In the world of skilled trades, few roles carry the immense responsibility and command the same level of respect as the Welding Inspector. You are not just looking at metal; you are scrutinizing the very seams that hold our modern world together—from the towering skyscrapers that define our skylines to the critical pipelines that fuel our economy. If you are driven by precision, possess an unwavering commitment to quality, and are looking for a lucrative career that is both challenging and indispensable, then becoming a welding inspector might be your calling.

This career is far more than a simple job; it is a profession that underpins the safety and integrity of countless structures and products. Consequently, the salary of a welding inspector reflects this critical importance, with experienced and certified professionals commanding impressive earnings. The national average salary often hovers around $75,000, but this is just the starting point. Depending on your certifications, experience, industry, and location, it's a career path where earning well over $120,000 per year is not just possible, but common for those at the top of their game.

I'll never forget standing on a partially completed suspension bridge, watching a Senior Certified Welding Inspector (SCWI) work. With a calm, focused demeanor, she moved along a massive support girder, meticulously examining a critical weld. To the untrained eye, it was just a line of metal. To her, it was a story of heat, material, and human skill that had to be perfect. She was the final line of defense against catastrophic failure, and at that moment, I understood that her salary wasn't just for her time; it was for her judgment, expertise, and the public's absolute trust.

This guide is designed to be your definitive resource for understanding the financial and professional landscape of a welding inspection career. We will dissect every factor that influences your earning potential, explore the day-to-day realities of the job, and provide a clear, actionable roadmap to get you started.

### Table of Contents

- [What Does a Welding Inspector Do?](#what-they-do)

- [Average Salary of a Welding Inspector: A Deep Dive](#salary-deep-dive)

- [Key Factors That Influence Salary](#key-factors)

- [Job Outlook and Career Growth](#job-outlook)

- [How to Get Started in This Career](#how-to-start)

- [Conclusion: Is a Career as a Welding Inspector Right for You?](#conclusion)

What Does a Welding Inspector Do?

A Welding Inspector is a highly skilled quality assurance professional responsible for verifying that welding work meets strict codes, standards, and project specifications. They are the impartial authority ensuring that the strength, quality, and integrity of a weld are flawless, thereby guaranteeing the safety and longevity of the final product, whether it's a vehicle frame, a pressure vessel, or a 100-story building.

Their role is a unique blend of hands-on examination, technical knowledge, and meticulous documentation. They act as the crucial link between engineering design and fabrication, translating complex blueprints and welding procedure specifications (WPS) into real-world quality control. They don't perform the welds themselves; rather, they ensure the conditions are perfect for a quality weld and then verify the final result.

Core Responsibilities and Daily Tasks:

A welding inspector's duties span the entire lifecycle of a welding project:

1. Pre-Weld Inspection: This is the foundation of quality. Before a single arc is struck, the inspector will:

- Review engineering drawings, blueprints, and specifications to understand the project requirements.

- Verify the Welding Procedure Specification (WPS) and ensure the welder is qualified to perform it by checking their Welder Performance Qualification (WPQ) record.

- Inspect the base materials for defects, proper dimensions, and correct type.

- Check the fit-up and joint preparation, ensuring bevel angles, root openings, and alignment are within tolerance.

- Confirm that the correct filler metals (electrodes, wires) are being used and have been stored properly.

- Verify that welding equipment is properly set up and calibrated.

2. In-Process Inspection: During the welding process, the inspector monitors key variables to prevent defects from occurring:

- Observing the welder's technique to ensure it conforms to the qualified procedure.

- Monitoring interpass temperature and cleaning between weld passes.

- Ensuring the welding parameters (voltage, amperage, travel speed) are maintained.

3. Post-Weld Inspection: This is the final verification stage. The inspector will:

- Perform a thorough Visual Inspection (VT) of the finished weld, looking for surface defects like cracks, porosity, undercut, or incomplete fusion.

- Conduct or oversee Nondestructive Testing (NDT) as required by the code. This can include methods like Magnetic Particle Testing (MT), Liquid Penetrant Testing (PT), Ultrasonic Testing (UT), or Radiographic Testing (RT) to find defects hidden beneath the surface.

- Verify the final dimensions and profile of the weld.

- Oversee any required post-weld heat treatment (PWHT).

