Table of Contents

- [What Does a Boiler Operator Do?](#what-they-do)

- [Average Boiler Operator Salary: A Deep Dive](#salary-deep-dive)

- [Key Factors That Influence a Boiler Operator's Salary](#key-factors)

- [Job Outlook and Career Growth for Boiler Operators](#job-outlook)

- [How to Become a Boiler Operator: Your Step-by-Step Guide](#how-to-start)

- [Conclusion: Is a Career as a Boiler Operator Right for You?](#conclusion)

---

I'll never forget a particularly brutal Chicago winter week where temperatures plunged to twenty below zero. While the city hunkered down, I was working in a downtown high-rise, and the building's ancient heating system was groaning under the strain. Down in the sub-basement, a man most of us never saw, the facility's chief stationary engineer, worked tirelessly through the night to coax life back into the massive boilers. He wasn't just fixing a machine; he was ensuring that hundreds of people remained safe and warm. This role, often unseen and unheard, is the very heartbeat of our infrastructure, providing the power, heat, and steam that run our hospitals, schools, and factories.

If you are a hands-on problem-solver, someone who finds satisfaction in understanding complex mechanical systems, and you're looking for a stable, respectable career with significant earning potential, then becoming a boiler operator or stationary engineer could be an exceptional path for you. But what does that path look like financially?

This guide is designed to be the definitive resource on boiler operator salary. We will move far beyond a simple average number and delve into every factor that impacts your earning potential—from your first day on the job to becoming a seasoned chief engineer. We'll explore how location, certifications, industry, and specialization can dramatically increase your paycheck. Using the most current data from authoritative sources like the U.S. Bureau of Labor Statistics (BLS), Salary.com, and Payscale, this article will provide you with the detailed, trustworthy information you need to build a prosperous career in this vital field.

What Does a Boiler Operator Do?

At its core, a boiler operator—often used interchangeably with the term "stationary engineer"—is a highly skilled technician responsible for the safe and efficient operation, maintenance, and repair of the equipment that provides heat, steam, power, and climate control to large buildings and industrial facilities. They are the guardians of a facility's mechanical soul, ensuring that everything from the heating in an office building to the sterile steam in a hospital operating room is functioning perfectly.

This is not a simple "on/off switch" job. It requires a deep understanding of thermodynamics, mechanics, electrical systems, and chemistry. Boiler operators are responsible for massive, high-pressure systems that, if mishandled, can be incredibly dangerous. Their work is a constant balancing act of efficiency, safety, and reliability.

Core Responsibilities and Daily Tasks:

A boiler operator's duties are varied and require a blend of routine monitoring and immediate, high-stakes problem-solving. Key responsibilities often include:

- System Monitoring: Constantly observing meters, gauges, and advanced computer-controlled systems (like SCADA or Building Management Systems) to verify temperature, pressure, water levels, and fuel consumption are within safe and efficient parameters.

- Equipment Operation: Starting up, shutting down, and adjusting boilers, engines, turbines, generators, and compressors. This requires precise, sequential procedures to prevent damage or accidents.

- Preventive Maintenance: Performing routine maintenance to ensure equipment longevity and prevent breakdowns. This includes lubricating moving parts, cleaning equipment, replacing worn-out gaskets and seals, and testing safety valves.

- Water Treatment: Testing boiler water chemistry and adding necessary chemicals to prevent corrosion, scale buildup, and other impurities that can reduce efficiency and damage the system.

- Troubleshooting and Repair: Diagnosing and repairing malfunctions. This is where expertise truly shines—identifying the root cause of an unusual noise, a pressure drop, or an alarm and executing the correct repair, often under pressure.

- Record Keeping: Maintaining detailed logs of all operations, maintenance activities, and meter readings. This data is crucial for compliance, efficiency analysis, and shift handovers.

- Safety and Compliance: Adhering to strict safety protocols and ensuring the boiler room complies with all federal, state, and local regulations. This is a non-negotiable aspect of the job.

---

### A Day in the Life of a Boiler Operator

To make this more concrete, let's walk through a typical first shift for a boiler operator at a large university campus.

7:00 AM: Arrive at the central utility plant, coffee in hand. The first order of business is the shift change briefing with the outgoing night shift operator. They discuss any issues from the previous night—a minor pressure fluctuation in Boiler #3, a planned maintenance task for the afternoon—and review the operations log.

