Every time you turn on a faucet, flush a toilet, or water your garden, you are the direct beneficiary of a hidden, essential, and remarkably stable profession. Behind the scenes, a dedicated team of professionals ensures that water is safe to drink and that wastewater is treated responsibly before being returned to the environment. These guardians of public health and environmental safety are Water and Wastewater Treatment Plant Operators.

If you're seeking a career that combines technical skill, hands-on problem-solving, and a profound sense of purpose, this field offers a compelling path. But purpose alone doesn't pay the bills. A crucial question for any prospective professional is: what is the earning potential? The national median water treatment plant operator salary hovers around $57,370 per year, but this single number only tells a fraction of the story. With experience, advanced certification, and strategic career moves, top operators can earn well over $90,000 annually.

I once found myself in a city under a week-long "boil water advisory" after a major main break and subsequent pressure loss. The inconvenience was minor, but the incident gave me a deep appreciation for the invisible system I took for granted. The calm, competent updates from the city's water department, and the round-the-clock work of the operators to flush, test, and recertify the system, highlighted the immense responsibility these professionals shoulder every single day. They are the bedrock of modern public health.

This guide is designed to be your definitive resource, moving far beyond a simple salary number. We will dissect every factor that influences your potential earnings, explore the career's promising future, and provide a step-by-step roadmap to get you started.

### Table of Contents

- [What Does a Water Treatment Plant Operator Do?](#what-does-a-water-treatment-plant-operator-do)

- [Average Water Treatment Plant Operator Salary: A Deep Dive](#average-water-treatment-plant-operator-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion: Is This the Right Career for You?](#conclusion-is-this-the-right-career-for-you)

What Does a Water Treatment Plant Operator Do?

At its core, a Water Treatment Plant Operator is a technician, scientist, and mechanic rolled into one. They are responsible for managing the complex systems and equipment that purify water for human consumption (drinking water treatment) or clean used water from homes and industries before it is released back into the environment (wastewater treatment). While the specifics differ between water and wastewater, the fundamental mission is the same: to ensure water quality meets or exceeds stringent local, state, and federal regulations.

These operators don't just push buttons; they are active managers of a dynamic biological and chemical process. Their work is a constant cycle of monitoring, testing, adjusting, and maintaining.

Core Responsibilities and Daily Tasks:

- Process Monitoring: Operators use a combination of manual readings from gauges and meters and sophisticated computerized systems (like SCADA - Supervisory Control and Data Acquisition) to monitor pumps, engines, valves, and chemical treatment processes 24/7.

- Sampling and Laboratory Testing: They regularly collect water samples from various stages of the treatment process and perform chemical and biological tests to check for pH levels, chlorine residuals, turbidity (clarity), bacteria, and other contaminants.

- Chemical Dosage Adjustment: Based on test results, operators calculate and adjust the feed rates of various chemicals, such as chlorine for disinfection, alum or polymers for coagulation (clumping particles together), and lime for pH control.

- Equipment Maintenance and Repair: Operators perform routine preventative maintenance on all plant machinery, including pumps, motors, filters, and clarifiers. They are often the first line of defense for troubleshooting and performing minor repairs to keep the plant running smoothly.

- Record Keeping and Reporting: Meticulous record-keeping is a legal requirement. Operators maintain detailed logs of all tests, maintenance activities, chemical usage, and water flow, often for submission to regulatory agencies like the Environmental Protection Agency (EPA).

- Responding to Alarms and Emergencies: Plants are equipped with alarms that signal equipment malfunctions or deviations from normal operating parameters. Operators must quickly diagnose and resolve these issues, day or night, to prevent service disruptions or environmental violations.

### A "Day in the Life" of a Water Operator

To make this tangible, let's follow a fictional operator, "David," on a typical day shift at a municipal drinking water plant.

- 7:00 AM: David arrives, grabs a coffee, and heads to the control room for the shift change briefing. The night operator updates him on plant status, any overnight alarms, and scheduled maintenance. They review the SCADA system, which shows a graphical overview of the entire plant's operations.