4. Documentation and Reporting: Perhaps the most critical administrative task, the inspector must:

- Meticulously document all inspections, tests, and observations.

- Prepare detailed reports that clearly state whether a weld is accepted or rejected.

- Maintain records for quality assurance audits and traceability.

- Communicate findings effectively to welders, supervisors, engineers, and project managers.

### A Day in the Life of a Welding Inspector

7:00 AM: Arrive at the fabrication shop for a large structural steel project. The first hour is spent in the site office. You review the day's work plan with the project foreman, go over the blueprints for the column-to-beam connections scheduled for today, and double-check the applicable code (e.g., AWS D1.1). You pull the WPS for the specific joint and flux-cored arc welding (FCAW) process being used.

8:30 AM: Head to the shop floor. Your first task is a pre-weld fit-up inspection on a massive girder assembly. You use your gauges—a V-WAC and a set of calipers—to measure the root opening and bevel angle, ensuring they match the WPS. You check the welder's qualification papers to confirm he's certified for this specific position and process. Everything checks out. You sign off on the fit-up, giving the go-ahead to weld.

10:00 AM: You move to another bay where a welder has just completed a multi-pass groove weld. You let it cool to a safe temperature and then begin your visual inspection. Using a strong flashlight and a magnifying glass, you carefully scan the weld's surface for any imperfections. You measure the weld reinforcement and check for any undercut along the toes. The weld looks clean, so you mark it for Nondestructive Testing.

12:00 PM: Lunch break. You chat with some of the senior welders, discussing a tricky out-of-position weld they tackled yesterday. Building rapport is key to a smooth workflow.

1:00 PM: The NDT technicians are on site. You oversee them as they perform Magnetic Particle Testing (MT) on the weld you inspected this morning. You watch as they apply the magnetic yoke and spray the iron particles, looking for any subsurface indications. The test is clear—no defects found.

2:30 PM: You spend the next two hours on documentation. At your computer, you meticulously fill out your daily inspection report. For each weld inspected, you log its identification number, the welder's ID, the WPS used, the results of your visual inspection, and the outcome of the NDT. This record is a permanent legal document of the project's quality.

4:30 PM: Before heading home, you do one last walkthrough of the shop, checking on work in progress and answering a question from a junior welder about proper interpass cleaning. You make a note for tomorrow to verify the calibration on a new set of welding machines that just arrived.

5:00 PM: Day's end. It was a day of constant vigilance, but knowing that your work ensures the structural integrity of a future building provides immense satisfaction.

Average Salary of a Welding Inspector: A Deep Dive

The compensation for a welding inspector is a direct reflection of their expertise, the level of responsibility they hold, and the critical nature of their work. While a single "average" salary provides a useful benchmark, the real story is in the wide range of potential earnings, which are heavily influenced by the factors we will explore in the next section.

To establish a baseline, let's look at data from several reputable sources. It's important to note that different platforms use different data sets and methodologies, which can lead to slight variations in their reported figures. However, they collectively paint a clear picture of a well-compensated profession.

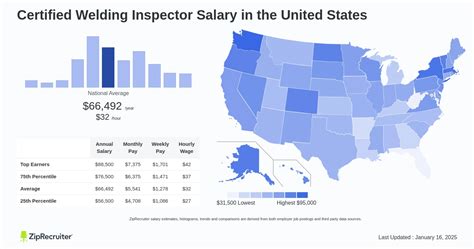

National Salary Benchmarks (Updated for 2024):

- Salary.com: Reports that the median annual salary for a Welding Inspector in the United States is approximately $74,860. The typical salary range falls between $66,120 and $86,470.

- Payscale: Provides a slightly lower average base salary at around $64,500 per year. However, it also highlights that total pay, including bonuses and overtime, can push the upper end to over $99,000.

- Glassdoor: Shows a national average salary of $77,350 per year, with the likely range spanning from $59,000 to $102,000.

- U.S. Bureau of Labor Statistics (BLS): While the BLS doesn't have a dedicated category for "Welding Inspector," they are included in the broader category of "Inspectors, Testers, Sorters, Samplers, and Weighers." The median annual wage for this group was $45,590 in May 2023. This figure is significantly lower because it includes a vast number of less-specialized quality control roles. A Certified Welding Inspector (CWI) is a high-specialization role within this category and commands a much higher salary, as reflected by the industry-specific aggregators.

