Are you searching for a career in healthcare that is essential, in-demand, and offers a stable pathway to a rewarding future, but without the years of medical school? Do you thrive in environments where precision, detail, and process are paramount? If so, you might be the perfect candidate for a career as a Central Sterile Processing Technician, one of the most critical—and often unseen—roles in the entire healthcare ecosystem.

While surgeons and nurses are the public faces of medical care, behind the scenes, a dedicated team ensures that every single instrument used in a procedure is perfectly decontaminated, functional, and sterile. This is the world of the Central Sterile Processing Technician (CSPT). A career in this field isn't just a job; it's a commitment to patient safety at its most fundamental level. The potential for professional growth and a competitive salary makes it an even more attractive path. Nationally, the average central sterile processing tech salary hovers around $45,000 to $55,000 per year, with significant potential for advancement based on certification, experience, and specialization.

I once had a conversation with a renowned cardiothoracic surgeon who told me, "I can't do my job unless they do theirs perfectly. The sterile processing department is the foundation upon which every successful surgery is built." That sentiment has always stuck with me, highlighting the immense responsibility and value these professionals bring to the operating room and beyond.

This comprehensive guide will illuminate every facet of a career as a CSPT. We will delve deep into salary expectations, the factors that drive higher earnings, the job outlook for the next decade, and a step-by-step roadmap to get you started.

### Table of Contents

1. [What Does a Central Sterile Processing Technician Do?](#what-does-a-central-sterile-processing-technician-do)

2. [Average Central Sterile Processing Tech Salary: A Deep Dive](#average-central-sterile-processing-tech-salary-a-deep-dive)

3. [Key Factors That Influence Your Salary](#key-factors-that-influence-your-salary)

4. [Job Outlook and Career Growth](#job-outlook-and-career-growth)

5. [How to Get Started in This Career](#how-to-get-started-in-this-career)

6. [Conclusion: Is This the Right Career for You?](#conclusion-is-this-the-right-career-for-you)

What Does a Central Sterile Processing Technician Do?

A Central Sterile Processing Technician—also known as a Sterile Processing Tech, Medical Equipment Preparer, or Central Service Technician—is the guardian of medical and surgical instrumentation within a healthcare facility. Their domain is the Central Sterile Services Department (CSSD), often called the "heart of the hospital." This department is responsible for the entire lifecycle of reusable medical equipment, ensuring that every tool is safe and ready for patient use.

The core function of a CSPT is to prevent healthcare-associated infections (HAIs) by executing a meticulous, multi-step process. Their work is a blend of science, technology, and extreme attention to detail. A single mistake—a missed piece of organic debris, a faulty instrument, or an incomplete sterilization cycle—could have dire consequences for a patient.

The responsibilities of a CSPT can be broken down into four primary stages:

1. Decontamination: This is the first and arguably most crucial step. Technicians receive used, contaminated instruments from operating rooms, emergency departments, and other clinical areas. Wearing full Personal Protective Equipment (PPE), they manually clean, brush, and flush instruments to remove visible bioburden (blood, tissue, etc.). They then use automated equipment like ultrasonic cleaners and washer-disinfectors to achieve a higher level of cleaning.

2. Inspection and Assembly: Once an instrument is decontaminated, it is carefully inspected under magnification and light for any remaining debris, damage, rust, or malfunction. This requires an encyclopedic knowledge of hundreds, sometimes thousands, of different instruments. Technicians then assemble complex instrument trays according to precise "recipe cards" or count sheets for specific surgical procedures, from a simple suture kit to a multi-level orthopedic or neurosurgery tray.

3. Sterilization: Assembled trays are packaged, wrapped, or placed in rigid containers, labeled, and then loaded into sterilizers. CSPTs operate and monitor various types of sterilization equipment, with the most common being steam autoclaves. They are also trained in other methods for heat-sensitive instruments, such as Ethylene Oxide (EtO) gas, hydrogen peroxide gas plasma, and vaporized hydrogen peroxide. They must meticulously document each sterilization cycle, verifying that all parameters (time, temperature, pressure) were met.

4. Storage and Distribution: After sterilization and a cooling period, the sterile packages are moved to a clean, climate-controlled storage area. CSPTs manage inventory, rotate stock (first-in, first-out), and fulfill orders for sterile supplies from various departments. They may assemble "case carts" with all the necessary instruments and disposable supplies for surgeries scheduled for the next day.

#### A Day in the Life of a Sterile Processing Tech

To make this role more tangible, let's follow "David," a certified tech on the second shift at a busy urban hospital.