- 7:30 AM: David begins his plant walk-through. He carries a clipboard and a keen ear, listening for any unusual noises from pumps or motors. He checks gauges, inspects the massive filter beds, and ensures the chemical feed pumps are working correctly.

- 9:00 AM: It's time for morning samples. David collects water from the raw water intake (from the river), after sedimentation, after filtration, and from the finished water storage tank.

- 9:30 AM: In the plant's laboratory, David performs a series of tests: chlorine residual, pH, turbidity, and alkalinity. He logs all results meticulously in the plant's digital database. Today, all readings are well within the required parameters.

- 11:00 AM: A preventative maintenance task is on the schedule. David, along with a maintenance technician, needs to inspect and lubricate the main raw water pump. They follow lockout/tagout procedures to ensure the pump cannot be started while they work, then perform the necessary service.

- 12:30 PM: Lunch break in the control room, keeping an eye on the SCADA monitors.

- 1:30 PM: An alarm sounds. The SCADA screen shows that a polymer feed pump has failed. David immediately switches to the backup pump via the computer system to ensure the treatment process is not interrupted. He then goes to the failed pump to diagnose the issue—it appears to be a simple clog in the line, which he can clear himself.

- 3:00 PM: David begins preparing his end-of-shift report, summarizing all tests, operational changes, and maintenance activities.

- 3:45 PM: The evening shift operator arrives. David provides a thorough briefing, highlighting the polymer pump issue and ensuring a smooth handover. His work ensures the next shift can continue the vital mission of providing safe, clean water to the community.

Average Water Treatment Plant Operator Salary: A Deep Dive

Understanding the financial landscape of this career requires looking beyond a single national average. The water treatment plant operator salary is a spectrum, influenced by a host of factors we'll explore in the next section. Here, we'll establish a baseline by examining data from the most reputable sources.

According to the U.S. Bureau of Labor Statistics (BLS), the most authoritative source for national employment data, the median annual wage for water and wastewater treatment plant and system operators was $57,370 as of May 2023.

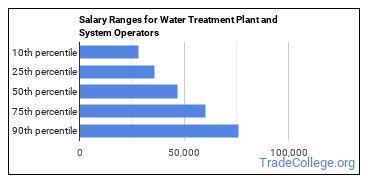

This median figure represents the midpoint—half of all operators earned more than this amount, and half earned less. To get a fuller picture, let's look at the entire pay scale as reported by the BLS:

- Lowest 10%: Earned less than $37,010

- Median (50%): Earned $57,370

- Highest 10%: Earned more than $86,470

This data reveals a wide potential range. An entry-level Operator-in-Training (OIT) will start closer to the bottom 10%, while a Chief Operator with decades of experience at a large, complex facility in a high-cost-of-living area could easily surpass the top 10% figure.

### Salary by Experience Level

Salary aggregators, which collect real-time data from job postings and self-reported salaries, provide a more granular view of how experience impacts earnings. While their figures can fluctuate more than BLS data, they offer a valuable snapshot.

Here is a composite breakdown based on data from sources like Salary.com, Payscale, and Glassdoor:

| Experience Level | Typical Years of Experience | Typical Salary Range (Annual) | Key Responsibilities & Certifications |

| :--- | :--- | :--- | :--- |

| Entry-Level / OIT | 0 - 2 years | $38,000 - $52,000 | Operator-in-Training (OIT) status. Learns basic operations, performs routine tasks under supervision, studies for initial certification. |

| Mid-Career / Certified Operator | 3 - 8 years | $50,000 - $68,000 | Holds a Class I/II or C/B state certification. Operates a shift independently, performs complex tests, handles minor troubleshooting. |

| Senior / Lead Operator | 8 - 15 years | $65,000 - $85,000 | Holds a Class III/IV or B/A state certification. Leads a team of operators, manages complex process control, trains junior staff, handles major incidents. |

| Chief Operator / Superintendent | 15+ years | $80,000 - $110,000+ | Holds the highest level of state certification. Manages the entire plant or system, handles budgeting, regulatory compliance, long-term planning, and personnel management. |

*Note: These salary ranges are national averages and can vary significantly based on the factors discussed in the next section.*

### Beyond the Base Salary: A Look at Total Compensation

The annual salary is just one piece of the compensation puzzle. For water operators, especially those in the public sector, the total compensation package is often a significant draw.

