In the intricate, high-stakes world of modern medicine, a silent army of technical experts works behind the scenes, ensuring that the life-saving technology at the heart of patient care functions flawlessly. These professionals are the Biomedical Equipment Specialists, also known as Biomedical Equipment Technicians (BMETs) or Medical Equipment Repairers. They are the guardians of the machines that monitor, diagnose, and treat patients, from the simplest infusion pump to the most complex MRI scanner. If you are a problem-solver with a passion for both technology and making a tangible difference, this career path offers not just profound job satisfaction but also a competitive and stable biomedical equipment specialist salary.

This guide is designed to be your definitive resource, pulling back the curtain on the financial and professional realities of this critical healthcare role. We will explore the national average salary, but more importantly, we will dissect the myriad factors that can significantly increase your earning potential—from your level of education and specialized certifications to the state you work in and the type of equipment you master. I recall a time when a family member was in the ICU, surrounded by a web of beeping machines. When one vital monitor suddenly glitched, a calm and focused BMET arrived within minutes, methodically diagnosing and fixing the issue with an expertise that was both fascinating and deeply reassuring. That moment crystalized the immense value these specialists bring to the front lines of patient safety. This article will provide you with the same level of clarity and confidence as you consider this rewarding career.

### Table of Contents

- [What Does a Biomedical Equipment Specialist Do?](#what-does-a-biomedical-equipment-specialist-do)

- [Average Biomedical Equipment Specialist Salary: A Deep Dive](#average-biomedical-equipment-specialist-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion: Is This the Right Career for You?](#conclusion-is-this-the-right-career-for-you)

What Does a Biomedical Equipment Specialist Do?

At its core, a Biomedical Equipment Specialist is the bridge between clinical care and medical technology. They are responsible for the entire lifecycle of medical devices within a healthcare facility. Their work ensures that every piece of equipment is safe, accurate, and ready for use when a patient's life may depend on it. This is a hands-on, technical role that requires a unique blend of mechanical aptitude, electronics knowledge, and a deep understanding of the clinical environment.

The responsibilities are vast and varied, going far beyond simple repairs. A BMET’s duties are governed by strict regulatory and quality standards set by organizations like The Joint Commission, the FDA, and the Association for the Advancement of Medical Instrumentation (AAMI).

Core Responsibilities Include:

- Installation and Setup: Properly installing new medical equipment, ensuring it integrates with existing hospital systems (like electronic health records and networks), and configuring it according to manufacturer specifications and clinical needs.

- Preventive Maintenance (PM): This is a cornerstone of the job. BMETs perform scheduled inspections, cleaning, calibration, and part replacements to prevent equipment failure before it happens. Meticulous documentation of these PMs is mandatory for hospital accreditation.

- Corrective Maintenance (Repair): When a device malfunctions, BMETs are the first responders. They troubleshoot the problem by reading schematics, using diagnostic software, and employing specialized testing tools. They then perform the necessary repairs, which can range from replacing a circuit board to fixing a complex mechanical assembly.

- Calibration and Safety Testing: Ensuring that devices are providing accurate readings and operating within safe electrical and mechanical limits. For example, they verify that a defibrillator delivers the correct amount of energy and that an infusion pump delivers the precise volume of medication.

- User Training and Support: Instructing nurses, doctors, and other clinical staff on the proper and safe use of equipment. They often act as the go-to technical resource for the clinical team.

- Inventory Management and Documentation: Maintaining a comprehensive inventory of all medical devices, tracking their maintenance history, managing service contracts, and ordering spare parts. This data is crucial for capital planning and regulatory compliance.

### A Day in the Life of a Hospital BMET

To make this role more tangible, let’s walk through a typical day for a "BMET II" working in a mid-sized community hospital.

- 7:30 AM - The Huddle: The day begins with a team meeting. The manager reviews any overnight emergency calls and assigns the day’s scheduled work orders. Today, there's a list of preventive maintenance tasks for the telemetry monitors on the cardiac floor and an urgent call about a faulty patient bed in the surgical ward.

- 8:00 AM - Preventive Maintenance Blitz: The BMET heads to the cardiac floor with a cart of tools and testing equipment. For the next three hours, they systematically work through a checklist for each telemetry monitor: testing alarms, verifying ECG accuracy, checking battery life, and cleaning a year's worth of accumulated dust and grime from internal components. Every action is logged in the hospital's computerized maintenance management system (CMMS).