- 2:45 PM: David clocks in, changes into his scrubs, and heads to the department huddle. The shift supervisor reviews the day's surgical load, highlights any urgent instrument turnarounds needed for the evening's emergency cases, and discusses any equipment issues.

- 3:00 PM: David dons his full PPE—fluid-resistant gown, gloves, face shield, and shoe covers—and enters the "Decon" (decontamination) side of the department. Carts loaded with contaminated instrument trays from the day's surgeries are waiting. He begins the methodical process of sorting and pre-soaking the instruments.

- 4:30 PM: After manually cleaning delicate laparoscopic instruments and loading several washer-disinfectors, David moves over to the "Prep and Pack" (assembly) side. A cart of cleaned instruments is ready. He pulls up a count sheet for a total knee replacement tray on his computer monitor. He meticulously inspects each clamp, retractor, and osteotome, ensuring they are pristine and functional before placing them in the correct spot in the tray.

- 6:30 PM: The knee tray is assembled and wrapped. David applies the appropriate chemical indicators and labels before placing it on a cart destined for the steam sterilizer. He then moves on to assembling a complex neurosurgery tray, which requires even greater focus due to the delicate and expensive nature of the instruments.

- 8:00 PM: David loads a large steam autoclave, carefully placing the heaviest trays on the bottom shelf. He selects the correct cycle, initiates it, and begins the documentation process in the electronic tracking system.

- 9:30 PM: While the cycle runs, David helps with inventory in the sterile storage area, pulling items to build a case cart for a C-section scheduled for the morning. He ensures all supplies are present and their sterile packaging is intact.

- 10:45 PM: The sterilization cycle is complete. David carefully unloads the hot cart, moving it to a designated cooling area. He reviews the cycle printout, confirming all physical, chemical, and biological indicators show a successful run. He signs off on the load, completing the quality assurance loop.

- 11:15 PM: David gives a handoff report to the incoming night shift technician, noting the status of the instruments still in process. He then clocks out, knowing his unseen work is the bedrock of patient safety for dozens of procedures.

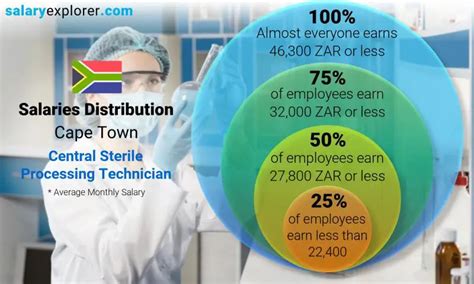

Average Central Sterile Processing Tech Salary: A Deep Dive

Understanding the earning potential is a critical step in evaluating any career. For Central Sterile Processing Technicians, the salary reflects the role's immense responsibility and the specialized knowledge required. While it is not one of the highest-paying clinical roles, it offers a solid, middle-class income with significant opportunities for financial growth through experience and certification.

It's important to note that salary data can vary slightly between sources due to different methodologies and data sets. For the most accurate picture, we will synthesize information from several authoritative sources.

#### National Salary Averages and Ranges

The U.S. Bureau of Labor Statistics (BLS), the gold standard for occupational data, classifies Sterile Processing Technicians under the category "Medical Equipment Preparers."

- According to the most recent BLS data (May 2023), the median annual wage for medical equipment preparers was $44,940, or approximately $21.61 per hour.

- The lowest 10 percent earned less than $31,430.

- The highest 10 percent earned more than $65,590.

This range highlights the significant impact that factors like experience, location, and certification can have on your earnings.

Reputable salary aggregator websites provide a similar, and often more real-time, perspective:

- Salary.com (as of May 2024) reports that the average salary for a Sterile Processing Technician in the United States is $42,887, but the typical range falls between $38,247 and $48,300.

- Payscale.com (as of June 2024) shows an average base salary of $20.72 per hour, which translates to an annual salary of approximately $43,000. Their reported range is from $16.14/hour ($33.5k/year) to $29.28/hour ($61k/year).

- Glassdoor (as of June 2024) estimates the total pay for a Sterile Processing Technician in the U.S. is around $54,345 per year, with a likely range between $45,000 and $66,000. This "total pay" figure often includes additional compensation like bonuses and profit sharing.

In summary: A new, uncertified technician might start in the low-to-mid $30,000s, while the national median for an experienced, certified technician is firmly in the $45,000 to $55,000 range. Highly experienced lead technicians or department supervisors in high-cost-of-living areas can easily earn $65,000 or more.

