---

Table of Contents

- [Introduction](#introduction)

- [What Does a Warehouse Manager Do?](#what-does-a-warehouse-manager-do)

- [Average Warehouse Manager Salary: A Deep Dive](#average-warehouse-manager-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

---

Introduction

In the intricate and fast-paced world of modern commerce, the warehouse is not just a building for storage; it is the beating heart of the supply chain. Every product you order online, every item you pick up from a store shelf, has passed through a complex network of logistics, and at the center of this critical hub is the Warehouse Manager. If you are a natural leader, a master of organization, and someone who thrives on optimizing complex systems, a career as a Warehouse Manager offers not just a stable and in-demand profession, but also significant financial rewards. The national average warehouse manager salary paints a compelling picture, often ranging from $65,000 to over $100,000 annually, with top earners in high-demand sectors pushing even higher.

I once had the opportunity to tour a state-of-the-art, 1.2-million-square-foot e-commerce fulfillment center during its peak holiday season. Witnessing the seamless ballet of automated guided vehicles (AGVs), robotic picking arms, and hundreds of employees working in perfect concert was awe-inspiring. The manager, calm amidst the controlled chaos, explained that her job was like conducting an orchestra where every instrument, from a forklift operator to a complex software algorithm, had to play its part perfectly to succeed. That experience solidified my understanding that this role is far more than just managing inventory; it's about leading people, mastering technology, and architecting the flow of global commerce from a single, critical location.

This comprehensive guide will serve as your roadmap to understanding and achieving success in this dynamic field. We will delve deep into the core responsibilities of the role, dissect the salary you can expect to earn at every stage of your career, and explore the key factors that can significantly increase your earning potential. Whether you're a student planning your future, a current warehouse employee looking to advance, or a professional considering a career change, this article will provide the authoritative, data-backed insights you need to build a prosperous career as a Warehouse Manager.

---

What Does a Warehouse Manager Do?

A Warehouse Manager is the strategic and operational leader responsible for the efficient and effective functioning of a warehouse or distribution center. Their primary goal is to ensure that goods are received, stored, and dispatched accurately, on time, and within budget, all while maintaining the highest standards of safety and security. This is a multifaceted leadership role that blends hands-on operational oversight with strategic planning, people management, and financial acumen.

The role transcends simply "watching over boxes." A modern Warehouse Manager is a data analyst, a process engineer, a human resources leader, and a safety officer rolled into one. They are accountable for the performance of the entire facility, which directly impacts customer satisfaction and the company's bottom line.

Core Responsibilities and Daily Tasks:

The duties of a Warehouse Manager are extensive and can vary based on the size and type of the facility. However, they generally encompass the following key areas:

- Operational Oversight: Managing the core processes of inbound logistics (receiving, unloading, and stocking inventory), storage (optimizing space and layout), and outbound logistics (order picking, packing, and shipping).

- Staff Management: Recruiting, hiring, training, scheduling, and supervising warehouse staff, including forklift operators, clerks, and team leads. This includes performance reviews, setting KPIs (Key Performance Indicators), and fostering a positive, productive work culture.

- Inventory Management: Implementing and overseeing systems for inventory control to ensure accuracy. This involves cycle counting, managing stock levels to prevent overstocking or stockouts, and using a Warehouse Management System (WMS) to track every item.

- Safety and Compliance: Enforcing all health and safety regulations to create a secure working environment. This includes conducting safety training, ensuring equipment is properly maintained, and complying with regulations from bodies like the Occupational Safety and Health Administration (OSHA).

- Budgeting and Financial Control: Developing and managing the warehouse's annual budget, controlling operational costs, and identifying opportunities for cost savings and efficiency improvements.

- Process Improvement: Continuously analyzing warehouse operations to identify bottlenecks and inefficiencies. They are often tasked with implementing new technologies (like automation or new software) or methodologies (like Lean or Six Sigma principles) to improve productivity and reduce errors.

- Reporting and Analysis: Tracking and reporting on warehouse KPIs to upper management. These metrics often include order accuracy rates, on-time shipping percentages, inventory turnover, and labor costs per unit.

> A Day in the Life of a Warehouse Manager

>

> * 7:30 AM: Arrive at the facility. Walk the floor to greet the morning shift, check for any overnight issues, and get a feel for the day's starting point.

> * 8:00 AM: Lead a daily huddle with shift supervisors. Review yesterday's performance metrics, discuss today's inbound and outbound volume, and address any potential challenges (e.g., a key employee calling in sick, a delayed truck).

