Thinking about a career that puts you at the heart of modern manufacturing? The role of a machine operator is a foundational pillar of the industrial world, offering a stable and rewarding career path with significant growth potential. But what can you expect to earn? While the answer varies, many skilled operators find themselves with a competitive salary that can exceed $49,000 per year, with top earners in specialized fields making much more.

This guide will break down the salary of a machine operator, exploring the data and the key factors that determine your earning potential in this dynamic and essential profession.

What Does a Machine Operator Do?

At its core, a machine operator sets up, runs, and maintains machinery in a manufacturing or production facility. Their work is crucial for transforming raw materials into finished products. Daily responsibilities often include:

- Setup and Calibration: Preparing machines for a production run by loading materials, installing parts, and calibrating settings.

- Operation and Monitoring: Overseeing machinery as it operates, watching gauges, dials, and other indicators to ensure it is running correctly.

- Quality Control: Performing routine checks on finished products to ensure they meet quality and safety standards.

- Maintenance: Conducting basic cleaning and maintenance on machinery to ensure its longevity and prevent breakdowns.

In today's advanced manufacturing environment, many operators work with Computer Numerical Control (CNC) machines, which involve programming and overseeing computer-driven equipment that performs highly precise work.

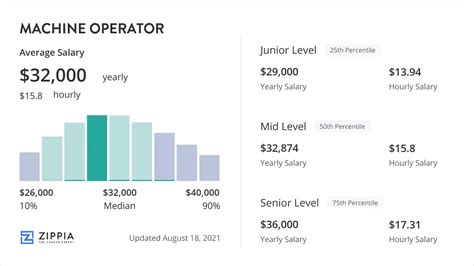

Average Machine Operator Salary

When analyzing compensation for a machine operator, it's helpful to look at data from multiple authoritative sources to get a complete picture.

According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for "Computer-Controlled Machine Tool Operators, Metal and Plastic" was $49,310 as of May 2023. This means that half of the workers in this occupation earned more than that amount, and half earned less. The BLS also reports that the lowest 10 percent earned less than $35,460, while the top 10 percent earned more than $68,810.

Salary aggregators provide a similar perspective and highlight the typical range you might encounter:

- Salary.com reports that the average salary for a Machine Operator I (entry-level) in the United States is around $42,869, but the typical range falls between $38,000 and $49,000. For a more senior CNC Machine Operator III, the average jumps to $63,130.

- Payscale notes an average base hourly rate of around $18.96 per hour, with an annual salary range typically spanning from $32,000 to $58,000 depending on factors like experience and location.

- Glassdoor places the total pay average for a machine operator at approximately $51,194 per year in the United States, which includes a base salary and potential additional pay like bonuses or profit sharing.

In summary, a typical salary range for a machine operator in the U.S. is between $38,000 and $60,000 annually, with significant potential for higher earnings based on the factors below.

Key Factors That Influence Salary

Your specific salary as a machine operator isn't just one number; it's influenced by a combination of your skills, location, and the specifics of your employer. Understanding these factors is key to maximizing your earning potential.

### Level of Education & Certification

While a high school diploma or equivalent is often the minimum requirement, further education and professional certifications can directly boost your pay.

- Vocational School/Technical College: Completing a program in machining, manufacturing technology, or a related field provides a strong theoretical and practical foundation that employers value.

- Associate's Degree: An associate's degree in manufacturing or engineering technology can lead to higher starting salaries and open doors to supervisory roles.

- Certifications: Credentials from organizations like the National Institute for Metalworking Skills (NIMS) are highly respected. Earning a certification in areas like CNC machining, programming, or industrial maintenance demonstrates a verified skill set and often leads to a significant pay increase.

### Years of Experience

Experience is one of the most powerful drivers of salary growth in this field. As you gain hands-on skills and prove your reliability and precision, your value to an employer increases.

- Entry-Level (0-2 years): Operators are typically in the lower end of the salary range, learning the basics of machine setup, operation, and safety protocols.

- Mid-Career (3-9 years): With several years of experience, operators can handle more complex machinery, troubleshoot problems, and work more independently, commanding a salary closer to or above the national median.

- Senior/Experienced (10+ years): Highly experienced operators, especially those who can program CNC machines, train junior staff, or take on lead roles, are in the top tier of earners.

### Geographic Location

Where you work matters. Salaries for machine operators can vary significantly by state and even by metropolitan area, often due to differences in industry concentration, demand for labor, and cost of living.

According to BLS data, some of the top-paying states for computer-controlled machine tool operators include:

- Washington

- Alaska

- Maryland

- Massachusetts

- Connecticut

Conversely, states in the Southeast and parts of the Midwest may offer salaries below the national median, but this is often balanced by a lower cost of living.

### Company Type & Industry

The type of company you work for and its industry play a massive role in compensation.

- High-Tech Industries: Companies in aerospace, medical device manufacturing, automotive, and defense often pay top dollar. The machines are highly complex, the required precision is extreme, and the value of the final products is very high.

- Large vs. Small Companies: Large, multinational corporations generally offer higher wages, better benefits packages, and more structured opportunities for advancement compared to smaller, local job shops.

- Union vs. Non-Union: Machine operators who are members of a union may have higher, collectively bargained wages and more comprehensive benefits.

### Area of Specialization

Not all machine operator roles are the same. Your specialization is arguably the most important factor in determining your income ceiling.

- CNC Machine Operator: This is the most in-demand and highest-paying specialization. CNC operators who can not only run but also program the machines (using G-code and CAM software) are highly sought after and command premium wages.

- Specialized Machinery: Expertise in operating specific, complex machinery like 5-axis mills, Swiss lathes, or large-scale industrial presses will also lead to higher pay than operating simple, single-function equipment.

- Quality Control/Inspection: Operators who also have skills in using advanced measurement tools like Coordinate Measuring Machines (CMM) are extremely valuable and can earn more.

Job Outlook

The future for skilled machine operators is promising. While automation is changing the landscape of manufacturing, it is also creating a need for highly skilled professionals who can program, operate, and maintain these sophisticated systems.

The U.S. Bureau of Labor Statistics projects that employment for computer-controlled machine tool operators is expected to have little or no change from 2022 to 2032. However, this statistic doesn't tell the whole story. The BLS anticipates about 14,500 openings for these operators each year, on average, over the decade. Most of those openings are expected to result from the need to replace workers who transfer to different occupations or exit the labor force, such as to retire.

This means that while the total number of jobs may not be growing rapidly, there is a strong and continuous demand for new, skilled talent—especially those with expertise in CNC technology.

Conclusion

A career as a machine operator offers a stable and financially rewarding path for individuals who are detail-oriented, technically minded, and enjoy hands-on work. While an entry-level position might start in the $38,000 to $45,000 range, your potential for growth is substantial.

To maximize your earnings, focus on continuous improvement. Pursue certifications, gain experience with complex machinery, and, most importantly, develop skills in CNC programming and operation. By investing in these high-demand specializations, you can build a long-lasting and lucrative career at the forefront of modern industry.