Are you fascinated by the science of joining materials, the force that holds our modern world together? From the soaring skyscrapers that define our cities to the deep-sea vessels exploring the abyss, the integrity of a single weld can mean the difference between triumph and disaster. This is the world of the welding engineer—a highly specialized, intellectually demanding, and financially rewarding profession that serves as the backbone of modern industry.

If you're considering this career, you're likely asking a critical question: what is the salary of a welding engineer? The answer is compelling. On average, welding engineers in the United States earn a robust salary, often ranging from $75,000 to well over $150,000 per year, depending on a host of factors we will explore in detail. But this career is about more than just the numbers; it's about being the expert who ensures that bridges don't collapse, pipelines don't fail, and spacecraft can withstand the rigors of launch. I'll never forget standing at the base of a massive wind turbine, watching a team of welders and engineers work in harmony. The senior welding engineer on site wasn't just supervising; she was a metallurgist, a physicist, and a project manager all in one, explaining how the specific welding procedure she designed would withstand decades of fatigue and stress. It was a powerful reminder that this is a career of immense responsibility and profound impact.

This guide is designed to be your definitive resource. We will dissect every component of a welding engineer's salary, explore the factors that can maximize your earning potential, and provide a clear, actionable roadmap for launching your own successful career in this vital field.

### Table of Contents

- [What Does a Welding Engineer Do?](#what-does-a-welding-engineer-do)

- [Average Welding Engineer Salary: A Deep Dive](#average-welding-engineer-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Become a Welding Engineer](#how-to-become-a-welding-engineer)

- [Conclusion: Forging Your Future](#conclusion-forging-your-future)

What Does a Welding Engineer Do?

While a welder is a highly skilled artisan who physically joins metal, a welding engineer is the master strategist and scientist behind the process. They are the architects of the weld, responsible for the 'how,' 'why,' and 'what' of every connection. They don't just know *how* to weld; they know *why* a specific process, material, and procedure is the only correct choice for a given application.

The role is a dynamic blend of office-based design and on-site, hands-on application. Welding engineers are problem-solvers who bridge the gap between theoretical design and practical manufacturing. Their expertise ensures that welded joints are not only strong and durable but also safe, compliant with stringent industry codes, and economically feasible to produce.

Core Responsibilities and Daily Tasks:

A welding engineer's duties are diverse and touch multiple stages of a project lifecycle:

- Design and Development: They develop and design Welding Procedure Specifications (WPS), which are the official "recipes" for a weld. This includes selecting the appropriate welding process (e.g., GMAW/MIG, GTAW/TIG, SMAW/Stick, SAW), filler metals, and joint configuration for a specific application.

- Code Compliance and Quality Assurance: A massive part of the job is ensuring all welding activities comply with industry standards and codes, such as those from the American Welding Society (AWS D1.1 for structural steel), the American Society of Mechanical Engineers (ASME Boiler and Pressure Vessel Code), and the American Petroleum Institute (API 1104 for pipelines).

- Metallurgical Analysis: They possess a deep understanding of metallurgy, studying how the heat from welding affects the microstructure and properties of different metals and alloys. This includes preventing defects like cracking, porosity, and distortion.

- Testing and Inspection: Welding engineers oversee Non-Destructive Testing (NDT) or Non-Destructive Examination (NDE) methods—such as ultrasonic, magnetic particle, radiographic, and dye penetrant testing—to verify the integrity of welds without destroying the component.

- Robotics and Automation: In modern manufacturing, welding engineers are increasingly responsible for programming, operating, and troubleshooting robotic welding systems to improve efficiency, consistency, and safety.

- Failure Analysis: When a weld fails, the welding engineer is the lead investigator, performing a root cause analysis to determine what went wrong and how to prevent it from happening again.

- Project Management & Cost Estimation: They often manage welding projects from conception to completion, including estimating costs, scheduling timelines, and supervising welding personnel and inspectors.

### A Day in the Life of a Welding Engineer

To make this tangible, let's follow "Alex," a mid-career welding engineer at an aerospace manufacturing company:

- 8:00 AM: Alex starts the day in a project meeting with design engineers. They are developing a new bracket for a satellite deployment system. Alex’s role is to advise on the best lightweight alloy and the most reliable welding process to join it, considering the extreme temperatures and vibrations it will face in space.

- 9:30 AM: Alex heads to the R&D lab to review the results of a test weld on the proposed new alloy. Using a microscope, Alex examines a cross-section of the weld, analyzing the grain structure to ensure there are no microscopic cracks or defects.

