In a world increasingly dominated by digital screens and abstract work, there is a profound and growing respect for those who create tangible, beautiful, and functional objects with their hands. Cabinet making is more than just a job; it is a time-honored craft that blends artistry with engineering, precision with creativity. For those drawn to the scent of freshly cut wood and the deep satisfaction of transforming a raw plank into a cornerstone of a home, a career as a cabinet maker offers a unique and fulfilling path. But beyond the passion, a crucial question remains: can you build a prosperous life on a cabinet maker's salary?

The answer is a resounding yes, but the path to a high income in this field is nuanced. While the national average salary for a cabinet maker provides a solid starting point, your ultimate earning potential is a masterpiece you craft yourself, shaped by your skills, experience, location, and specialization. A baseline salary might hover around $47,920 per year, according to the U.S. Bureau of Labor Statistics, but highly skilled artisans running their own custom shops in affluent markets can command earnings well into the six figures. I once had the privilege of commissioning a set of built-in bookcases for my home office. The cabinet maker wasn't just a woodworker; he was a design consultant, a space planner, and an artist who transformed a simple room into a library of personal significance, demonstrating that the value of this work goes far beyond its material cost.

This comprehensive guide will serve as your blueprint for understanding and maximizing a cabinet maker's salary. We will dissect every factor that influences your pay, from your first apprenticeship to mastering advanced technologies. We will explore the job outlook, detail the steps to get started, and provide the expert insights you need to build not just cabinets, but a rewarding and lucrative career.

### Table of Contents

- [What Does a Cabinet Maker Do?](#what-does-a-cabinet-maker-do)

- [Average Cabinet Maker Salary: A Deep Dive](#average-cabinet-maker-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

What Does a Cabinet Maker Do?

At its heart, the role of a cabinet maker is to design, build, finish, and install wooden cabinets, furniture, and fixtures. However, this simple description belies the incredible range of skills and responsibilities the profession entails. A cabinet maker is a multifaceted professional who acts as a designer, an engineer, a project manager, and a master craftsperson. They are experts in the properties of wood, the intricacies of joinery, and the art of the perfect finish.

The scope of their work can range from producing standardized cabinetry for large-scale residential developments to creating one-of-a-kind, heirloom-quality pieces for high-end clients. Their work is essential in kitchens, bathrooms, libraries, offices, retail stores, and luxury homes.

Core Responsibilities and Daily Tasks:

The day-to-day work of a cabinet maker is a dynamic mix of creative design and hands-on production. Key tasks include:

- Consultation and Design: Meeting with clients, architects, or designers to understand project requirements, style preferences, and functional needs. This often involves taking precise measurements and creating initial sketches or digital mockups.

- Blueprint and Plan Interpretation: Reading and interpreting detailed architectural drawings, schematics, and CAD (Computer-Aided Design) files to understand dimensions, materials, and construction methods.

- Material Selection: Choosing the appropriate type of wood (e.g., oak, maple, cherry, walnut) or wood-based products (plywood, MDF, veneers) based on the project's budget, aesthetic, and intended use.

- Milling and Cutting: Operating a variety of woodworking machinery to cut and shape wood to exact specifications. This includes table saws, miter saws, band saws, jointers, planers, and routers.

- CNC Operation: In modern shops, this involves programming and operating Computer Numerical Control (CNC) machines, which automate the cutting of complex parts with extreme precision.

- Assembly and Joinery: Assembling the cut pieces using a wide range of joinery techniques, from simple dowels and screws to complex dovetails and mortise-and-tenon joints. This requires precision, a steady hand, and a deep understanding of wood movement.

- Finishing: Sanding, staining, sealing, and applying protective topcoats like lacquer or polyurethane. The finishing stage is critical and can make the difference between a good piece and a masterpiece.

- Hardware and Installation: Fitting hinges, handles, drawer slides, and other hardware. The final step often involves transporting the finished cabinets to the job site and installing them, ensuring they are level, plumb, and securely fastened.

