Introduction

Have you ever looked at a product—from the gasoline in your car to the life-saving vaccine in a vial—and wondered about the invisible genius who ensured it could be made safely, efficiently, and at a massive scale? That genius is the process engineer. They are the masterminds of production, the architects of efficiency, and the guardians of quality in nearly every industry that creates a physical product. If you're drawn to a career that blends intricate problem-solving with tangible, real-world impact, then process engineering might be your calling.

This is a field that doesn't just offer intellectual satisfaction; it provides substantial financial rewards. A career as a process engineer is one of the most stable and lucrative paths an engineering graduate can pursue, with average salaries comfortably reaching into the six-figure range and significant potential for growth. While the national average salary hovers around $95,000 to $110,000 per year, it's not uncommon for experienced professionals in high-demand sectors to earn well over $150,000, and even approach the $200,000 mark with specialized expertise and leadership responsibilities.

I once spoke with a senior process engineer at a major pharmaceutical company who described her job as "solving a million-dollar puzzle every single day." She explained how a tiny tweak she developed for a filtration process not only saved the company over $2 million annually but also reduced waste by 30%, a win for both the bottom line and the environment. It was a powerful reminder that this role isn't just about diagrams and data; it's about creating immense value.

This comprehensive guide will serve as your roadmap to understanding and navigating the financial landscape of a process engineering career. We will dissect salary expectations, explore the critical factors that dictate your earning potential, and provide a clear, step-by-step plan to help you launch and accelerate your journey in this exciting field.

### Table of Contents

- [What Does a Process Engineer Do?](#what-does-a-process-engineer-do)

- [Average Process Engineer Salary: A Deep Dive](#average-process-engineer-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

What Does a Process Engineer Do?

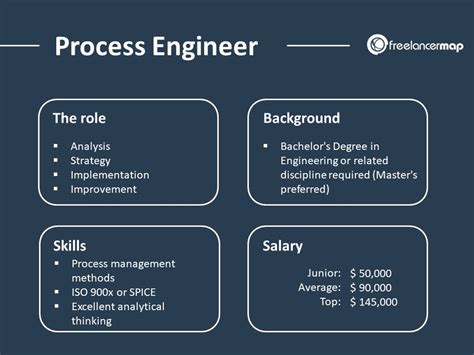

At its core, a process engineer designs, implements, controls, and optimizes industrial processes, particularly continuous ones within the chemical, petrochemical, agricultural, mineral processing, and pharmaceutical industries. They are the vital link between a product's initial concept or laboratory-scale creation and its full-scale, profitable production. Think of them as the conductors of a massive industrial orchestra, ensuring every instrument—every pump, valve, reactor, and control system—plays its part in perfect harmony to create a flawless final product.

Their primary goal is to ensure that processes are running efficiently, safely, and with consistent quality. This involves a unique blend of engineering principles, data analysis, hands-on troubleshooting, and project management.

Core Responsibilities and Daily Tasks:

A process engineer's work is incredibly varied and project-dependent, but their responsibilities typically revolve around these key areas:

- Process Design and Development: They design new processes or modify existing ones. This includes creating process flow diagrams (PFDs), piping and instrumentation diagrams (P&IDs), and calculating the required equipment sizes and specifications.

- Optimization and Improvement: They are constantly seeking ways to make things better. This could mean reducing energy consumption, minimizing waste, increasing production yield, improving product quality, or cutting operational costs. This is often achieved through methodologies like Six Sigma or Lean Manufacturing.

- Troubleshooting: When a production line goes down or a product batch is out of spec, the process engineer is the first person called. They use their deep understanding of the system to diagnose the root cause of the problem and implement a solution.

- Data Analysis: They collect, monitor, and analyze process data to identify trends, predict issues, and validate improvements. They are fluent in the language of data, using it to justify decisions and demonstrate results.

- Safety and Compliance: Ensuring the process is safe for workers and the environment is paramount. They conduct safety audits (like HAZOP studies) and ensure the facility complies with all government regulations (e.g., from the EPA and OSHA).

- Project Management: They often lead capital projects, such as installing new equipment or scaling up a new production line. This involves managing budgets, timelines, contractors, and internal stakeholders.

> ### A Day in the Life of a Mid-Level Process Engineer

>

> 8:00 AM: Arrive at the plant. Start with the daily production meeting with operators and maintenance staff. Review yesterday's performance data, discuss any overnight issues, and set priorities for the day.

>

> 9:30 AM: Plant Walk-Through. Put on a hard hat and safety glasses to physically inspect the equipment related to an ongoing optimization project. Talk with operators on the floor to get their direct feedback on a recent control system adjustment.

