Table of Contents

- [What Does a CMM Programmer Do?](#what-is-a-cmm-programmer)

- [Average CMM Programmer Salary: A Deep Dive](#average-salary)

- [Key Factors That Influence Salary](#key-factors)

- [Job Outlook and Career Growth](#job-outlook)

- [How to Get Started in This Career](#how-to-get-started)

- [Conclusion: Is a CMM Programmer Career Right for You?](#conclusion)

In the vast and intricate world of modern manufacturing, where microns can mean the difference between a revolutionary product and a catastrophic failure, there exists a specialized and indispensable role: the CMM Programmer. If you are drawn to the intersection of digital design and physical reality, possess an almost obsessive attention to detail, and find satisfaction in being the ultimate guardian of quality, this career path may not only be fulfilling but also highly lucrative. While it may not have the mainstream recognition of a software developer or data scientist, the C-M-M Programmer salary reflects the critical importance and specialized skillset required to ensure that what is designed is precisely what is made.

The financial potential is significant. A skilled CMM Programmer can expect a national average salary in the range of $70,000 to $85,000 per year, with senior-level experts in high-demand industries commanding well over $100,000. Early in my career as a consultant for a major aerospace manufacturer, I witnessed firsthand the reverence held for the lead metrologist. When a new, multi-million dollar jet engine component came off the CNC machine, it wasn't the engineers or the executives who had the final say; it was the CMM Programmer whose report would greenlight the part or send it back to the drawing board. That experience cemented my understanding: this role is not just about measuring things; it's about validating innovation and guaranteeing safety at the highest level.

This guide is designed to be your definitive resource for understanding every facet of a CMM Programmer's career, with a laser focus on salary potential and the factors that drive it. We will dissect the role, analyze compensation data from authoritative sources, explore the career ladder, and provide a clear, step-by-step roadmap for you to forge your own path in this rewarding field of precision metrology.

What Does a CMM Programmer Do?

A Coordinate Measuring Machine (CMM) Programmer, also known as a Metrologist or Quality Engineer, is a highly skilled professional who operates at the critical junction of design engineering and manufacturing. Their primary responsibility is to verify that a manufactured part's physical geometry conforms to the precise specifications laid out in its design blueprints or Computer-Aided Design (CAD) models. They are the ultimate arbiters of quality, using sophisticated, computer-controlled machines to measure objects in three-dimensional space with astonishing accuracy.

Think of it this way: a team of engineers designs a complex part for a car's transmission in a digital CAD program. A team of machinists then uses advanced CNC machines to cut that part from a block of metal. The CMM Programmer is the person who takes that finished physical part, places it on the granite table of a multi-hundred-thousand-dollar CMM, and writes a complex program that directs a sensitive probe to touch hundreds, or even thousands, of points on the part's surface. The machine's software then compares these real-world measurements against the original digital CAD model. The CMM Programmer's final report definitively states whether the part is perfect, within acceptable tolerance, or needs to be scrapped or reworked.

Core Responsibilities and Daily Tasks:

The role is a blend of hands-on work, complex programming, and data analysis. A typical day or week involves:

- Interpreting Blueprints and CAD Models: This is the foundation of the job. CMM Programmers must be experts in reading and understanding complex engineering drawings, with a particular mastery of Geometric Dimensioning and Tolerancing (GD&T). GD&T is the symbolic language used on drawings to define the allowable deviation for a part's form, orientation, and location.

- Programming the CMM: Using specialized software like PC-DMIS, Calypso, MCOSMOS, or Verisurf, the programmer writes a detailed inspection routine. This involves defining the coordinate system, selecting the correct probes and styli, plotting the measurement path to avoid collisions, and programming the analysis of the collected data points.

- Fixture Design and Setup: Parts must be held securely and in the correct orientation on the CMM for accurate measurement. The programmer is often responsible for designing or selecting the proper clamps, vises, and fixtures for this purpose.

- Machine Operation and Calibration: They run the inspection programs they've written, carefully monitoring the machine. They are also responsible for the regular calibration and maintenance of the CMM and its probes to ensure measurement integrity.

