Introduction

In every bustling construction site, every complex manufacturing plant, and every high-tech laboratory, there exists a critical, often unseen, guardian. This professional isn't operating heavy machinery or mixing chemicals; they are the strategic mind ensuring that every employee who clocks in can clock out safely at the end of the day. This is the world of the Safety Manager—a career that is not only profoundly impactful but also financially rewarding. If you're driven by a desire to protect people, solve complex problems, and build a stable, lucrative career, you’ve come to the right place.

The salary for a safety manager can be substantial, reflecting the immense responsibility and specialized knowledge the role demands. While entry-level positions start strong, experienced professionals in high-risk industries can command salaries well into the six figures. Nationally, the average total pay often hovers around $95,000 to $115,000 per year, with top earners exceeding $150,000 or more when bonuses and other compensation are factored in.

I'll never forget a site visit to a massive skyscraper project in a downtown metropolis. Amidst the cacophony of steel and concrete, I watched the lead Safety Manager calmly halt a crane operation due to shifting high-altitude winds—a decision that was initially met with grumbles about delays but was undeniably crucial for preventing a catastrophe. It was a powerful, real-time lesson in the quiet authority and life-saving foresight that defines this profession.

This guide is designed to be your definitive resource, whether you're a student contemplating this path or a seasoned professional looking to maximize your earning potential. We will dissect every component of a safety manager's salary, explore the factors that drive compensation, and lay out a clear roadmap for you to enter and advance in this vital field.

### Table of Contents

- [What Does a Safety Manager Do?](#what-does-a-safety-manager-do)

- [Average Safety Manager Salary: A Deep Dive](#average-safety-manager-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

What Does a Safety Manager Do?

A Safety Manager, often known by titles like Environmental, Health, and Safety (EHS) Manager or Occupational Health and Safety (OHS) Manager, is the primary architect and enforcer of an organization's safety culture and programs. Their fundamental mission is to prevent workplace accidents, injuries, and illnesses. They achieve this by identifying, evaluating, and controlling hazards, ensuring the organization complies with local, state, and federal regulations.

This is far from a desk-only job. It’s a dynamic role that blends strategic planning with hands-on, on-the-ground action. A Safety Manager acts as a consultant, an educator, an investigator, and a leader, all rolled into one.

Core Responsibilities and Daily Tasks:

- Policy Development and Implementation: They create, review, and update comprehensive safety policies and procedures tailored to their specific work environment (e.g., lockout/tagout procedures, fall protection plans, emergency response protocols).

- Regulatory Compliance: They are experts in regulations from agencies like the Occupational Safety and Health Administration (OSHA), the Environmental Protection Agency (EPA), and other relevant bodies. A significant part of their job is ensuring the company remains in full compliance to avoid fines, legal action, and harm to workers.

- Risk Assessment and Hazard Analysis: They conduct regular site inspections and job hazard analyses (JHAs) to proactively identify potential dangers in equipment, processes, and work environments.

- Incident Investigation: When an accident or near-miss occurs, the Safety Manager leads the investigation. Their goal is not to assign blame but to determine the root cause and implement corrective actions to prevent a recurrence.

- Training and Education: They are the primary safety educators in a company. This involves developing and delivering engaging training sessions for all levels of employees, from new hire orientation to specialized training on topics like confined space entry or hazardous material handling.

- Data Management and Reporting: They track key safety metrics (e.g., incident rates, lost time injuries), analyze trends, and prepare detailed reports for senior management to demonstrate the effectiveness of the safety program and identify areas for improvement.

- Emergency Preparedness: They are responsible for developing and practicing emergency action plans for events like fires, chemical spills, or natural disasters.

### A Day in the Life of a Manufacturing Plant Safety Manager

To make this role more tangible, let's walk through a typical day:

- 7:30 AM: The day starts not at a desk, but on the plant floor. The Safety Manager does a "Gemba walk" (a practice of going to the actual place where work happens) to observe morning shift start-up procedures, check on any new equipment, and chat informally with machine operators about any safety concerns.

- 9:00 AM: Back in the office, they review the previous day's safety observation reports and near-miss logs. They notice a recurring issue with improper machine guarding on a specific production line and schedule a meeting with the line supervisor to discuss it.

