Introduction

In a world increasingly dominated by digital services and abstract concepts, there exists a profession that is profoundly tangible, fundamentally creative, and absolutely essential to modern manufacturing. This is the world of the tool and die maker—the highly skilled artisan of the industrial age, whose precision work forms the backbone of everything from the car you drive to the smartphone in your pocket. If you are drawn to the satisfaction of creating something real with your hands and mind, a career that rewards meticulous skill with financial stability, then understanding the salary for a tool and die maker is your first step toward a fulfilling future.

This profession offers a robust and respectable income, with the U.S. Bureau of Labor Statistics reporting a median annual salary of $61,650 as of May 2023. However, this single number is just the beginning of the story. With the right skills, experience, and specialization, top-tier tool and die makers can command salaries well over $90,000 per year, plus significant overtime and benefits.

I once had the opportunity to tour a state-of-the-art medical device manufacturing facility. Amidst the hum of advanced machinery, the plant manager pointed to a small, intricately shaped metal block and said, "That's the heart of our entire operation. A master toolmaker spent 200 hours on it. Without that one piece, millions of dollars of equipment are useless, and a life-saving product doesn't get made." That moment crystallized for me the immense value and hidden prestige of this critical trade.

This comprehensive guide will illuminate every facet of a tool and die maker's career, with a special focus on compensation. We will explore the responsibilities of the role, dissect salary expectations at every career stage, and uncover the key factors that can dramatically increase your earning potential. Whether you're a high school student exploring options, a machinist looking to advance, or someone considering a career change, this article is your definitive roadmap.

### Table of Contents

- [What Does a Tool and Die Maker Do?](#what-does-a-tool-and-die-maker-do)

- [Average Tool and Die Maker Salary: A Deep Dive](#average-tool-and-die-maker-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

What Does a Tool and Die Maker Do?

Tool and die makers are elite specialists within the machining and manufacturing world. They are not assembly-line workers; they are the master craftspeople who create the tools, dies, molds, jigs, and fixtures that enable mass production. In essence, they build the "master parts" that shape, cut, form, and mold thousands or even millions of identical products. Their work requires an exceptional blend of mechanical aptitude, mathematical precision, computer literacy, and creative problem-solving.

The distinction between a "toolmaker" and a "die maker" can be subtle, and many professionals are skilled in both areas:

- Toolmakers primarily produce jigs and fixtures (devices that hold workpieces in place for machining), gauges for quality inspection, and cutting tools used in manufacturing processes. Their work ensures consistency and precision across countless operations.

- Die Makers specialize in creating dies—hardened metal devices used to shape, cut, or form materials, typically sheet metal, through processes like stamping, forging, or punching. The body panels of a car, for example, are all formed using massive, complex dies.

- Mold Makers are a closely related specialization, focusing on producing molds for plastic injection molding, die-casting of metals, and other molding processes.

Regardless of the specific title, the core responsibilities are a fascinating mix of old-world craftsmanship and new-world technology.

Core Responsibilities and Daily Tasks:

- Blueprint and Specification Analysis: The process begins with a deep analysis of technical drawings, blueprints, sketches, or 3D CAD (Computer-Aided Design) models to understand the required dimensions, tolerances, and material specifications.

- Material Selection: Choosing the right type of metal or alloy (like high-carbon tool steel) and preparing it for machining.

- Planning and Layout: Strategizing the sequence of operations needed to create the part efficiently and accurately.

- Machine Operation: Setting up and operating a wide array of conventional and computer numerically controlled (CNC) machine tools, including:

- Lathes (for turning cylindrical parts)

- Milling machines (for shaping flat or complex surfaces)

- Grinding machines (for achieving ultra-fine finishes and tight tolerances)

- Electrical Discharge Machines (EDM) (for creating complex shapes with extreme precision using electrical sparks)

- Hand Finishing: Using hand tools like files, stones, and scrapers to achieve the final, perfect fit and finish—a skill that separates the good from the great.

- Assembly and Testing: Carefully assembling the components of the tool or die, and then running tests to ensure it functions correctly and produces parts that meet all quality standards.

- Quality Control and Inspection: Using precision measuring instruments like micrometers, calipers, gauges, and Coordinate Measuring Machines (CMM) to verify that every dimension is within the specified tolerance, which can be as tight as a few ten-thousandths of an inch.