- Data Analysis and Reporting: After an inspection run, the programmer analyzes the output data. This often involves generating detailed reports that show which dimensions are in or out of tolerance, creating color maps to visualize surface deviations, and performing statistical process control (SPC) analysis to identify trends in manufacturing.

- Collaboration and Troubleshooting: When a part is found to be out of spec, the CMM Programmer collaborates directly with design engineers, machinists, and other manufacturing personnel to diagnose the root cause of the problem—whether it's a worn tool, an incorrect machine setting, or a flaw in the original design.

### A Day in the Life of a CMM Programmer

To make this more concrete, let's walk through a hypothetical day for "Alex," a mid-career CMM Programmer at a medical device company:

- 8:00 AM: Alex arrives and starts the day by reviewing the First Article Inspection (FAI) queue. A new batch of titanium spinal implants has just come off the 5-axis CNC mill, and the first part needs a complete dimensional validation before the full production run can begin.

- 8:30 AM: Alex pulls up the CAD model and the engineering drawing for the implant. He spends 30 minutes meticulously reviewing the GD&T callouts, paying special attention to the critical profile tolerances and true position of the mounting holes.

- 9:00 AM: He moves to the Zeiss CMM, which runs on Calypso software. He designs a simple fixture to hold the implant securely and establishes the part's datum reference frame, just as it's defined on the drawing.

- 9:45 AM: Alex begins writing the inspection program. He programs a path for the ultra-fine ruby stylus to measure over 250 distinct points, including complex curved surfaces and the precise location of several threaded holes. He builds in logic to automatically generate a graphical report.

- 11:30 AM: The program is written and simulated digitally to check for potential collisions. Everything looks good. He carefully cleans the implant, places it in the fixture on the CMM, and executes the program. The machine hums to life, its probe moving with uncanny precision.

- 1:00 PM: After a lunch break, the 45-minute inspection cycle is complete. Alex reviews the report. Most dimensions are perfect, but the report flags the position of one hole as being 15 microns outside its allowable tolerance zone.

- 1:15 PM: Alex walks over to the machine shop floor and meets with the lead machinist. He shows him the CMM report and the color map indicating the deviation. Together, they theorize that a slight tool deflection on the mill might be the cause.

- 2:30 PM: The machinist makes a small offset adjustment in the CNC program and runs another part. Alex takes this second part back to the CMM and runs a quick check program focusing only on the problematic hole.

- 3:00 PM: Success. The new part is perfectly within tolerance. Alex documents his findings, officially approves the First Article Inspection report, and gives the green light for the full production run to commence.

- 4:00 PM: For the rest of the day, Alex works on a longer-term project: performing a Gage R&R (Repeatability and Reproducibility) study to validate a new laser scanning system for a different product line.

This "day in the life" illustrates the critical, problem-solving nature of the role. A CMM Programmer isn't just a button-pusher; they are a detective, a programmer, and a vital communication hub for the entire manufacturing process.

Average CMM Programmer Salary: A Deep Dive

The salary for a CMM Programmer is a direct reflection of their specialized knowledge, the precision required in their work, and their impact on a company's bottom line by preventing costly errors and ensuring product quality. Compensation is competitive and shows significant growth potential with experience.

For our analysis, we will synthesize data from several reputable sources to provide a comprehensive and trustworthy picture of the earning potential. It's important to note that the U.S. Bureau of Labor Statistics (BLS) does not have a distinct category for "CMM Programmer." The role is often classified under broader categories like "Quality Control Inspectors" (SOC 51-9061) or the more technical "Industrial Engineering Technologists and Technicians" (SOC 17-3026). Therefore, to get a precise salary picture, we must turn to industry-specific salary aggregators that survey this exact job title.

### National Average and Salary Range

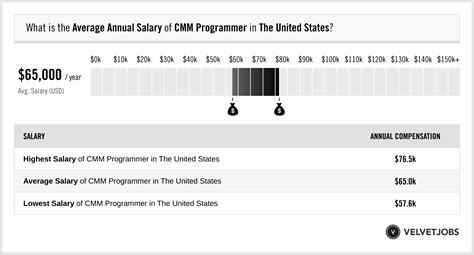

Based on an aggregation of recent data from major platforms, the salary landscape for a CMM Programmer in the United States is as follows:

- Median National Salary: Approximately $76,500 per year, which translates to about $36.78 per hour.