- 11:00 AM - The Urgent Call: A page comes in: an electrosurgical unit (ESU) in Operating Room 3 is failing its pre-use check. Surgery is scheduled in an hour. The BMET heads to the OR, consults with the distressed surgical nurse, and begins troubleshooting. Using a specialized ESU analyzer, they determine a foot pedal switch is faulty. They rush to the workshop, find a replacement part, install it, and run a full safety and performance test. The unit is back online with 20 minutes to spare.

- 12:30 PM - Lunch & Research: While eating, the BMET scrolls through a professional forum on their phone, reading about a new software patch for the hospital’s infusion pumps that addresses a cybersecurity vulnerability. They make a note to discuss deployment with the IT department.

- 1:30 PM - Incoming Inspection: A brand-new vital signs monitor has just arrived from the manufacturer. The BMET unboxes it, assembles it, and begins the incoming inspection process. This involves verifying all parts are present, performing extensive electrical safety tests, and adding the device to the hospital's official inventory with a unique control number.

- 3:30 PM - Documentation and Parts Ordering: Back in the workshop, the BMET spends the last hour of the day meticulously documenting all the work performed. They log the ESU repair, complete the PM records for the telemetry monitors, and finalize the inspection report for the new monitor. They also notice they're low on a common type of battery and place an order through the procurement system.

- 4:30 PM - End of Shift: The BMET cleans their workbench and checks in with the team lead before heading home, knowing their work directly contributed to the smooth and safe operation of the hospital.

This example illustrates the dynamic nature of the role—a constant blend of planned tasks and unpredictable, high-pressure situations that demand quick thinking and technical mastery.

Average Biomedical Equipment Specialist Salary: A Deep Dive

The biomedical equipment specialist salary is a reflection of the critical nature of the work, the specialized skills required, and the high demand for qualified professionals. While compensation can vary significantly based on the factors we'll explore in the next section, we can establish a strong baseline by looking at national data from authoritative sources.

It's important to note that the U.S. Bureau of Labor Statistics (BLS) classifies this role under the official title of "Medical Equipment Repairers." This is the most reliable source for broad employment and wage data.

According to the most recent BLS Occupational Employment and Wage Statistics data (May 2023), the national salary landscape for Medical Equipment Repairers is as follows:

- Median Annual Wage: $57,630 per year. This means that 50% of all medical equipment repairers in the U.S. earned more than this amount, and 50% earned less.

- Mean Annual Wage: $61,640 per year. This is the average salary, which can be slightly skewed by very high earners.

- Salary Range: The BLS provides a percentile wage estimate, which paints a much more detailed picture of the earning potential across different stages of a career:

- Bottom 10%: Earned less than $38,060 (typically representing entry-level or apprentice positions).

- 25th Percentile: Earned $47,150.

- 75th Percentile: Earned $75,230.

- Top 10%: Earned more than $85,630 (representing senior specialists, those with high-demand specializations, or managers).

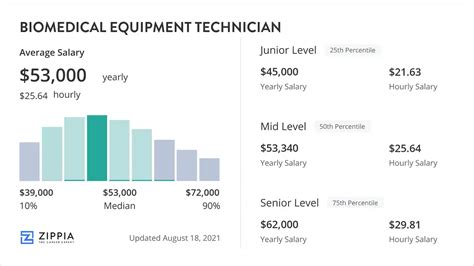

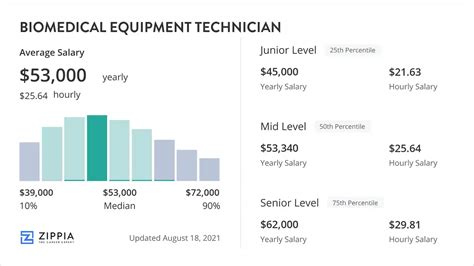

Reputable salary aggregators, which often use real-time, user-reported data, provide a similar and often slightly higher salary picture as of early 2024. This can be due to their ability to capture data more frequently and to differentiate by more specific job titles like "Biomedical Equipment Technician (BMET)".

- Salary.com: Reports the average salary for a Biomedical Equipment Technician I (Entry-Level) in the U.S. is around $55,101, while a BMET II is $66,134, and a BMET III (Senior) is $78,295. The overall range they report spans from roughly $45,000 to over $90,000.

- Payscale.com: Shows the average base salary for a Biomedical Equipment Technician (BMET) is approximately $63,000 per year. Their reported range is from $46,000 to $89,000.

- Glassdoor: Places the total pay for a BMET at an average of $72,137 per year in the United States, with a likely range between $58,000 and $90,000. This "total pay" figure often includes additional compensation like bonuses.