7:30 AM: The first "round" of the day. This is a physical walk-through of the entire plant. You're not just looking; you're listening and smelling. You listen for the familiar hum of the machinery, alert for any new vibrations or unusual noises. You check sight glasses for correct water levels, feel for excessive heat on bearings, and scan for any signs of steam or water leaks.

9:00 AM: Back in the control room, you analyze the data from the plant's computerized control system. You notice that the efficiency of Boiler #2 has dipped slightly. You cross-reference this with your logbook and decide to check the fuel-to-air ratio and schedule a "soot blow" to clean the boiler tubes later in the shift.

10:30 AM: Time for water testing. You take samples from each active boiler and run a series of chemical tests to check pH, alkalinity, and conductivity. Based on the results, you precisely measure and add chemical treatments to the feedwater system to prevent corrosion.

12:00 PM: Lunch break in the control room, keeping an eye on the monitors.

1:00 PM: A contractor arrives to perform the annual inspection on a fire suppression system in the boiler room. You oversee their work, ensure they follow all safety lockout/tagout procedures, and sign off on their work permit.

2:30 PM: An alarm sounds. The feedwater pump for Boiler #1 has tripped offline. You immediately acknowledge the alarm and switch to the backup pump to ensure the boiler maintains its water level. Now the real work begins: you must diagnose why the primary pump failed. You check the electrical breakers, inspect the motor, and discover a failed bearing. You log the issue and schedule the repair.

3:45 PM: You complete your detailed shift log, noting the pump failure, the water treatment adjustments, and the completed soot blow.

4:00 PM: The second shift operator arrives. You provide a thorough briefing, highlighting the issue with the feedwater pump and the plan for its repair. After a complete handover, you head home, knowing you kept the campus powered and warm for another day.

---

Average Boiler Operator Salary: A Deep Dive

Now, let's get to the critical question: how much can you earn in this profession? The compensation for a boiler operator is competitive and reflects the high level of skill, responsibility, and potential risk involved. The salary is not a single number but a wide spectrum influenced by the factors we will discuss in the next section.

### National Averages and Salary Ranges

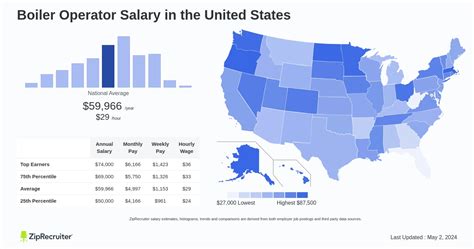

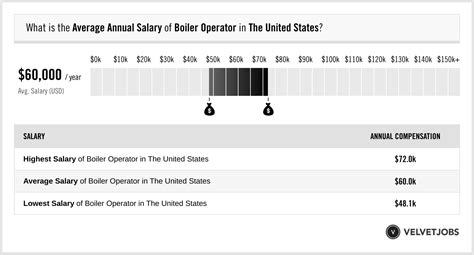

To establish a baseline, we'll look at data from the most reputable sources. It's important to cross-reference these sources, as they use different methodologies. The BLS relies on broad employer surveys, while sites like Salary.com and Payscale use a mix of employer-reported data and real-time, user-submitted information.

- U.S. Bureau of Labor Statistics (BLS): The BLS groups boiler operators under the category "Stationary Engineers and Boiler Operators." As of May 2022 (the most recent detailed data available), the BLS reports a median annual wage of $71,100. This means half of all operators earned more than this, and half earned less. The salary spread is significant:

- Lowest 10% earned less than: $44,220

- Highest 10% earned more than: $108,350

- Salary.com: As of late 2023, Salary.com reports that the median salary for a "Boiler Operator" in the United States is slightly higher, at $73,268. Their data shows a typical range falling between $63,913 and $82,499. This range often excludes factors like extensive overtime or specialized licenses, which can push the total compensation higher.

- Payscale.com: Payscale's data provides a similar view, with an average base salary of around $64,000 per year, or about $29.00 per hour. Their model particularly emphasizes how experience impacts pay, which we will explore below.

Key Takeaway: A reasonable expectation for a national average salary is in the $65,000 to $75,000 range. However, entry-level positions will start lower, while highly experienced, licensed operators in high-cost-of-living areas can easily command six-figure salaries.