- Typical Salary Range: Most CMM Programmers earn between $62,000 and $94,000 annually.

- Entry-Level Salaries: Professionals new to the field, perhaps with an associate's degree and some foundational knowledge, can expect to start in the $55,000 to $65,000 range.

- Senior-Level Salaries: Highly experienced CMM Programmers, especially those with expertise in complex software, multiple machine platforms, and in-demand industries like aerospace or medical devices, can easily command salaries of $95,000 to $120,000+.

Authoritative Source Breakdown (as of late 2023/early 2024):

- Salary.com reports the median salary for a "CMM Programmer/Operator III" (representing a senior-level role) to be around $87,135, with a range typically falling between $77,539 and $97,295. Their data for a mid-level "CMM Programmer/Operator II" shows a median of $72,593.

- Payscale.com indicates a national average base salary of approximately $68,910 per year, but with bonuses and other compensation, the total pay can extend much higher. Their data heavily emphasizes the impact of experience on pay.

- Glassdoor lists the "Most Likely Range" for a CMM Programmer salary between $61,000 and $98,000, with an average base pay of $77,329 per year based on user-submitted data.

These figures confirm a strong, consistent earning potential that places the role comfortably in the mid-to-upper tier for skilled technical positions in the manufacturing sector.

### Salary by Experience Level

Career progression brings a significant and predictable increase in compensation. As a programmer's skills deepen—from basic operation to complex programming, fixture design, data analysis, and mentoring—so does their value to an employer.

Here is a typical salary trajectory based on years of experience:

| Experience Level | Years in Field | Typical Annual Salary Range | Key Responsibilities & Skills |

| :--- | :--- | :--- | :--- |

| Entry-Level CMM Programmer/Operator | 0-2 Years | $55,000 - $68,000 | Operating pre-written programs, performing basic setups, reading simple blueprints, running routine inspections, basic CMM maintenance. |

| Mid-Career CMM Programmer | 3-8 Years | $68,000 - $88,000 | Writing original CMM programs for moderately complex parts, solid GD&T knowledge, designing simple fixtures, analyzing inspection data, troubleshooting common manufacturing defects. |

| Senior/Lead CMM Programmer | 9-15+ Years | $88,000 - $110,000+ | Programming highly complex parts (e.g., 5-axis components, gears), expert-level GD&T, advanced software skills (loops, variables), designing complex fixtures, training junior staff, leading process improvement projects. |

| Metrology Engineer / Quality Manager | 15+ Years | $100,000 - $140,000+ | Overseeing the entire metrology lab, managing a team of programmers, developing quality standards, validating new equipment and processes, interfacing with senior management and customers. |

### Beyond the Base Salary: Understanding Total Compensation

A CMM Programmer's W-2 is often more than just their base salary. Manufacturing environments frequently offer additional forms of compensation that significantly boost total earnings.

- Overtime Pay: This is a major factor. Manufacturing facilities often run multiple shifts and have tight production deadlines. CMM Programmers are frequently required to work overtime, which is typically paid at 1.5 times their hourly rate. For an hourly programmer, this can add 10-25% to their annual income.

- Shift Differentials: Programmers who work second or third shifts almost always receive a "shift differential," which is an additional amount (either a flat rate or a percentage) added to their hourly wage. This can range from an extra $1 to $5 per hour.

- Bonuses: Annual or quarterly performance bonuses are common, especially in profitable companies. These are often tied to company performance, department quality metrics (e.g., reducing scrap rates), or individual achievements. Bonuses can range from a few thousand dollars to 10% or more of the base salary.

- Profit Sharing: Some companies, particularly privately-held ones, offer profit-sharing plans where a portion of the company's profits is distributed among employees. This can be a substantial addition to annual income.

- Benefits Package: While not direct cash, a strong benefits package is a crucial part of total compensation. This includes:

- Health Insurance: Medical, dental, and vision insurance.

- Retirement Plans: 401(k) or 403(b) plans, often with a generous company match. A 50% match on the first 6% of your contribution is like an instant, guaranteed 3% raise.