- 10:30 AM: They lead a mandatory 30-minute "toolbox talk" for the maintenance team on new electrical safety protocols (lockout/tagout) before a major equipment overhaul scheduled for the weekend.

- 11:30 AM: A call comes in from a supervisor—a minor chemical spill has occurred in the mixing area. The manager heads to the scene, ensures the spill response team is following proper procedure using the Spill Prevention, Control, and Countermeasure (SPCC) plan, and begins the initial incident report.

- 1:00 PM: After lunch, they spend two hours conducting a formal, documented audit of the facility's fire suppression systems, checking extinguisher tags, sprinkler head clearance, and emergency exit pathways.

- 3:00 PM: They meet with the plant's leadership team to present the safety performance data for the previous month. They highlight a 15% reduction in minor hand injuries since implementing a new glove policy but recommend a budget for ergonomic mats to address growing complaints of back strain.

- 4:30 PM: The final hour is spent completing the investigation report for the morning's chemical spill, documenting the root cause (a worn-out hose fitting) and issuing a corrective action for the maintenance team to inspect and replace similar fittings plant-wide.

This example illustrates the constant blend of proactive strategy and reactive problem-solving that defines the role of a Safety Manager.

Average Safety Manager Salary: A Deep Dive

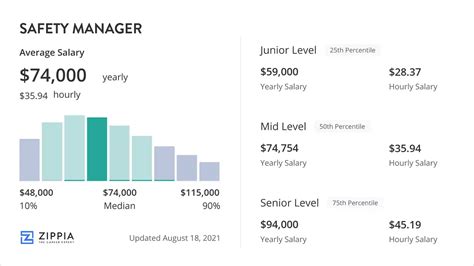

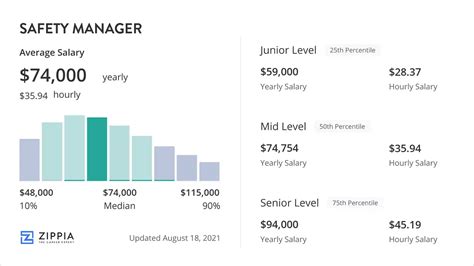

The salary for a safety manager is not a single number but a wide spectrum influenced by a host of factors we'll explore in the next section. However, by aggregating data from authoritative sources, we can build a clear picture of the compensation landscape. The role's importance is directly reflected in its pay, which is significantly higher than the national median for all occupations.

According to the U.S. Bureau of Labor Statistics (BLS), the broader category of "Occupational Health and Safety Specialists," which includes many safety management functions, had a median annual wage of $79,760 in May 2022. The top 10 percent of earners in this category made more than $124,190. It's crucial to note that "Safety Manager" is a more senior role within this category, and thus typically commands a higher salary.

Let's look at data from salary aggregators that focus specifically on the "Safety Manager" title (data as of late 2023/early 2024):

- Salary.com: Reports the median base salary for a Safety Manager in the United States to be around $110,132, with a typical range falling between $87,090 and $131,299.

- Payscale.com: Shows a median base salary of approximately $83,500, but with bonuses and profit sharing, the total pay can reach up to $115,000.

- Glassdoor.com: Estimates the average total pay (including base salary and additional compensation like cash bonuses) for a Safety Manager to be $103,450 per year.

The slight variation in these numbers highlights why it's important to look at multiple sources. The consensus is clear: a six-figure income is not an exception but a common reality for experienced professionals in this field.

### Salary by Experience Level

One of the most significant drivers of salary is experience. As a Safety Manager gains expertise, their ability to manage more complex risks, lead larger teams, and develop enterprise-wide strategies grows, and their compensation rises accordingly.