#### Salary Growth by Experience Level

Your salary as a CSPT will not remain static. As you gain expertise and prove your reliability, your value and compensation will increase accordingly. Here is a typical salary progression based on years of experience, compiled from industry data:

| Experience Level | Typical Years in Role | Average Annual Salary Range | Key Responsibilities & Milestones |

| :--- | :--- | :--- | :--- |

| Entry-Level Technician | 0-1 Year | $35,000 - $42,000 | Learning basic decontamination and sterilization procedures. Working under close supervision. Often preparing for initial certification. |

| Certified Technician (CSPT/CRCST) | 1-4 Years | $42,000 - $52,000 | Achieved core certification (CRCST or CSPDT). Can work independently on standard instrument trays. Proficient in all department areas. |

| Experienced Technician / Specialist | 5-9 Years | $50,000 - $60,000 | Possesses advanced certifications (e.g., CIS). Trusted with the most complex trays (robotics, neuro, ortho). May act as a preceptor for new hires. |

| Lead Technician / Shift Coordinator | 8-15 Years | $55,000 - $70,000+ | Acts as the point person for a shift. Handles scheduling, troubleshoots equipment, resolves conflicts, and assists the department manager. |

| Supervisor / Manager | 10+ Years | $65,000 - $85,000+ | Manages department budget, staffing, quality control, and compliance. Requires leadership certifications (CHL) and extensive experience. |

*(Salary ranges are estimates and can vary significantly based on location and other factors discussed in the next section.)*

#### Beyond the Base Salary: Understanding Total Compensation

Your annual salary is only one part of your total compensation package. In a hospital or surgical center environment, additional pay and benefits can significantly increase your overall earnings and financial well-being.

- Shift Differentials: This is a major factor. Working second shift (evenings), third shift (nights), or weekends almost always comes with a pay differential, which can be an extra $2 to $8 per hour on top of your base rate. Over a year, this can add thousands of dollars to your income.

- On-Call Pay: Many facilities require technicians to be "on-call" to handle emergency surgeries. You receive a small hourly stipend just for being available (e.g., $3-$5/hour), and if you are called in, you are paid at a premium rate (often time-and-a-half) for a guaranteed number of hours.

- Overtime: Due to the 24/7 nature of healthcare, overtime opportunities are frequently available and are paid at 1.5 times your standard hourly rate.

- Bonuses and Sign-On Bonuses: In areas with high demand for technicians, facilities may offer sign-on bonuses ranging from $1,000 to $10,000 to attract qualified, certified candidates.

- Standard Benefits: Full-time CSPTs typically receive a comprehensive benefits package, including:

- Health, dental, and vision insurance

- Paid time off (PTO) and sick leave

- Retirement savings plans (e.g., 401(k) or 403(b)), often with a company match

- Tuition reimbursement for continuing education and advanced certifications

- Life insurance and disability insurance

When evaluating a job offer, it is crucial to consider the value of this entire compensation package, not just the hourly wage. A job with a slightly lower base pay but an excellent shift differential and a generous 401(k) match may be the better financial choice in the long run.

Key Factors That Influence Your Salary

While national averages provide a useful benchmark, your actual central sterile processing tech salary will be determined by a combination of several critical factors. Understanding these variables is the key to maximizing your earning potential throughout your career. This section will provide an in-depth analysis of the elements that have the most significant impact on your paycheck.

### 1. Certification and Education

This is arguably the most important controllable factor in your salary. While it's possible to get an entry-level job without certification, being certified is the non-negotiable standard for professional advancement and higher pay.

- Baseline Education: A high school diploma or GED is the minimum requirement. However, completing a formal Sterile Processing Technician certificate or associate degree program from an accredited institution is highly advantageous. These programs, typically 6-24 months long, provide the foundational knowledge of microbiology, infection control, decontamination, and sterilization principles. Graduates are better prepared for the certification exam and are more attractive to employers.

- Core Certifications: The two primary, nationally recognized certifications are the gatekeepers to higher earnings. Most employers either require certification upon hiring or mandate that you obtain it within 6-12 months.

- CRCST (Certified Registered Central Service Technician) offered by the Healthcare Sterile Processing Association (HSPA). This is the most widely recognized certification in the industry.

- CSPDT (Certified Sterile Processing and Distribution Technician) offered by the Certification Board for Sterile Processing and Distribution (CBSPD). This is also a highly respected credential.

Achieving one of these certifications can instantly boost your hourly wage by $2 to $5 per hour, or an additional $4,000 to $10,000 per year, compared to an uncertified counterpart.

