Introduction

In a world where you can order a product online and have it on your doorstep the next day, it’s easy to take for granted the intricate, high-stakes ballet of global logistics that makes it happen. But for the professionals who orchestrate this dance—the Directors of Supply Chain—it's a world of immense challenge, strategic importance, and significant financial reward. If you are an ambitious professional with a talent for strategy, negotiation, and leadership, a career as a Director of Supply Chain could be your path to a highly impactful and lucrative future. The director of supply chain salary not only reflects the critical nature of the role but also its potential as a launchpad to executive leadership. On average, these professionals command salaries well into the six figures, often ranging from $140,000 to over $250,000 annually, with top earners in major corporations exceeding that significantly.

I once consulted for a mid-sized electronics company that was on the verge of missing a massive holiday season order due to a sudden port closure halfway across the world. It was their new Director of Supply Chain who, in a matter of 72 hours, re-routed a hundred containers via air freight and alternative sea lanes, negotiating with three new logistics partners in the process. She not only saved the quarter but solidified the company's reputation for reliability, proving that a brilliant supply chain leader isn't a cost center—they are a powerful engine for growth and resilience.

This guide is designed to be your definitive resource, whether you are a student mapping out your future, a manager aiming for the next level, or a professional considering a career change. We will dissect every facet of the director of supply chain salary, explore the factors that drive it, and lay out the strategic roadmap you need to follow to achieve this prestigious role.

### Table of Contents

- [What Does a Director of Supply Chain Do?](#what-does-a-director-of-supply-chain-do)

- [Average Director of Supply Chain Salary: A Deep Dive](#average-director-of-supply-chain-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

---

What Does a Director of Supply Chain Do?

A Director of Supply Chain is far more than just a manager of trucks and warehouses. They are the strategic architects of a company's entire physical and information flow, from the procurement of raw materials to the final delivery of a product to the customer. Their primary objective is to create a supply chain that is efficient, cost-effective, resilient, and responsive to market demands. This requires a unique blend of analytical prowess, leadership acumen, and strategic foresight.

The role operates at the intersection of operations, finance, and customer service. A Director of Supply Chain is ultimately responsible for ensuring that the right products are in the right place, at the right time, and at the right cost.

Core Responsibilities and Daily Tasks:

- Strategic Planning: Designing and implementing the overall supply chain strategy to align with the company's business goals. This includes decisions on sourcing, manufacturing locations, inventory levels, and transportation networks.

- Team Leadership and Development: Managing and mentoring a team of supply chain professionals, including procurement managers, logistics coordinators, warehouse managers, and demand planners. They set performance goals, provide training, and foster a culture of continuous improvement.

- Vendor and Supplier Management: Identifying, vetting, and negotiating contracts with suppliers, manufacturers, and logistics partners (3PLs). They are responsible for building strong relationships and ensuring vendor performance meets quality, cost, and delivery standards.

- Inventory Optimization: Overseeing inventory management to minimize holding costs while preventing stockouts. This involves sophisticated forecasting, demand planning, and implementing systems like Just-In-Time (JIT) or Safety Stock strategies.

- Logistics and Distribution Oversight: Managing the entire transportation and distribution network, including freight, warehousing, and final-mile delivery. They work to optimize routes, reduce transit times, and lower shipping costs.

- Budgeting and Cost Control: Developing and managing the supply chain department's budget. They constantly analyze costs and identify opportunities for efficiency gains and cost reduction without sacrificing quality or speed.

- Risk Management and Resilience: Identifying potential risks in the supply chain (e.g., geopolitical instability, natural disasters, supplier bankruptcy) and developing contingency plans to mitigate their impact. This has become a paramount responsibility in the post-pandemic era.

- Technology and Systems Integration: Overseeing the use of supply chain management (SCM) software, Enterprise Resource Planning (ERP) systems, and data analytics tools to improve visibility, tracking, and decision-making.

### A "Day in the Life" of a Supply Chain Director

To make this more tangible, here’s what a typical day might look like:

- 8:00 AM: Arrive and review the overnight logistics dashboard. Check for any critical alerts: a delayed shipment from Asia, a warehouse reporting low stock on a key product, or an urgent request from sales.

- 8:30 AM: Lead a daily operational huddle with direct reports (logistics, procurement, planning managers). Discuss yesterday's performance metrics, address the morning's critical alerts, and align on priorities for the day.