> * 9:00 AM: In the office, review WMS dashboards. Analyze labor productivity, order fulfillment rates, and inventory levels. Notice that a particular product line is running low and coordinate with the purchasing department.

> * 11:00 AM: Conduct a safety audit on the packing lines. Observe processes, speak with employees about potential hazards, and ensure all safety guards on machinery are in place.

> * 12:30 PM: Lunch, often taken while catching up on emails and responding to queries from other departments like customer service or transportation.

> * 1:30 PM: A major inbound shipment has arrived with damaged pallets. The manager goes to the receiving dock to assess the situation, instruct staff on how to handle the damaged goods, and communicates with the vendor to resolve the issue.

> * 3:00 PM: Meet with a project team to discuss the upcoming implementation of a new voice-picking technology system. Review the project timeline and address team concerns.

> * 4:30 PM: Prepare the end-of-day report for the Director of Operations, summarizing the day's achievements, challenges, and key performance indicators.

> * 5:30 PM: One last walk of the floor to check on the progress of the evening shift before heading home.

---

Average Warehouse Manager Salary: A Deep Dive

The compensation for a Warehouse Manager is a compelling aspect of the career, reflecting the critical responsibility and complex skill set required. While the "average" salary provides a useful benchmark, the actual earning potential can vary significantly. To provide a comprehensive picture, we'll examine data from multiple authoritative sources and break down the complete compensation package.

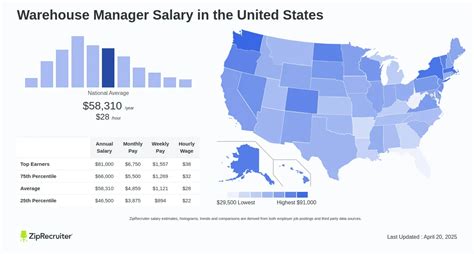

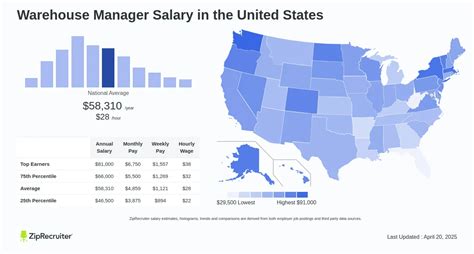

The U.S. Bureau of Labor Statistics (BLS) groups Warehouse Managers under the broader category of "Transportation, Storage, and Distribution Managers." As of May 2023, the BLS reports the following for this category:

- Median Annual Salary: $102,990

- Lowest 10% Earned: Less than $62,190

- Highest 10% Earned: More than $173,980

This data from the BLS, which surveys employers across the nation, provides a highly reliable but broad overview. For a more role-specific perspective, we turn to major salary aggregators that collect real-time, user-submitted, and job-posting data.

As of late 2023 and early 2024, here's what leading platforms report for "Warehouse Manager":

- Salary.com: Reports a median salary of $95,310, with a typical range falling between $83,828 and $108,820.

- Payscale.com: Shows a median salary of approximately $67,800, but notes a broad range from $48,000 to $94,000, heavily influenced by experience and location.

- Glassdoor.com: Estimates a "Total Pay" (including bonuses and other compensation) of around $88,500 per year, with a likely range between $70,000 and $113,000.

Why the variation? The differences between sources can be attributed to methodology. The BLS provides a broad, statistically rigorous government figure, while aggregators like Salary.com often focus on HR-reported data from established companies. Payscale and Glassdoor rely heavily on self-reported user data, which can sometimes include professionals at smaller companies or earlier in their careers. For our analysis, it's reasonable to conclude that a mid-career Warehouse Manager can realistically expect to earn within the $70,000 to $105,000 base salary range, with significant upside potential.