### A Day in the Life of a Custom Cabinet Maker

To make this role more tangible, let's walk through a typical day for a mid-career cabinet maker working in a small, custom shop:

- 8:00 AM - 9:00 AM: The day begins with a review of the work schedule. Maria checks the plans for a set of walnut kitchen cabinets. She confirms her cut list and verifies the lumber pulled from the rack is acclimated and ready for milling. She spends a few minutes sharpening a set of chisels and a plane blade.

- 9:00 AM - 12:00 PM: This is machine time. With her safety glasses and hearing protection on, Maria heads to the workshop floor. She uses the jointer to create a flat face on each piece of walnut, then the planer to bring them to a precise thickness. The air fills with the sharp, pleasant scent of cut wood and the hum of machinery. She then moves to the table saw to rip the boards to width and cut the cabinet box components from high-quality plywood.

- 12:00 PM - 12:30 PM: Lunch break with the rest of the small team, discussing a tricky installation planned for later in the week.

- 12:30 PM - 3:30 PM: The focus shifts to joinery and assembly. Maria uses a router table to create the cope-and-stick profiles for the cabinet doors. She then moves to the clamping station, carefully applying glue and assembling the face frames, checking each one for squareness. In the background, a CNC machine is precisely cutting the intricate fretwork for a different project's glass-paned doors.

- 3:30 PM - 4:30 PM: Maria transitions to the finishing room. She meticulously sands a set of previously assembled drawer fronts, working her way through progressively finer grits of sandpaper to achieve a glass-smooth surface, ready for staining tomorrow morning.

- 4:30 PM - 5:00 PM: The final half-hour is for cleanup. Maria sweeps her workstation, organizes her tools, and empties the dust collector. She does a final check on the clamped frames and makes a note of the materials she'll need for the next day. She leaves the shop with a sense of accomplishment, having turned raw materials into the functional art that will soon be the centerpiece of a family's kitchen.

Average Cabinet Maker Salary: A Deep Dive

Understanding the earning potential of a cabinet maker requires looking beyond a single number. Compensation in this field is a spectrum, influenced by a multitude of factors we will explore in the next section. However, by examining data from authoritative sources, we can establish a reliable baseline and understand the typical salary range from entry-level to senior positions.

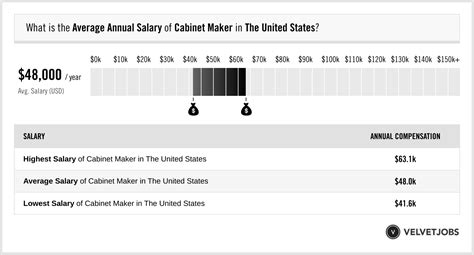

National Averages and Salary Ranges

The most authoritative source for occupational data in the United States is the U.S. Bureau of Labor Statistics (BLS). In its May 2023 Occupational Employment and Wage Statistics report, the BLS categorizes cabinet makers under the broader "Woodworkers" category. The key data points are:

- Median Annual Wage: $47,920 (or $23.04 per hour). This is the midpoint—half of all woodworkers earned more than this amount, and half earned less.

- Salary Range: The BLS provides a percentile breakdown, which is incredibly useful for understanding the full spectrum:

- Lowest 10%: Earned less than $31,590

- Lower 25% (Entry-Level): Earned less than $37,640

- Top 25% (Experienced): Earned more than $59,600

- Top 10% (Senior/Master): Earned more than $65,580

It's important to note that the BLS data includes all types of woodworkers, from those in large-scale furniture manufacturing plants to those making musical instruments. Custom cabinet makers, especially those with specialized skills, often fall into the upper half of this range.

Reputable salary aggregators, which collect real-time data from job postings and user submissions, provide a slightly different and often more current snapshot:

- Payscale.com: Reports an average base salary for a Cabinet Maker of approximately $22.51 per hour, with a typical annual salary range of $38,000 to $74,000.