- 11:00 AM: A call comes in from the production floor. A robotic welding cell is producing welds with inconsistent penetration. Alex goes to the floor, reviews the robot’s programming, checks the gas flow rate, and inspects the wire feeder. After making a few adjustments to the robot's travel speed and voltage, the issue is resolved.

- 1:00 PM: After lunch, Alex spends two hours writing a detailed Welding Procedure Specification (WPS) for the new satellite bracket, citing specific ASME codes. This document will be the official guide for the welders who will perform the work.

- 3:00 PM: Alex conducts a training session for a group of new welding technicians, explaining the critical aspects of the WPS and demonstrating proper visual inspection techniques.

- 4:30 PM: The day ends with reviewing NDT reports from the quality control team for a batch of recently completed components, signing off on those that pass inspection and flagging one for further review.

This "day in the life" illustrates the multifaceted nature of the role—a constant cycle of analysis, problem-solving, documentation, and collaboration.

Average Welding Engineer Salary: A Deep Dive

The compensation for a welding engineer is a direct reflection of the high level of technical expertise, responsibility, and value they bring to an organization. While salaries can vary significantly, the profession offers a lucrative and stable career path with substantial growth potential.

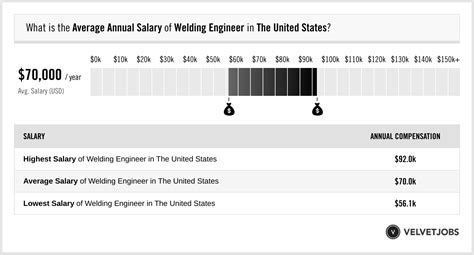

According to data from several authoritative sources, the national average salary for a welding engineer in the United States falls into a strong upper-middle-class bracket.

- Salary.com reports the median salary for a Welding Engineer in the U.S. is $86,521 as of late 2023, with a typical range falling between $78,929 and $96,757.

- Payscale.com provides a broader spectrum, showing an average base salary of $79,852 per year, with the full range for the profession spanning from $63,000 to $118,000.

- Glassdoor.com estimates the total pay for a welding engineer to be around $96,558 per year in the United States, which includes a base salary of approximately $85,153 and additional pay (bonuses, profit sharing) of around $11,405.

- ZipRecruiter.com shows an even higher national average of $98,390 per year, with top earners reaching as high as $158,000.

Synthesizing this data, a realistic expectation for a welding engineer's salary in the U.S. is a median base salary of approximately $80,000 to $98,000, with a total compensation package that often pushes the figure into the low six figures.

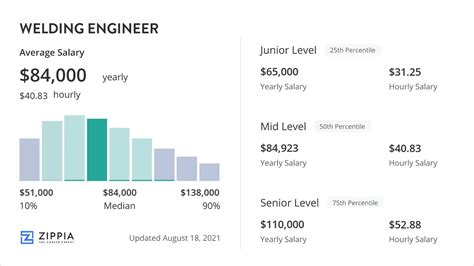

### Salary by Experience Level

One of the most significant determinants of a welding engineer's salary is their years of experience. The career path offers a clear and rewarding progression from entry-level positions to senior and principal roles.

| Experience Level | Typical Years of Experience | Typical Salary Range (Base) | Key Responsibilities |

| :--- | :--- | :--- | :--- |

| Entry-Level Welding Engineer | 0-3 Years | $65,000 - $80,000 | Assisting senior engineers, developing basic WPS documents, overseeing routine tests, learning company standards and industry codes. |

| Mid-Career Welding Engineer | 4-9 Years | $80,000 - $110,000 | Leading small to medium-sized projects, developing complex welding procedures, mentoring junior staff, direct interaction with clients and vendors. |

| Senior/Principal Welding Engineer | 10+ Years | $110,000 - $150,000+ | Setting departmental strategy, managing large-scale projects and teams, signing off on critical procedures, serving as the company's subject matter expert. |

*Note: Salary ranges are estimates based on aggregated data from sources like Payscale, Salary.com, and Glassdoor, and can vary based on the factors discussed in the next section.*

### Beyond the Base Salary: Understanding Total Compensation

A welding engineer's earnings are not limited to their base salary. The total compensation package is often significantly higher, thanks to a variety of additional financial incentives that are common in engineering and manufacturing fields.

- Annual Bonuses: This is one of the most common forms of additional compensation. Bonuses are often tied to individual performance, team project success, or overall company profitability. According to Payscale, the average annual bonus for a welding engineer can range from $2,000 to $15,000.

- Profit Sharing: Some companies, particularly those in manufacturing and heavy industry, offer profit-sharing plans where a portion of the company's annual profits is distributed among employees. This can add another $1,000 to $10,000 or more to an engineer's yearly income.