- Paid Time Off (PTO): Vacation days, sick leave, and paid holidays.

- Tuition Reimbursement: Many companies will pay for continuing education, including certifications or even a bachelor's degree, which directly increases future earning potential.

When evaluating a job offer, it is crucial to look beyond the base salary and calculate the value of the entire compensation package. A role with a slightly lower base salary but excellent overtime opportunities, a strong bonus structure, and a great 401(k) match could ultimately be more lucrative.

Key Factors That Influence CMM Programmer Salary

While the national averages provide a solid baseline, a CMM Programmer's actual salary can vary dramatically based on a combination of six key factors. Understanding these drivers is essential for maximizing your earning potential throughout your career. This section provides an in-depth analysis of each factor, giving you the knowledge to strategically position yourself for a higher salary.

### 1. Level of Education and Certification

Formal education and professional certifications provide the theoretical foundation and validated proof of your skills, directly impacting your starting salary and long-term career ceiling.

- High School Diploma / Vocational Training: It is possible to enter the field with a strong high school background in math and shop classes, starting as a CMM Operator or Quality Inspector. However, this path typically has the lowest starting salary and a slower growth trajectory. A certificate from a vocational or technical college in a field like Precision Machining or Metrology can significantly improve prospects over a high school diploma alone.

- Associate's Degree (A.A.S.): This is the most common and effective entry point into the career. An Associate of Applied Science in Manufacturing Engineering Technology, Quality Assurance, or Metrology provides a powerful combination of hands-on lab experience and theoretical knowledge in blueprint reading, GD&T, and CMM fundamentals. Graduates with an A.A.S. can expect to start in the $60,000 to $70,000 range and are well-positioned for mid-career growth.

- Bachelor's Degree (B.S.): While not strictly required for a programming role, a Bachelor of Science in Mechanical Engineering, Industrial Engineering, or Manufacturing Engineering opens the door to the highest earning potential. Individuals with a B.S. may start in a similar role but are on a fast track to senior and management positions. They can transition from CMM Programmer to a Metrology Engineer, Quality Engineer, or Quality Manager role, where salaries routinely exceed $100,000. The B.S. provides a deeper understanding of the underlying principles of design, materials science, and statistical analysis, making these individuals invaluable for process improvement and high-level problem-solving.

The Impact of Certifications:

Certifications are a powerful way to increase your salary without pursuing a full degree. They serve as third-party validation of your specific expertise.

- ASQ Certifications: The American Society for Quality (ASQ) is the gold standard.

- Certified Quality Technician (CQT): Demonstrates a strong understanding of quality tools and techniques. Can add $3,000 - $7,000 to your annual salary.

- Certified Quality Inspector (CQI): Validates expertise in inspection techniques and blueprint reading.

- Certified Mechanical Inspector (CMI): A more advanced certification that directly addresses the skills used by CMM programmers, including GD&T and measurement systems analysis. Highly valued.

- Software-Specific Certifications: Certifications from the CMM software developers themselves are extremely valuable. A certificate from Hexagon (for PC-DMIS), Zeiss (for Calypso), or Mitutoyo (for MCOSMOS) proves you have mastery of that specific platform and can command a premium, often adding $5,000+ to salary offers.

- GD&T Professional Certification (GDTP): The American Society of Mechanical Engineers (ASME) offers a GDTP certification. Achieving the Senior or Technologist level is considered a mark of a true expert and can be a significant salary differentiator, as GD&T is the absolute bedrock of CMM programming.

### 2. Years of Experience

As highlighted in the previous section, experience is arguably the single most powerful driver of salary growth in this field. The value of a CMM Programmer is not just in knowing *how* to run the machine, but in the accumulated wisdom of *why* things go wrong and *how* to fix them.

- 0-2 Years (The Learner): In this phase, you are absorbing knowledge. Your primary value is your ability to learn quickly and reliably execute tasks given to you. Salary is modest as the company is investing in your training.

- 3-8 Years (The Practitioner): You are now a fully independent contributor. You can take a drawing and a part and produce a reliable inspection program and report without significant supervision. You have seen common failure modes and can offer initial diagnoses. This is where you see the most significant percentage-based salary growth, often jumping 30-50% from your starting pay.

