Does a PLC Technician Do?](#what-is-a-plc-technician)

- [Average PLC Technician Salary: A Deep Dive](#salary-deep-dive)

- [Key Factors That Influence PLC Technician Salary](#key-factors)

- [Job Outlook and Career Growth for PLC Technicians](#job-outlook)

- [How to Become a PLC Technician: Your Step-by-Step Guide](#how-to-get-started)

- [Conclusion: Is a Career as a PLC Technician Right for You?](#conclusion)

What Does a PLC Technician Do?

Before we dive into the numbers, it's essential to understand the core of the profession. What exactly is a PLC, and what does a technician who specializes in them do all day?

A Programmable Logic Controller (PLC) is a ruggedized industrial computer that forms the central nervous system of most automated processes. Think of it as the specialized brain that tells a machine or a series of machines what to do, when to do it, and how to react to various inputs. It takes in information from sensors (like temperature, pressure, or proximity switches) and makes decisions to control outputs (like starting a motor, opening a valve, or moving a robotic arm).

A PLC Technician is a highly skilled professional responsible for the entire lifecycle of these critical controllers. Their work is a dynamic blend of electrical engineering, computer programming, and hands-on mechanical troubleshooting.

Core Responsibilities and Daily Tasks:

The duties of a PLC Technician are varied and project-driven. While no two days are exactly alike, their work generally revolves around these key functions:

- Installation and Commissioning: When a new automated system or piece of machinery is installed, the PLC Technician is on the front lines. They wire the controller, connect sensors and actuators, upload the initial program, and meticulously test the entire system to ensure it operates according to design specifications. This process, known as commissioning, is critical to a successful launch.

- Programming and Logic Development: This is the "coding" aspect of the job. Technicians write and modify programs using specialized languages, the most common being Ladder Logic, which visually resembles an electrical relay schematic. They also use other languages like Function Block Diagram (FBD) and Structured Text (ST) to create the sequences of operations that control the machinery. This could be as simple as "if sensor A is triggered, start motor B" or as complex as a multi-stage chemical mixing process.

- Troubleshooting and Repair: This is arguably the most crucial and demanding part of the role. When a machine on a production line stops working, every second of downtime costs the company money. The PLC Technician is the first responder. They use their laptop to connect to the PLC, diagnose the fault by analyzing the code and I/O (Input/Output) status, and determine if the issue is a failed sensor, a faulty motor, a wiring problem, or a bug in the program. Their ability to quickly and accurately pinpoint and resolve these issues is what makes them invaluable.

- Maintenance and Optimization: PLC Technicians perform routine preventive maintenance to keep systems running smoothly. This includes backing up programs, checking battery health on PLCs, calibrating sensors, and inspecting wiring. They are also constantly looking for ways to make processes better—tweaking program timing for more speed, improving safety interlocks, or adding new features to enhance efficiency.

- Documentation: Meticulous record-keeping is vital. Technicians document program changes, update electrical schematics, and maintain logs of maintenance and repairs. This documentation is essential for future troubleshooting and for training other personnel.

### A Day in the Life of a PLC Technician

To make this more concrete, let's walk through a typical day for "Alex," a mid-career PLC Technician at a large automotive parts manufacturing plant:

- 7:00 AM: Alex arrives, grabs a coffee, and heads to the maintenance shop. The first task is to review the logs and work orders from the overnight shift. A note mentions an intermittent fault on "Assembly Line 3's" robotic welding station.

- 7:30 AM: Alex attends the morning production meeting with shift supervisors and engineers. They discuss production targets and any known equipment issues. Alex provides an update on the plan to investigate Line 3.

- 8:00 AM: With a laptop in hand, Alex heads to the factory floor. The air is loud with the hum and clatter of machinery. At Line 3, Alex connects the laptop to the welding robot's Allen-Bradley PLC. The program shows a specific proximity sensor is failing to register a part in position, causing the robot to pause.

- 9:15 AM: After confirming the issue in the code, Alex performs a physical inspection. Using a multimeter, Alex tests the sensor and its wiring, discovering a frayed wire at the connection point. Alex powers down the station (following strict lock-out/tag-out safety procedures), replaces the damaged section of the cable, and re-terminates the connection.

- 10:30 AM: After powering the station back on, Alex runs the robot through several test cycles. The new connection is solid, and the fault is cleared. Alex marks the work order as complete, documenting the cause and the fix in the maintenance system.

- 11:30 AM: Back at the desk, Alex spends time working on a longer-term project: upgrading the Human-Machine Interface (HMI) screen for a different production line. This involves designing new graphics, adding more diagnostic information for the operators, and ensuring the HMI communicates properly with the PLC.

- 1:00 PM: Lunch.