- Advanced Certifications: To move into specialist or leadership roles, advanced certifications are essential. Each one demonstrates a higher level of expertise and can lead to significant pay increases.

- CIS (Certified Instrument Specialist) from HSPA: Focuses on advanced knowledge of surgical instruments. Highly valued for roles in Level 1 trauma centers or facilities with complex surgical specialties.

- CHL (Certified in Healthcare Leadership) from HSPA: Designed for those aspiring to supervisor, manager, or educator roles.

- CSIS (Certified Surgical Instrument Specialist) from CBSPD: A similar advanced credential to the CIS.

- CFER (Certified Flexible Endoscope Reprocessor) from HSPA/CBSPD: A specialized certification for the high-risk and complex process of cleaning flexible endoscopes.

### 2. Years of Experience

As detailed in the previous section, experience is a direct driver of salary growth. A seasoned technician is faster, more accurate, and more adept at problem-solving than a novice.

- 0-2 Years (Novice to Competent): You are learning the ropes, mastering basic instrument sets, and understanding the workflow. Your value is in your potential and willingness to learn. Salary is at the lower end of the spectrum.

- 3-7 Years (Proficient to Expert): You are now a reliable, independent contributor. You can handle most trays, troubleshoot minor equipment issues, and may begin to mentor new staff. This is where you see the most significant salary growth after initial certification. You can comfortably earn at or above the national median.

- 8+ Years (Lead/Expert): You are the go-to person on your shift. You have encyclopedic knowledge of instrumentation, especially for complex specialties like orthopedics, neurosurgery, or robotics. You likely hold advanced certifications and are involved in training, quality assurance, and process improvement. Your salary will be in the upper quartile, and you are a prime candidate for leadership positions.

### 3. Geographic Location

Where you work matters immensely. Salary ranges for CSPTs vary dramatically by state, city, and even between urban and rural areas within the same state. This variation is often tied to the local cost of living, demand for healthcare services, and the presence of unionized hospitals.

According to the BLS (May 2023 data), the top-paying states for Medical Equipment Preparers are:

1. California: Annual Mean Wage - $62,130

2. Nevada: Annual Mean Wage - $60,260

3. District of Columbia: Annual Mean Wage - $58,360

4. Alaska: Annual Mean Wage - $56,760

5. Massachusetts: Annual Mean Wage - $56,120

Conversely, states in the Southeast and parts of the Midwest tend to have lower average salaries, though the cost of living in these areas is also substantially lower.

The disparity is even more pronounced at the metropolitan level. Here are some of the top-paying metropolitan areas:

1. San Jose-Sunnyvale-Santa Clara, CA: $76,140

2. San Francisco-Oakland-Hayward, CA: $72,590

3. Sacramento-Roseville-Arden-Arcade, CA: $68,090

4. Reno, NV: $63,600

5. Vallejo-Fairfield, CA: $62,810

When considering a job, always weigh the salary against the local cost of living. A $60,000 salary in San Francisco is very different from a $50,000 salary in a smaller city in the Midwest where housing and transportation costs are a fraction of the price.

### 4. Work Environment and Employer Type

The type of facility you work for can influence your pay, benefits, and work-life balance.

- Large, University-Affiliated or Trauma I Hospitals: These facilities typically offer the highest salaries. They perform the most complex surgeries (transplants, advanced robotics, etc.), requiring the highest level of skill and specialization from their CSPTs. The work environment is fast-paced and high-pressure, but the compensation reflects these demands. They are also more likely to be unionized, which often leads to higher wages and better benefits.

- Community Hospitals and Smaller Healthcare Systems: Salaries here are generally competitive and close to the national average. The pace may be slightly less frantic than at a major trauma center, though they still handle a high volume of standard procedures.

- Ambulatory Surgery Centers (ASCs): These are outpatient surgery centers that do not operate 24/7. Pay can be competitive, but the main appeal is a more predictable schedule (typically no nights, weekends, or on-call requirements). Benefits packages might be less robust than those at large hospitals.

- Third-Party Medical Device Reprocessors: These are companies that specialize in sterilizing for multiple client hospitals and clinics. They operate like a production facility and can offer competitive wages.

- Dental Offices and Specialty Clinics: These environments often have a smaller scale of sterilization needs. The work is typically less complex, and the pay is often on the lower end of the spectrum for the profession.

### 5. Area of Specialization

Within the sterile processing field, developing a specialized skill set can make you a more valuable asset and lead to higher pay. While most techs are generalists, those who master high-stakes instrumentation are in high demand.