- 10:00 AM: Conference call with a key supplier in Europe to negotiate terms for the next fiscal year's raw material contract. The goal is to secure a 5% cost reduction while improving delivery lead times.

- 11:30 AM: Meet with the IT department to review the progress of a new Warehouse Management System (WMS) implementation. Discuss potential roadblocks and user adoption strategies.

- 1:00 PM: Lunch while reviewing an industry report on rising fuel costs and their projected impact on the freight budget for the second half of the year.

- 2:00 PM: Present the quarterly supply chain performance review to the executive team (CEO, COO, CFO). Highlight key wins (e.g., reduced inventory carrying costs by 12%), explain challenges (e.g., port congestion on the West Coast), and present the strategic plan for the next quarter.

- 4:00 PM: One-on-one coaching session with the new Demand Planning Manager to help them develop their forecasting models.

- 5:00 PM: Respond to emails, approve purchase orders over a certain threshold, and create a preliminary agenda for a risk assessment workshop planned for next week.

- 6:00 PM: Final check of the dashboard before heading home, confident that the day's challenges have been met and the team is positioned for success tomorrow.

---

Average Director of Supply Chain Salary: A Deep Dive

The director of supply chain salary is a reflection of the role's immense responsibility and direct impact on a company's profitability. Compensation for this senior-level position is substantial and multifaceted, often including a competitive base salary supplemented by significant variable pay.

### National Averages and Salary Ranges

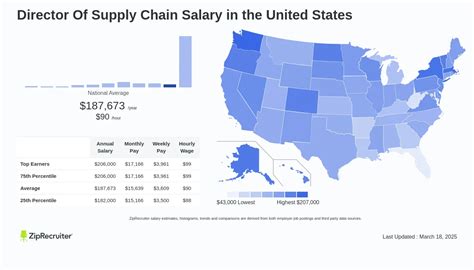

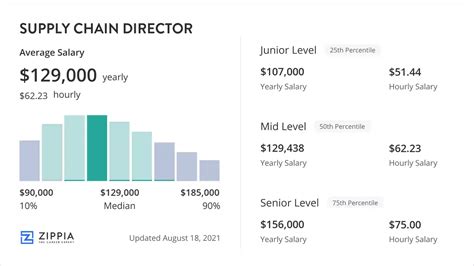

While figures vary based on the data aggregator, a clear and consistent picture emerges. As of late 2023 and early 2024, the data points to a strong six-figure income.

- Salary.com reports the median base salary for a Supply Chain Director in the United States is approximately $165,861. The typical salary range falls between $145,584 and $188,895. However, this range represents the core middle of the market.

- Glassdoor, which incorporates user-submitted data, reports a slightly higher total pay estimate. The average total pay (including bonuses and additional compensation) for a Director of Supply Chain is around $178,000 per year, with a likely range between $139,000 and $236,000.

- Payscale provides a median base salary of $135,000, but shows that total pay, once bonuses and profit sharing are included, can push the upper end well over $200,000.

It's crucial to understand these figures as a national benchmark. As we will explore in the next section, factors like experience, location, and company size can cause these numbers to swing dramatically. An experienced director at a Fortune 100 company in a high-cost-of-living area could easily earn a base salary exceeding $220,000, with total compensation approaching or surpassing $300,000.

### Salary Progression by Experience Level

The journey to a director-level salary is a progressive climb. Here is a typical trajectory, illustrating how compensation grows with increasing responsibility.

| Experience Level | Typical Title(s) | Typical Base Salary Range | Key Responsibilities |

| :--- | :--- | :--- | :--- |

| Early Career (0-5 Years) | Supply Chain Analyst, Logistics Coordinator, Buyer | $60,000 - $85,000 | Data analysis, tracking shipments, processing purchase orders, supporting managers. |

| Mid-Career (5-10 Years) | Supply Chain Manager, Logistics Manager, Procurement Manager | $90,000 - $130,000 | Managing a specific function (e.g., warehousing, transportation), leading a small team, managing smaller budgets and vendor relationships. |

| Senior/Director Level (10+ Years) | Director of Supply Chain, Senior Supply Chain Manager | $140,000 - $220,000+ | Overall strategic oversight of the entire supply chain, managing multiple teams and functions, significant budget control, executive reporting. |

| Executive Level (15+ Years) | VP of Supply Chain, Chief Supply Chain Officer (CSCO) | $220,000 - $400,000+ | Setting global supply chain vision, member of the C-suite, direct influence on corporate strategy, managing a global organization. |

*(Source: Data compiled and synthesized from Salary.com, Glassdoor, and industry observations.)*

### Beyond the Base Salary: Understanding Total Compensation

A Director of Supply Chain's earnings are rarely limited to their base salary. A significant portion of their compensation package is often variable and tied to performance—both personal and company-wide.