The takeaway is clear: A certified, skilled welding inspector can expect a median salary in the $70,000 to $80,000 range, but this is far from the ceiling.

### Salary Progression by Experience Level

Your earnings as a welding inspector will grow significantly as you gain experience, build a track record of reliability, and acquire advanced certifications. Here’s a breakdown of what you can expect at different stages of your career.

| Experience Level | Typical Title(s) | Typical Annual Salary Range | Key Characteristics & Responsibilities |

| :--- | :--- | :--- | :--- |

| Entry-Level (0-2 Years) | Assistant Inspector, QC Technician, Trainee Inspector | $45,000 - $65,000 | Working under supervision, performing basic visual inspections, learning codes and procedures, assisting with documentation. May not yet have CWI certification but is working towards it. |

| Mid-Career (3-9 Years) | Certified Welding Inspector (CWI), QC Inspector | $65,000 - $90,000 | Holds AWS CWI certification. Works independently, interprets complex blueprints, makes acceptance/rejection decisions, proficient in at least one NDT method, writes detailed reports. |

| Senior-Level (10-19 Years) | Senior CWI (SCWI), Senior QC Inspector, NDT Specialist | $85,000 - $120,000+ | Often holds a Senior Certified Welding Inspector (SCWI) certification and/or multiple ASNT Level II/III NDT certifications. Manages teams of inspectors, develops inspection plans, audits quality systems, acts as a subject matter expert. |

| Lead/Management (20+ Years) | QA/QC Manager, Chief Inspector, Quality Director | $100,000 - $150,000+ | Oversees the entire quality program for a company or large-scale project. Develops quality manuals, manages budgets, interfaces with clients and regulatory bodies, responsible for high-level strategy and compliance. |

*Note: These are base salary ranges and do not include overtime, per diem, or other potential compensation.*

### Beyond the Base Salary: Understanding Total Compensation

A welding inspector's W-2 is often much more than just their base salary. The nature of the work, especially in field-based roles, leads to several other forms of compensation that can dramatically increase total earnings.

- Overtime Pay: This is a huge factor. Projects in construction, manufacturing, and energy often run on tight deadlines, requiring work beyond the standard 40-hour week. Overtime is typically paid at 1.5 times the hourly rate and can add tens of thousands of dollars to an inspector's annual income.

- Per Diem: For inspectors who travel for work ("road warriors"), companies provide a daily allowance (per diem) to cover lodging, food, and incidental expenses. This can range from $75 to $200+ per day and is often non-taxable, making it a significant financial benefit.

- Bonuses and Profit Sharing: Many companies, particularly in the private sector, offer annual or project-based bonuses tied to performance, project profitability, and safety records.

- Company Vehicle and Tools: In many field positions, the company provides a work truck, a fuel card, and all necessary inspection equipment, saving the inspector significant personal expense.

- Benefits Package: A comprehensive benefits package is standard and includes health, dental, and vision insurance, as well as a 401(k) or other retirement savings plan, often with a company match.

When you combine a strong base salary with consistent overtime and other benefits, it becomes clear why a seasoned inspector in a high-demand industry can easily achieve a six-figure income.

Key Factors That Influence a Welding Inspector's Salary

The difference between earning $60,000 and $120,000 as a welding inspector is not a matter of luck. It is a direct result of a combination of strategic career choices, continuous learning, and geographic positioning. This section will provide an exhaustive breakdown of the six primary factors that dictate your earning potential.

### 1. Certifications and Education

In welding inspection, certifications are the currency of the realm. While a formal degree can be helpful, it is the professional certifications that truly unlock higher pay grades and more significant responsibilities.

- The Gold Standard: AWS Certified Welding Inspector (CWI): The CWI certification from the American Welding Society is the single most important credential you can earn. It is recognized globally and is often a minimum requirement for any serious inspection role. Earning your CWI immediately elevates you from a general QC technician to a certified professional, often resulting in a salary increase of $10,000-$20,000 or more.

- The Elite Level: Senior Certified Welding Inspector (SCWI): For those with at least six years of experience as a CWI, the SCWI certification represents the pinnacle of the profession. SCWIs are qualified to develop inspection programs, audit quality systems, and train other inspectors. This credential is a direct pathway to management roles and salaries often exceeding $100,000.