- 1:30 PM: An urgent call comes in. The main conveyor system that feeds parts to multiple lines has stopped. Downtime is critical. Alex rushes to the main control panel.

- 1:45 PM: Connecting to the Siemens PLC that controls the conveyor network, Alex sees a safety circuit fault. By systematically tracing the logic and checking the physical E-stop buttons and light curtains along the conveyor's length, Alex finds an E-stop button that was accidentally pressed and not reset.

- 2:30 PM: After getting clearance from the area supervisor, Alex resets the system, and the conveyor rumbles back to life. Another fire is extinguished.

- 3:00 PM: Alex returns to the HMI upgrade project, writing and testing the new code in a simulated environment before it can be deployed to the live system.

- 4:30 PM: Alex backs up all program changes made during the day to the central server, cleans up the workspace, and writes a brief handoff report for the evening shift technician.

This "day in the life" illustrates the dynamic nature of the role—a constant cycle of proactive project work and reactive, high-stakes problem-solving.

Average PLC Technician Salary: A Deep Dive

Now for the central question: How much can you expect to earn as a PLC Technician? The compensation for this role is strong, reflecting the specialized skills required and the critical impact technicians have on a company's bottom line.

It's important to note that PLC Technicians are often classified under broader categories by government agencies like the U.S. Bureau of Labor Statistics (BLS). The BLS groups them with "Electrical and Electronics Engineering Technologists and Technicians" or "Industrial Machinery Mechanics." For the most accurate, role-specific data, we will primarily reference leading salary aggregators that collect real-world salary data directly for the title "PLC Technician."

### National Averages and Typical Salary Ranges

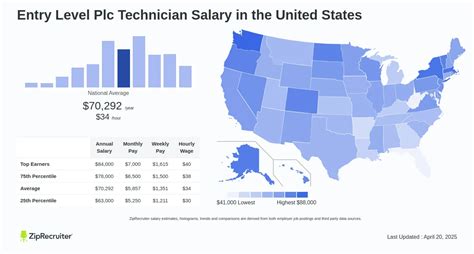

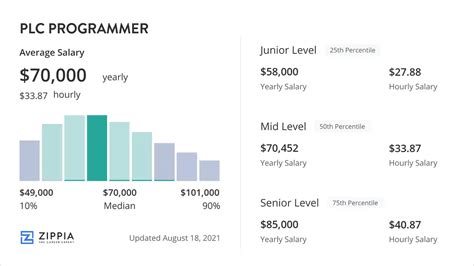

Across the United States, the salary for a PLC Technician is highly competitive. Here's a look at the data from several authoritative sources as of late 2023 and early 2024:

- Salary.com: Reports the median annual salary for a PLC Technician in the U.S. is $77,410. The typical range falls between $66,975 (25th percentile) and $88,143 (75th percentile). The top 10% of earners can exceed $98,157.

- Payscale: Shows a slightly wider range, with an average base salary of $68,891 per year. The full range reported by their user data spans from $51,000 to $94,000 for base salary alone, not including overtime or bonuses.

- Glassdoor: Cites a total pay average of $81,677 per year, with a likely range of $65,000 to $103,000. This figure includes base salary as well as additional compensation like cash bonuses.

- U.S. Bureau of Labor Statistics (BLS): While not specific to PLC Technicians, the median annual wage for Electrical and Electronics Engineering Technologists and Technicians was $70,000 in May 2022. The broader category of Industrial Machinery Mechanics had a median pay of $60,330, though PLC specialists within this group typically earn significantly more due to their programming skills.

Key Takeaway: A conservative estimate for the median national salary is around $75,000, with a common entry-level starting point in the $55,000 to $65,000 range and senior-level or highly specialized technicians earning $90,000 to $110,000+.

### Salary by Experience Level

As with any skilled profession, experience is one of the most significant drivers of salary growth. A technician's value increases dramatically as they move from basic maintenance to complex system integration and troubleshooting.

Here is a typical salary progression you can expect throughout your career:

| Career Stage | Years of Experience | Typical Annual Salary Range (Base) | Key Responsibilities & Skills |

| :--- | :--- | :--- | :--- |

| Entry-Level PLC Technician | 0 - 2 years | $55,000 - $68,000 | Assisting senior technicians, performing preventive maintenance, basic troubleshooting, reading schematics, making minor program edits under supervision. |

| Mid-Career PLC Technician | 3 - 8 years | $69,000 - $85,000 | Independent troubleshooting of complex faults, programming small-to-medium projects, HMI development, VFD configuration, mentoring junior technicians. |

| Senior/Lead PLC Technician | 8+ years | $86,000 - $105,000+ | Designing and commissioning new automation systems, advanced programming (Structured Text, etc.), managing large-scale upgrade projects, robotics integration, system optimization. |

| Controls Engineer / Specialist | 10+ years (often w/ degree) | $95,000 - $130,000+ | Full system architecture design from the ground up, managing teams of technicians, R&D for new technologies, high-level project management, OT network design. |

*Source: Data compiled and synthesized from Salary.com, Payscale, and Glassdoor career progression data.*

### Beyond the Base Salary: Understanding Total Compensation

Your annual salary is only one piece of the puzzle. Total compensation for a PLC Technician can be significantly higher once you factor in additional pay and benefits, which are common in the industrial sector.