- Overtime Pay: Water treatment is a 24/7/365 operation. This means shifts cover nights, weekends, and holidays. Furthermore, when emergencies like a main break or equipment failure occur, operators are called in to work extended hours. This overtime is typically paid at 1.5 times the regular hourly rate and can substantially increase an operator's take-home pay.

- Shift Differential: To compensate for working less desirable hours, many employers offer a "shift differential"—a pay increase (e.g., an extra $1-3 per hour) for working evening, night, or weekend shifts.

- Benefits (The Public Sector Advantage): This is a major differentiator. Most operators are employed by local governments (cities, counties, special water districts). These roles typically come with excellent benefits packages that can be worth tens of thousands of dollars per year.

- Pensions/Retirement Plans: Defined-benefit pension plans, while rare in the private sector, are still common in municipal government. This provides a guaranteed income stream in retirement.

- Health Insurance: Comprehensive and affordable health, dental, and vision insurance for the employee and their family.

- Paid Time Off: Generous vacation, sick leave, and holiday pay policies.

- Bonuses and Profit Sharing: These are less common, primarily found in the private sector where operators might work for an industrial facility (e.g., a food processing plant with its own wastewater treatment system) or a private utility company. Bonuses may be tied to plant performance, safety records, or company profitability.

When evaluating a job offer, it's critical to look at the entire compensation package. A public sector job with a slightly lower base salary but a robust pension and low-cost health insurance could be far more valuable in the long run than a private sector job with a higher salary but minimal benefits.

Key Factors That Influence Salary

Now we arrive at the most critical part of our salary analysis. Why does one operator earn $45,000 while another, in a different state with more certifications, earns $95,000? The variance is driven by a predictable set of factors. Understanding these levers is key to maximizing your own earning potential throughout your career.

### 1. Certification and Education

This is arguably the single most important factor in a water operator's career and salary progression. The field is governed by a state-mandated certification system. While the specific names vary (e.g., Class I, II, III, IV in some states; Grade A, B, C, D in others), the principle is universal: the higher the certification level, the greater the responsibility and the higher the pay.

- Operator-in-Training (OIT): The starting point. Requires a high school diploma or GED. OITs work under the direct supervision of a certified operator and must gain a specific number of hands-on hours before they can sit for the first certification exam.

- Lowest Level Certification (e.g., Class I or D): This is the first rung on the professional ladder. It allows an operator to work independently on a shift at a smaller, less complex facility or as part of a team at a larger plant. Achieving this first certification typically comes with a significant pay bump over an OIT salary.

- Mid-Level Certifications (e.g., Class II/III or C/B): Each successive level requires more experience and passing a more difficult exam covering more complex treatment processes, advanced mathematics, and management principles. These certifications qualify an operator for lead roles and work at larger, more sophisticated plants. Each step up in certification is almost always tied directly to a pay grade increase.

- Highest Level Certification (e.g., Class IV or A): This is the top tier. It is required to be the "Operator in Responsible Charge" of the largest and most complex treatment facilities. Reaching this level signifies mastery of the profession and unlocks the highest salary potential, including positions like Plant Superintendent or Operations Manager.

The Impact of Formal Education:

While a four-year degree is not typically required to enter the field, postsecondary education can accelerate advancement and increase earnings.

- Vocational Certificates/Associate's Degrees: Programs in Water Quality Technology, Environmental Science, or a related field are highly valuable. They provide the foundational knowledge needed to pass certification exams more easily and can sometimes substitute for a portion of the required on-the-job experience.

- Bachelor's Degree (BS): A BS in Environmental Science, Chemistry, Biology, or Civil/Environmental Engineering opens doors to management and leadership roles. An operator with the highest-level certification *and* a relevant bachelor's degree is a prime candidate for top-paying positions like Water Department Director or Utility Manager, roles that can command salaries well into the six-figure range.