- The Force Multiplier: Nondestructive Testing (NDT) Certifications: A CWI who is also certified in various NDT methods is a powerhouse. Certifications are typically governed by the American Society for Nondestructive Testing (ASNT) SNT-TC-1A or CP-189 standards.

- Level II Certifications: A CWI with ASNT Level II certifications in high-demand methods like Ultrasonic Testing (UT) and Radiographic Testing (RT) Film Interpretation is exceptionally valuable. These skills allow them to detect subsurface flaws that visual inspection cannot, making them essential for critical applications like pressure vessels and pipelines. Each additional Level II cert can add thousands to your base salary.

- Level III Certifications: An ASNT Level III professional is an NDT expert. They can write NDT procedures, train and certify Level I and II technicians, and represent their company as the final authority on testing matters. A CWI/ASNT Level III is one of the highest-paid non-executive roles in the quality field, with earnings frequently pushing $130,000 or more.

- Code-Specific Endorsements: The AWS offers endorsements to the CWI certification for specific codes, such as API 1104 (Pipelines), AWS D1.1 (Structural Steel), and ASME Section IX (Boilers & Pressure Vessels). Holding these endorsements proves your expertise in a specific industry and makes you a more attractive candidate for high-paying jobs in those sectors.

- Formal Education: While not as critical as certifications, an Associate's or Bachelor's degree in Welding Engineering Technology, Metallurgy, or a related field can be beneficial. It can sometimes substitute for a portion of the experience requirement for the CWI exam and provides a strong theoretical foundation, which is particularly useful for those aspiring to high-level management or engineering roles.

### 2. Years of Experience

As detailed in the salary table above, experience is a primary driver of compensation growth. However, it's not just about time served; it's about the *quality* and *diversity* of that experience.

- Foundation (0-2 years): The initial years are about absorbing knowledge. You are building credibility by working under senior inspectors, learning to navigate complex codes, and mastering basic inspection techniques. Your value is in your potential and willingness to learn.

- Independence (3-9 years): With your CWI in hand, you are now an independent decision-maker. Your salary increases as you prove your ability to reliably interpret codes, manage your own workflow, and produce clear, concise documentation without constant supervision. Each successfully completed project adds to your professional reputation.

- Expertise (10+ years): At this stage, you have likely seen thousands of welds across various applications. You can anticipate problems before they happen, troubleshoot complex welding issues, and mentor junior inspectors. Your value is now in your deep knowledge base and sound judgment. This is when you can leverage your experience to specialize or move into leadership, leading to the most significant salary jumps.

### 3. Geographic Location

Where you work is one of the most powerful factors influencing your paycheck. The demand for welding inspectors is not uniform across the country; it is concentrated in regions with heavy industrial, energy, or construction activity. High-demand areas combined with a high cost of living typically result in the highest salaries.

Top-Paying States and Metropolitan Areas:

| State/Region | Average Salary for Experienced CWI | Key Industries |

| :--- | :--- | :--- |

| Alaska | $95,000 - $130,000+ | Oil & Gas (pipelines), Mining, Defense |

| Texas (Houston, Permian Basin) | $85,000 - $120,000+ | Oil & Gas (refineries, offshore), Petrochemical, Manufacturing |

| Louisiana | $80,000 - $115,000+ | Shipbuilding, Petrochemical, Oil & Gas |

| California (SoCal) | $85,000 - $110,000+ | Aerospace, Defense, Heavy Construction, Manufacturing |

| North Dakota | $80,000 - $110,000+ | Oil & Gas (Bakken Shale), Power Generation |

| Wyoming | $75,000 - $105,000+ | Mining, Energy, Pipeline Construction |

Factors to Consider:

- Cost of Living: A $100,000 salary in Houston, TX, will go much further than the same salary in Los Angeles, CA. You must weigh salary against living expenses.

- "Shutdown" and "Turnaround" Work: Many inspectors increase their income significantly by working on plant shutdowns or turnarounds. These are intensive, short-term projects (a few weeks to a few months) where refineries or power plants shut down for maintenance. The work involves long hours (70-84 hours/week) but pays extremely well, often including overtime, per diem, and travel pay.