### Salary by Experience Level

Experience is arguably the single most powerful factor in determining a boiler operator's salary. A seasoned operator who has seen and solved countless problems is invaluable. Their ability to prevent catastrophic failures and optimize plant efficiency translates directly into higher pay.

Here is a typical salary progression based on years of experience, compiled from data across Salary.com and Payscale:

| Experience Level | Years of Experience | Typical Annual Salary Range | Key Characteristics |

| :--- | :--- | :--- | :--- |

| Entry-Level Boiler Operator / Apprentice | 0-2 Years | $45,000 - $60,000 | Works under direct supervision, focuses on routine monitoring, basic maintenance, and learning system operations. May hold a low-pressure license or be working towards a higher-class license. |

| Mid-Career Boiler Operator | 3-9 Years | $60,000 - $80,000 | Operates systems independently, performs complex troubleshooting, holds higher-level state or national licenses (e.g., 2nd Class or 1st Class). Can handle most common issues without assistance. |

| Senior / Lead Boiler Operator | 10-19 Years | $75,000 - $95,000+ | Expert-level troubleshooter, manages complex systems (e.g., cogeneration plants), trains junior operators, may have supervisory duties. Often holds the highest-class license available (e.g., Chief Engineer). |

| Chief Stationary Engineer / Plant Manager | 20+ Years | $90,000 - $120,000+ | Manages the entire utility plant or engineering department. Responsible for budgeting, staffing, long-term planning, and major capital projects. This is a management role built on decades of hands-on experience. |

*Note: These are base salary ranges. Total compensation can be significantly higher.*

### Beyond the Base Salary: Understanding Total Compensation

A boiler operator's W-2 is often much more than just their base salary. The nature of 24/7 operations creates numerous opportunities for additional earnings.

- Overtime Pay: This is a major component of total compensation. Boiler plants must be staffed around the clock, 365 days a year. Covering shifts for sick colleagues, holidays, and extended maintenance periods often results in substantial overtime, typically paid at 1.5 times the hourly rate. It is not uncommon for overtime to add 15-25% or more to an operator's annual income.

- Shift Differentials: Operators who work second shift (evenings), third shift (overnights), or weekends almost always receive a pay differential—an extra dollar amount per hour or a percentage bonus on top of their base rate.

- Bonuses: While less common than in corporate roles, annual bonuses can be awarded based on plant efficiency, safety records, and overall company performance.

- Benefits Package: This is a huge, often underestimated, part of the compensation. Because these roles are often unionized or with large, stable employers (hospitals, governments, universities), the benefits are typically excellent. This includes:

- Health Insurance: Comprehensive medical, dental, and vision plans with low premiums.

- Retirement Plans: Generous 401(k) matching or, in many cases, traditional pension plans, which are rare in other sectors.

- Paid Time Off (PTO): Ample vacation time, sick leave, and paid holidays.

- Tuition Reimbursement: Many employers will pay for training and certifications to help you advance your licenses.

When you factor in overtime, shift differentials, and the cash value of a strong benefits package, the total compensation for a skilled boiler operator can easily exceed the base salary figures by a significant margin.

Key Factors That Influence a Boiler Operator's Salary

While experience is the primary driver, several other critical factors combine to determine your specific salary. Understanding these variables is key to maximizing your earning potential throughout your career. This is the most crucial section for anyone serious about mapping out a high-earning career path in this field.

1. Level of Education, Licensing, and Certification

In this profession, formal academic degrees are less important than demonstrable, certified expertise. While a high school diploma or GED is the minimum requirement, your path to higher earnings is paved with licenses and certifications.

- Vocational School / Associate's Degree: A degree from a technical or vocational school in a field like "Stationary Engineering Technology" or "Power Plant Technology" provides a massive advantage. These programs offer foundational knowledge in thermodynamics, electrical theory, and hands-on lab experience, making you a much more attractive candidate and often shortening the time it takes to get your first license. Graduates of these programs often start at a higher salary than those who learn purely on the job.

- Apprenticeships: A formal apprenticeship, often run by a union or a large employer, is a gold-standard pathway. You earn a wage while you learn on the job from seasoned professionals, supplemented with classroom instruction. Completing a 4-year apprenticeship is a powerful credential that leads to higher pay and better job opportunities.