### 2. Years of Experience

Experience works in tandem with certification. You cannot get higher-level certifications without accumulating thousands of hours of hands-on experience. This creates a natural and structured salary growth trajectory.

- 0-2 Years (The Learning Phase): Salary is at its lowest as you function as an apprentice (OIT). The focus is on learning, not earning.

- 3-8 Years (The Journeyman Phase): With one or two levels of certification, you are a fully functional and independent operator. This is where you see steady salary growth as you master your craft and move from a junior to a solid mid-career professional. Pay might increase from the low $50s to the high $60s (in today's dollars).

- 8-15 Years (The Senior/Lead Phase): As a senior operator with advanced certifications, you're not just doing the job; you're improving it. You are troubleshooting the most difficult problems, training new operators, and taking on leadership responsibilities. Your salary reflects this expertise, pushing into the $70,000 - $85,000 range.

- 15+ Years (The Master/Management Phase): With over a decade and a half of experience and the highest certifications, you are an expert. You are qualified for chief operator and superintendent roles. This is where salaries peak, often exceeding $90,000 or $100,000, especially when combined with management duties.

### 3. Geographic Location

Where you work matters immensely. A water treatment plant operator salary is heavily influenced by regional cost of living and local demand. BLS data provides a clear picture of this variance.

Top-Paying States for Water and Wastewater Treatment Plant Operators (Annual Mean Wage, May 2023):

1. District of Columbia: $86,300

2. California: $84,400

3. Washington: $80,070

4. Nevada: $77,930

5. Alaska: $76,760

Top-Paying Metropolitan Areas (Annual Mean Wage, May 2023):

1. San Jose-Sunnyvale-Santa Clara, CA: $109,010

2. Vallejo-Fairfield, CA: $102,680

3. San Francisco-Oakland-Hayward, CA: $99,760

4. Santa Rosa, CA: $94,930

5. Los Angeles-Long Beach-Anaheim, CA: $91,620

It's crucial to balance these high salaries against the cost of living. While an operator in San Jose earns a six-figure salary, the housing and living expenses are among the highest in the nation. Conversely, a salary of $60,000 in a lower-cost state like Alabama (annual mean wage: $49,500) or Arkansas (annual mean wage: $46,550) might provide a similar or even better quality of life.

### 4. Employer Type & Size

The type and size of the entity that owns the treatment plant also play a significant role in compensation.

- Local Government (Municipalities, Counties, Water Districts): This is the largest employer for water operators. These positions are known for their exceptional job security, union representation (in many cases), and outstanding benefits, especially pensions. Base salaries are competitive and follow a structured, transparent pay scale tied to certification levels.

- Private Utility Companies: In some regions, water and wastewater services are run by private, for-profit companies. These positions may offer higher base salaries and the potential for performance bonuses, but often with less job security and benefits packages that are less generous than their public-sector counterparts (e.g., 401(k)s instead of pensions).

- Industrial / Commercial Facilities: Large manufacturing plants, food processors, chemical facilities, and power stations often have their own specialized water and wastewater treatment systems to handle their industrial effluent. These roles can be very high-paying, as operators must manage unique and sometimes hazardous waste streams. These jobs often require specialized knowledge and may offer higher compensation to attract qualified candidates.

- Federal Government: The federal government employs operators at military bases, national parks, and EPA research facilities. These jobs follow the General Schedule (GS) pay scale, which is very structured and transparent, with salaries varying by geographic location.

Plant size, which often correlates with the size of the population served, is also key. A large metropolitan plant serving millions of people will have more complex technology (e.g., ozone, UV, membrane filtration), a larger staff, and more stringent requirements. The chief operator of such a facility will have immense responsibility and a correspondingly high salary compared to an operator at a small, rural plant serving a few thousand people.

### 5. Area of Specialization

Within the broader field, operators can develop specialized expertise that makes them more valuable.

- Water Treatment (Potable Water) vs. Wastewater Treatment: These are two sides of the same coin. While skills are transferable, the science differs (chemistry and filtration for water vs. biology and solids handling for wastewater). Wastewater treatment is often considered more complex due to the biological processes involved, and operators in this specialty can sometimes command slightly higher salaries. Many operators hold dual certifications, making them exceptionally versatile and valuable.