- International Opportunities: Experienced CWIs, especially those with NDT and pipeline experience, can find highly lucrative contract work overseas, particularly in the Middle East, Southeast Asia, and Africa. These positions often come with hardship pay, completion bonuses, and generous rotation schedules (e.g., 28 days on, 28 days off).

### 4. Industry and Area of Specialization

The industry you choose to specialize in has a profound impact on your work environment, required knowledge, and, most importantly, your salary.

- Oil & Gas (Upstream, Midstream, Downstream): (Highest Earning Potential). This sector consistently offers the highest pay due to the critical nature of the work and often harsh conditions.

- *Midstream (Pipelines):* Inspectors with an API 1104 endorsement are in constant demand. The work involves extensive travel and long hours but is exceptionally well-compensated.

- *Downstream (Refineries/Petrochemical):* Requires knowledge of ASME codes for pressure vessels and piping. Shutdown work is a major source of high income.

- Aerospace & Defense: (High Pay, High Scrutiny). This industry has zero tolerance for failure. Inspectors here work on aircraft, spacecraft, and military hardware. They must be experts in advanced materials (like titanium and composites) and sophisticated NDT methods. The pay is excellent, and the work is at the cutting edge of technology.

- Power Generation: (Stable and Lucrative).

- *Nuclear:* The highest level of quality assurance. Nuclear inspectors are among the most rigorously trained and vetted professionals. The pay is at the top end of the scale, but the regulatory burden is immense.

- *Fossil Fuel/Renewables:* Inspecting boilers, turbines, and structural components for power plants provides stable, well-paying employment.

- Heavy Construction & Infrastructure: (Strong, Cyclical Demand). Inspectors working on bridges, high-rise buildings, and stadiums must be masters of the AWS D1.1 (Structural Steel) and D1.5 (Bridge Welding) codes. Pay is very good, especially in major metropolitan areas with booming construction.

- Manufacturing: (Varies Widely). This includes everything from automotive frames to heavy equipment. Pay can be more modest than in energy or aerospace but often provides a more stable, 9-to-5 work environment with less travel.

### 5. In-Demand Skills (Technical and Soft)

Beyond your core certifications, specific skills will make you a more effective and valuable inspector, directly translating to higher pay.

High-Value Technical Skills:

- Advanced NDT Proficiency: Moving beyond basic MT/PT to being an expert in Phased Array Ultrasonic Testing (PAUT) or Time of Flight Diffraction (TOFD) can set you apart and command a premium salary.

- Robotics and Automated Welding Inspection: As automation becomes more prevalent, inspectors who understand the quality control aspects of robotic welding and can interpret data from automated inspection systems will be in high demand.

- Metallurgical Knowledge: A deep understanding of metallurgy—how different metals react to the heat and stress of welding—allows you to be a problem-solver, not just an inspector.

- Code Mastery: Being the go-to person who can interpret the nuances of multiple codes (e.g., being fluent in both ASME and API standards) makes you invaluable on complex projects that span different regulatory environments.

- Advanced Computer & Software Skills: Proficiency in quality management software, digital reporting tools, and even basic CAD software to navigate complex 3D models is increasingly expected.

Essential Soft Skills:

- Communication and Diplomacy: You must be able to tell a highly-skilled welder that their work is not acceptable without creating a hostile environment. You need to write clear, unambiguous reports for engineers and managers.

- Unquestionable Integrity: Your signature on a report is a bond of trust. A reputation for honesty and ethical rigor is your most valuable asset.

- Attention to Detail: A tiny crack or inclusion missed can have catastrophic consequences. Meticulousness is not a preference; it is a job requirement.

- Problem-Solving: When a weld fails, you need to work with the team to understand *why*—was it the procedure, the material, the welder, or the environment?

By strategically developing these five areas, you can actively steer your career towards its maximum earning potential.

Job Outlook and Career Growth

Investing time and money into a career path requires a clear understanding of its future stability and growth potential. For welding inspectors, the outlook is robust and promising, driven by fundamental needs of the U.S. and global economy.

### Job Growth Projections

The U.S. Bureau of Labor Statistics (BLS) projects the employment of "Inspectors, Testers, Sorters, Samplers, and Weighers" to have little or