For anyone who has ever looked up at a soaring passenger jet and felt a spark of fascination, the question isn't just "how does it fly?" but "who keeps it flying?" Behind every on-time departure and safe arrival of a Delta Air Lines flight is a team of highly skilled, dedicated, and well-compensated professionals: the Aviation Maintenance Technicians (AMTs). This career is more than just a job; it's a commitment to safety, precision, and the intricate dance of engineering that underpins modern global travel. If you're considering this path, you're not just looking for a paycheck; you're looking for a purpose. But let's be clear: the paycheck is substantial. A career as a Delta mechanic can lead to earnings well into the six figures, coupled with world-class benefits and unparalleled job security.

I once had the privilege of touring a Delta TechOps facility in Atlanta. Standing in the shadow of a massive Airbus A350, with its engine cowlings open like a giant metallic flower, I spoke with a 30-year veteran AMT. He didn't talk about the glamour of travel; he talked about the deep, personal satisfaction of signing his name in a logbook, a legally binding declaration that the 300-plus souls on board the next flight would be safe because of his work. That conversation solidified for me that this is one of the most vital and rewarding blue-collar professions in the world.

This guide is designed to be your comprehensive flight plan for a career as a Delta Air Lines mechanic. We will dissect every component of the role, from the day-to-day responsibilities to the intricate factors that determine your salary. We will explore the long-term career outlook and provide a step-by-step roadmap on how to get started. Whether you're a high school student dreaming of aviation, a military veteran transitioning to civilian life, or a current mechanic looking to join a major airline, this is your ultimate resource.

### Table of Contents

- [What Does a Delta Air Lines Aviation Maintenance Technician Actually Do?](#what-they-do)

- [Delta Air Lines Mechanic Salary: A Deep Dive into Your Earning Potential](#salary-deep-dive)

- [Key Factors That Influence a Delta Mechanic's Salary](#key-factors)

- [Job Outlook and Career Growth for Aviation Mechanics](#job-outlook)

- [Your Flight Plan: How to Become a Delta Air Lines Mechanic](#how-to-start)

- [Conclusion: Is a Career as a Delta Mechanic Right for You?](#conclusion)

---

What Does a Delta Air Lines Aviation Maintenance Technician Actually Do?

An Aviation Maintenance Technician (AMT), commonly referred to as an aircraft mechanic, is a highly trained professional licensed by the Federal Aviation Administration (FAA). Their core responsibility is to ensure the airworthiness and safety of an aircraft. For a Delta AMT, this means working on one of the world's largest and most modern fleets, from the domestic workhorse Airbus A220 to the long-haul flagship Airbus A350.

The role is far more complex than simply "fixing what's broken." It's a proactive, meticulous, and heavily regulated profession that blends hands-on skill with deep technical knowledge. The work can be broadly categorized into two main areas: line maintenance and base maintenance.

Line Maintenance: This is the fast-paced, "front lines" work you might see happening at the airport gate. Line mechanics are responsible for the aircraft between flights. Their tasks include:

- Pre-flight and Post-flight Inspections: Conducting walk-around inspections to check for visible damage, leaks, or wear on tires, brakes, and control surfaces.

- Routine Servicing: Replenishing hydraulic fluid and engine oil.

- Troubleshooting and Minor Repairs: Addressing pilot-reported issues (squawks) that arise during flight, such as a faulty reading on a gauge or an issue with the cabin's environmental system.

- The "Sign-Off": Ultimately, the line maintenance AMT is responsible for signing the aircraft's logbook, legally clearing it for its next flight. This requires immense confidence and trust in their work.

Base Maintenance (or Heavy Maintenance): This takes place in massive hangars, often at Delta's primary maintenance hub, Delta TechOps in Atlanta. These are longer, more in-depth checks that are scheduled months or even years in advance.

- Letter Checks (A, B, C, D Checks): These are tiered levels of inspection. An "A-Check" might happen every few weeks and take about 10 hours, while a "D-Check" happens every 6-10 years and involves completely stripping the aircraft down to its frame, inspecting every structural component, and essentially rebuilding it. This can take over 50,000 man-hours.

- Major Repairs and Modifications: Performing complex structural repairs, replacing landing gear, installing new cabin interiors, or upgrading avionics systems.