>

> 11:00 AM: Data Analysis. Back in the office, pull data from the plant's historian (a database of process variables). Use software like Minitab or a custom Python script to analyze the performance of a reactor before and after a catalyst change.

>

> 1:00 PM: Project Meeting. Lead a conference call with a vendor supplying a new heat exchanger. Finalize the technical specifications and delivery timeline for this capital project.

>

> 2:30 PM: Simulation and Design. Use process simulation software like Aspen HYSYS or ChemCAD to model a proposed change to the distillation column. The goal is to increase product purity without a significant increase in energy cost.

>

> 4:00 PM: Documentation and Reporting. Update the P&ID for the proposed change and write a short technical memo summarizing the simulation results and potential ROI to be presented to the plant manager.

>

> 5:00 PM: Wrap up. Check emails one last time and create a to-do list for tomorrow.

This blend of analytical desk work and hands-on plant floor engagement makes the role both challenging and rewarding.

Average Process Engineer Salary: A Deep Dive

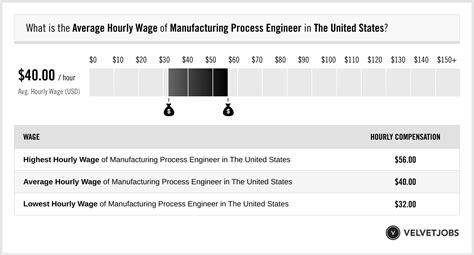

The salary of a process engineer is one of the most compelling aspects of the career, offering a high return on investment for the rigorous education required. Compensation is competitive and grows substantially with experience. Let's break down the numbers from several authoritative sources to build a clear picture of earning potential in the United States.

It's important to note that the role of "Process Engineer" is a specialized discipline, often falling under the broader umbrella of "Chemical Engineer" in government statistics. Therefore, we will look at data for both titles to provide a comprehensive view.

National Averages and Salary Ranges

According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for Chemical Engineers was $106,260 as of May 2022. The lowest 10 percent earned less than $70,700, while the highest 10 percent earned more than $173,190. This BLS data is a fantastic benchmark, as it's one of the most reliable and widely cited sources for occupational data.

Reputable salary aggregators, which collect real-time, self-reported data, often provide a more specific look at the "Process Engineer" title:

- Salary.com: As of November 2023, the median salary for a Process Engineer I (entry-level) is $78,901, while a Process Engineer III (senior) has a median of $105,793, and a Process Engineer V (principal/lead) commands a median of $145,593. The overall range typically falls between $75,000 and $120,000, depending heavily on the factors we'll discuss later.

- Payscale.com: Reports the average salary for a Process Engineer to be $82,217 per year, with a common range of $62,000 to $112,000. This data highlights the significant impact of experience on compensation.

- Glassdoor: Shows a total pay average of $99,944 per year for Process Engineers in the United States as of December 2023. This "total pay" figure includes an estimated base pay of $89,122 and additional pay (bonuses, profit sharing) of around $10,822.

Salary Progression by Experience Level

One of the most attractive features of a process engineering career is the steep and consistent salary growth. Your value to an organization increases dramatically as you accumulate practical experience, solve complex problems, and lead larger projects.

Here's a typical salary progression, compiled from the sources above:

| Experience Level | Years of Experience | Typical Base Salary Range | Key Responsibilities |

| :--- | :--- | :--- | :--- |

| Entry-Level / Junior | 0-2 Years | $65,000 - $85,000 | Assisting senior engineers, data collection, basic calculations, process monitoring, documentation. |

| Mid-Career | 3-7 Years | $85,000 - $115,000 | Managing small to medium projects, process optimization, troubleshooting, leading small teams, equipment specification. |

| Senior | 8-15 Years | $115,000 - $150,000+ | Leading large capital projects, complex process design, mentoring junior engineers, strategic planning, developing new technologies. |

| Principal / Lead / Manager | 15+ Years | $150,000 - $200,000+ | Setting technical direction for a department, managing teams of engineers, high-level business strategy, R&D leadership. |

*(Source: Synthesized data from Salary.com, Payscale, and Glassdoor, late 2023.)*

Beyond the Base Salary: Understanding Total Compensation

A process engineer's paycheck is often more than just their base salary. Total compensation is a critical concept to understand, as it can significantly increase overall earnings.

- Annual Bonuses: This is the most common form of additional compensation. Bonuses are often tied to individual performance, team/department goals, and overall company profitability. They can range from 5% to 20% (or more) of the base salary, especially at senior levels.