- 9+ Years (The Expert/Mentor): You are now a go-to problem solver. You've encountered a vast array of manufacturing challenges and can program the most complex parts with ease. You understand the nuances of different materials, machine capabilities, and inspection strategies. You are likely training junior programmers, designing complex fixtures, and leading initiatives to improve the overall quality process. Your salary reflects this expert status, placing you at the top end of the pay scale, with earning potential well over $100,000 as a Lead Programmer or individual contributor.

### 3. Geographic Location

Where you work matters. Salaries for CMM Programmers are heavily influenced by the cost of living and the concentration of manufacturing in a particular region. High-tech manufacturing hubs command a significant salary premium.

High-Paying States and Metropolitan Areas:

States with strong aerospace, defense, medical device, and automotive industries tend to offer the highest salaries.

- California: (Especially Los Angeles and Orange County) - Home to a massive aerospace and defense sector. Salaries can be 15-25% above the national average.

- Massachusetts: (Boston/Cambridge area) - A hub for medical device and biotech manufacturing. Salaries are often 10-20% above average.

- Washington: (Seattle area) - Dominated by Boeing and its vast network of suppliers. Strong demand and high pay, often 10-18% above average.

- Connecticut: (Hartford area) - A major center for aerospace manufacturing (e.g., Pratt & Whitney, Sikorsky).

- Michigan: (Detroit Metro area) - The heart of the U.S. automotive industry. Competitive salaries, particularly for those with automotive-specific experience.

- Texas: (Dallas-Fort Worth, Houston) - Booming aerospace, defense, and energy sectors drive up demand and wages.

Average and Lower-Paying Regions:

Salaries tend to be closer to or slightly below the national average in the Midwest and Southeast (outside of major manufacturing hubs) and in more rural areas. While the sticker price of the salary is lower, this is often offset by a significantly lower cost of living, meaning your purchasing power may be comparable. States like Ohio, Indiana, Pennsylvania, and the Carolinas have strong manufacturing bases with salaries generally clustering around the national median.

Example Salary Comparison by City:

| City | Average CMM Programmer Salary | Cost of Living Index (vs. Nat'l Avg of 100) |

| :--- | :--- | :--- |

| San Jose, CA | ~$98,000 | 216.5 |

| Boston, MA | ~$92,000 | 153.4 |

| Seattle, WA | ~$90,000 | 152.7 |

| Detroit, MI | ~$78,000 | 104.5 |

| Wichita, KS | ~$74,000 | 82.1 |

| Greenville, SC | ~$71,000 | 88.6 |

*(Note: Salary figures are estimates based on aggregated data; cost of living data from sources like Payscale or BestPlaces.net)*

This table clearly illustrates that while you can earn more in San Jose, the extremely high cost of living may negate the salary advantage compared to a city like Wichita, a major aerospace hub with a much lower cost of living.

### 4. Company Type & Industry

The type of company you work for and the industry it serves have a profound impact on your compensation. This is driven by profit margins, regulatory requirements, and the complexity of the products being manufactured.

- Aerospace & Defense: This is typically the highest-paying industry. The products (jet engines, missile components, satellite parts) have no room for error. The tolerances are incredibly tight, the materials are exotic and expensive, and the regulatory oversight (from the FAA, Department of Defense) is intense. Companies are willing to pay a premium for top-tier CMM programmers who can guarantee this level of quality.

- Medical Devices: This industry is a very close second to aerospace. Similar to aerospace, product failure is not an option. The FDA imposes strict validation and documentation requirements (e.g., IQ/OQ/PQ processes). Programmers with experience in this regulated environment are highly sought after and well-compensated.

- Automotive: A massive employer of CMM Programmers. Salaries are very competitive, but the work is often focused on high-volume production and statistical process control (SPC). Expertise in automotive quality standards (e.g., IATF 16949) is a major plus.

- General Manufacturing / Job Shops: This category is the most varied. A small, local job shop will likely pay less than a large, multinational corporation that manufactures heavy equipment or consumer electronics. However, job shops can offer a wider variety of work, which can be excellent for skill development early in your career.

- Company Size: Large corporations (e.g., Boeing, Johnson & Johnson