Here is a typical salary progression you can expect throughout your career.

| Career Stage | Years of Experience | Typical Salary Range (Base + Bonus) | Role & Responsibilities |

| :--- | :--- | :--- | :--- |

| Entry-Level | 0-3 years | $65,000 - $85,000 | Often titled Safety Coordinator or EHS Specialist. Focuses on inspections, data entry, assisting with training, and supporting senior managers. |

| Mid-Career | 4-9 years | $85,000 - $120,000 | Full title of Safety Manager. Manages a facility or a large project, develops safety programs, conducts complex investigations, and supervises junior staff. |

| Senior/Experienced | 10-15+ years | $120,000 - $160,000+ | Titled Senior Safety Manager, Regional EHS Manager, or Director of Safety. Oversees multiple sites or an entire business unit, sets corporate safety strategy, manages large budgets, and reports to executive leadership. |

| Executive-Level | 15+ years | $160,000 - $250,000+ | Vice President of EHS or Chief Safety Officer. Operates at the C-suite level, responsible for global safety performance, corporate governance, and integrating EHS into the company's core business strategy. |

*Source: Analysis compiled from Salary.com, Payscale, and industry job postings.*

### Deconstructing Your Compensation Package

A safety manager's salary is more than just a base paycheck. The total compensation package often includes several valuable components that significantly increase overall earnings.

- Base Salary: This is the fixed, annual amount you are paid for fulfilling the core duties of your role. It forms the foundation of your compensation.

- Annual Bonuses: This is a very common component for Safety Managers. Bonuses are variable pay tied to performance—both individual and company-wide. For a Safety Manager, this is often linked to achieving specific safety metrics, such as a reduction in the Total Recordable Incident Rate (TRIR) or Lost Time Injury Rate (LTIR), or passing a major regulatory audit with no violations. Bonuses can range from 5% to 20% or more of the base salary.

- Profit Sharing: Some companies, particularly in manufacturing and private industry, offer a profit-sharing plan where a portion of the company's profits is distributed among employees. This can add several thousand dollars to your annual income in a good year.

- Company Vehicle or Vehicle Allowance: Because Safety Managers often need to travel between job sites, plants, or offices, a company car or a monthly vehicle allowance is a common and valuable perk.

- Retirement & Health Benefits: Look beyond the immediate pay. A strong 401(k) or 403(b) plan with a generous employer match is a critical part of long-term wealth building. Comprehensive health, dental, and vision insurance are also standard.

- Professional Development Budget: Many employers will pay for you to attend industry conferences (like those hosted by the ASSP or NSC), pursue advanced certifications (like the CSP), and take continuing education courses. This is a direct investment in your career growth and future earning potential.

When evaluating a job offer, it's essential to look at this complete picture. A slightly lower base salary at a company with an outstanding bonus structure, a 10% 401(k) match, and a full professional development budget may be far more valuable in the long run.

Key Factors That Influence Salary

While the national averages provide a useful benchmark, your personal salary as a safety manager will be determined by a specific combination of factors. Understanding these levers is the key to maximizing your earning potential throughout your career. This is the most critical section for anyone looking to strategically build their value in the safety profession.

### ### Level of Education and Professional Certifications

Your educational background and credentials are the foundation of your expertise and a primary determinant of your starting salary and long-term growth.

Educational Degrees:

- Bachelor's Degree: This is the standard entry-level requirement for most Safety Manager positions. The most relevant and sought-after degrees are in Occupational Health and Safety, Industrial Hygiene, Environmental Science, or a related engineering field. A degree in business or management with a safety concentration can also be effective.

- Master's Degree: Pursuing a Master of Science (MS) in Occupational Safety, a Master of Public Health (MPH) with an environmental/occupational health focus, or an MS in Industrial Hygiene can significantly boost earning potential and open doors to senior leadership and specialized technical roles. According to Payscale, professionals with a master's degree often earn 10-15% more than those with only a bachelor's. It signals a higher level of expertise, particularly in complex areas like toxicology, epidemiology, and advanced safety management systems.

Professional Certifications (The Game Changer):

Certifications are arguably more impactful on a safety manager's salary than an advanced degree. They are the industry's gold standard for validating competence and knowledge.

- Certified Safety Professional (CSP): This is the premier certification for safety professionals, administered by the Board of Certified Safety Professionals (BCSP). Achieving the CSP designation requires a combination of education, experience, and passing a rigorous exam. It demonstrates a mastery of safety management principles. Holding a CSP can increase your salary by an average of $15,000 to $30,000 per year. It is often a requirement for senior and director-level positions.

- Associate Safety Professional (ASP): The ASP is the common stepping-stone to the CSP. Earning it demonstrates foundational knowledge and is a powerful signal to employers that you are on the path to top-tier certification.