- Maintenance and Repair: Troubleshooting, sharpening, and repairing existing tools and dies to keep production lines running smoothly.

### A Day in the Life of a Senior Tool and Die Maker

To make this more concrete, let's imagine a day for "Alex," a senior tool and die maker at an aerospace manufacturing company.

- 7:00 AM: Alex arrives, grabs a coffee, and heads to the tool room floor. The first task is to review the production schedule and any overnight reports. There's a high-priority job: a new fixture is needed for holding a complex turbine blade during a CNC milling operation.

- 7:30 AM: Alex pulls up the 3D CAD model and digital blueprints for the fixture on a workstation. For the next hour, Alex meticulously studies the design, identifies the critical tolerances, and plans the entire manufacturing process—from selecting the raw block of A2 tool steel to the final grinding sequence.

- 8:30 AM: After securing the steel block in a large CNC milling center, Alex spends time programming the machine using CAM (Computer-Aided Manufacturing) software, creating the precise toolpaths that will cut the metal.

- 10:00 AM: The CNC machine is running. While it executes the program, Alex moves to another bench to work on a different task: repairing a stamping die that has been producing parts with a slight burr. This requires a sharp eye, a steady hand, and years of experience to diagnose the cause—a minuscule chip on a cutting edge. Alex carefully disassembles the die, uses a surface grinder to restore the edge, and polishes it by hand.

- 12:30 PM: Lunch break with fellow machinists, discussing a tricky heat-treating problem.

- 1:00 PM: The initial CNC cycle on the turbine blade fixture is complete. Alex removes the part, cleans it, and takes it to the quality control lab. Using a CMM, Alex measures dozens of critical points, comparing them to the digital model. Everything is within the .0005" tolerance required.

- 3:00 PM: The fixture now needs heat treatment to harden the steel. Alex prepares it for the in-house furnace, carefully setting the temperature and time parameters. While it's being treated, Alex begins the setup for the final grinding operations that will take place tomorrow morning.

- 4:30 PM: Before leaving, Alex documents all the work completed in the company's manufacturing execution system (MES), updates the project status, and cleans the workspace, leaving it ready for the next day. The day was a blend of digital programming, heavy machinery operation, precision measurement, and meticulous handwork—all contributing to the success of a multi-million dollar manufacturing program.

Average Tool and Die Maker Salary: A Deep Dive

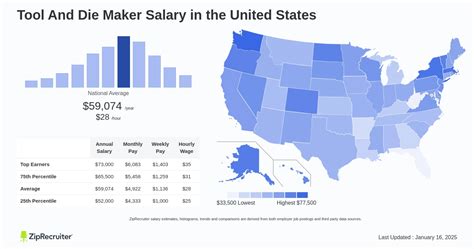

The salary for a tool and die maker reflects the high level of skill, training, and responsibility the job entails. It is a career that provides a strong, stable, middle-to-upper-middle-class income, with significant opportunities for growth based on expertise and performance. Let's break down the compensation landscape using data from the most reliable sources.

### National Averages and Salary Ranges

When looking at salary, it's important to consider both the median and the typical range, as this gives a more complete picture of earning potential.

- The U.S. Bureau of Labor Statistics (BLS), the gold standard for occupational data, reports the median annual wage for tool and die makers was $61,650 in May 2023. This means that 50% of tool and die makers earned more than this amount, and 50% earned less. The hourly equivalent is approximately $29.64 per hour. The BLS also provides a wider range: the lowest 10 percent earned less than $40,150, and the highest 10 percent earned more than $85,020.

- Salary.com, which aggregates real-time employer-reported data, shows a slightly higher range. As of late 2023, they report the median salary for a Tool and Die Maker III (an experienced professional) in the United States to be around $69,327. Their typical range falls between $61,154 and $77,935, with top earners in the 90th percentile reaching $86,220.

- Payscale, which uses self-reported professional data, shows a national average base salary of approximately $65,000 per year. Their data indicates a total pay range (including bonuses and overtime) from $46,000 to $97,000.

Summary of National Salary Data (as of late 2023/early 2024):

- Median Salary: Approximately $61,000 - $69,000

- Typical Salary Range: $50,000 - $80,000

- Entry-Level Potential (Bottom 10-25%): $40,000 - $50,000

- Senior/Top-Tier Potential (Top 10-25%): $85,000 - $97,000+

### Salary by Experience Level

Experience is arguably the single most important factor in a tool and die maker's salary. The progression from a new apprentice to a master craftsperson is marked by significant increases in responsibility, skill, and, consequently, pay.