- Salary.com: Places the median salary for a Cabinet Maker I (entry-level) around $46,929, while a Cabinet Maker III (senior) has a median salary of $61,281. Their data shows the top 10% of senior cabinet makers can earn over $71,000.

- Glassdoor: Lists a total pay average of around $56,381 per year, which includes base pay and additional compensation like bonuses or profit sharing.

Salary Progression by Experience Level

Your value—and therefore your salary—grows significantly as you move from an apprentice to a master craftsperson. Experience translates into speed, precision, problem-solving ability, and the capacity to handle complex, high-value projects.

Here is a typical salary progression, synthesized from BLS, Payscale, and Salary.com data:

| Experience Level | Typical Years of Experience | Annual Salary Range (Estimated) | Key Skills and Responsibilities |

| :--- | :--- | :--- | :--- |

| Apprentice / Entry-Level | 0-2 Years | $32,000 - $45,000 | Learning safety protocols, operating basic machinery under supervision, material handling, sanding, assisting with assembly and cleanup. |

| Journeyman / Mid-Career | 3-9 Years | $45,000 - $60,000 | Working independently from plans, operating all standard machinery, performing complex joinery, managing smaller projects, some finishing work. |

| Senior / Master Cabinet Maker | 10-20+ Years | $60,000 - $80,000+ | Designing complex projects, programming/operating CNC machinery, leading teams, training apprentices, client management, advanced finishing techniques, estimating jobs. |

| Shop Owner / Self-Employed | Varies | $50,000 - $150,000+ | All of the above, plus business management, marketing, sales, accounting, and payroll. Earnings are directly tied to business success and can far exceed a salaried employee. |

Beyond the Base Salary: Understanding Total Compensation

A cabinet maker's salary is just one piece of the puzzle. Total compensation can significantly increase your overall earnings and job satisfaction. When evaluating a job offer, consider these components:

- Overtime Pay: Especially common in manufacturing settings or when deadlines for custom projects are tight. Time-and-a-half pay for hours worked over 40 per week can substantially boost income.

- Bonuses: Project-based or performance-based bonuses are often offered in custom shops for completing a job under budget or ahead of schedule.

- Profit Sharing: Many smaller, successful shops offer a profit-sharing plan, giving employees a direct stake in the company's success. This is a powerful incentive for efficiency and quality.

- Health Insurance: A comprehensive benefits package including medical, dental, and vision insurance is a significant financial benefit.

- Retirement Plans: Access to a 401(k) or similar retirement plan, especially with an employer match, is crucial for long-term financial security.

- Paid Time Off (PTO): Includes vacation days, sick leave, and paid holidays.

- Tool Allowance: Some employers provide an annual stipend to help you purchase or upgrade your personal hand tools.

- Disability and Life Insurance: Employer-provided insurance policies offer a vital safety net.

When comparing opportunities, always look at the full compensation package, not just the hourly wage or annual salary. A job with a slightly lower base pay but excellent benefits and profit sharing might be the more lucrative option in the long run.

Key Factors That Influence Salary

While averages provide a useful benchmark, your individual cabinet maker salary will be determined by a specific set of variables. Mastering these factors is the key to accelerating your career and maximizing your earning potential. As a career analyst, I've seen countless professionals transform their income by strategically focusing on these areas. Let's break down each factor in detail.

### ### Level of Education and Certification

While a four-year university degree is not required to become a cabinet maker, formal education and certifications can significantly impact your starting salary and long-term career trajectory.

- High School Diploma / GED: This is the minimum requirement. Many cabinet makers start their careers with on-the-job training or an apprenticeship right out of high school. While this is a viable path, it often means starting at the lowest end of the pay scale.

