Introduction

In a world increasingly dominated by digital services and intangible products, there's a profound and growing respect for those who create the physical world around us. From the intricate components in your smartphone to the life-saving medical implants and the powerful engines that propel us into the skies, skilled hands and brilliant minds are at work. At the heart of this modern manufacturing revolution is the CNC Machining Operator—a professional who bridges the gap between digital design and physical reality. If you're drawn to the hum of machinery, the precision of a well-executed plan, and the satisfaction of holding a perfectly crafted part in your hand, a career as a CNC Machinist might be your calling.

This career is not just about pushing buttons; it's a dynamic, challenging, and financially rewarding path. The national average salary for a CNC Machinist hovers around $54,900 per year, but this figure is merely the starting point. With the right skills, specialization, and experience, top-tier professionals can command salaries well over $80,000 or even $100,000 annually.

I remember touring an advanced aerospace manufacturing facility a few years ago. In a climate-controlled cleanroom, a 5-axis CNC mill was meticulously carving a single, complex turbine blade from a solid block of titanium alloy. The machinist overseeing the process wasn't just an operator; she was a conductor, a problem-solver, and a guardian of quality, responsible for a part worth more than most cars. That moment crystallized for me the immense value and expertise this role embodies—it's the critical intersection of technology, engineering, and hands-on skill.

This comprehensive guide is designed to be your blueprint for understanding and navigating a career as a CNC Machining Operator. We will dissect every facet of the role, from daily responsibilities to the nuanced factors that dictate your earning potential. Whether you're a high school student exploring options, a veteran looking for a new mission, or a professional seeking a career change, this article will provide the authoritative, data-driven insights you need to succeed.

### Table of Contents

- [What Does a CNC Machining Operator Do?](#what-does-a-cnc-machining-operator-do)

- [Average CNC Machining Operator Salary: A Deep Dive](#average-cnc-machining-operator-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

What Does a CNC Machining Operator Do?

At its core, a Computer Numerical Control (CNC) Machining Operator uses computer-controlled machinery to cut, shape, and form raw materials—primarily metals and plastics—into precise, finished parts. They are the essential link between a digital blueprint (a CAD/CAM file) and a functional component. While the term "operator" might suggest a passive role, the reality is far more dynamic and requires a sophisticated blend of technical knowledge, mechanical aptitude, and meticulous attention to detail.

The role's complexity can vary significantly, from an entry-level operator who primarily loads material and monitors a pre-programmed machine, to a senior-level machinist or programmer who can take a project from a raw engineering drawing to a final, inspected part.

Core Responsibilities and Daily Tasks:

- Reading and Interpreting Blueprints: The process begins with technical drawings and specifications (blueprints). Machinists must be adept at reading these documents to understand the part's dimensions, required tolerances (the acceptable margin of error, which can be as small as a few ten-thousandths of an inch), materials, and finish requirements.

- Machine Setup (The "Setup Machinist"): This is one of the most critical phases. It involves selecting, installing, and calibrating the correct cutting tools (like end mills, drills, and taps), fixtures (workholding devices that secure the material), and jigs. They must also load the correct CNC program into the machine's controller.

- Programming and Program Editing: While some shops have dedicated CNC Programmers, most experienced machinists are expected to have some programming skills. This involves understanding and writing G-code (which controls the machine's movements) and M-code (which controls miscellaneous functions like coolant flow and tool changes). Often, they use CAM (Computer-Aided Manufacturing) software like Mastercam or Fusion 360 to generate the toolpaths and then may need to edit the code at the machine for optimization or to correct errors.

- Operating the Machine: Once the machine is set up and programmed, the operator initiates the machining cycle. This is not a "set it and forget it" task. They must carefully monitor the machine's operation, listening for unusual sounds, watching for tool wear, and ensuring the process runs smoothly and safely.

- Quality Control and Inspection: Precision is paramount. During and after the machining process, operators use a variety of precision measuring instruments—such as digital calipers, micrometers, height gauges, and even Coordinate Measuring Machines (CMM)—to verify that the finished parts meet the exact specifications laid out in the blueprint.