Here is a typical salary progression based on years of experience, synthesized from data from Payscale and industry observations:

| Career Stage | Years of Experience | Typical Annual Salary Range | Key Characteristics |

| :--- | :--- | :--- | :--- |

| Apprentice/Entry-Level | 0 - 2 years | $40,000 - $52,000 | Learning basic machine operation, safety protocols, and assisting senior makers. Pay often starts at a percentage of a journeyman's rate and increases with each year of the apprenticeship. |

| Journeyman/Mid-Career | 3 - 9 years | $55,000 - $70,000 | Fully competent in operating a wide range of machines. Can work independently from blueprints to create standard tools and dies. Begins to develop troubleshooting skills. |

| Senior/Experienced | 10 - 19 years | $68,000 - $85,000 | Master of multiple machine types, including advanced CNC and EDM. Can design and build highly complex, multi-part dies and molds. Often takes on leadership, training, or project management roles. |

| Master/Lead | 20+ years | $80,000 - $97,000+ | Acknowledged expert in a specific area (e.g., progressive dies, plastic injection molds). Manages the entire tool room, designs tooling from scratch, and solves the most difficult manufacturing challenges. May own their own shop. |

### Beyond the Base Salary: A Look at Total Compensation

A tool and die maker's W-2 is often significantly higher than their base salary suggests. The nature of manufacturing work means that total compensation is frequently supplemented by other valuable components.

- Overtime Pay: This is a major factor. Manufacturing facilities often run multiple shifts and need to meet tight production deadlines. When a critical die breaks down or a new tool is needed urgently, tool and die makers are called upon to work extra hours. Overtime is typically paid at 1.5 times the regular hourly rate, and double-time for holidays or Sundays is not uncommon. It's realistic for a skilled maker to add 10-20% to their base salary through overtime alone.

- Bonuses and Profit Sharing: Many manufacturing companies, particularly successful ones, offer annual or quarterly bonuses based on individual performance, team goals, or overall company profitability. This can range from a few hundred to several thousand dollars per year.

- Shift Differentials: Working the second or third shift almost always comes with a pay premium, known as a shift differential. This is typically an extra dollar amount per hour or a percentage (e.g., 10%) of the base hourly rate, providing a substantial boost to annual earnings.

- Comprehensive Benefits: This is a crucial part of the package. Most full-time tool and die makers receive a strong benefits package that includes:

- Health Insurance: Medical, dental, and vision coverage.

- Retirement Plans: 401(k) plans, often with a company match. In some union shops, pensions may still be available.

- Paid Time Off: Vacation days, sick leave, and paid holidays.

- Tool Allowance: Some companies provide an annual allowance to help makers purchase and maintain their own precision hand tools and measuring instruments.

- Tuition Reimbursement: Companies often invest in their top talent by paying for advanced training, certifications, or even an Associate's or Bachelor's degree in a related field.

When you combine a strong base salary with significant overtime potential and a robust benefits package, the total value of a career as a tool and die maker becomes exceptionally competitive.

Key Factors That Influence Salary

While national averages and experience levels provide a solid baseline, your specific salary as a tool and die maker will be determined by a complex interplay of several key factors. Understanding and strategically navigating these variables is how you can maximize your earning potential and accelerate your career growth. This section provides an exhaustive breakdown of what truly moves the needle on your paycheck.

###

1. Level of Education and Certification

While a four-year university degree is not a requirement for this trade, the type and quality of your foundational training have a direct impact on your starting salary and long-term trajectory.

- High School Diploma / GED: This is the absolute minimum entry requirement. Students who took shop classes, drafting, trigonometry, and computer science will have a distinct advantage.

- Formal Apprenticeship: This is the traditional and most highly respected pathway. A formal, state-registered or federally-registered apprenticeship combines 4-5 years of paid, on-the-job training (OJT) with related classroom instruction. Apprentices start at a lower wage (typically 50-60% of a journeyman's rate) but receive guaranteed pay increases as they master new skills. Upon completion, they earn a "journeyman" card, a nationally recognized credential that immediately qualifies them for higher-paying positions. Employers heavily favor candidates who have completed a formal apprenticeship.