- Commission: While less common, some welding engineers in sales-oriented or consulting roles may earn a commission based on the projects or products they sell.

- Retirement Plans (401k/403b): A strong employer match on a 401(k) is a significant part of total compensation. A company that matches 100% of employee contributions up to 6% of their salary is effectively giving that employee a 6% raise dedicated to their retirement savings.

- Stock Options and Grants: In publicly traded companies, particularly in high-tech sectors like aerospace or advanced manufacturing, stock options can be a highly lucrative part of the compensation package for senior-level engineers.

- Benefits: The value of a comprehensive benefits package cannot be overstated. This includes health, dental, and vision insurance, paid time off (PTO), life insurance, and disability insurance. A premium-free family health plan, for example, can be worth over $20,000 per year in saved costs.

- Perks and Allowances: Depending on the industry, other perks might include a company vehicle (for field engineers), relocation assistance, and a generous budget for professional development and certifications.

When evaluating a job offer, it is crucial to look beyond the base salary and calculate the value of the entire compensation and benefits package to understand the true earning potential of the role.

Key Factors That Influence Salary

While the national averages provide a solid benchmark, a welding engineer's actual salary is determined by a complex interplay of several key factors. Understanding these variables is the first step toward maximizing your earning potential throughout your career. This section will provide an in-depth analysis of the most influential factors, supported by data and industry insights.

### 1. Level of Education and Certifications

Your educational foundation is the launching pad for your career and has a direct impact on your starting salary and long-term growth.

- Bachelor's Degree (The Standard): A Bachelor of Science (B.S.) is the standard entry-level requirement. The most direct path is a B.S. in Welding Engineering. This specialized degree, offered by a handful of universities like The Ohio State University and LeTourneau University, is highly sought after and often commands the highest starting salaries. However, many successful welding engineers enter the field with related degrees, such as:

- B.S. in Materials Science & Engineering: Focuses on the properties of materials, a core competency.

- B.S. in Mechanical Engineering: Provides a broad foundation in design and systems, with welding as a potential specialization.

- B.S. in Welding Engineering Technology (WET): More hands-on and application-focused than a traditional engineering degree. Graduates are highly practical and valuable on the shop floor.

- Master's Degree (The Accelerator): Pursuing a Master of Science (M.S.) in Welding Engineering or a related field can significantly accelerate your career and earning potential. An advanced degree typically qualifies you for more specialized roles in Research & Development (R&D), failure analysis, consulting, and senior management. An engineer with a Master's degree can often expect a starting salary that is $10,000 to $20,000 higher than a candidate with only a Bachelor's degree. It signals a deeper level of expertise that is highly valued in critical industries like nuclear power and aerospace.

- Professional Certifications (The Game Changer): In the world of welding, professional certifications are often as valuable as academic degrees. They are a testament to your proven knowledge and expertise.

- Certified Welding Inspector (CWI): Offered by the American Welding Society (AWS), the CWI is arguably the most recognized and valuable credential in the industry. While technically an inspector certification, many welding engineers hold it. It demonstrates a profound understanding of welding processes, procedures, quality control, and code compliance. Holding a CWI can instantly boost a candidate's marketability and add $5,000 to $15,000 to their annual salary.

- Senior Certified Welding Inspector (SCWI): The next level up from CWI, requiring more experience and demonstrating leadership capabilities.

- Certified Welding Engineer (CWE): Also from AWS, this certification is specifically for engineers and validates their ability to direct welding operations as defined by company and industry standards. It is a highly respected credential that can open doors to senior-level positions.

- NDE Certifications (Level II or III): Certifications in Non-Destructive Examination methods (like UT, MT, RT) from the American Society for Nondestructive Testing (ASNT) can make an engineer extremely valuable, especially in quality-critical roles.

### 2. Years of Experience

As highlighted in the salary table above, experience is the most powerful driver of salary growth. The career trajectory is marked by a steady increase in responsibility and, consequently, compensation.

- 0-3 Years (Foundation Building): Entry-level engineers focus on learning. They absorb company procedures, assist with WPS creation, and spend significant time on the production floor or in the field. Their value lies in their academic knowledge and potential.

- 4-9 Years (Becoming the Expert): Mid-career engineers transition from learning to leading. They manage their own projects, solve complex production problems, mentor junior engineers, and are trusted to make significant technical decisions. This is often the period of the most rapid salary growth as they prove their value.

- 10+ Years (Strategic Leadership): Senior and Principal Welding Engineers operate at a strategic level. They don't just solve problems; they anticipate them. They develop new technologies, set company-wide welding standards, manage multi-million dollar projects, and act as the ultimate authority on all welding-related matters. Their salaries reflect this immense responsibility and expertise, often reaching well into the $150,000+ range, especially in high-paying industries.