- Engine Overhaul: Working in specialized engine shops to completely disassemble, inspect, repair, and reassemble the massive turbofan engines that power the fleet.

### A "Day in the Life" of a Delta Line Maintenance AMT

> 05:00: The alarm goes off. You're on the early shift today. After a quick coffee, you drive to the employee parking lot at Hartsfield-Jackson Atlanta International Airport (ATL).

>

> 05:45: You badge into the maintenance operations center, change into your uniform, and attend the morning briefing. The lead mechanic outlines the day's flight schedule, known maintenance issues from overnight arrivals, and any specific safety alerts.

>

> 06:15: Your first assignment: Flight 1289, an Airbus A321 arriving from Seattle. The flight crew reported a "slow to respond" flap indicator. You head to the assigned gate with your toolbox.

>

> 06:45: The aircraft taxis in. As passengers deplane, you perform a walk-around, checking tires, brakes, and looking for any fluid leaks or external damage. You then connect your laptop to the aircraft's diagnostic port.

>

> 07:15: After conferring with the flight crew and running diagnostics, you isolate the problem to a faulty sensor in the wing. It's a quick replacement. You head to the parts depot to get a new one.

>

> 08:00: With the new sensor installed, you run a full operational test of the flap system. Everything checks out perfectly. You make a detailed entry in the aircraft's maintenance logbook, documenting the issue, the corrective action, and the part number used. You sign your name and A&P license number—your personal guarantee of a job well done. The aircraft is cleared for its next flight to Boston.

>

> 09:00 - 14:00: The rest of your day involves a mix of scheduled transit checks, responding to other minor squawks, and performing routine servicing on several more aircraft. One flight needs a tire change, another a top-off of hydraulic fluid.

>

> 14:30: Your shift ends. You attend the shift-change briefing, passing on the status of your aircraft to the incoming crew. As you walk back to your car, you see Flight 1289 taking off, and you feel a quiet sense of pride knowing you played a critical role in its safe journey.

---

Delta Air Lines Mechanic Salary: A Deep Dive into Your Earning Potential

The compensation for a Delta Air Lines mechanic is among the best in the industry. It's crucial to understand that salary at a major unionized airline like Delta is not typically negotiated on an individual basis. Instead, it is governed by a collective bargaining agreement between the company and the mechanics' union, the Aircraft Mechanics Fraternal Association (AMFA).

This agreement sets a transparent, predictable pay scale based primarily on one factor: years of service.

### The National Picture: How Delta Stacks Up

First, let's establish a baseline. The U.S. Bureau of Labor Statistics (BLS) reports that the median annual wage for all Aircraft Mechanics and Service Technicians was $70,010 as of May 2022. The top 10% in the profession earned more than $109,240.

However, major airlines like Delta, United, and American, as well as cargo giants like FedEx and UPS, pay significantly above this median. For these top-tier jobs, a six-figure income is not just possible; it is the standard for experienced technicians.