- Advanced Treatment Technologies: As regulations become stricter and water sources more challenged, plants are installing advanced technologies. An operator with proven expertise in Reverse Osmosis (RO), Ultrafiltration/Microfiltration (UF/MF), Ultraviolet (UV) Disinfection, or Ozone systems is highly sought after, especially in water-scarce regions like the Southwest. This specialized knowledge directly translates to higher earning potential.

- Instrumentation and Control (SCADA/ICS): Modern plants are heavily automated. An operator who is not just a user but an expert in the plant's Supervisory Control and Data Acquisition (SCADA) and Industrial Control Systems (ICS) is invaluable. The ability to troubleshoot, program, and optimize these systems is a high-value skill that bridges the gap between operations and IT/engineering.

- Distribution and Collection Systems: Some operators specialize in what happens *outside* the plant: the vast network of pipes, pump stations, and storage tanks that make up the water distribution system or the sewer collection system. This work involves leak detection, hydraulic modeling, and maintaining remote assets, and it requires a distinct skillset.

### 6. In-Demand Skills

Beyond certifications, certain practical skills can set you apart and justify a higher salary.

- Mechanical and Electrical Aptitude: The ability to not just operate but also diagnose and repair pumps, motors, and valves saves a utility significant money and downtime.

- Laboratory Proficiency: Strong analytical skills and precision in the lab are fundamental. Expertise in advanced testing procedures beyond the daily basics is a plus.

- Regulatory Knowledge: A deep understanding of the Safe Drinking Water Act (SDWA), the Clean Water Act (CWA), and specific state regulations is crucial for senior and management roles.

- Data Analysis: The ability to look at operational data, identify trends, and make proactive adjustments to optimize the treatment process is a highly valued modern skill.

- Communication and Training: As you become more senior, your ability to clearly train junior operators and communicate complex technical information to non-technical managers or the public becomes a key part of your job.

Job Outlook and Career Growth

When considering a long-term career, salary is only one part of the equation; job security and opportunities for advancement are equally important. The outlook for water treatment plant operators is nuanced but ultimately very positive for those entering the field today.

The U.S. Bureau of Labor Statistics (BLS) projects that overall employment for water and wastewater treatment plant operators will show little or no change from 2022 to 2032, with a slight decline of 2 percent.

At first glance, this might seem discouraging. However, this statistic is deeply misleading if taken out of context. The overall number of positions isn't growing because increasing automation and the regionalization of smaller utilities into larger ones allow for more efficient operation with slightly fewer personnel.

The real story lies in replacement needs. The water industry is facing a well-documented and imminent "Silver Tsunami"—a massive wave of retirements from the Baby Boomer generation who have comprised the backbone of the workforce for decades.

According to the BLS, despite the flat growth projection, there will be about 9,200 openings for water and wastewater treatment plant operators each year, on average, over the decade. The vast majority of these openings will result from the need to replace workers who transfer to different occupations or exit the labor force, such as to retire.

This creates a paradox: while the total number of jobs may not be growing, the number of available job openings for qualified candidates will be high for the foreseeable future. Utilities are already struggling to find and train the next generation of operators. This high demand for new talent provides excellent job security for those who get certified and commit to the profession.

### Emerging Trends and Future Challenges

The role of a water operator is not static; it's evolving. Staying ahead of these trends is key to long-term career growth and relevance.

1. Stricter Regulations: The EPA and state agencies are continually updating regulations for contaminants. The recent focus on "forever chemicals" like PFAS (per- and polyfluoroalkyl substances) will require new, advanced treatment processes and more sophisticated monitoring, increasing the technical demands on operators.

2. Advanced Automation and AI: SCADA systems will become even more powerful, incorporating AI and machine learning to predict process upsets and optimize chemical and energy usage. The operator of the future will need to be more of a data analyst and system manager than a manual laborer. Those who embrace this technology will thrive.

3. Water Scarcity and Reuse: In arid and drought-prone regions