- Profit Sharing: Some companies, particularly in manufacturing, offer profit-sharing plans where a portion of the company's annual profits is distributed among employees. This directly links your work in improving efficiency to your personal earnings.

- Stock Options and RSUs (Restricted Stock Units): More common in publicly traded companies, stock options or RSUs give you a stake in the company's success. This can be a significant wealth-building tool, particularly in high-growth sectors like biotech or semiconductors.

- Retirement Contributions (401k Matching): While not direct cash-in-hand, a generous 401k matching program is a vital part of compensation. A company that matches 100% of your contribution up to 6% of your salary is effectively giving you a 6% raise dedicated to your retirement.

- Relocation Packages: For in-demand roles, companies will often offer robust relocation packages that can include moving expenses, temporary housing, and even assistance with selling your old home.

- Paid Time Off (PTO) and Other Benefits: Generous PTO, comprehensive health insurance, and continuing education stipends are all valuable components of the total compensation package that affect your financial well-being.

When evaluating a job offer, it's crucial to look beyond the base salary and calculate the total value of the entire compensation and benefits package.

Key Factors That Influence Salary

While the national averages provide a great starting point, the actual salary of a process engineer can vary dramatically. Two engineers with the same job title and five years of experience might have a salary difference of $40,000 or more. This variance is driven by a predictable set of key factors. Understanding these levers is the first step to maximizing your own earning potential.

### Level of Education

Your educational foundation is the price of entry, and advanced degrees can unlock higher starting salaries and specialized, higher-paying roles.

- Bachelor's Degree (B.S.): A Bachelor of Science in Chemical Engineering is the gold standard and the most common requirement. Degrees in Mechanical Engineering, Industrial Engineering, or Materials Science can also be pathways, but Chemical Engineering is often preferred for its deep focus on thermodynamics, fluid dynamics, and reaction kinetics. This degree will qualify you for the vast majority of entry-level and mid-career process engineering jobs.

- Master's Degree (M.S. or M.Eng.): A Master's degree can provide a salary bump of 5-15% and make you a more competitive candidate, especially for R&D-focused roles or positions in highly technical fields like pharmaceuticals or semiconductor fabrication. It allows for specialization in areas like process control, biochemical engineering, or materials science. It can also sometimes count as one year of experience towards a Professional Engineer (PE) license.

- Doctorate (Ph.D.): A Ph.D. is typically pursued by those aiming for a career in pure research and development (R&D), academia, or highly specialized consulting. A Ph.D. can command a significantly higher starting salary, often placing a candidate directly into a senior scientist or senior R&D engineer role with salaries often starting above $120,000.

- Certifications: Beyond degrees, professional certifications are a powerful way to signal expertise and increase your value.

- Professional Engineer (PE) License: This is one of the most respected credentials. Earning a PE license demonstrates a high level of competence and ethical commitment. It is often required for engineers who sign off on public projects and can be a prerequisite for promotion to principal-level roles, carrying a significant salary premium.

- Six Sigma Certification (Green Belt, Black Belt, Master Black Belt): Six Sigma is a data-driven methodology for process improvement. A Black Belt certification shows you can lead complex projects that deliver measurable financial results, making you highly attractive to employers. This can easily add $10,000-$20,000 to your salary.

- Project Management Professional (PMP): As process engineers often manage large capital projects, a PMP certification is highly valuable. It validates your ability to manage scope, budget, and schedule, which is critical for senior and management positions.

### Years of Experience

As highlighted in the previous section, experience is arguably the single most significant factor in salary growth. The value you provide shifts from executing tasks to driving strategy.

- Entry-Level (0-2 years): Your primary value is your academic knowledge and potential. You're learning the company's specific processes, tools, and culture. Salary is based on this potential.

- Mid-Career (3-7 years): You are now an independent contributor. You've seen problems before, can troubleshoot effectively, and can be trusted to manage small to medium projects. Your salary reflects this reliability and proven problem-solving ability.

- Senior (8-15 years): You are a subject matter expert and a leader. You're not just solving today's problems; you're anticipating tomorrow's. You mentor others, manage large, high-impact projects, and contribute to the company's strategic direction. Your salary reflects your impact on the bottom line.

- Principal/Managerial (15+ years): At this stage, your value is strategic. You might be the ultimate technical authority in a specific area for the entire company or be responsible for managing a whole department of engineers. Compensation is tied to leadership, innovation, and business results, often with a significant performance-based component.

### Geographic Location

Where you work matters—a lot. Salaries are adjusted for the local cost of living and, more importantly, the concentration of high-paying industries.