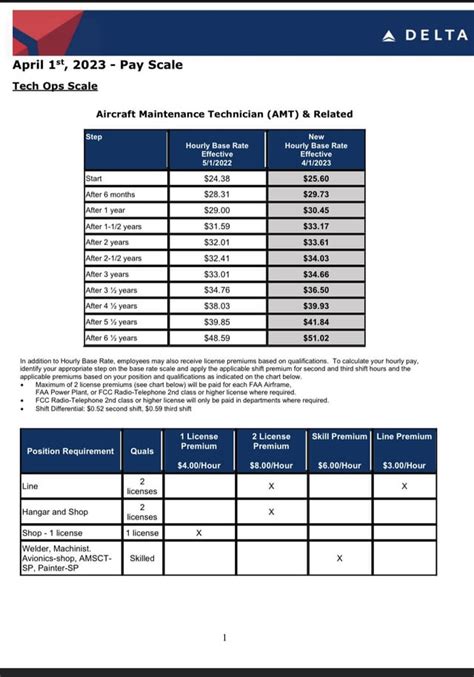

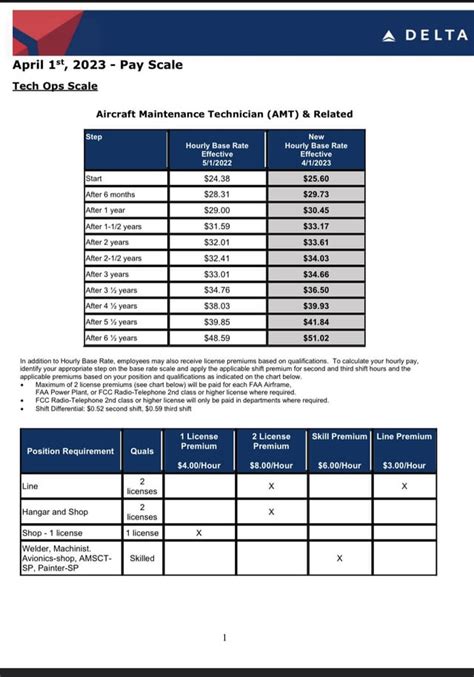

### Delta's Pay Scale: From New Hire to Top-Out

A new hire at Delta, even with a fresh A&P license and some prior experience (e.g., from a regional airline), starts at a specific "probationary" or "first-year" rate. This rate then increases automatically each year until the mechanic reaches the "top of scale" (TOS) wage.

While the exact figures change with each new contract negotiation, we can analyze recent and publicly reported data to build a highly accurate picture. As of the most recent contracts, the progression looks something like this (Note: these are base hourly rates and do not include overtime, premiums, or profit sharing).

| Years of Service | Approximate Hourly Rate | Approximate Annual Salary (Base, 40-hr week) |

| :--- | :--- | :--- |

| New Hire (Probation) | $35.00 - $40.00 | $72,800 - $83,200 |

| Year 1 | $42.00 | $87,360 |

| Year 2 | $45.00 | $93,600 |

| Year 3 | $49.00 | $101,920 |

| Year 4 | $53.00 | $110,240 |

| Year 5 | $57.00 | $118,560 |

| Year 6 (Top of Scale) | ~$63.00+ | ~$131,040+ |

*Sources: Data synthesized from AMFA union contract reports, Glassdoor, and Payscale for Delta Air Lines Aircraft Maintenance Technicians as of late 2023/early 2024.*

It is crucial to note that Top of Scale (TOS) is achieved in approximately 6-7 years. This means that within a relatively short time frame, a dedicated mechanic can reach the highest base pay rate offered by the company.

### Beyond the Base Salary: The Total Compensation Package

The hourly rate is just the beginning. A Delta AMT's total compensation is significantly boosted by several other factors, often adding 20-50% or more to their base salary.

- Overtime: This is the single biggest salary enhancer. Due to the 24/7 nature of airline operations, overtime opportunities are plentiful. Working overtime is typically paid at 1.5x the base rate ("time and a half"), while working on designated holidays can be paid at 2.0x or even 2.5x the base rate. It is not uncommon for top-of-scale mechanics who actively seek overtime to earn $180,000 - $220,000+ per year.

- Profit Sharing: Delta is famous for its generous profit-sharing program. Every year, the company distributes a portion of its profits to its employees. In strong years, this has resulted in a bonus equivalent to 10-20% of an employee's annual earnings. For a TOS mechanic earning a base of $131,000, a 15% profit-sharing bonus would be an additional $19,650.

- License Premiums: Holding specific licenses adds a small hourly premium to your pay.

- A&P License Premium: An additional amount (e.g., $1.75/hour) for holding the required Airframe & Powerplant license.

- FCC License Premium: Avionics technicians who hold a General Radiotelephone Operator License (GROL) from the FCC receive an additional premium.

- Shift Differential: Mechanics who work undesirable shifts (afternoons, midnights, weekends) receive an hourly pay differential, which can add a few thousand dollars to their annual income.

- Lead/Crew Chief Premium: Mechanics who step into a lead role, responsible for a small team and signing off on group work, receive a significant hourly premium for their added responsibility.

- World-Class Benefits:

- Health Insurance: Comprehensive medical, dental, and vision plans for employees and their families.

- Retirement: A robust 401(k) plan with a generous company match.

- Flight Benefits: One of the most famous perks. Employees and their eligible family members can fly for free (on a standby basis) on Delta flights anywhere in the world. They also have access to discounted fares on partner airlines.