- Maintenance and Troubleshooting: Machinists are often the first line of defense for their equipment. This includes routine maintenance like cleaning the machine, checking fluid levels, and performing minor repairs. They also troubleshoot issues that arise during production, such as tool breakage, poor surface finishes, or dimensional inaccuracies.

### A Day in the Life of a Mid-Career CNC Machinist

To make this more tangible, let's walk through a typical day for a machinist named Alex, working in a mid-sized job shop that produces parts for various industries.

- 7:00 AM: Alex arrives, grabs a coffee, and heads to the morning production meeting. The shop foreman reviews the day's priorities: a new prototype job for a medical device company and a recurring production run of 500 aluminum brackets for an automotive client.

- 7:15 AM: Alex is assigned the medical prototype. He reviews the job packet, which contains the blueprint, a 3D model, and a list of required materials and tools. The part is complex, with tight tolerances specified using GD&T (Geometric Dimensioning and Tolerancing).

- 8:00 AM: He moves to his assigned Haas VF-4, a 3-axis vertical milling center. He spends the next hour setting up the job. This involves deep cleaning the machine table, installing a specialized vise to hold the small, oddly-shaped piece of PEEK (a high-performance plastic), and loading the dozen different cutting tools required into the machine's tool carousel.

- 9:00 AM: Alex loads the CAM-generated program into the machine's Fanuc controller. He carefully reviews the code line by line, simulating the toolpaths on the screen to ensure there are no crashes or inefficient moves. He makes a few minor edits to optimize the feed rates for the specific material.

- 10:00 AM: Time to make the first cut. He meticulously touches off each tool to set its length and diameter offsets. He runs the program in "single block" mode, executing one line of code at a time to ensure everything is perfect before starting the full cycle.

- 11:30 AM: The first part is finished. Alex takes it to the quality control bench. Using a calibrated micrometer, calipers, and a vision inspection system, he painstakingly measures every dimension, comparing it against the blueprint. The part is perfect.

- 12:00 PM: Lunch break.

- 12:30 PM: With the prototype process validated, Alex starts the small production run of 10 identical medical parts. He continues to monitor the machine and performs spot checks on every third part to ensure consistency.

- 3:00 PM: The medical job is complete. He deburrs the parts, cleans them, and sends them to the quality department for final CMM inspection. He then cleans his machine and begins setting up for the automotive bracket job, which will run overnight.

- 4:30 PM: The setup for the next job is complete and the first part has been successfully run and inspected. He starts the full production cycle, ensuring the machine has enough material and that all safety protocols are engaged for unattended operation. He documents his work, cleans his station, and clocks out, leaving with the satisfaction of turning a complex design into a tangible, critical component.

Average CNC Machining Operator Salary: A Deep Dive

Understanding the earning potential is a critical step in evaluating any career. For CNC Machining Operators, compensation is not a single number but a spectrum influenced by a host of factors we'll explore in the next section. However, by consolidating data from authoritative sources, we can build a clear and reliable picture of what you can expect to earn.

According to the most recent data from the U.S. Bureau of Labor Statistics (BLS), the median annual wage for machinists was $54,900 in May 2023. This means that half of all machinists earned more than this amount, and half earned less. The BLS also provides a range, stating that the lowest 10 percent earned less than $37,930, and the highest 10 percent earned more than $77,930.

It's important to note that the BLS often groups several related roles together. Salary aggregator websites, which collect real-time, user-reported data, can provide an even more granular view.

- Payscale.com reports an average base salary for a CNC Machinist of approximately $55,000 per year (as of late 2023), with a typical range falling between $40,000 and $75,000.

- Salary.com offers a more stratified view based on skill level. Their data shows a "CNC Machine Operator I" earning an average of $46,670, a "CNC Machine Operator II" earning $54,924, and a highly experienced "CNC Machine Operator III" earning an average of $64,305. Their data suggests top earners in this role can reach the high $70,s.

- Glassdoor.com estimates the total pay (including base salary and additional compensation like bonuses) for a CNC Machinist in the United States to be around $62,500 per year, with a "likely range" of $51,000 to $77,000.

These figures paint a consistent picture: a solid middle-class income is readily achievable, with significant upside potential for those who invest in their skills and advance their careers.