### 3. Geographic Location

Where you work matters—a lot. Salaries for welding engineers can vary dramatically by state and even by metropolitan area due to differences in industry concentration, demand for talent, and cost of living.

- High-Paying States & Regions: Salaries are typically highest in states with a heavy concentration of industries that rely on advanced welding.

- Texas & Louisiana (Oil & Gas): The massive oil and gas infrastructure, including offshore platforms, refineries, and pipelines, creates immense demand for welding engineers. Cities like Houston, TX, often report some of the highest salaries in the nation, frequently exceeding the national average by 15-25%.

- California & Washington (Aerospace & Tech): The aerospace and defense hubs in Southern California and the Seattle area (home to Boeing) require engineers with expertise in exotic materials and zero-failure tolerance, commanding premium salaries.

- Michigan (Automotive): The automotive industry's focus on robotics, automation, and lightweight materials keeps demand for skilled welding engineers high.

- East Coast (Shipbuilding & Defense): States with major shipyards like Virginia and Connecticut have a consistent need for welding engineers for naval and commercial shipbuilding projects.

- Lower-Paying Regions: Conversely, states with less heavy industry or a lower cost of living will generally offer lower salaries. This might include more rural areas in the Midwest and Southeast, though even there, specific manufacturing plants can create pockets of high demand.

Example Salary Variation by City (Estimates):

- Houston, TX: ~$115,000

- Los Angeles, CA: ~$110,000

- Seattle, WA: ~$108,000

- Detroit, MI: ~$95,000

- National Average: ~$87,000

- Kansas City, MO: ~$82,000

It is crucial to balance a higher salary against the cost of living. A $110,000 salary in Los Angeles may offer a similar quality of life to an $85,000 salary in a smaller Midwestern city.

### 4. Company Type & Industry

The industry you work in is perhaps as influential as your geographic location. The criticality and profitability of welding vary enormously from one sector to another.

- Aerospace & Defense: This is often the pinnacle of pay and prestige. Working on military aircraft, spacecraft, or missile systems involves exotic materials (like titanium and Inconel), zero-defect requirements, and extensive security clearances. Companies like Boeing, Lockheed Martin, SpaceX, and Northrop Grumman pay a premium for top-tier talent.

- Oil & Gas (Upstream/Midstream): This sector is known for its high salaries, driven by the immense profitability and the hazardous, high-stakes environment of drilling, extraction, and transportation. Welding engineers here specialize in pipelines, pressure vessels, and offshore structures. The work can be cyclical, with pay peaking during oil booms.

- Nuclear Power: The ultimate in high-stakes welding. The regulatory oversight and the absolute need for flawless execution in a nuclear environment mean that welding engineers in this field are among the most highly vetted and compensated.

- Heavy Construction & Infrastructure: Working on bridges, skyscrapers, and dams. This involves large-scale structural steel welding and adherence to AWS D1.1 and other construction codes. Salaries are solid, often tied to government funding and economic cycles.

- Automotive Manufacturing: A high-tech environment focused on efficiency and automation. Engineers specialize in robotic welding (GMAW) and resistance spot welding for high-volume production lines.

- Shipbuilding: Involves massive-scale welding of thick steel plates for naval and commercial vessels. It's a stable field, often concentrated in specific coastal regions.

- General Manufacturing: This broad category includes everything from making agricultural equipment to fabricating industrial machinery. Salaries can vary widely based on the size and profitability of the company.

Large, multinational corporations generally offer higher salaries, better benefits, and more structured career paths than smaller, privately-owned fabrication shops. However, a smaller company might offer more hands-on experience and a faster track to a position of significant responsibility.

### 5. Area of Specialization

Within the field of welding engineering, certain specializations are in higher demand and command a salary premium.

- Robotics and Automation: As manufacturing becomes more automated, engineers who can design, program, and manage robotic welding systems are incredibly valuable. This skill set is essential in the automotive, aerospace, and general manufacturing industries.

- Metallurgy and Failure Analysis: Engineers who are true experts in materials science and can perform sophisticated root cause analysis on failed components are rare and highly sought after, especially for consulting and senior roles in critical industries.

- Non-Destructive Examination (NDE): While NDE is often a separate discipline, a welding engineer who is also a certified expert (e.g., ASNT Level III) in advanced NDE techniques like Phased Array Ultrasonic Testing (PAUT) is a dual threat and can command a top-tier salary.