### Salary Progression by Experience Level

Your biomedical equipment specialist salary will grow substantially as you gain experience, master more complex equipment, and take on greater responsibility. Here is a typical salary progression, combining data from the sources above:

| Experience Level | Typical Years of Experience | Typical Job Title | Estimated Annual Salary Range | Key Responsibilities & Skills |

| :--- | :--- | :--- | :--- | :--- |

| Entry-Level | 0-2 Years | BMET I / Apprentice | $45,000 - $58,000 | Performing basic preventive maintenance, safety checks on low-risk devices (e.g., beds, infusion pumps), assisting senior techs, and learning documentation procedures. |

| Mid-Career | 3-9 Years | BMET II / BMET III | $59,000 - $75,000 | Working independently on a wide range of general medical equipment, troubleshooting complex issues, performing corrective maintenance, and training junior staff or clinical users. May begin to specialize. |

| Senior/Experienced| 10+ Years | Senior BMET / Lead Tech / Specialist | $76,000 - $90,000+ | Specializing in high-acuity equipment (e.g., anesthesia, ventilators, imaging), leading projects, managing equipment lifecycles, training teams, and serving as a key technical expert. |

### Beyond the Base Salary: Understanding Total Compensation

The base salary is only one part of the equation. Total compensation for a biomedical equipment specialist can be significantly higher once you factor in other financial benefits.

- Overtime Pay: Due to the 24/7 nature of healthcare, overtime is common and can be a substantial income booster. A scheduled equipment installation after hours or an emergency repair on a weekend is typically paid at 1.5x the normal hourly rate.

- On-Call Pay / Standby Pay: Many BMETs are part of an on-call rotation to handle after-hours emergencies. They receive a stipend (e.g., a few dollars per hour) just for being on-call, and if they are called in, they receive their overtime rate, often with a guaranteed minimum number of hours paid.

- Bonuses: While not universal, performance-based bonuses are common, especially in roles with third-party service organizations or manufacturers. These can be tied to metrics like repair turnaround time, customer satisfaction, or team performance.

- Profit Sharing: Some private companies offer profit-sharing plans, which distribute a portion of the company's profits to employees.

- Health and Retirement Benefits: A comprehensive benefits package is standard. This includes medical, dental, and vision insurance, as well as a retirement plan, such as a 401(k) or 403(b), often with a company matching contribution. The value of these benefits can easily add $10,000-$20,000 to the total compensation package annually.

- Tuition Reimbursement & Professional Development: Many employers, particularly hospitals, will invest in their technicians by paying for certifications (like the CBET), advanced training courses from manufacturers, or even a Bachelor's degree.

When evaluating a job offer, it's crucial to look beyond the base salary and consider the full scope of the compensation and benefits package to understand your true earning potential.

Key Factors That Influence Salary

While national averages provide a useful benchmark, your individual biomedical equipment specialist salary is determined by a powerful combination of personal qualifications, job characteristics, and market forces. Mastering these factors is the key to maximizing your earning potential throughout your career. This section provides a granular look at the variables that matter most.

While you can enter the field without a four-year degree, your educational background sets the foundation for your starting salary and long-term career trajectory.

- Associate of Applied Science (A.A.S.) in Biomedical Equipment Technology (BMET) or Electronics Engineering Technology: This is the most common and widely accepted educational path. A two-year A.A.S. degree from a community college or technical school provides the essential mix of coursework in electronics, anatomy and physiology, medical terminology, and hands-on lab experience. Graduates with this degree typically qualify for BMET I positions and can expect salaries in the entry-level range ($45,000 - $58,000).

- Military Training: The U.S. Armed Forces have an outstanding reputation for producing highly skilled BMETs. Military training (like the DoD's Medical Education and Training Campus program) is rigorous, comprehensive, and highly respected by civilian employers. Veterans often exit the military with several years of experience and are prime candidates for BMET II or even higher-level positions, commanding salaries well above the typical entry-level.

- Bachelor of Science (B.S.) in Biomedical Engineering, Clinical Engineering, or a related field: While less common for entry-level technician roles, a four-year degree opens doors to higher-level opportunities. It can lead to roles in clinical engineering, technology management, or specialized R&D positions with manufacturers. Individuals with a B.S. may start at a slightly higher salary than those with an A.A.S., but the main advantage is the faster track to leadership roles like a BMET Manager or Director of Healthcare Technology Management, where salaries can exceed $100,000.

- Certifications: Professional certifications are one of the most powerful tools for boosting your salary and demonstrating your expertise. The primary certifying body is the Association for the Advancement of Medical Instrumentation (AAMI).