### Salary by Experience Level

Your salary as a Warehouse Manager will grow substantially as you accumulate experience, master new skills, and demonstrate a track record of success.

| Experience Level | Typical Years of Experience | Average Base Salary Range | Key Characteristics |

| :--- | :--- | :--- | :--- |

| Entry-Level Warehouse Manager / Supervisor | 0-3 years | $55,000 - $70,000 | Often promoted from within or a recent graduate. Manages a small team or a single shift. Focus is on learning core operations and people management. |

| Mid-Career Warehouse Manager | 4-9 years | $70,000 - $95,000 | Manages an entire warehouse or a significant department in a large DC. Responsible for budgets, KPIs, and some process improvement initiatives. |

| Senior Warehouse Manager / General Manager | 10-15+ years | $95,000 - $130,000+ | Oversees a large, complex facility (e.g., >500k sq. ft.), multiple sites, or a highly specialized operation (e.g., automated or cold storage). Drives strategy and major technology implementations. |

| Director of Warehousing / Operations | 15+ years | $130,000 - $180,000+ | A senior leadership role, responsible for a company's entire warehousing network across a region or nationally. Focus is on long-term strategy, network optimization, and P&L ownership. |

*(Salary ranges are estimates compiled from data on Salary.com, Payscale, and industry job postings.)*

### Beyond the Base Salary: Understanding Total Compensation

A Warehouse Manager's base salary is only one piece of the puzzle. The total compensation package is often significantly higher, thanks to variable pay components that reward performance.

- Annual Bonuses: This is the most common form of additional compensation. Bonuses are typically tied to the achievement of specific Key Performance Indicators (KPIs). These can be based on individual performance, facility performance, or company-wide profitability. According to Payscale, the average annual bonus for a Warehouse Manager can range from $2,000 to over $12,000, with senior managers at profitable companies seeing much larger figures. A typical bonus target might be 10-20% of the base salary.

- *Examples of Bonus-Driving KPIs:* Order accuracy rate > 99.8%, reducing operational costs by 5%, improving on-time shipping to 99.5%, achieving zero lost-time safety incidents for a year.

- Profit Sharing: Some companies, particularly those with a strong employee-centric culture, offer a profit-sharing plan. A portion of the company's annual profits is distributed among employees. For a manager, this can add several thousand dollars to their annual income, directly linking their performance to the company's success.

- Stock Options and RSUs (Restricted Stock Units): More common in large, publicly traded corporations (like Amazon, Walmart, or Home Depot), stock-based compensation can be a highly lucrative benefit. This gives managers an ownership stake in the company, aligning their long-term interests with those of shareholders.

- Comprehensive Benefits: While not direct cash, the value of a strong benefits package is substantial.

- Health Insurance: Medical, dental, and vision coverage for the employee and their family.

- Retirement Plans: Access to a 401(k) or similar plan, often with a generous company match (e.g., a 100% match on the first 3-6% of your contributions). This is a critical component of long-term wealth building.

- Paid Time Off (PTO): Includes vacation days, sick leave, and paid holidays.

- Professional Development: Many companies will pay for relevant certifications, training courses, and even tuition reimbursement for advanced degrees.

When evaluating a job offer, it is crucial to look at the Total Compensation figure, not just the base salary. A job with a $90,000 base salary and a 15% target bonus plus a strong 401(k) match is far more lucrative than a role with a $95,000 base salary and no variable pay or retirement benefits.

---

Key Factors That Influence Salary

Your earning potential as a Warehouse Manager isn't set in stone. It's a dynamic figure influenced by a combination of your qualifications, your choices, and the environment in which you work. Mastering these factors is the key to maximizing your income over the course of your career. This section, the most detailed in our guide, will break down the seven primary drivers of a warehouse manager's salary.

### 1. Level of Education

While hands-on experience is paramount in warehousing, formal education provides the foundational knowledge in business, logistics, and analytics that employers increasingly demand. It directly impacts your starting salary and your long-term career ceiling.

- High School Diploma or GED: It is possible to become a Warehouse Manager by working your way up from an entry-level position (e.g., picker, forklift operator, clerk) to supervisor and then manager. This path requires immense dedication and a proven track record. Managers with only a high school diploma typically find themselves at the lower end of the salary spectrum (e.g., $55,000 - $75,000) and may face challenges moving into senior corporate roles without further education.

- Associate's Degree: An A.S. in Logistics, Supply Chain Management, or Business Administration can provide a significant advantage. It demonstrates a formal understanding of key principles and can accelerate the path to a supervisory role. This can lead to a higher starting salary compared to having no degree and opens more doors.

- Bachelor's Degree (The Gold Standard): A four-year degree is now the preferred, and often required, qualification for manager-level positions at mid-to-large-sized companies. A Bachelor of Science (B.S.) in Supply Chain Management, Logistics, Industrial Engineering, or Business Administration is highly desirable. Graduates can often enter management training programs or secure supervisory roles more quickly. A Bachelor's degree is typically a prerequisite for salaries exceeding $90,000 and is essential for advancing to Director or VP-level positions.