- Overtime Pay: This is a major factor. PLC Technicians are often hourly employees, even at high pay rates, making them eligible for time-and-a-half or even double-time pay. Because machine downtime is so costly, technicians are frequently called upon to work extra hours during breakdowns, shutdowns, or project installations. It's not uncommon for a skilled technician's W-2 to be 20-30% higher than their base salary due to overtime.

- Bonuses: Many manufacturing companies offer annual or quarterly performance bonuses tied to production goals, uptime metrics, or overall company profitability. These can range from a few thousand dollars to 10-15% of your base salary.

- Profit Sharing: Some companies, particularly privately-owned or employee-focused ones, offer profit-sharing plans where a portion of the company's profits is distributed to employees.

- On-Call Stipends: Technicians who are part of a rotating on-call schedule for after-hours emergencies often receive a weekly stipend simply for being available, plus their hourly rate (and often a minimum call-out time) if they are actually called in.

- Comprehensive Benefits: Employer-provided benefits are a significant part of the compensation package. This typically includes:

- Health, dental, and vision insurance

- 401(k) or 403(b) retirement plans with company matching

- Paid time off (vacation, sick days, holidays)

- Life insurance and disability coverage

- Tuition Reimbursement: Many employers will pay for you to pursue an Associate's or Bachelor's degree, or for high-value certifications.

- Tool and Clothing Allowances: It's common for companies to provide an annual allowance for new tools, steel-toed boots, and safety gear.

When evaluating a job offer, it's crucial to look beyond the base salary and consider the full value of the total compensation package. A role with a slightly lower base salary but excellent overtime potential and a strong benefits package could be far more lucrative in the long run.

Key Factors That Influence PLC Technician Salary

While the national averages provide a good baseline, your specific salary as a PLC Technician will be determined by a combination of several key factors. Mastering these elements is the key to maximizing your earning potential throughout your career. This section is the most critical for understanding how to strategically build your value in the marketplace.

###

Level of Education and Certification

Your formal education and professional certifications provide the foundational knowledge and validated proof of your skills, directly impacting your starting salary and long-term growth.

- High School Diploma / Vocational Training: It is possible to enter the field with a strong mechanical/electrical aptitude and a high school diploma, often starting in a general maintenance role and learning PLCs on the job. However, this path typically results in a lower starting salary and a slower progression.

- Associate's Degree (A.A.S.): This is the sweet spot and the most common educational pathway for successful PLC Technicians. An Associate of Applied Science in a field like Electrical Engineering Technology, Mechatronics, Industrial Automation, or Instrumentation and Control Technology is highly valued by employers. These two-year programs provide the perfect blend of theoretical knowledge (Ohm's law, digital logic) and hands-on lab experience with real PLCs, motors, and sensors. Graduates with an A.A.S. can command starting salaries at the higher end of the entry-level range, often $5,000 to $10,000 more per year than candidates without a degree.

- Bachelor's Degree (B.S.): A four-year degree in Electrical Engineering Technology (BSET) or Mechatronics Engineering opens the door to higher-level roles, often blurring the line between a senior technician and a full-fledged Controls Engineer. These roles involve more system design, project management, and R&D. While the initial starting salary may not be drastically higher than an experienced A.A.S. graduate, the long-term ceiling is significantly elevated, often reaching well into the six-figure range ($110,000 - $140,000+).

- Certifications: This is where you can truly differentiate yourself. Certifications prove your expertise on specific, widely-used platforms.

- Vendor-Specific Certifications: These are the most valuable. Holding a certification from a major manufacturer like Rockwell Automation (the makers of Allen-Bradley PLCs), Siemens, or Mitsubishi is a powerful signal to employers that you can be effective on their equipment from day one. A Rockwell Automation CCP/CCNP (ControlLogix Certified Professional) or a Siemens TIA Portal Certification can easily add $5,000 or more to your annual salary.

- Vendor-Neutral Certifications: Organizations like the Electronics Technicians Association (ETA) offer certifications like the Certified Automation Technician (CAT) or Industrial Electronics Technician (IND). These are excellent for validating your foundational knowledge across different platforms.