- Certified Industrial Hygienist (CIH): For those specializing in health hazards (chemical exposures, noise, radiation), the CIH is the most prestigious credential. It requires a science or engineering background and deep knowledge of toxicology, exposure assessment, and controls. CIHs are among the highest-paid professionals in the EHS field due to their highly specialized and in-demand skills.

- OSHA 30-Hour Training: While not a "certification" in the same vein as the CSP, completing the OSHA 30-Hour course (in either Construction or General Industry) is a fundamental, non-negotiable requirement for virtually every safety position. It's a baseline credential that demonstrates core regulatory knowledge.

### ### Years of Experience

As highlighted in the salary table, experience is a direct and powerful driver of compensation. However, it's not just the number of years that matters, but the *quality* and *progression* of that experience.

- 0-3 Years (Coordinator/Specialist): At this stage, you are learning the ropes. Your value is in your ability to execute tasks assigned by senior managers: conducting inspections, delivering basic training, maintaining safety records, and participating in incident investigations. Your salary reflects your role as a key supporter of the safety program.

- 4-9 Years (Manager): Here, you transition from task-doer to program owner. You are now responsible for the safety performance of a specific site, project, or department. Your experience should demonstrate your ability to develop and implement safety policies, manage a budget, influence line management, and achieve measurable improvements in safety metrics (e.g., "Led a targeted fall protection campaign that reduced fall-related incidents by 40% over two years"). This demonstrated impact is what justifies the significant salary jump into the six-figure range.

- 10+ Years (Senior Manager/Director): At this level, your influence becomes strategic and enterprise-wide. You are managing other safety professionals, overseeing multiple locations, and interacting with executive leadership. Your experience should reflect your ability to develop long-term EHS strategy, manage complex legal and regulatory challenges, and integrate safety into the core business operations. Salaries at this level are high because your decisions impact the entire company's risk profile and profitability.

### ### Geographic Location

Where you work has a massive impact on your paycheck. Salaries for safety managers vary significantly by state and metropolitan area, driven by cost of living, the concentration of high-risk industries, and state-level regulations.

Top-Paying States for Safety Professionals:

According to BLS data for occupational health and safety specialists, some of the highest-paying states and districts include:

1. District of Columbia: High concentration of federal government and consulting roles.

2. California: Major construction, tech manufacturing, and agriculture industries, coupled with a high cost of living and stringent state-specific regulations (Cal/OSHA).

3. Washington: Aerospace (Boeing), tech, and maritime industries drive demand.

4. New Jersey: Hub for pharmaceutical, chemical, and manufacturing industries.

5. Alaska: Dominated by the high-risk, high-pay oil and gas, mining, and fishing industries.

Top-Paying Metropolitan Areas:

Cities with heavy industrial bases or major corporate headquarters often offer higher salaries. Areas like:

- San Jose-Sunnyvale-Santa Clara, CA

- San Francisco-Oakland-Hayward, CA

- Houston-The Woodlands-Sugar Land, TX (Oil & Gas hub)

- Bridgeport-Stamford-Norwalk, CT (Corporate HQs)

- Anchorage, AK

Conversely, salaries tend to be lower in rural areas and states with a lower cost of living and a less industrial-heavy economy. A safety manager position in a low-risk industry in rural Mississippi will likely pay significantly less than a comparable role in the construction sector of Los Angeles. When considering a job, always use a cost-of-living calculator to understand how far your salary will actually go.

### ### Industry and Company Size

The type of work environment and the size of your employer are two of the most significant salary differentiators. The simple rule is: higher risk often equals higher pay.

Salary by Industry (Highest to Lowest Potential):

1. Oil and Gas Extraction / Mining: This is consistently the highest-paying sector for safety professionals. The work involves managing extreme, life-threatening hazards (explosions, high-pressure systems, remote locations), and the potential for catastrophic failure is immense. Companies pay a premium for top-tier talent to manage this risk. Salaries can easily be 25-50% higher than the national average.

2. Heavy Construction & Infrastructure: Large-scale construction projects (skyscrapers, bridges, tunnels) are complex and fraught with hazards like falls, electrical shocks, and "struck-by" incidents. Experienced construction safety managers are highly valued.

3. Chemical and Pharmaceutical Manufacturing: Managing process safety, highly hazardous chemicals, and complex EPA regulations requires specialized expertise (like Process Safety Management - PSM), which commands a higher salary.