- Master's Degree (MBA or MS): While not necessary for most Warehouse Manager roles, a Master's degree (especially an MBA with a concentration in Operations or Supply Chain Management) is a powerful differentiator for senior leadership positions. It signals a high level of strategic thinking, financial acumen, and leadership capability. Professionals with a master's degree often manage the largest, most complex distribution networks and command salaries well into the six figures ($120,000 - $180,000+).

### 2. Years of Experience

Experience is arguably the single most important factor in determining salary. The logistics industry values proven ability to handle real-world challenges—from managing difficult employees to solving complex inventory discrepancies under pressure. The salary growth trajectory is steep and rewarding.

- 0-2 Years (Associate/Supervisor): At this stage, you're learning the ropes. Your focus is on mastering team leadership, shift scheduling, and basic operational execution. Salary.com data suggests this level aligns with the 25th percentile, around $65,000 - $75,000, depending heavily on the other factors listed here.

- 3-8 Years (Mid-Career Manager): You are now a fully-fledged manager, trusted with an entire facility or a major department. You're responsible for budgets, process improvement, and the overall performance of your site. This is where you cross the national median, with salaries typically ranging from $75,000 to $95,000. Your ability to showcase quantifiable achievements (e.g., "reduced picking errors by 15%") is key to salary negotiation.

- 9-15+ Years (Senior Manager/General Manager): With a decade or more of experience, you are a seasoned expert. You've likely managed multiple types of facilities, led technology implementations (like a new WMS), and have a deep understanding of P&L statements. You are qualified to run flagship distribution centers for major corporations. Salaries at this level push into the $100,000 to $130,000+ range, with significant bonus potential.

- 15+ Years (Director Level): These professionals have transcended single-site management. They are responsible for regional or national networks, setting broad strategy, negotiating with major carriers, and leading large teams of other managers. This is an executive role, with compensation packages often exceeding $150,000 - $200,000.

### 3. Geographic Location

Where you work has a dramatic impact on your paycheck. This is driven by two main forces: the local cost of living and the concentration of logistics and distribution hubs. A high salary in a major metropolitan area may not have the same purchasing power as a slightly lower salary in a more affordable region.

High-Paying States and Metropolitan Areas:

These locations often combine a high cost of living with a massive demand for logistics professionals due to their status as major ports, e-commerce hubs, or manufacturing centers.

- California: Cities like San Jose, San Francisco, Los Angeles, and the Inland Empire (a massive logistics hub) offer some of the highest salaries. Managers here can expect to earn 15-30% above the national average. For example, a manager earning $95,000 nationally might command $115,000 - $125,000 in San Jose.

- Northeast Corridor: Areas like New York City, Northern New Jersey, Boston, and Philadelphia are major population centers with intense distribution needs. Salaries are similarly elevated, often 10-25% above average.

- Washington State: Driven by the Port of Seattle and the headquarters of companies like Amazon and Costco, Washington offers highly competitive salaries.

- Texas: Major hubs like Dallas-Fort Worth, Houston, and Austin have booming economies and are central distribution points for the entire country, leading to strong salary potential.

Average and Lower-Paying States:

Salaries in states with a lower cost of living and less concentrated industrial activity will naturally be closer to or slightly below the national average. However, the purchasing power can be much higher.

- Midwest: States like Ohio, Indiana, and Illinois (outside of Chicago) are critical logistics corridors ("Crossroads of America") and offer solid opportunities with salaries often near the national median.

- Southeast: States like North Carolina, Georgia (especially around Atlanta), and Florida have rapidly growing logistics sectors, but salaries may lag slightly behind the top-tier coastal markets.

- Rural Areas: Managers in smaller towns or rural locations will almost always earn less than their urban counterparts, reflecting a much lower cost of living. A salary of $65,000 in rural Arkansas might provide a better quality of life than $90,000 in Los Angeles.

### 4. Company Type and Size

The type of company you work for and its scale are major determinants of your compensation and the complexity of your role.

- Small, Local, or Family-Owned Businesses: These companies typically offer salaries on the lower end of the spectrum. The role might be less complex, but you may also have broader responsibilities. The trade-off for lower pay might be a better work-life balance or a tighter-knit company culture.

- Mid-Sized Regional Companies (e.g., a regional grocery chain): Salaries here are often competitive and hover around the national average. These roles offer a good balance of responsibility, professional growth, and reasonable compensation.

