In the world of modern manufacturing, few roles are as critical or as highly skilled as the tool and die maker. These master craftspeople are the architects of the industrial process, creating the precise tools, molds, and dies that enable the mass production of everything from car parts to medical devices. This skilled trade not only offers a rewarding career for those with a knack for precision and problem-solving but also provides a stable and competitive income.

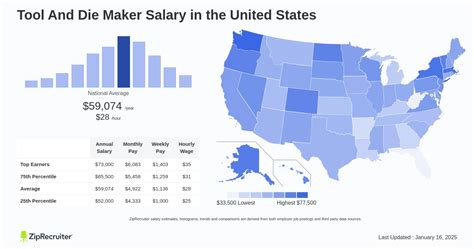

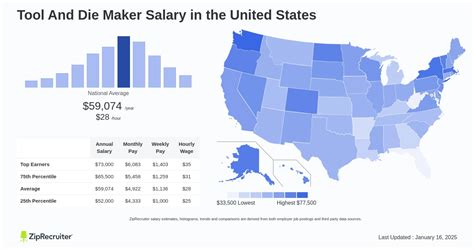

So, what can you expect to earn? On average, a tool and die maker in the United States earns a median salary of over $60,000 per year, with a typical range falling between $55,000 and $75,000 annually. Experienced professionals in high-demand industries can command salaries well over $90,000.

This guide will break down everything you need to know about a tool and die maker's salary, the factors that drive it, and the future of this essential profession.

What Does a Tool and Die Maker Do?

Before diving into the numbers, it's important to understand the high level of skill this role demands. Tool and die makers are elite machinists who specialize in producing and maintaining the tools of manufacturing. Their core responsibilities include:

- Reading and interpreting complex blueprints and technical drawings.

- Operating a wide range of machinery, both conventional (lathes, milling machines, grinders) and computer numerically controlled (CNC).

- Building, fitting, and assembling jigs, fixtures, gauges, dies, and molds with extreme precision, often to tolerances of one ten-thousandth of an inch.

- Troubleshooting and repairing worn or damaged tools and dies to ensure production lines run smoothly.

It's a role that blends advanced technical knowledge with the hands-on skill of a true artisan, making them indispensable to the manufacturing sector.

Average Tool and Die Maker Salary

Salary data provides a clear picture of the earning potential for this career. By synthesizing information from several authoritative sources, we can establish a reliable baseline.

According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for tool and die makers was $60,940 in May 2023. This means that half of all tool and die makers earned more than this amount, and half earned less. The hourly median wage was $29.30.

Reputable salary aggregators offer a complementary view:

- Salary.com reports that the typical salary range for a Tool and Die Maker in the U.S. falls between $61,048 and $78,819, with an average of around $69,142 as of late 2023.

- Payscale.com shows a broad range from approximately $49,000 for entry-level positions to over $82,000 for experienced, late-career professionals.

- Glassdoor lists a national average base pay of around $68,500 per year.

Taking these sources together, a clear pattern emerges:

- Entry-Level (0-3 years): Expect to earn in the range of $48,000 to $60,000.

- Mid-Career/Journeyman (4-15 years): Salaries typically range from $60,000 to $75,000.

- Senior/Lead (15+ years): Top earners with specialized skills and supervisory duties can command salaries of $75,000 to $90,000 or more.

Key Factors That Influence Salary

Your specific salary as a tool and die maker will depend on several key variables. Understanding these factors is crucial for maximizing your earning potential throughout your career.

### Level of Education

While a high school diploma followed by a multi-year apprenticeship is the traditional path, formal education can significantly impact your starting salary and career trajectory. An Associate of Applied Science (A.A.S.) in Machine Tool Technology or a related field provides a strong theoretical foundation in metallurgy, computer-aided design (CAD), and CNC programming. This formal training can make you a more attractive candidate and potentially place you on a higher pay scale from day one. Furthermore, earning professional certifications, such as those from the National Institute for Metalworking Skills (NIMS), validates your expertise and can lead to increased pay.

### Years of Experience

Experience is arguably the most significant factor in a tool and die maker's salary. The profession relies on accumulated knowledge and hands-on problem-solving skills that can only be developed over time.