- Paid Time Off: Generous vacation, holiday, and sick leave policies.

When you combine a top-of-scale base salary with significant overtime, a healthy profit-sharing bonus, and license premiums, the true earning potential for a senior Delta mechanic is well over $200,000 per year, making it one of the most lucrative skilled-trade careers available.

---

Key Factors That Influence a Delta Mechanic's Salary

While the union pay scale creates a standardized path, several key factors determine not just your starting point but also your ultimate earning potential and career trajectory within Delta's ecosystem. Understanding these factors is crucial for maximizing your income.

### `

` Level of Education and Certification: The A&P License is King

In this profession, traditional academic degrees (like a Bachelor's) have little to no direct impact on the pay scale. The single most important credential is the FAA Airframe and Powerplant (A&P) License. You cannot be an aircraft mechanic without it.

- A&P License: This is the foundational requirement. Obtaining it proves to the FAA and to employers that you have the knowledge and skill to work on aircraft structures (Airframe) and engines (Powerplant). There is no "higher" version of this core license.

- Specialized Certifications: While they may not all come with a direct pay premium like the A&P license, advanced certifications make you a more valuable and versatile technician, opening doors to specialized roles or making you a more attractive candidate for overtime or promotions. These include:

- Avionics and FCC License: As mentioned, the FCC General Radiotelephone Operator License (GROL) is essential for avionics technicians and comes with a pay premium. Deep expertise in troubleshooting complex electrical and navigation systems is highly sought after.

- Aircraft Type Ratings: Some mechanics pursue formal training and certification on specific aircraft models (e.g., A350, B777). While Delta provides this training, having prior experience or ratings on their fleet types can be a significant advantage when applying.

- Composite Repair Certification: Modern aircraft like the A350 and B787 use extensive composite materials. Technicians certified in advanced composite inspection and repair are incredibly valuable.

- Welding and Non-Destructive Testing (NDT): NDT technicians use methods like ultrasonic, eddy current, and x-ray inspections to find flaws in metal structures without taking them apart. These are highly specialized, well-compensated roles.

### `

` Years of Experience: The Union Scale is Your Roadmap

This is the most straightforward factor at a major airline. Unlike in a corporate office where you might negotiate a raise based on performance, your base pay as a Delta mechanic is almost exclusively determined by your seniority.

- Entry-Level (0-2 Years at Delta): You start at the bottom of the pay scale, but the annual raises are steep and automatic. The primary focus during this period is learning the company's procedures, the specifics of the fleet, and proving your competence.

- Mid-Career (3-6 Years at Delta): You are rapidly ascending the pay scale, reaching the top-out rate around year six or seven. Your annual base salary will cross the $100,000 mark during this phase. You are now a fully proficient and trusted member of the team.

- Senior/Top-of-Scale (7+ Years at Delta): You are earning the highest base hourly rate. Your income growth from this point comes not from base pay increases (which will now only come with new union contracts) but from overtime, shift selection, profit sharing, and moving into lead or management roles. Seniority also gives you priority in bidding for shifts, vacation time, and desirable work assignments.

### `

` Geographic Location: It's All About the Hubs

For a Delta mechanic, the union pay scale is national. A top-of-scale mechanic in Atlanta, GA, makes the same base hourly rate as one in Los Angeles, CA. However, location is still a massive factor for two reasons: opportunity and cost of living.

Delta's maintenance operations are concentrated at its major hubs and maintenance bases. This is where the jobs are.

High Opportunity / High Cost-of-Living Hubs:

- Atlanta (ATL): Delta's world headquarters and largest hub. Home to the massive Delta TechOps maintenance facility. The greatest number of jobs and overtime opportunities are here.

- Detroit (DTW), Minneapolis-St. Paul (MSP), Salt Lake City (SLC): Major hubs with significant maintenance facilities and many job opportunities.

- Los Angeles (LAX), Seattle (SEA), New York (JFK/LGA): Major coastal hubs. While there are many line maintenance jobs, the cost of living in these cities is extremely high, which can significantly impact the real value of your salary.

Lower Cost-of-Living Considerations:

Living in a city like Atlanta or Detroit allows a mechanic's salary to go much further than in New York or Los Angeles. A $150,000 salary provides a very different lifestyle in Georgia than it does in Southern California. Therefore, while the *pay* is the same, the *financial outcome* can vary dramatically by location. Aspiring mechanics must weigh the job opportunities at a given hub against its cost of living.