- Large National/Multinational Corporations (e.g., Walmart, Home Depot, P&G, FedEx): These are the top payers in the industry. Their distribution centers are massive, technologically advanced, and operationally complex. They demand a high level of skill and experience and compensate accordingly. Senior managers at these firms routinely earn well into the six figures with substantial bonus and stock opportunities.

- Third-Party Logistics (3PL) Providers (e.g., DHL, XPO Logistics, C.H. Robinson): 3PLs manage warehousing and distribution for other companies. A manager at a 3PL needs to be adept at managing multiple clients, each with different requirements and systems. These roles can be highly demanding but also offer excellent pay and exposure to a wide variety of industries.

- E-commerce Giants (e.g., Amazon, Chewy): These companies operate at an unprecedented scale and pace. Managers in these fulfillment centers are masters of high-volume, high-speed "e-fulfillment." The pressure is immense, but the compensation is among the highest in the field, with significant stock awards (RSUs) being a common part of the package for successful managers.

### 5. Area of Specialization

Not all warehouses are created equal. Specializing in a high-value or complex type of warehousing can make you a more sought-after candidate and significantly boost your salary.

- Cold Chain / Refrigerated Warehousing: Managing warehouses for perishable food or pharmaceuticals requires strict temperature control, rigorous compliance with FDA regulations, and specialized handling procedures. This complexity commands a salary premium of 10-20% over standard ambient warehousing.

- Automated and Robotic Warehouses: As facilities become more technologically advanced, managers with experience implementing and running automated systems (like Automated Storage and Retrieval Systems - AS/RS, AGVs, or robotic picking) are in extremely high demand. This is a future-proof skill set that puts you at the top of the pay scale.

- Hazardous Materials (Hazmat): Managing a warehouse that stores and handles hazardous materials involves extensive knowledge of safety protocols, government regulations (from DOT, EPA, etc.), and emergency response procedures. The high risk and specialized knowledge required lead to higher compensation.

- E-commerce Fulfillment: While increasingly common, high-volume, direct-to-consumer fulfillment is a specialty in itself. It requires expertise in managing small-parcel shipping, high SKU counts, and rapid pick-pack-ship cycles. Managers with a proven track record of success at major e-commerce players are highly valued.

- Foreign Trade Zone (FTZ) / Bonded Warehousing: Managing a facility that handles imported goods before they have cleared customs requires a deep understanding of customs regulations and compliance. This niche expertise is valuable to import/export businesses and commands a higher salary.

### 6. In-Demand Skills

Beyond your formal qualifications, the specific skills you possess and can demonstrate on your resume are what truly set you apart in salary negotiations.

High-Value Hard Skills:

- Warehouse Management System (WMS) Proficiency: Expertise in a major WMS platform (e.g., Manhattan, Blue Yonder/JDA, Oracle NetSuite, SAP EWM) is non-negotiable. Being a "power user" or having experience leading a WMS implementation is a massive resume booster.

- Data Analysis and Analytics: The ability to use data to drive decisions is critical. This means going beyond basic reporting and using tools like Excel (at an advanced level), SQL, or data visualization software (like Tableau or Power BI) to analyze trends, identify inefficiencies, and forecast labor needs.

- Lean / Six Sigma Methodologies: A certification (e.g., Green Belt or Black Belt) and a proven ability to apply Lean principles to eliminate waste, improve workflow, and drive continuous improvement in a warehouse setting is highly valued and can directly lead to higher pay.

- Budgeting and P&L Management: Demonstrating that you can not only manage but also own a P&L statement for your facility shows that you think like a business owner, a trait that is highly prized for senior roles.

- Automation and Robotics Integration: As mentioned above, direct experience with selecting, implementing, or managing automated warehouse technology is one of the most lucrative skills you can possess today.

Essential Soft Skills:

- Leadership and Team Building: You manage people first, inventory second. The ability to motivate, develop, and retain a large and often diverse workforce is the most fundamental soft skill.

- Communication: You must be able to communicate clearly and effectively with everyone from an entry-level associate on the floor to the C-suite executive in a boardroom.

- Problem-Solving: When a critical shipment is delayed or the WMS goes down, people will look to you. Your ability to remain calm, think critically, and execute a solution under pressure is what defines a great manager.

- Negotiation: You will negotiate with vendors, carriers, and staffing agencies. Strong negotiation skills can save the company millions of dollars over time and are a key executive function.

---

Job Outlook and Career Growth

For those considering a long-term