- Licensing (The Most Critical Factor): Licensing is the single most important credential. Most states and many major cities (like New York City, Chicago, and Boston) have legal requirements for boiler operators, mandating that they hold a government-issued license to operate equipment above a certain pressure or size. These licenses are tiered, and each successive level unlocks the ability to operate larger, more complex plants—and command a much higher salary.

- Example Licensing Tiers:

- Low-Pressure License: Allows operation of smaller, low-pressure boilers (often found in schools or small commercial buildings). This is an entry-level license.

- High-Pressure Licenses (e.g., 3rd Class, 2nd Class, 1st Class): Each tier allows for the operation of progressively larger and more complex high-pressure steam plants. Moving from a 2nd Class to a 1st Class license can result in a salary jump of $10,000 to $20,000 annually, as it qualifies you for lead operator roles in major facilities.

- Chief Engineer License: The highest level, qualifying you to have legal charge of the largest and most complex power plants. This is a six-figure credential.

- National Certifications (NIULPE): The National Institute for the Uniform Licensing of Power Engineers (NIULPE) offers a nationally recognized, five-class licensing system. While not a legal requirement in all states, holding a NIULPE license is a highly respected credential that demonstrates a standardized level of expertise, making you more marketable and increasing your earning power, especially when moving between states.

2. Years of Experience (The Growth Trajectory)

As detailed in the previous section, experience is paramount. But *why* does it command such a premium? It's about the accumulation of institutional knowledge and troubleshooting acumen.

- 0-2 Years (Entry-Level): At this stage, you are paid to learn and perform routine tasks safely. Your value is in your potential and your ability to follow instructions. Salary: ~$45k - $60k.

- 3-9 Years (Mid-Career): You have now encountered a wide range of common problems—pump failures, valve issues, control system glitches—and can solve them independently. You understand the specific quirks of your plant. Your value is in your reliability and efficiency. Salary: ~$60k - $80k.

- 10+ Years (Senior/Lead): You have faced not just common problems, but rare and complex ones. You can diagnose cascading failures and can predict issues before they happen. You have likely been through major equipment overhauls or installations. Your value is in your deep expertise, your ability to prevent catastrophic failures, and your capacity to mentor others. Salary: ~$75k - $95k+.

The salary growth is not just a reward for loyalty; it's a direct reflection of the value and risk-mitigation an experienced operator brings to a facility.

3. Geographic Location

Where you work has a massive impact on your paycheck. This is driven by two main factors: local cost of living and the concentration of industries that rely on large boiler plants.

According to the BLS (May 2022 data), the top-paying states for Stationary Engineers and Boiler Operators are:

1. Alaska: Annual Mean Wage: $98,900

2. District of Columbia: Annual Mean Wage: $95,080

3. California: Annual Mean Wage: $93,250

4. Washington: Annual Mean Wage: $90,920

5. New Jersey: Annual Mean Wage: $89,950

Conversely, states with lower costs of living and fewer large industrial or institutional facilities tend to have lower average salaries. States like Arkansas ($56,530), Mississippi ($57,280), and South Carolina ($59,380) are on the lower end of the pay scale.

Metropolitan Areas Matter: Even within a state, salaries can vary dramatically. Large metropolitan areas with significant commercial, medical, and industrial infrastructure pay a premium.

- Top-Paying Metro Areas (BLS Data):

- San Jose-Sunnyvale-Santa Clara, CA: $112,650

- San Francisco-Oakland-Hayward, CA: $104,180

- Vallejo-Fairfield, CA: $102,670

- Seattle-Tacoma-Bellevue, WA: $96,690

It's crucial to balance the higher salary with the higher cost of living in these areas. A $90,000 salary in San Francisco may not provide the same quality of life as a $75,000 salary in a more affordable Midwestern city.

4. Industry, Company Type, and Size

The type of facility you operate has a direct correlation with your salary. This is because different industries have different requirements for uptime, precision, and power, and therefore place a different value on the operators who run their systems.

- Electric Power Generation and Distribution: This is consistently one of the highest-paying industries for boiler operators. The complexity of running a utility power plant, the immense scale of the equipment, and the critical importance of keeping the grid online mean these employers demand the most skilled operators and pay them accordingly. Salaries here are often 15-25% higher than the national average.

- Hospitals and Healthcare: Hospitals require uninterrupted 24/7/365 operation for heating, cooling, and, most importantly, high-pressure sterile steam for sterilization. The life-and-death consequences of a system failure mean hospitals pay a premium for reliable, highly licensed operators.