- Vocational/Technical School Certificate: A 1-2 year program from a vocational school (like the North Bennet Street School or the Center for Furniture Craftsmanship) is a powerful career accelerator. These programs provide intensive, hands-on training in joinery, machine operation, finishing, and design principles. Graduates enter the workforce with a solid portfolio and a comprehensive skillset, often allowing them to bypass entry-level "helper" roles and start as a junior cabinet maker, commanding a salary 10-20% higher than someone with no formal training.

- Associate's Degree: A two-year associate's degree from a community college, often in Woodworking Technology or a related field, combines hands-on skills with academic coursework in areas like mathematics, business management, and CAD. This balanced education is particularly valuable for those who aspire to become a shop foreman, project manager, or business owner.

- Industry Certifications: Certifications act as a third-party validation of your skills. The Architectural Woodwork Institute (AWI) offers highly respected quality certification programs, and the Woodwork Career Alliance (WCA) provides a national credentialing system. Holding a WCA "Green Credential" or higher, or being part of an AWI-certified shop, signals a high level of professionalism and can be a significant factor in wage negotiations, particularly in the commercial millwork sector.

### ### Years of Experience

In a skilled trade like cabinet making, there is no substitute for experience. Your salary growth is directly correlated with the years you've spent honing your craft.

- Apprentice (0-2 years): In this phase, you are paid to learn. Your primary value is in assisting senior makers and handling basic tasks. Your salary will be at the lower end of the spectrum, likely $32,000 to $45,000, but the real compensation is the knowledge you gain.

- Journeyman (3-9 years): You are now a fully productive member of the team. You can work independently, read complex plans, and solve routine problems. Your speed and efficiency have increased dramatically. Your salary reflects this competence, typically rising to the $45,000 to $60,000 range. This is often the period of fastest salary growth as your skills solidify.

- Master Craftsperson (10+ years): After a decade or more, you possess a level of skill that is almost intuitive. You can tackle the most complex and challenging projects, from curved cabinetry to intricate inlay work. You likely have specialized skills (e.g., advanced finishing, CNC programming) and may be responsible for training junior staff and managing projects. Your salary will be in the top quartile, ranging from $60,000 to $80,000+, with potential for more in high-demand roles. For these professionals, their reputation becomes a key asset, driving high-value commission work.

### ### Geographic Location

Where you work is one of the single most significant factors determining your salary. The cost of living and the demand for high-end custom woodwork create vast salary disparities across the country. A cabinet maker in a major metropolitan area with a booming luxury real estate market will earn significantly more than one in a rural area with a lower cost of living.

Here's a comparative look at estimated average cabinet maker salaries in various U.S. metropolitan areas, based on data from Indeed, Glassdoor, and Salary.com (data as of mid-2024):

| Metropolitan Area | High/Low Cost of Living | Estimated Average Annual Salary | Analysis |

| :--- | :--- | :--- | :--- |

| San Jose, CA | Very High | $65,000 - $85,000+ | The proximity to Silicon Valley wealth and a high cost of living drives wages up significantly for skilled trades. |

| New York, NY | Very High | $60,000 - $80,000+ | A massive market for both high-end residential renovations and commercial architectural millwork. |

| Boston, MA | High | $58,000 - $75,000 | Strong demand from historic home restorations and new luxury construction. |

| Denver, CO | High | $55,000 - $72,000 | A rapidly growing city with a booming construction sector creates high demand for cabinet makers. |

| Seattle, WA | High | $55,000 - $70,000 | Similar to San Jose, tech industry wealth fuels a market for premium custom work. |

| Chicago, IL | Medium-High | $50,000 - $65,000 | A large, stable market with both commercial and residential opportunities. |

| Dallas, TX | Medium | $45,000 - $60,000 | A strong housing market, but a lower cost of living keeps wages more moderate than on the coasts. |

| Atlanta, GA | Medium | $44,000 - $58,000 | Home to the IWF, a major woodworking trade show, with a solid manufacturing and construction base. |

| Phoenix, AZ | Medium | $43,000 - $57,000 | A consistent housing market provides steady work, with wages reflecting the regional cost of living. |

| Rural Mississippi | Low | $35,000 - $48,000 | A lower cost of living and less demand for high-end custom work result in salaries closer to the lower end of the national average. |

Key Takeaway: If maximizing income is your primary goal, targeting high-cost-of-living urban centers with a strong luxury construction market is the most effective strategy.