- Additive Manufacturing (3D Printing): The emerging field of metal 3D printing, like Direct Metal Laser Sintering (DMLS) or Wire Arc Additive Manufacturing (WAAM), requires a new breed of engineer who understands both welding physics and additive processes. This is a high-growth, high-salary niche.

### 6. In-Demand Skills

Beyond your degree and title, specific, demonstrable skills on your resume can directly increase your value to an employer.

- Hard Skills:

- CAD/CAM Software: Proficiency in software like SolidWorks, AutoCAD, CATIA, or Creo for designing parts and fixtures.

- Welding Simulation/FEA: Experience with software (like those from Abaqus or ANSYS) that simulates the stresses and distortions caused by welding.

- Code Mastery: Deep, working knowledge of specific codes like ASME Section IX, API 1104, AWS D1.1, or AWS D17.1 (for aerospace) is non-negotiable for high-level roles.

- Robotic Programming: Familiarity with programming languages for Fanuc, ABB, or Kuka robots.

- Soft Skills:

- Project Management: The ability to manage budgets, timelines, and personnel is crucial for advancement. PMP certification is a plus.

- Communication: The ability to clearly explain complex technical concepts to non-technical managers, clients, and shop floor personnel.

- Problem-Solving: A demonstrated track record of identifying issues, analyzing root causes, and implementing effective solutions.

- Leadership and Mentoring: As you become more senior, your ability to train and develop the next generation of engineers and technicians becomes a key part of your value.

Job Outlook and Career Growth

For anyone considering a long-term career as a welding engineer, the future looks bright and stable. The demand for these professionals is intrinsically linked to the health of the industrial, manufacturing, and infrastructure sectors of the economy—sectors that are foundational to modern society.

The U.S. Bureau of Labor Statistics (BLS) does not track "Welding Engineers" as a distinct category. Instead, they are often grouped within broader categories like Materials Engineers or Mechanical Engineers. Analyzing the outlook for these related fields provides a strong proxy for the future of welding engineering.

- Materials Engineers: The BLS projects employment for materials engineers to grow 2 percent from 2022 to 2032. While this appears modest, it's important to note the specialized nature of the field. The growth is driven by the need to develop new and improved materials for aviation, aerospace, healthcare, and advanced manufacturing.

- Mechanical Engineers: Employment for mechanical engineers is projected to grow 10 percent from 2022 to 2032, much faster than the average for all occupations. The BLS attributes this strong growth to the need for professionals in emerging areas like robotics, automation, and additive manufacturing—all core components of modern welding engineering.

Combining these outlooks, the career path for a welding engineer is robust. The demand is not just about growth; it's also about replacement. A significant portion of the current expert-level engineering workforce is approaching retirement age, creating a "knowledge gap" that well-qualified new engineers are needed to fill. This "brain drain" creates immense opportunities for advancement for those entering the field now.

### Emerging Trends and Future Opportunities

The role of the welding engineer is not static; it is constantly evolving with technology. Staying ahead of these trends is the key to long-term career growth and sustained high earnings.

1. Automation and Industry 4.0: The "smart factory" is here. Welding engineers are no longer just managing welders; they are managing data. This includes integrating robotic welding cells with sensors, machine vision, and AI-driven quality control systems. Engineers who can speak the language of both welding and data analytics will be in the highest demand.

2. Advanced Materials: The push for lighter, stronger, and more corrosion-resistant products is driving the use of advanced materials like high-strength steel, aluminum-lithium alloys, composites, and superalloys. Each new material requires new welding procedures and expertise, creating a constant need for R&D-focused engineers.

3. Additive Manufacturing (AM): Metal 3D printing is revolutionizing prototyping and the production of complex, low-volume parts. Welding engineers are perfectly positioned to lead this transition, as many AM processes (like WAAM) are fundamentally advanced welding techniques. This is a major growth area for the next decade.

4. Infrastructure Renewal: Much of the infrastructure in the United States—bridges, dams, pipelines, and power plants—is aging and in need of repair or replacement. This will drive sustained, long-term demand for welding engineers who specialize in structural steel and pressure vessel codes.

5. Green Technology: The transition to a green economy creates new opportunities. Welding engineers are critical in the manufacturing of wind turbines, the construction of nuclear power plants, the production of electric vehicle components, and the development of hydrogen fuel cells and pipelines.

### How to Stay Relevant and Advance

Advancement in this field is not passive. It requires a commitment to continuous learning and professional development.

- Never Stop Learning: Actively seek out new knowledge. Attend webinars, go to industry conferences like the AWS FABTECH expo, and read trade publications like the *Welding Journal*.

- Pursue Advanced Certifications: Don't stop at a CWI. Consider an SCWI, CWE, or specialized NDE certifications