### Salary Progression by Experience Level

Your salary as a CNC Machinist will grow in lockstep with your experience and capabilities. The journey from a novice operator to a lead machinist or programmer is marked by clear increases in responsibility and, consequently, compensation.

Here is a typical salary progression you can expect throughout your career, compiled from the sources above:

| Experience Level | Typical Years of Experience | Average Annual Salary Range | Key Responsibilities & Skills |

| :--- | :--- | :--- | :--- |

| Entry-Level / Apprentice | 0-2 Years | $38,000 - $48,000 | Loading/unloading materials, monitoring machine operation, basic quality checks with calipers, deburring parts, shop cleanup, and learning from senior machinists. |

| Mid-Career / CNC Machinist II | 2-7 Years | $49,000 - $65,000 | Performing machine setups, making tool and work offsets, reading and interpreting complex blueprints, minor G-code editing, operating multiple machines simultaneously. |

| Senior / Lead Machinist / CNC Machinist III | 8-15+ Years | $66,000 - $80,000+ | Complex 4/5-axis machine setups, full G-code programming or advanced CAM software proficiency, troubleshooting difficult machining problems, training junior machinists, process improvement. |

| CNC Programmer / Manufacturing Engineer| 10+ Years (Career Advancement)| $75,000 - $110,000+ | Primarily focused on creating CNC programs from scratch using CAM software, designing fixtures, developing manufacturing processes, and optimizing production for efficiency and quality. |

### Beyond the Base Salary: Understanding Total Compensation

Your annual salary is only one piece of the puzzle. The manufacturing industry often provides several avenues for additional income and valuable benefits that contribute to your overall financial well-being.

- Overtime Pay: Manufacturing is often project-driven and subject to tight deadlines. Overtime is common and can significantly boost your income. Paid at 1.5 times your hourly rate (or more), consistent overtime can add 10-25% to your annual earnings.

- Shift Differentials: Many manufacturing facilities operate 24/7. To incentivize employees to work less desirable hours, companies offer a "shift differential"—an increase in your hourly pay for working the second (evening) or third (overnight) shift. This differential can range from an extra $1 to $5 per hour, which can add up to thousands of dollars over a year.

- Bonuses and Profit Sharing: When the company does well, you often do well. Many companies offer annual or quarterly bonuses based on individual, team, or company performance. Profit-sharing plans are also common, where a portion of the company's profits is distributed among employees. According to Glassdoor, the average additional cash compensation for a CNC Machinist is around $7,000 per year, though this varies widely.

- Health and Retirement Benefits: This is a crucial, non-salary part of compensation. Most established manufacturing companies offer competitive benefits packages, including comprehensive health, dental, and vision insurance. Furthermore, 401(k) retirement plans with a company match are standard. A company that matches your 401(k) contributions up to 5% is effectively giving you a 5% raise dedicated to your future.

- Paid Time Off (PTO) and Holidays: Standard benefits include paid vacation time, sick leave, and paid public holidays, all of which contribute to a healthy work-life balance.

When evaluating a job offer, it's essential to look at the total compensation package, not just the base salary. A job with a slightly lower base salary but excellent health benefits, a generous 401(k) match, and regular overtime opportunities might be more lucrative in the long run than a job with a higher base pay but minimal benefits.

Key Factors That Influence Salary

While national averages provide a useful benchmark, your individual earning potential as a CNC Machinist is determined by a specific set of factors. Mastering these elements is the key to unlocking the highest possible salary in this field. This section delves into the six most critical variables that will shape your career and your paycheck.

### 1. Level of Education and Certification

While a four-year university degree is not a prerequisite for becoming a successful CNC machinist, formal training and industry-recognized certifications have a direct and substantial impact on your starting salary and long-term growth.

- High School Diploma / GED: This is the absolute minimum entry point. Individuals starting with only a high school diploma will typically begin in the lowest salary bracket, often in a shop helper or basic operator role, learning entirely on the job. Their initial earning potential might be limited to the $38,000 - $42,000 range.