### `

` Company Type & Size: Why Majors Reign Supreme

Where you work in the aviation industry has the largest impact on your salary ceiling. A&P mechanics are needed everywhere, but the pay structures differ vastly.

| Company Type | Typical Starting Pay | Top Pay Potential | Key Characteristics |

| :--- | :--- | :--- | :--- |

| Major Airlines (Delta, United, American) | High | Highest ($130k+ base, $200k+ total) | Unionized, strict pay scale, incredible benefits, profit sharing, flight perks, high competition for jobs. |

| Major Cargo Carriers (FedEx, UPS) | Highest | Highest+ ($135k+ base, $220k+ total) | Unionized, often the industry pay leaders, demanding night-sort schedules, fewer passenger flight perks. |

| Regional Airlines (SkyWest, Endeavor Air) | Low | Moderate ($70k - $90k) | The "minor leagues." Excellent place to gain experience on jet aircraft right out of school. Lower pay and benefits. Many mechanics start here and move to a major after 2-5 years. |

| MROs (Maintenance, Repair, Overhaul) | Moderate | High ($60k - $110k+) | Non-airline facilities that perform contract maintenance. Pay can be very good but often lacks the benefits, job security, and profit sharing of a major airline. Can be non-union. |

| General Aviation / Corporate Jets | Variable | Variable ($60k - $120k+) | Working on smaller private or corporate aircraft. Pay depends heavily on the wealth of the aircraft owner or flight department. Less structured, but can offer a better work-life balance. |

For those aiming for the highest possible earnings, the path is clear: gain experience at a regional or MRO, then apply to a major passenger or cargo airline.

### `

` Area of Specialization within Delta

Within Delta's vast maintenance operation, there are specialized roles that can enhance your career path, though not always with a direct pay premium (outside of Avionics). The specialization is more about work style, environment, and future opportunities.

- Line Maintenance: Ideal for those who enjoy a fast-paced, problem-solving environment and the satisfaction of seeing an immediate result.

- Hangar/Base Maintenance: Suited for mechanics who prefer long-term, in-depth projects and a more predictable schedule.

- Avionics: A high-tech field for those with a passion for electronics, computers, and troubleshooting. Requires an FCC license and comes with a pay premium. These technicians are in extremely high demand.

- Engine Shop: A highly specialized and respected field. You become an expert on the most expensive and complex component of the aircraft.

- Support Shops: Roles in sheet metal, composite repair, welding, and NDT. These are craft-based specializations that require incredible precision and skill.

### `

` In-Demand Skills to Maximize Your Earnings

At Delta, maximizing your salary isn't about negotiating—it's about positioning yourself to earn more within the existing structure.

1. Embrace Overtime: The #1 way to significantly boost your income. Be the person who volunteers for extra shifts, especially on holidays.

2. Get Additional Qualifications: Pursue qualifications that allow you to do more. This includes:

- Run/Taxi Qualification: Certified to run engines and taxi aircraft on the airfield. This comes with great responsibility and is a key step toward lead roles.

- ETOPS Qualification: Certified to sign off on aircraft designated for Extended-range Twin-engine Operational Performance Standards (ETOPS) flights, such as transatlantic routes.

3. Specialize in Avionics: The increasing complexity of modern aircraft means avionics specialists are more critical than ever.

4. Develop Leadership Skills: Aim for a Lead AMT or Crew Chief position. The added responsibility comes with a significant hourly pay bump.

5. Master the New Fleet: Become an expert on Delta's newest and most technologically advanced aircraft, like the A350 and A220. Your expertise will be in high demand.

---

Job Outlook and Career Growth for Aviation Mechanics

The future for aspiring and current Aviation Maintenance Technicians is exceptionally bright. The industry is facing a "perfect storm" of factors that are creating immense demand and driving up wages and benefits across the board.

According to the U.S. Bureau of Labor Statistics (BLS) Occupational Outlook Handbook, employment for aircraft and avionics equipment mechanics and technicians is projected to grow, with robust demand over the next decade. The BLS projects about 12,500 openings for these technicians each year, on average, from 2