- Certified Biomedical Equipment Technician (CBET): This is the gold standard certification for general BMETs. It requires a combination of education and experience to be eligible. According to a survey by *24x7 Magazine*, holding a CBET certification can increase a technician's salary by an average of $5,000 to $10,000 per year. Many employers require or strongly prefer the CBET for BMET II and III positions.

- Specialty Certifications: AAMI also offers specialized certifications for high-paying niches, including CLES (Certified Laboratory Equipment Specialist), CRES (Certified Radiology Equipment Specialist), and CHTM (Certified Healthcare Technology Manager). Earning these demonstrates advanced, focused expertise and can command an even higher salary premium.

Experience is arguably the single most significant factor in salary growth. The field is structured with clear tiers of progression, each with a corresponding increase in compensation.

- BMET I (0-2 years): In this initial phase, you are learning the ropes. Your value is in your potential and your ability to learn quickly. You focus on low-risk devices and preventive maintenance. Salary is at the lower end of the spectrum.

- BMET II (3-5 years): You are now a competent, independent technician. You can handle a wide variety of equipment, troubleshoot effectively, and work with minimal supervision. This is where you see your first significant salary jump, often 20-30% above your starting wage. This is also the point where most technicians earn their CBET certification.

- BMET III (5-10 years): As a BMET III, you are a senior team member. You are proficient with complex systems, may have a specialization (like anesthesia or ventilators), and are trusted to handle high-stakes repairs in critical care environments. You mentor junior technicians and may lead small projects. Your salary moves into the upper quartile.

- Senior/Lead/Specialist (10+ years): At this stage, you are a subject matter expert. You might be the go-to person for all diagnostic imaging equipment or the hospital's entire fleet of sterilizers. If you work for a manufacturer, you are a field service engineer handling their most advanced systems. These roles carry the highest salaries for non-managerial technicians, often exceeding $85,000 or $90,000, especially with in-demand specializations.

Where you work has a massive impact on your paycheck. Salaries are higher in states and metropolitan areas with a high cost of living and a high concentration of large hospital systems and medical device companies.

According to the BLS (May 2023), the top-paying states for Medical Equipment Repairers are:

1. Nevada: $82,340 (average annual salary)

2. Oregon: $78,570

3. Washington: $75,990

4. California: $75,540

5. Massachusetts: $73,630

Conversely, states in the Southeast and parts of the Midwest tend to offer lower average salaries, though the lower cost of living can sometimes offset this difference.

The effect is even more pronounced at the metropolitan level. Major cities with world-renowned medical centers are hotspots for high-paying BMET jobs. For example, BLS data shows metropolitan areas like San Francisco-Oakland-Hayward, CA ($86,300), Boston-Cambridge-Nashua, MA-NH ($75,080), and Seattle-Tacoma-Bellevue, WA ($77,540) offer salaries well above the national average.

The type of organization you work for is a critical salary determinant.

- Hospitals (In-House Teams): Working directly for a hospital is the most common employment path. Salaries are generally stable and competitive, tracking closely with the national averages. The benefits are often excellent (pension plans, great health insurance), and the work-life balance can be better than in other sectors. Large, urban teaching hospitals tend to pay more than small, rural community hospitals.

- Original Equipment Manufacturers (OEMs): Companies like GE Healthcare, Siemens Healthineers, Philips, and Medtronic hire BMETs as Field Service Engineers (FSEs). These are often the highest-paying jobs in the field. FSEs specialize in their company's proprietary equipment (e.g., MRI, CT scanners, linear accelerators) and travel to various hospitals to perform installations, complex repairs, and upgrades. These roles can easily command salaries exceeding $80,000 to $100,000+ plus a company car, travel expenses, and significant bonuses. However, they demand extensive travel and long hours.

- Independent Service Organizations (ISOs): These are third-party companies that hospitals contract with to service their medical equipment. ISOs can offer competitive salaries, sometimes slightly higher than hospitals, to attract talent. The work is diverse, as you may service equipment from many different manufacturers. The environment can be more fast-paced and sales-oriented.

- Government/Military: Working for the Department of Veterans Affairs (VA) or the Department of Defense offers competitive salaries based on the government's General Schedule (GS) pay scale, exceptional job security, and outstanding federal benefits. These roles are highly structured and provide a clear path for advancement.

Generalist BMETs are always in demand, but specializing in complex, high-revenue-generating equipment is the fastest way to become a top earner.

- Diagnostic Imaging: This is the most lucrative specialization. Technicians who can service and repair MRI machines, CT scanners, PET scanners, and X-ray systems are in extremely high demand. The training is intensive and often provided by the OEM. Imaging specialists regularly earn salaries in the $90,000 to $120,000+ range.