- Vocational/Technical School Certificate: A 6-to-12-month certificate program from a community college or technical school is a powerful accelerator. These programs provide foundational knowledge in blueprint reading, shop math, safety, and hands-on experience with manual and CNC machines. Graduates can often bypass the most basic entry-level roles and start as a CNC Operator I, commanding a starting salary closer to $45,000 - $50,000.

- Associate's Degree in Machining Technology or Manufacturing: A two-year Associate of Applied Science (A.A.S.) degree provides a much deeper and more comprehensive education. These programs typically include advanced topics like CAM software programming, GD&T, metallurgy, and CMM operation. Graduates are highly sought after and can start at a mid-level machinist salary, often in the $50,000 - $58,000 range, with a much faster track to senior roles.

- Industry Certifications (NIMS): This is perhaps the most crucial differentiator. The National Institute for Metalworking Skills (NIMS) offers a range of nationally recognized, portable credentials. Earning certifications in areas like "Measurement, Materials & Safety," "CNC Milling Operations," or "CNC Turning Programming" provides verifiable proof of your skills to employers. Holding multiple NIMS certifications can add $5,000 or more to your annual salary and makes you a far more competitive candidate. Employers often pay for their existing employees to get certified, and many actively seek out certified individuals.

### 2. Years of Experience and Proven Expertise

In a hands-on trade like machining, there is no substitute for experience. Your salary will grow directly in proportion to the depth and breadth of your practical knowledge.

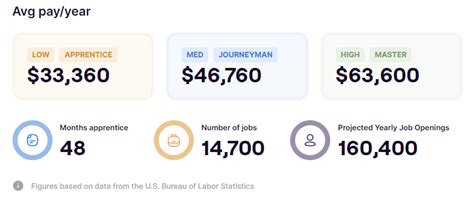

- 0-2 Years (The Apprentice Stage): At this stage, you are primarily learning. You can perform basic tasks but require supervision for complex setups. Your value is in your potential and your ability to learn quickly. Salary: ~$40,000 - $48,000.

- 2-7 Years (The Journeyman Stage): You are now a reliable, independent machinist. You can handle most 2-axis and 3-axis setups on your own, read complex prints, and perform minor program edits. You are a productive and valuable member of the team. Salary: ~$49,000 - $65,000.

- 8-15+ Years (The Master Stage): You are now a subject matter expert. You can set up and operate the most complex machinery, such as 5-axis mills or multi-turret lathes. You can likely program parts from scratch, troubleshoot any production issue, and are looked upon to train and mentor junior machinists. You may hold a title like Lead Machinist, Setup Specialist, or Cell Leader. Salary: ~$66,000 - $80,000+. Machinists at this level who also have strong programming and process development skills can easily exceed $90,000.

### 3. Geographic Location

Where you work has a significant impact on your paycheck, driven by local demand for skilled labor and the cost of living. Salaries can vary by as much as 30-40% between the highest and lowest paying regions in the United States.

High-Paying States and Metropolitan Areas:

These areas typically have a high concentration of aerospace, defense, medical device, or high-tech manufacturing industries.

- Washington: Home to Boeing and a massive aerospace supply chain, cities like Seattle and Everett offer some of the highest wages. Machinists here can expect to earn 15-25% above the national average.

- Massachusetts: A hub for defense contractors and medical device companies, the Boston-Worcester corridor has strong demand. Salaries often range from 10-20% above average.

- California: While the cost of living is high, the sheer scale of manufacturing in tech, aerospace, and defense in areas like Los Angeles and the Bay Area drives competitive wages, often 10-20% above the national median.

- Minnesota: Known for its world-class medical device manufacturing cluster (Medical Alley), the Minneapolis-St. Paul area pays a premium for machinists skilled in producing high-precision components.

- Alaska: Due to its unique economy driven by oil and gas and a very high cost of living, wages for skilled trades, including machinists, are exceptionally high, often exceeding the national average by 25% or more.

Lower-Paying States:

States with a lower cost of living and less concentration of high-tech manufacturing will generally offer salaries closer to or slightly below the national median. These might include states in the Southeast and parts of the Midwest, although skilled machinists are still in demand everywhere.

### 4. Company Type & Size

The type of company you work for will influence not only your salary but also your daily work experience and career trajectory.