Top-Paying States and Metropolitan Areas:

States with a heavy presence of oil and gas, petrochemicals, and advanced pharmaceuticals tend to offer the highest salaries.

- Texas (Houston, Dallas): As the heart of the U.S. oil and gas and petrochemical industry, Houston offers some of the highest salaries for process engineers in the country.

- California (San Francisco Bay Area, Los Angeles): Driven by biotech, pharmaceuticals, and semiconductor industries, California offers high salaries, though they are offset by a very high cost of living.

- Louisiana (Baton Rouge, New Orleans): Similar to Texas, a high concentration of chemical manufacturing and refineries drives up demand and wages.

- Delaware and New Jersey: These states have a long history of chemical and pharmaceutical manufacturing, with major companies like DuPont and Merck driving a competitive market for talent.

- Massachusetts (Boston/Cambridge): A global hub for biotechnology and pharmaceuticals, offering premium salaries for specialized process engineers.

Average and Lower-Paying Areas:

Regions with a focus on less capital-intensive manufacturing, such as food processing or general consumer goods, or with a lower cost of living, may offer salaries closer to or slightly below the national average. This includes many parts of the Midwest and Southeast, though even there, strong manufacturing hubs will have competitive wages.

When considering a job, always use a cost-of-living calculator to compare offers. A $110,000 salary in Houston may provide a better quality of life than a $130,000 salary in San Jose.

### Industry and Company Size

The industry you work in is a massive determinant of your salary. Some sectors are simply more profitable and capital-intensive than others.

- Oil and Gas (Upstream and Downstream): Historically and currently the highest-paying industry for process engineers. The sheer scale, complexity, and profitability of oil extraction and refining command top-tier salaries. Senior engineers can easily surpass $180,000.

- Pharmaceuticals and Biotechnology: A very high-paying sector due to the high value of products, stringent FDA regulations, and the need for meticulous process control and validation.

- Semiconductors: A booming industry with extremely complex manufacturing processes (e.g., photolithography). The demand for process engineers to improve yields and develop new fabrication techniques is intense, leading to very high compensation.

- Specialty Chemicals: Companies producing high-margin specialty chemicals (e.g., polymers, catalysts, electronic materials) pay very well.

- Consulting (EPC Firms - Engineering, Procurement, and Construction): Working for a firm like Bechtel or Fluor that designs and builds plants for other companies can be very lucrative, especially with travel and overseas assignments.

- Food and Beverage: Generally pays less than the sectors above but offers great stability. Processes are often less complex than in a refinery, leading to salaries closer to the national average.

- Pulp and Paper / Consumer Goods: Similar to food and beverage, these are mature industries that offer stable careers but typically lower salaries than high-tech or energy sectors.

Company size also plays a role:

- Large Corporations (Fortune 500): Tend to offer higher base salaries, structured career paths, excellent benefits, and significant bonuses. They have the resources to pay top dollar for top talent.

- Startups: Might offer a lower base salary but compensate with significant equity (stock options). This is a high-risk, high-reward scenario. A process engineer at a successful biotech startup could see a massive payday if the company goes public or is acquired.

- Mid-Sized Companies: Often provide a balance of competitive salary and a more agile, less bureaucratic work environment.

### In-Demand Skills

Beyond your degree and experience, specific technical and soft skills can make you a more valuable—and thus higher-paid—professional.

High-Value Technical Skills:

- Process Simulation Software: Mastery of tools like Aspen HYSYS, Aspen Plus, or ChemCAD is non-negotiable for design and optimization roles. Expertise here is a core competency.

- Data Analysis and Programming: Skills in Python or R for data analysis, along with experience in statistical software like Minitab or JMP, are becoming increasingly crucial. The ability to automate data collection and perform advanced statistical analysis sets you apart.

- Process Control and Automation: Knowledge of Distributed Control Systems (DCS), Programmable Logic Controllers (PLCs), and the principles of advanced process control (APC) is highly valuable, as automation is key to modern manufacturing.

- CAD and 3D Modeling: Proficiency in AutoCAD for P&IDs and familiarity with 3D modeling software for plant layout are important practical skills.

- Specific Industry Knowledge: Expertise in cGMP (current Good Manufacturing Practices) for pharma, or PSM (Process Safety Management) for chemical/oil and gas, makes you an instant asset in those fields.

Crucial Soft Skills:

- Problem-Solving: This is the absolute essence of engineering. You must be able to break down complex, ambiguous problems into manageable parts and develop logical, data-driven solutions.

- Communication: You must be able to clearly explain complex technical concepts to non-technical audiences, from plant operators to senior management. Strong writing skills for reports and presentations are essential.