- Associate's Degree (A.A.S.): Many community colleges and technical schools offer an Associate of Applied Science (A.A.S.) degree in Machine Tool Technology, Tool & Die Making, or a related field. These two-year programs provide a strong theoretical foundation in metallurgy, blueprint reading, CAD/CAM, and CNC programming. Graduates often enter the workforce with advanced skills and may be able to secure a higher starting salary or shorten the time required for an apprenticeship. An employee with an A.A.S. degree plus 3 years of experience might command a higher salary than someone with just a 5-year apprenticeship, due to their deeper theoretical knowledge.

- Professional Certifications: Industry-recognized certifications act as proof of your skills and can lead to higher pay. The most prominent certifying body is the National Institute for Metalworking Skills (NIMS). Earning NIMS credentials in areas like:

- Measurement, Materials & Safety

- Job Planning, Benchwork & Layout

- CNC Milling & Turning Operations

- Tool & Die Making (specific credentials)

- Metalforming

These certifications validate your abilities to employers and can be a key differentiator, particularly when negotiating salary or seeking promotion.

###

2. Years of Experience (The Apprenticeship-to-Mastery Arc)

As detailed in the previous section, experience is paramount. However, it's not just about the number of years; it's about the *quality* and *diversity* of that experience.

- Apprentice (0-4 Years): Salary is structured and predictable, rising with training milestones. The focus is on learning, not earning.

- Journeyman (5-10 Years): This is where salary growth accelerates. A journeyman who has worked in a shop that produces simple stamping dies will earn less than one who has spent those years building complex, multi-station progressive dies for the automotive industry. The more complex the projects you master, the more valuable you become.

- Senior/Lead (10-20 Years): At this stage, salary is a reflection of your reputation for problem-solving. Can you diagnose why a die is failing in the press? Can you recommend design changes to improve tool life and part quality? Can you lead a team of younger makers on a complex project? Answering "yes" to these questions puts you in a higher pay bracket. Senior makers who can reverse-engineer worn parts without blueprints or who can work with exotic materials are at the top of the pay scale.

- Master/Consultant (20+ Years): The highest earners are those who have become true masters of the craft. They are not just executing plans; they are conceptualizing solutions. Some transition into roles like Tooling Engineer, Manufacturing Manager, or even open their own successful job shops, where their earning potential is limited only by their business acumen.

###

3. Geographic Location

Where you work has a massive impact on your paycheck. Salaries for tool and die makers vary significantly by state and even by metropolitan area, largely driven by the concentration of manufacturing industries and the local cost of living.

According to the U.S. Bureau of Labor Statistics (May 2023), the states with the highest annual mean wages for tool and die makers are:

| State | Annual Mean Wage |

| :--- | :--- |

| Washington | $79,840 |

| Connecticut | $70,890 |

| Minnesota | $70,300 |

| California | $68,340 |

| Massachusetts | $68,200 |

Conversely, some states with a lower concentration of high-tech manufacturing or a lower cost of living will have lower average salaries. It's important to balance the higher wage with the cost of living. A $75,000 salary in Seattle, Washington goes a lot less far than a $65,000 salary in Grand Rapids, Michigan.

The BLS also provides data for metropolitan areas. The top-paying metro areas often reflect hubs of specific industries, such as aerospace in Seattle or medical devices in Minneapolis.

- High-Paying Metro Areas: Seattle-Tacoma-Bellevue, WA; Minneapolis-St. Paul-Bloomington, MN-WI; Boston-Cambridge-Nashua, MA-NH.

- Major Manufacturing Hubs: Areas like Detroit-Warren-Dearborn, MI (automotive), and Chicago-Naperville-Elgin, IL-IN-WI (diverse manufacturing) have a very high number of jobs and competitive, though not always the nation's highest, wages.

###

4. Industry and Company Type/Size

The industry you serve and the size of your employer create different economic realities and, therefore, different salary structures.

- Top-Paying Industries (BLS Data):

- Aerospace Product and Parts Manufacturing: Often requires working with exotic materials (like titanium and Inconel) to extreme tolerances. This industry pays a premium for the highest level of skill and reliability. Average salaries here can be 15-25% higher than the national median.