- Annual Bonuses: This is the most common form of additional cash compensation. Bonuses are typically tied to Key Performance Indicators (KPIs) such as:

- Cost savings achieved (e.g., reducing freight spend by 7%).

- Inventory accuracy and turn rates.

- On-Time In-Full (OTIF) delivery metrics.

- Supplier performance improvements.

These bonuses can range from 15% to 35% of the base salary, and sometimes even higher in exceptional years. For a director with a $170,000 base salary, this could mean an additional $25,500 to $59,500 in annual cash.

- Profit Sharing: Some companies, particularly in manufacturing and retail, offer a profit-sharing plan where a portion of the company's annual profits is distributed among employees. As a senior leader, a director would receive a significant share of this pool.

- Stock Options and Restricted Stock Units (RSUs): In publicly traded companies, equity is a major component of executive compensation. Directors are often granted stock options (the right to buy company stock at a predetermined price) or RSUs (shares of company stock that vest over time). This long-term incentive (LTI) aligns the director's financial interests with the long-term health and stock performance of the company and can be extremely lucrative.

- Comprehensive Benefits: Beyond direct compensation, the package for a director-level role is typically robust and includes:

- Premium health, dental, and vision insurance plans.

- Generous 401(k) or other retirement plans with a high percentage of company matching.

- Significant paid time off (PTO) and holidays.

- Company car allowance or vehicle.

- Life and disability insurance.

- Executive-level professional development and coaching allowances.

When evaluating a job offer, it is essential to look at the Total Compensation Package, not just the base salary. A lower base salary with an outstanding bonus structure and equity grants in a high-growth company could ultimately be far more valuable than a higher base salary with limited upside.

---

Key Factors That Influence Salary

The national averages provide a solid baseline, but the actual director of supply chain salary you can command is influenced by a powerful combination of factors. Mastering and strategically leveraging these elements is the key to maximizing your earning potential throughout your career. This is the most critical section for understanding how to move from an average earner to a top-tier professional.

###

1. Level of Education and Certifications

Your educational foundation is the launching pad for your supply chain career. While experience eventually becomes the dominant factor, the right academic credentials can open doors and accelerate your initial trajectory.

- Bachelor's Degree: A bachelor's degree is the standard minimum requirement for a professional supply chain role. Degrees in Supply Chain Management, Logistics, Business Administration, or Industrial Engineering are most common and highly relevant. They provide the fundamental knowledge of operations, finance, and management necessary for the field.

- Master's Degree (MBA, MS SCM): Earning a master's degree, particularly a Master of Business Administration (MBA) or a specialized Master of Science in Supply Chain Management (MS SCM), can provide a significant salary boost and is often a preferred qualification for director-level roles at larger corporations. An MBA equips you with a broader strategic business perspective, covering finance, marketing, and leadership, which is invaluable for a director who must interact with all parts of the organization. A specialized MS SCM offers deep, technical expertise in areas like global logistics, risk modeling, and lean methodologies. Professionals with a master's degree often command a 10-20% salary premium over those with only a bachelor's degree, according to various university career reports.

- Professional Certifications: In the world of supply chain, certifications are not just resume-builders; they are respected credentials that validate your expertise and commitment to the profession. Holding one or more of these can directly lead to higher salary offers and promotions. Key certifications include:

- Certified Supply Chain Professional (CSCP) from ASCM (APICS): This is arguably the most recognized certification, covering the end-to-end global supply chain. It signals a high level of strategic knowledge and is highly sought after for director roles.

- Certified in Logistics, Transportation and Distribution (CLTD) from ASCM (APICS): This focuses on the logistics and distribution side of the chain, ideal for roles in transportation-heavy industries.

- Certified Professional in Supply Management (CPSM) from ISM: This certification is heavily focused on the procurement and sourcing aspects of supply chain management.