- Apprentice/Entry-Level: In the first few years, your focus is on learning from senior mentors and mastering fundamental skills. Your pay will be on the lower end of the scale but will increase steadily as you gain competency.

- Journeyman: After completing an apprenticeship (typically 4-5 years), you become a journeyman. At this stage, you can work independently on complex projects, leading to a substantial jump in earning potential into the industry's median range.

- Master/Senior Toolmaker: With over a decade of experience, you become a go-to expert for the most challenging projects. Many senior toolmakers move into lead or supervisory roles, managing teams, planning workflows, and taking responsibility for the entire tool room, which comes with top-tier compensation.

### Geographic Location

Where you work matters. Salaries for tool and die makers vary significantly based on the local cost of living and the concentration of manufacturing industries. States with strong automotive, aerospace, and industrial manufacturing sectors typically offer higher wages.

According to BLS data, some of the top-paying states and metropolitan areas for tool and die makers are often found in the Midwest and other manufacturing hubs. For example, states like Michigan, Illinois, Ohio, and Wisconsin often have a high demand and competitive wages due to the deep roots of the automotive and heavy equipment industries. Similarly, regions with significant aerospace manufacturing, like Washington or Connecticut, may also offer premium pay.

### Company Type

The type of company you work for plays a large role in your compensation package.

- Large Corporations: Major automotive (e.g., Ford, General Motors) and aerospace (e.g., Boeing, Lockheed Martin) companies often have union-negotiated contracts, which lead to structured pay scales, strong benefits, and high earning potential.

- Specialized Industries: Companies in the medical device, defense, or electronics sectors demand extreme precision and work with exotic materials. Skilled tool and die makers in these fields are highly sought after and often receive premium pay.

- Small and Medium-Sized Job Shops: These companies offer more variability. While the base salary might sometimes be lower than at a large corporation, they can provide opportunities for profit-sharing, overtime, and a broader range of hands-on experience.

### Area of Specialization

Within the trade, certain specializations are in higher demand and can command better pay.

- Mold Making: Creating complex injection molds for the plastics industry is a highly lucrative specialty, as it is essential for producing everything from consumer goods to intricate medical components.

- Stamping Die Making: This is crucial for the automotive and appliance industries, involving the creation of large, complex dies used to stamp sheet metal into body panels and parts.

- CNC Programming and Operation: Tool and die makers who are also expert CNC programmers are exceptionally valuable. The ability to take a design from a CAD file to a finished tool using advanced computer-aided manufacturing (CAM) software is a top-tier skill that puts you at the high end of the pay scale.

Job Outlook

The career outlook for tool and die makers is a story of quality over quantity. The BLS projects that employment for machinists and tool and die makers will see little to no change from 2022 to 2032, with a projected growth of 1%.

However, this statistic doesn't tell the whole story. While automation and increased efficiency may limit the creation of new positions, the BLS also projects about 6,700 openings each year, on average, over the decade. These openings will primarily arise from the need to replace workers who retire or transfer to different occupations.

This creates a significant opportunity for the next generation. As a large portion of the current highly skilled workforce nears retirement, there will be a strong, consistent demand for new talent, especially for those proficient in modern CNC technology and advanced manufacturing techniques.

Conclusion

A career as a tool and die maker is a commitment to precision, skill, and continuous learning. It offers a direct path to a stable and financially rewarding future without the requirement of a four-year degree.

Key Takeaways:

- Solid Earning Potential: With a median salary of over $60,000 and a clear path to earning $90,000+, this career provides a very competitive income.

- Experience is King: Your salary will grow significantly as you move from an apprentice to a journeyman and, eventually, a senior-level expert.

- Your Value is Malleable: You can actively increase your earning potential by pursuing formal education, specializing in high-demand areas like mold making or CNC programming, and choosing to work in robust manufacturing regions.

- A Stable Future: Despite modest overall growth, the constant need to replace a retiring workforce ensures that skilled tool and die makers will remain in high demand for years to come.

For those with a passion for building, a meticulous eye for detail, and a problem-solver's mindset, the role of a tool and die maker is more than just a job—it's a craft that builds the foundation of our modern world.