4. Utilities and Energy Generation: Working with high-voltage electricity, power plants, and distribution networks presents significant risks.

5. General Manufacturing & Warehousing: This is a broad category with a wide salary range. A manager at a heavy steel fabrication plant will likely earn more than one at a light assembly or food processing facility.

6. Healthcare: Safety managers in hospitals focus on patient safety, infection control (a form of biological safety), and worker safety (e.g., preventing slips, trips, and ergonomic injuries).

7. Government (Federal, State, Local): Government roles (e.g., working for OSHA as a compliance officer or for a federal agency) often offer excellent job security and benefits but may have a lower base salary compared to high-risk private industries.

8. Consulting: Safety consultants can have very high earning potential, but it's often more variable and dependent on their ability to build a client base.

Company Size:

- Large Corporations (Fortune 500): These companies typically have larger, more structured EHS departments, leading to more opportunities for advancement into regional and corporate roles. They generally offer higher salaries, more robust bonus structures, and superior benefits packages.

- Small to Medium-Sized Businesses (SMBs): A safety manager at an SMB might be a "one-person show," responsible for everything. The salary might be slightly lower, but the breadth of experience gained can be immense.

### ### Area of Specialization

Within the broad field of safety, specializing in a high-demand niche can make you a more valuable and higher-paid professional.

- Industrial Hygiene (IH): Focuses on the "health" in EHS. Experts in assessing and controlling chemical, physical, and biological health hazards are rare and highly compensated.

- Process Safety Management (PSM): A highly technical specialization required in facilities that manage hazardous chemicals (refineries, chemical plants). PSM experts are in constant demand and command premium salaries.

- Ergonomics: Specialists who can redesign workstations and processes to prevent musculoskeletal disorders (the leading cause of worker's compensation claims) are increasingly valuable, especially in manufacturing and office environments.

- Construction Safety: A deep specialization with its own set of standards (OSHA 1926). Experts in crane safety, fall protection, and excavation are critical for any major construction project.

- Environmental Compliance: Professionals who can manage both safety and environmental regulations (EPA rules on air, water, waste) have a broader skill set, making them more valuable, especially in manufacturing. This is the "E" in EHS.

### ### In-Demand Skills

Beyond your formal credentials, specific skills can directly impact your salary negotiations and career trajectory.

High-Value Hard Skills:

- Deep Regulatory Knowledge (OSHA, EPA, DOT): You must be a true expert. The ability to interpret and apply complex regulatory text is non-negotiable.

- Data Analysis & Metrics: Modern safety management is data-driven. The ability to use software (even just Excel, but increasingly specialized EHS software) to track trends, calculate incident rates, and create compelling dashboards for leadership is a must.

- Root Cause Analysis Techniques: Proficiency in methods like "5 Whys," Fishbone Diagrams, or Fault Tree Analysis to conduct thorough, unbiased incident investigations.

- Safety Management Systems (SMS): Experience with implementing and auditing formal systems like ISO 45001 or ANSI Z10.

Crucial Soft Skills (often more important at senior levels):

- Influence and Leadership: A safety manager rarely has direct authority over the workers or line managers they need to keep safe. Your success depends on your ability to persuade, influence, and lead without formal authority. You must be able to build trust and get buy-in from the front line to the C-suite.

- Communication (Written and Verbal): You must be able to write clear, concise policies and reports, as well as deliver engaging and effective training to diverse audiences—from construction workers to a board of directors.

- Problem-Solving and Critical Thinking: Every day brings new, unexpected challenges. You must be able to think on your feet, assess situations quickly, and make sound decisions under pressure.

By strategically developing these factors—pursuing a CSP, gaining experience in a high-risk industry, and honing your leadership skills—you can actively steer your career towards the upper echelons of the salary range for a safety manager.

Job Outlook and Career Growth

Investing time and money into a career path requires a clear understanding of its future viability. For safety managers, the outlook is stable and promising, driven by a persistent need for safe workplaces and evolving societal and regulatory landscapes.

The U.S. Bureau of Labor Statistics (BLS) projects employment for Occupational Health and Safety Specialists and Technicians to grow 4 percent from 2022 to 2032, which is about as fast as the average for all occupations. This translates to approximately **10,