- Project Management Professional (PMP): While not specific to supply chain, the PMP is incredibly valuable as directors frequently lead large-scale, complex projects like implementing new software or opening a new distribution center.

###

2. Years and Quality of Experience

Experience is, without a doubt, the single most significant factor in determining a director's salary. However, it's not just about the number of years on your resume; it's about the quality, scope, and impact of that experience.

- 5-7 Years (The Manager Path): Professionals in this range are typically in a Supply Chain Manager role. They have proven they can manage a specific function and a small team. Their salary reflects this competence, usually falling in the $90,000 to $130,000 range. To advance, they need to seek out cross-functional projects and demonstrate leadership beyond their immediate team.

- 8-12 Years (The Senior Manager / New Director Path): This is the sweet spot for transitioning into a director role. By this point, a professional should have a track record of successful projects, significant cost savings, and leadership of multiple functions or larger teams. Their first director role might start in the $140,000 to $160,000 range at a mid-sized company.

- 12-15+ Years (The Seasoned Director): A director with over a decade of experience, particularly with a history of managing complex, global supply chains and leading large-scale transformations, is in high demand. They command salaries at the top end of the spectrum, from $170,000 to $250,000+. Their value is in their strategic foresight, their ability to manage crises, and their deep network of industry contacts.

- VP/CSCO Level (15+ Years): The most experienced and successful directors are on a clear path to Vice President of Supply Chain or even Chief Supply Chain Officer (CSCO). At this level, they are part of the executive leadership team, and their compensation package, heavily weighted with equity and long-term incentives, can easily reach $300,000 to $500,000 or more.

###

3. Geographic Location

Where you work has a massive impact on your paycheck. Salaries are adjusted for the local cost of living and the concentration of corporate headquarters and major logistics hubs.

- Top-Tier Metropolitan Areas: Major cities with high costs of living and a high density of large corporations offer the highest salaries. These are often hubs for tech, international trade, or manufacturing.

- San Jose/San Francisco Bay Area, CA: Highest salaries, driven by the tech industry's complex global supply chains. A director here can expect to earn 20-35% above the national average.

- New York, NY: A hub for finance, retail, and international CPG companies. Salaries are typically 15-25% above average.

- Seattle, WA: Home to giants like Amazon and Microsoft, creating intense demand for top supply chain talent. Salaries are also 15-25% above average.

- Boston, MA: Strong in biotech, medical devices, and technology.

- Major Logistics Hubs: Cities that are critical nodes in the national supply chain network also offer competitive salaries.

- Chicago, IL: A central rail and trucking hub.

- Atlanta, GA: A major distribution hub for the Southeast.

- Dallas-Fort Worth, TX: A booming logistics and e-commerce fulfillment center.

Salaries in these cities are often 5-15% above the national average.

- Lower-Cost States: States in the Midwest and Southeast with lower costs of living will naturally have lower base salaries, though the purchasing power may be comparable. A director role in a city like Omaha, NE, or Birmingham, AL, might pay closer to the lower end of the national range, around $130,000 - $150,000.

*(Source: Data trends observed from location-based salary calculators on Salary.com and Payscale.)*

###

4. Company Type, Size, and Industry

The type of company you work for is a huge variable.

- Fortune 500/Large Corporations: These companies have the most complex—and often global—supply chains. They pay top dollar for experienced directors who can manage this scale and complexity. Expect salaries at the highest end of the range ($180,000 - $250,000+), with robust bonus structures and excellent benefits. Industries like pharmaceuticals, automotive, technology, and consumer packaged goods (CPG) are known for being top payers.

- Mid-Sized Companies ($50M - $2B in revenue): This is a common environment for many supply chain directors. The roles offer significant responsibility, often with a broader scope than at a larger company. Salaries are very competitive, typically falling squarely within the national median range ($150,000 - $180,000).

- Startups/High-Growth Tech: Startups, especially in e-commerce or hard-tech, present a different kind of package. The base salary might be slightly lower than at an established corporation, perhaps in the $140,000 - $170,000 range. However, the major draw is equity (stock options). If the startup succeeds, this equity can be worth far more than any salary difference, offering a high-risk, high-reward proposition.

- Public Sector/Non-Profit: Government agencies (e.g., Department of Defense, FEMA) and large non-profits (e.g., global aid organizations) require sophisticated supply chain management. While the base salaries are generally lower than in the private sector, they offer unparalleled job security, excellent government benefits, and a strong sense of mission.