- Government (Federal, State, Local): Government jobs—at federal facilities, state universities, or municipal buildings—are known for their stability and exceptional benefits, particularly pension plans. While the base salary may sometimes be slightly less than top-tier private industry, the total compensation package is often superior and highly sought after.

- Heavy Manufacturing and Food Production: Large factories, chemical plants, and food processing facilities rely on massive steam boilers for their production processes. These jobs often pay very well, aligning with industrial and union pay scales.

- Commercial Real Estate and Education: Operating the plant for a large office complex, a university campus, or a school district. These jobs offer good, stable pay and are often excellent places to start a career, though their salaries may not reach the peaks of power generation or heavy industry.

5. System Complexity and Area of Specialization

Not all boiler operator jobs are the same. Specializing in more complex and in-demand systems is a clear path to a higher salary. This is the equivalent of a software developer specializing in AI versus general web development.

- High-Pressure vs. Low-Pressure Systems: The distinction is fundamental. Operating a small, low-pressure boiler for heating an apartment building is a vastly different (and lower-paying) job than managing a bank of high-pressure boilers that power turbines in a cogeneration plant. The licensing and skill required for high-pressure systems command a significant pay premium.

- Cogeneration (Combined Heat and Power - CHP): Specializing in CHP plants, which produce both electricity and useful thermal energy from a single fuel source, is a high-value skill. These systems are complex and require a deeper understanding of both power generation and thermal dynamics.

- Building Automation Systems (BAS/BMS) and SCADA: Modern plants are heavily automated. Operators who are not just mechanically adept but are also proficient with computerized control systems (like Siemens, Johnson Controls, or Rockwell's SCADA platforms) are in high demand. This digital skillset is becoming essential and can add thousands to your salary.

- Refrigeration and HVACR: Many Stationary Engineer roles are combined with responsibility for the facility's large-scale air conditioning and refrigeration systems (chillers, cooling towers, etc.). Holding a Universal EPA 608 certification for handling refrigerants and having deep HVACR expertise makes you a more versatile and valuable employee, leading to higher pay.

- Specialized Environments: Operating systems for unique environments like pharmaceutical clean rooms, data centers (which require precise climate control), or marine vessels (Marine Engineer) are niche specializations that carry significant salary premiums due to their critical nature and the extra training required.

6. In-Demand Skills

Beyond formal licenses, cultivating a specific set of technical and soft skills will make you a more effective and better-paid operator.

High-Value Technical Skills:

- Advanced Troubleshooting and Diagnostics: The ability to quickly and accurately diagnose the root cause of a problem.

- Welding and Pipefitting: While not always required, having hands-on fabrication skills makes you invaluable for performing repairs in-house.

- Electrical Skills: The ability to read electrical schematics and troubleshoot control circuits, motors, and variable frequency drives (VFDs).

- PLC (Programmable Logic Controller) Knowledge: Understanding the logic that controls automated processes.

- Digital Literacy: Proficiency in using computerized maintenance management systems (CMMS) for logging work orders and tracking maintenance history.

Essential Soft Skills:

- Attention to Detail: Missing a small change on a gauge can have major consequences.

- Calm Under Pressure: When alarms are blaring, the ability to think clearly and act methodically is crucial.

- Problem-Solving: A logical, analytical approach to figuring out what went wrong and how to fix it.

- Strong Communication: Clearly explaining complex technical issues to management or to the next operator on shift.

- Commitment to Safety: An unwavering focus on safe work practices.

Job Outlook and Career Growth for Boiler Operators

Understanding the long-term career prospects is just as important as knowing the current salary. The forecast for boiler operators is a story of transformation rather than simple growth or decline.

### The BLS Outlook: A Nuanced Picture

The U.S. Bureau of Labor Statistics (BLS) projects that employment for Stationary Engineers and Boiler Operators will decline by 2 percent from 2022 to 2032. At first glance, this may seem discouraging, but it's essential to look at the reasons behind this projection and the opportunities it creates.

- Why the Decline? The primary driver is automation. Newer boiler plants and building management systems are more sophisticated and automated, capable of self-diagnosis and remote operation. This allows a single operator to manage a system that might have required several operators in the past. Additionally, some industries are moving away from centralized steam plants toward decentralized or more energy-efficient technologies.

- The Hidden Opportunity: Despite the