- Laboratory and Pathology: Clinical laboratory equipment, such as blood gas analyzers and chemistry analyzers, is incredibly complex. Certified Laboratory Equipment Specialists (CLES) are highly sought after and command premium pay.

- Sterilization: Expertise in steam sterilizers (autoclaves) and other central sterile processing department equipment is a valuable niche. Proper sterilization is fundamental to preventing hospital-acquired infections, making these specialists vital.

- Anesthesia and Respiratory: Servicing life-support equipment like anesthesia machines and mechanical ventilators requires an exceptional level of skill and responsibility. Technicians with this expertise are critical to any hospital and are compensated accordingly.

- Dialysis: Technicians specializing in hemodialysis machines are essential for nephrology clinics and hospitals. This is a stable and growing niche.

Beyond your core technical abilities, certain skills will make you a more valuable—and thus, higher-paid—professional.

- IT and Networking: As medical devices become more interconnected (the "Internet of Medical Things" or IoMT), networking skills are no longer optional. Understanding TCP/IP, DICOM, HL7 standards, and server integration is crucial. BMETs who can troubleshoot a device's network connection as effectively as its electronic components are indispensable.

- Cybersecurity: Medical devices are a prime target for cyberattacks. A BMET with knowledge of cybersecurity best practices—how to harden devices, apply security patches, and identify vulnerabilities—is incredibly valuable to a hospital's risk management strategy and can command a higher salary.

- Soft Skills: Technical skills get you the job, but soft skills get you promoted. Excellent communication is vital when explaining a complex technical problem to a non-technical nurse or doctor. Strong problem-solving under pressure is essential when an OR device fails mid-procedure. Meticulous documentation and attention to detail are non-negotiable for regulatory compliance.

By strategically focusing on these key factors—pursuing certifications, gaining experience in a high-paying specialty, and developing in-demand IT skills—you can actively steer your career towards the highest rungs of the biomedical equipment specialist salary ladder.

Job Outlook and Career Growth

For those considering a career as a biomedical equipment specialist, the future is bright and full of opportunity. The demand for skilled technicians is projected to grow steadily, driven by powerful and enduring trends in healthcare and technology. This section examines the data behind the job outlook and outlines the pathways for long-term career advancement.

### Strong Job Growth Projections

The U.S. Bureau of Labor Statistics (BLS) provides the most authoritative forecast for the profession. In its latest projections, the BLS estimates that employment for Medical Equipment Repairers is projected to grow 5 percent from 2022 to 2032.

This growth rate translates to approximately 2,700 new job openings each year, on average, over the decade. These openings are expected to result from both the creation of new positions and the need to replace workers who transfer to different occupations or exit the labor force, such as through retirement. This steady demand creates a high degree of job security for qualified professionals.

### Key Drivers of Growth

The positive job outlook is not arbitrary; it's fueled by several fundamental shifts in the healthcare landscape:

1. An Aging Population: As the large baby-boomer generation ages, the demand for medical services—from diagnostic imaging to long-term care—is increasing significantly. This directly translates to a greater need for the medical devices used in these procedures and, consequently, for the technicians who maintain them.

2. Increasing Technological Sophistication: Medical technology is advancing at an explosive rate. Devices are becoming more complex, software-driven, and interconnected. Hospitals are continuously investing in state-of-the-art equipment to improve patient outcomes. This constant influx of new technology requires a highly skilled workforce to install, maintain, and repair it.

3. The Rise of the Internet of Medical Things (IoMT): The integration of medical devices with hospital networks and electronic health records is a major trend. While this enhances patient care, it also introduces new complexities related to networking, data integration, and cybersecurity. BMETs with IT and networking skills are becoming essential, creating a new and growing demand within the field.

4. Focus on Preventive Maintenance and Cost-Containment: Hospitals are under constant pressure to control costs. Well-maintained equipment lasts longer and is less likely to fail unexpectedly, which can cause costly surgical delays or patient safety incidents. A skilled in-house or contracted BMET team is a crucial investment in operational efficiency and risk management, making them more valuable than ever.

### The Career Ladder: From Technician to Leader

A career as a biomedical equipment specialist is not a static job; it is a pathway with numerous opportunities for advancement. The skills you develop as a technician are a springboard to roles with greater responsibility, leadership, and, of course, a higher salary.

Typical Career Progression:

1. BMET I → BMET II → BMET III: This is the foundational technical track, as detailed previously. The goal is to master a broad range of