### ### Company Type and Size

The type of company you work for dramatically shapes your role, your daily tasks, and your compensation structure.

- Small Custom Cabinet Shop (1-10 employees): This is the quintessential cabinet maker experience.

- *Pros:* High creative freedom, opportunity to work on a project from start to finish, close-knit team, potential for profit sharing.

- *Cons:* Pay may be less consistent, benefits can be weaker, and you'll be expected to wear many hats.

- *Salary Impact:* Base salary might be average, but the potential for profit sharing in a successful year can lead to high total compensation.

- Large-Scale Production/Manufacturing (50+ employees): These companies produce standardized or semi-custom cabinets in high volume.

- *Pros:* Higher base pay, excellent benefits (health, retirement), predictable hours, potential for overtime, clear advancement path (e.g., from operator to line supervisor).

- *Cons:* Work can be repetitive, less creative input, and you may only work on one part of the process (e.g., only operating the CNC or only doing assembly).

- *Salary Impact:* Often provides the most stable and predictable income with the best benefits package, making it a secure choice.

- Architectural Millwork Firm: These firms work on high-end commercial and residential projects, creating custom fixtures, paneling, and cabinetry for luxury homes, corporate offices, hotels, and retail stores.

- *Pros:* Highest earning potential for salaried employees, work on prestigious and challenging projects, often use cutting-edge technology.

- *Cons:* Extremely high standards for precision and quality, demanding deadlines, may require travel for installations.

- *Salary Impact:* This sector consistently offers the highest wages due to the high value and complexity of the work.

- Self-Employed / Business Owner: This is the path with the highest risk and the highest potential reward.

- *Pros:* Unlimited earning potential, complete control over your projects and schedule, immense personal satisfaction.

- *Cons:* You are responsible for everything—sales, marketing, accounting, insurance, and client management. Income can be inconsistent, especially in the beginning.

- *Salary Impact:* There is no ceiling. A successful custom cabinet business owner in a good market can easily earn $100,000 to $200,000 or more per year. However, they also absorb all the costs and risks.

### ### Area of Specialization

Within the field of cabinet making, developing a specialization can make you a highly sought-after expert and significantly increase your salary.

- Custom Kitchen & Bath Specialist: This is the most common specialization, requiring skills in design, space planning, and working with a wide range of materials and finishes.

- CNC Programmer and Operator: As shops become more automated, a cabinet maker who can not only operate but also program CNC machinery is invaluable. They can translate complex CAD drawings into machine code, increasing shop efficiency exponentially. This specialized technical skill can command a salary premium of 15-25%.

- Finishing Specialist: A flawless finish can elevate a project from good to extraordinary. Experts in complex finishing techniques—such as high-gloss lacquers, custom-matched stains, cerused finishes, or French polishing—are rare and highly paid.

- Installation Specialist: The final installation is a critical step that requires precision, problem-solving skills, and customer-facing professionalism. A dedicated installer who can guarantee a perfect fit and finish on-site is a key asset to any shop.

- Architectural Millwork / High-End Furniture: This niche involves working with exotic veneers, complex joinery, and non-traditional materials to create one-of-a-kind statement pieces. It is the most technically demanding and often the most lucrative specialization.

### ### In-Demand Skills

Beyond your core woodworking abilities, developing a portfolio of complementary skills will directly translate into a higher paycheck. These are the skills that employers are actively seeking and willing to pay more for:

1. CAD/CAM Software Proficiency: Mastery of software like AutoCAD, SketchUp, Cabinet Vision, Mozaik, or AlphaCAM is no longer a bonus; it's nearly a requirement in modern shops. The ability to create detailed