- Motor Vehicle Parts Manufacturing: A massive employer of tool and die makers. Union shops within the "Big Three" automakers (Ford, GM, Stellantis) often offer excellent wages and outstanding benefits packages, though non-union suppliers can be more variable.

- Medical Equipment and Supplies Manufacturing: Similar to aerospace, this industry demands incredible precision for items like surgical instruments and implants. It's a growing field with high-paying opportunities.

- Metalworking Machinery Manufacturing: Working for a company that builds the machines themselves often comes with higher pay and deep technical challenges.

- Company Size:

- Large Corporations (e.g., Boeing, Johnson & Johnson, Toyota): These companies typically offer structured pay scales, excellent benefits (pensions, great 401k matching), and clear career ladders. The work might be more specialized and bureaucratic, but the pay and stability are often top-tier.

- Small to Medium-Sized Job Shops: These are the backbone of the industry. Pay can be more variable but is often highly competitive for top talent. A star performer in a 50-person shop may have more influence and see more direct rewards (like larger bonuses) than in a 50,000-person corporation. These roles often offer more variety in the day-to-day work.

- Government/Defense Contractors: Working for a government arsenal or a large defense contractor often involves security clearances and highly precise work. These jobs typically offer competitive pay and exceptional job security and benefits.

###

5. Area of Specialization

Just as doctors specialize, so do tool and die makers. Your chosen niche can significantly influence your value and salary.

- Die Maker (Stamping/Forging): Building dies for sheet metal is a core skill. Those who can design and build complex *progressive dies*—which perform multiple operations in a single press stroke—are in extremely high demand and are among the highest-paid specialists.

- Mold Maker (Plastic Injection): This is a highly lucrative specialization. The complexity of a multi-cavity, hot-runner injection mold for a high-volume consumer product is immense. Master mold makers who can achieve flawless surface finishes and intricate cooling channels command premium salaries, often exceeding $100,000 in high-cost areas.

- Toolmaker (Jigs & Fixtures): While perhaps seen as more generalist, a toolmaker who specializes in creating complex, automated, or robotic fixtures for high-tech industries like aerospace or electronics is incredibly valuable.

- Gage Maker: This ultra-specialized role involves creating the custom inspection gages used to quality-check manufactured parts. It requires an almost perfect understanding of Geometric Dimensioning and Tolerancing (GD&T) and the ability to work to the tightest possible tolerances.

###

6. In-Demand Technical and Soft Skills

In today's manufacturing environment, your toolkit is both physical and digital. Cultivating high-value skills is the most direct way to increase your salary.

- Advanced CNC Programming & Operation: It's no longer enough to just run a pre-written program. The ability to program complex 5-axis CNC machines directly at the controller or using advanced CAM software (like Mastercam, GibbsCAM, or Esprit) is a high-dollar skill.

- CAD/CAM Proficiency: Expertise in Computer-Aided Design (CAD) software like SolidWorks, Siemens NX, or CATIA allows you to not just read blueprints but to interact with, modify, and even design tooling yourself. This bridges the gap between engineering and the shop floor and makes you immensely more valuable.

- Metrology and CMM Operation: Knowing how to operate and program a Coordinate Measuring Machine (CMM) to perform complex inspection routines is a critical and well-compensated skill.

- EDM Expertise: Proficiency with both wire EDM and sinker EDM machines, which are used for creating intricate shapes that are impossible to machine traditionally, is a highly sought-after specialization.

- Understanding of Lean Manufacturing/Six Sigma: Knowledge of modern manufacturing principles shows you are focused on efficiency, quality, and continuous improvement, which is attractive to all employers.

- Problem-Solving and Troubleshooting: This is perhaps the most important "soft" skill. When a tool crashes or a part is out of spec, the maker who can calmly diagnose the root cause and implement a solution saves the company thousands of dollars in downtime and scrap. This ability is what separates a good machinist from a true tool and die master.

By strategically developing these skills and aligning your career with high-demand industries and locations, you can chart a course to the upper echelons of the tool and die maker salary range.

Job Outlook and Career Growth

When considering a long-term career, salary is only one part of the equation. Job security, opportunities for advancement, and the future direction of the profession are equally critical. The outlook for tool and die makers is nuanced, presenting both significant challenges and compelling opportunities for those willing to adapt.

### The Official Outlook: A Story in Numbers

The U.S. Bureau of Labor Statistics (BLS), in its 202