- Project Management: The ability to manage budgets, timelines, and stakeholders is critical for career advancement.

- Teamwork and Leadership: No process is improved in a vacuum. You will constantly work with operators, maintenance crews, lab technicians, and managers. The ability to lead and influence these teams is what separates senior engineers from junior ones.

Job Outlook and Career Growth

When investing years in education and training, you want to enter a field with long-term stability and opportunities for advancement. Process engineering excels in both areas. The skills you develop are fundamental to the physical economy and are transferable across a wide range of essential industries.

Official Job Growth Projections

The U.S. Bureau of Labor Statistics (BLS) projects that employment for Chemical Engineers, the closest proxy for process engineers, is expected to grow 6 percent from 2022 to 2032. This is faster than the average for all occupations. The BLS anticipates about 1,800 openings for chemical engineers each year, on average, over the decade.

This steady growth is driven by the demand for engineers in manufacturing and R&D. As the BLS notes, "Chemical engineers will be needed to devise and implement processes for emerging technologies and for producing a variety of products. These include new chemicals, cleaner energy sources, and more efficient and environmentally friendly manufacturing processes."

Emerging Trends Shaping the Future of Process Engineering

The 6% growth figure only tells part of the story. The *nature* of the work is evolving rapidly, creating exciting new opportunities for those who stay ahead of the curve.

- Sustainability and Green Engineering: This is perhaps the most significant trend. Companies are under immense pressure to reduce their carbon footprint, minimize waste, use less water, and develop products from renewable sources. Process engineers are on the front lines of this movement, designing processes for carbon capture, creating biofuels, developing biodegradable plastics, and optimizing energy usage across the board. This is not just a niche; it's becoming a core competency.

- Industry 4.0: Digitalization and Data Analytics: The "smart factory" is here. The proliferation of sensors, IoT devices, and cloud computing has created a firehose of process data. Process engineers who can leverage this data—using machine learning, AI, and advanced statistical analysis—to build predictive models, optimize processes in real-time, and prevent failures before they happen will be in extremely high demand. The "Process Data Scientist" is an emerging and highly lucrative role.

- Advanced Manufacturing and Reshoring: There is a growing movement to bring manufacturing back to the United States, particularly in critical sectors like semiconductors, pharmaceuticals, and batteries. This requires building new, state-of-the-art facilities, all of which need to be designed, commissioned, and run by skilled process engineers.

- Biotechnology and Personalized Medicine: The growth in cell and gene therapies and other advanced biologics requires entirely new manufacturing paradigms. Process engineers are needed to scale up these complex and sensitive processes from the lab to commercial production, a field known as bioprocess engineering.

How to Stay Relevant and Advance Your Career

A career in process engineering is not static; it requires a commitment to lifelong learning. Here’s how to ensure you remain a top-tier candidate throughout your career:

1. Embrace New Technologies: Don't be afraid of the digital wave. Take online courses in Python, machine learning, or data visualization. Become the go-to person on your team for data-driven decision-making.

2. Develop a Specialization: While it's good to be a generalist early on, developing deep expertise in a high-growth area (like sustainability, process control, or a specific industry like biotech) will make you a sought-after expert.

3. Pursue Advanced Certifications: As mentioned earlier, a PE, PMP, or Six Sigma Black Belt is a clear signal of your commitment and expertise. They are often the key to unlocking senior and management-level roles.

4. Hone Your Soft Skills: Technical brilliance alone won't get you into management. Actively work on your presentation skills, learn how to write persuasive proposals, and take on leadership roles, even informal ones, on project teams.

5. Network, Network, Network: Join professional organizations like the American Institute of Chemical Engineers (AIChE) or the International Society for Pharmaceutical Engineering (ISPE). Attend conferences, participate in webinars, and connect with peers on LinkedIn. Your next great opportunity will likely come through your network.

The career path for a process engineer is not a single ladder but a branching tree. You can grow into a technical fellow (the ultimate subject matter expert), a plant manager, a director of engineering, a consultant, or even move into business-focused roles like supply chain management or technical sales. The foundational problem-solving skills you learn are applicable everywhere.

How to Get Started in This Career

The path to becoming a successful process engineer is challenging but well-defined. It requires a strong academic foundation, practical experience, and a proactive approach to skill development. Here is a step-by-step guide for aspiring professionals.

Step 1: Earn a Relevant Bachelor's Degree

This is the non-negotiable first step. Your primary goal should be to enroll in and graduate from an ABET-accredited engineering program.

- Major of Choice: A **Bachelor of Science