- Small, Independent "Job Shops" (1-50 employees): These shops are the backbone of American manufacturing.

- *Pros:* You'll work on a wide variety of parts and projects, learn very quickly, and have a close-knit team environment.

- *Cons:* Pay and benefits may be slightly lower than at large corporations. Technology and equipment might be older.

- *Salary Impact:* Often around the national average, but with more variability.

- Large Corporations / OEMs (Original Equipment Manufacturers): Think companies like General Electric, Ford, Caterpillar, or Lockheed Martin.

- *Pros:* Typically offer higher base salaries, excellent benefits packages (pensions, top-tier health insurance, 401k matching), and structured career advancement paths. They use the latest technology.

- *Cons:* The work can be more specialized and repetitive (e.g., making the same part for years). There is often more bureaucracy and less flexibility.

- *Salary Impact:* Often 10-20% above the national average, with superior benefits.

- Government / Defense Contractors: Working for a government entity or a major defense contractor (e.g., Raytheon, Northrop Grumman) that requires a security clearance.

- *Pros:* Extreme job stability, excellent government benefits, and the opportunity to work on cutting-edge, mission-critical projects.

- *Cons:* The security clearance process can be lengthy, and the work environment can be rigid.

- *Salary Impact:* Very competitive salaries, often matching or exceeding large corporations, to attract and retain cleared personnel.

### 5. Area of Specialization

The term "CNC Machinist" covers a wide range of specializations. Developing expertise in a high-demand, high-value niche is the most reliable way to maximize your earnings.

- General Production Operator: Focuses on running pre-programmed jobs with established setups. This is the entry point for the profession.

- Setup Machinist: Specializes in the critical task of setting up machines for new jobs. This requires a higher level of skill and problem-solving. A good setup machinist is highly valued and earns more than a production operator.

- CNC Programmer: Focuses on writing the code that the machines run, using CAM software. This is a highly skilled, often office-based role that commands a significant salary premium. CNC Programmers often earn $75,000 to $100,000+.

- Industry Specialization: Machining for the aerospace or medical device industries pays significantly more than general commercial fabrication. These fields require working with exotic materials (titanium, Inconel, PEEK), holding extremely tight tolerances, and adhering to strict quality standards (like AS9100 or ISO 13485). A machinist with proven experience in these sectors can command a 15-30% salary premium.

- Machine Specialization (5-Axis Machining): A standard CNC mill has 3 axes (X, Y, Z). A 5-axis machine can move a part or the cutting tool on two additional rotary axes. This allows for the creation of incredibly complex shapes in a single setup. A machinist who can set up, program, and operate a 5-axis machine is in the top tier of the profession and is compensated accordingly.

### 6. In-Demand Skills

Beyond your title, specific, demonstrable skills on your resume will make you stand out and justify a higher salary.

- CAM Software Proficiency: Expertise in software like Mastercam, GibbsCAM, Fusion 360, or Esprit is a game-changer. This moves you from an operator to a programmer and is one of the single biggest salary boosters.

- G-Code and M-Code Fluency: The ability to read, write, and edit G-code directly at the machine controller (without relying on CAM) is a powerful skill. It allows for quick optimization, troubleshooting, and custom macros.

- Controller Expertise: Being an expert on a specific control system, such as Fanuc, Haas, Siemens, or Mazatrol, makes you highly valuable to shops that use that equipment.

- Geometric Dimensioning & Tolerancing (GD&T): This is the symbolic language used on engineering drawings to define the precise form, orientation, and location of features on a part. A deep understanding of GD&T is essential for high-precision work (aerospace, medical) and is a hallmark of a senior-level machinist.

- Metrology and CMM Operation: The ability to use advanced inspection equipment, especially programming and operating a Coordinate Measuring Machine (CMM), adds a quality assurance dimension to your skill set that is highly compensated.

- Lean Manufacturing and Process Improvement: Knowledge of principles like 5S, Kaizen, and Six Sigma shows that you think beyond just making a part; you think about making the entire process more efficient and less wasteful. This is a skill highly valued in leadership roles.

Job Outlook and Career Growth

Investing your time and energy into a career path requires