- Robotics (e.g., da Vinci Surgical System): The instruments for robotic surgery are incredibly complex, delicate, and expensive. Technicians who are experts at reprocessing these instruments are highly sought after.

- Orthopedics: Orthopedic trays are notoriously large, heavy, and complex, with hundreds of components. Being the "ortho expert" on a shift is a valuable position.

- Neurosurgery and Spine: These instruments are extremely fine and delicate. A deep understanding of how to handle and inspect them is a critical specialty.

- Flexible Endoscopes: Reprocessing endoscopes is a highly specialized, multi-step process that carries a high risk of patient infection if done incorrectly. Technicians with a CFER certification who specialize in the "scope room" often earn a premium.

### 6. In-Demand Skills

Beyond certifications and experience, a specific set of hard and soft skills can directly impact your performance and, consequently, your value to an employer. Highlighting these on your resume and demonstrating them on the job can pave the way for promotions and raises.

High-Value Hard Skills:

- Instrument Tracking Systems: Proficiency with software like Censitrac, SPM, or T-DOC. This shows you can work efficiently in a modern, data-driven department.

- Advanced Sterilization Modalities: Deep knowledge of not just steam autoclaves but also EtO, Sterrad (hydrogen peroxide gas plasma), and V-Pro sterilizers.

- Complex Instrumentation Assembly: The proven ability to accurately and efficiently assemble intricate trays for specialties like cardiothoracic surgery, orthopedics, or robotics.

- Quality Assurance and AAMI Standards: A thorough understanding of industry standards from the Association for the Advancement of Medical Instrumentation (AAMI) and the ability to conduct and interpret quality tests (e.g., Bowie-Dick tests, biological indicators).

Essential Soft Skills:

- Meticulous Attention to Detail: This is the single most important soft skill. The ability to spot a tiny crack in an instrument or a misaligned component is non-negotiable.

- Problem-Solving: What do you do when a sterilizer fails mid-cycle or a critical instrument is missing from a tray? The ability to think critically under pressure is vital.

- Communication and Teamwork: CSPTs must communicate clearly with operating room staff, their own team members, and supervisors to ensure a smooth workflow.

- Adaptability and a Sense of Urgency: The needs of the hospital can change in an instant. You must be able to pivot from routine work to processing an emergency trauma set without delay.

By strategically developing these skills, pursuing certifications, and gaining experience in high-demand specialties, you can actively steer your career towards the higher end of the salary spectrum.

Job Outlook and Career Growth

Choosing a career path requires not only understanding the current salary but also a clear vision of its future stability and growth potential. For Central Sterile Processing Technicians, the outlook is exceptionally positive. This field is projected to grow steadily, driven by fundamental trends in the U.S. healthcare system.

#### Strong Projected Job Growth

The U.S. Bureau of Labor Statistics provides a very encouraging forecast for this profession.

- The BLS projects that employment of Medical Equipment Preparers will grow by 6 percent from 2022 to 2032. This growth rate is faster than the average for all occupations, which is projected at 3 percent.

- This growth is expected to result in approximately 4,500 new job openings each year, on average, over the decade.

- Many of these openings will stem from the need to replace workers who transfer to different occupations or exit the labor force, such as through retirement.

This data paints a picture of a stable and secure career field. The demand for skilled, certified technicians is robust and is expected to remain so for the foreseeable future.

#### Key Drivers of Growth

Several powerful trends are fueling the demand for Sterile Processing Technicians:

1. Aging Population: The large baby-boomer generation is aging and will require more medical procedures, particularly surgeries like joint replacements, cardiac procedures, and cataract removals. Every surgery relies on perfectly sterilized instruments, directly increasing the workload and demand for CSPTs.

2. Advances in Medical and Surgical Technology: As medicine advances, surgical instruments become more complex, delicate, and numerous. Robotic surgical systems, minimally invasive tools, and sophisticated implantable devices all require specialized, meticulous cleaning and sterilization protocols, necessitating a more highly skilled sterile processing workforce.

3. Increased Focus on Infection Control: Hospitals and regulatory bodies are placing an unprecedented emphasis on preventing Healthcare-Associated Infections (HAIs). A highly functioning Sterile Processing department is the first line of defense against HAIs. This focus has elevated the importance of the role and driven demand for well-trained, certified professionals.

4. Growth in Outpatient Surgery: An increasing number of procedures are being performed in Ambulatory Surgery Centers (ASCs). The proliferation of these centers creates new job opportunities for CSPTs outside of the traditional hospital setting.