- Robotics Certifications: As automation and robotics become more integrated, certifications from robotics giants like FANUC, KUKA, or ABB are becoming extremely valuable for PLC technicians working in advanced manufacturing.

###

Years of Experience

As detailed in the table above, experience is the single greatest determinant of salary. The reason is simple: an experienced technician's troubleshooting ability is exponentially more valuable than a novice's.

- Entry-Level (0-2 Years): Salary Range: $55,000 - $68,000. At this stage, you are learning the specific systems of your employer and proving your fundamental skills. Your value is in your potential and your ability to learn quickly.

- Mid-Career (3-8 Years): Salary Range: $69,000 - $85,000. You are now a trusted, independent problem-solver. You can handle most common faults without supervision and are beginning to contribute to new projects. Your ability to minimize downtime is now a proven asset, justifying a significant pay increase.

- Senior/Lead (8+ Years): Salary Range: $86,000 - $105,000+. You are the expert. You are called for the most complex, "unsolvable" problems. You lead system upgrades, mentor junior staff, and contribute to the strategic direction of the company's automation efforts. Your salary reflects your status as a critical asset and knowledge repository. Many senior technicians in high-cost-of-living areas or specialized industries can earn well over $120,000 with overtime.

###

Geographic Location

Where you work has a massive impact on your paycheck, driven by two main forces: cost of living and the concentration of industrial activity.

- High-Paying States/Regions: States with a high cost of living and a heavy concentration of advanced manufacturing, technology, pharmaceuticals, or energy production tend to offer the highest salaries.

- Examples: California (especially the Bay Area and Southern California), Massachusetts, Washington, Alaska (driven by the oil and gas industry), New York, and New Jersey. A PLC technician in San Jose, CA, might earn 25-35% more than the national average.

- Mid-Range/Average-Paying States/Regions: These are often the industrial heartland states, which have a lower cost of living but a very high demand for technicians.

- Examples: Texas, Michigan, Ohio, Indiana, Illinois, Pennsylvania, and Wisconsin. While the nominal salary might be closer to the national average, the purchasing power of that salary is much greater.

- Lower-Paying States/Regions: States with a lower cost of living and less concentrated industrial or manufacturing sectors will typically offer salaries below the national average.

- Examples: Mississippi, Arkansas, South Dakota, Montana.

Sample City-Level Salary Comparison (Median Base Salary):

| City | Estimated Median Salary | Comparison to National Average |

| :--- | :--- | :--- |

| San Jose, CA | $98,500 | ~+27% |

| Boston, MA | $89,800 | ~+16% |

| Houston, TX | $80,100 | ~+3% |

*Detroit, MI | $78,300 | ~+1% |

| Chicago, IL | $82,500 | ~+6% |

| Charlotte, NC | $75,500 | ~-2% |

| Kansas City, MO | $74,000 | ~-4% |

*Source: Data synthesized from Salary.com and Indeed's location-based salary tools, January 2024. These figures are estimates and can vary.*

###

Company Type and Industry

The type of company you work for and the industry it operates in create different demands, cultures, and compensation structures.

- Large Corporations / Fortune 500 Manufacturers:

- Examples: Procter & Gamble, Ford, Toyota, Johnson & Johnson, Amazon.

- Pros: Typically offer higher base salaries, outstanding benefits packages, structured career paths, and access to cutting-edge technology.

- Cons: Can be more bureaucratic, and your role might be more specialized and narrowly focused.

- System Integrators:

- Examples: Companies that design and build custom automation solutions for other factories.

- Pros: Extremely high learning potential as you work on diverse projects across various industries. Pay can be very high, often with project-based bonuses. Involves travel, which can be a pro or con.

- Cons: Can be high-stress with tight deadlines. Work-life balance can be challenging during project commissioning.

- OEMs (Original Equipment Manufacturers):

- Examples: Companies that build the industrial machines themselves (e.g., a packaging machine manufacturer).

- Pros: You become a deep expert on a specific set of equipment. Often involves travel to customer sites for installation and support (often called a Field Service Technician), which comes with premium pay.

- Cons: Your skills might become less transferable if you only work on one type of proprietary system.

- Small to Medium-Sized Manufacturers (SMMs):

- Pros: You get to be a jack-of-all-trades, gaining broad experience. You often have a greater impact on the company's success.

- Cons: Base salary and benefits might be lower than at large corporations, though this can sometimes be offset by profit sharing or a more flexible work environment.

- Industry Specialization: Your salary is also influenced by the industry's specific demands.

- Pharmaceutical/Biotech: Requires strict adherence to FDA regulations (e.g., 21 CFR Part 11). Technicians with this knowledge are in high demand and command premium salaries.

- Oil & Gas: Often involves working in harsh