###

5. Area of Specialization

Within supply chain management, certain specializations are in higher demand and can command premium pay. A director with deep expertise in a critical area is a highly valuable asset.

- Global Sourcing and Procurement: Directors who are expert negotiators and can build resilient, cost-effective global supplier networks are always in demand.

- Supply Chain Analytics and Technology: Professionals who can leverage data, AI, and machine learning to model, predict, and optimize the supply chain are at the forefront of the industry. This is one of the fastest-growing and highest-paid specializations.

- E-commerce and Omni-Channel Fulfillment: The explosion of e-commerce has created immense demand for directors who can design and manage fast, accurate, and cost-effective direct-to-consumer fulfillment networks.

- Cold Chain Logistics: Highly specialized and regulated, this involves managing temperature-sensitive supply chains for food and pharmaceutical products. The expertise required commands a significant salary premium.

- Sustainability and Green Supply Chains: As companies face increasing pressure from consumers and regulators, directors who can design and implement environmentally sustainable and ethical supply chains are becoming increasingly valuable.

###

6. In-Demand Skills

Finally, your specific skill set can differentiate you from other candidates and justify a higher salary.

- Hard Skills (The "What you can do"):

- ERP/SCM Software Proficiency: Deep knowledge of major systems like SAP S/4HANA, Oracle NetSuite, or Blue Yonder is often a prerequisite.

- Data Analysis & Visualization: The ability to not just read data but to analyze it and communicate insights using tools like Tableau, Power BI, and advanced Excel is non-negotiable. Knowledge of SQL is a significant plus.

- Financial Acumen: A director must understand P&L statements, be able to build a business case for capital expenditures, and manage a multi-million dollar budget.

- Lean/Six Sigma Methodologies: A proven ability to use these frameworks to drive process improvement and eliminate waste is highly valued.

- Soft Skills (The "How you do it"):

- Strategic Thinking: The ability to see the big picture and design a supply chain that supports the company's goals three to five years out.

- Negotiation and Influence: Securing favorable terms with suppliers and logistics partners can save a company millions of dollars.

- Leadership and Team Building: A director's success is dependent on the performance of their team. The ability to hire, mentor, and inspire is crucial.

- Crisis Management: When disruption hits—a pandemic, a port strike, a natural disaster—the director must be a calm, decisive leader who can navigate the company through the chaos. This skill alone is worth a premium.

---

Job Outlook and Career Growth

Investing time and effort into a career path requires a clear understanding of its future prospects. For aspiring Supply Chain Directors, the outlook is exceptionally positive, driven by global economic trends, technological advancements, and a newfound appreciation for the strategic importance of supply chain management.

### Strong Projected Job Growth

The U.S. Bureau of Labor Statistics (BLS) provides authoritative data on job outlooks. While there isn't a direct category for "Director of Supply Chain," the most relevant and closely aligned role is "Transportation, Storage, and Distribution Managers."

According to the latest BLS Occupational Outlook Handbook (updated September 2023), employment for this group is projected to grow 11 percent from 2022 to 2032. This is much faster than the average for all occupations, which is 3 percent.

This growth is expected to result in about 18,500 job openings each year, on average, over the decade. These openings are anticipated to arise not only from new job creation but also from the need to replace workers who transfer to different occupations or exit the labor force, such as to retire. This robust demand ensures a competitive job market for qualified professionals, which in turn helps to support strong salary growth.

The BLS directly attributes this growth to the overall expansion of the economy and the continued rise of e-commerce. As companies need to move more goods, they require skilled managers and directors to organize and run these complex logistics networks efficiently and effectively.

### Emerging Trends and Future Challenges

The role of a Supply Chain Director is not static; it is constantly evolving. Staying ahead of these trends is crucial for long-term career success and for commanding a top-tier salary.

- Digital Transformation (Supply Chain 4.0): The industry is undergoing a massive technological shift. Directors of the future must be fluent in:

- Internet of Things (IoT): Using sensors to provide real-time tracking and condition monitoring for shipments and inventory.

- Artificial Intelligence (AI) and Machine Learning (ML): Leveraging predictive analytics for more accurate demand forecasting, route optimization, and preventative maintenance.

- Blockchain: Exploring its potential for providing a secure, transparent, and immutable record of transactions across the supply chain.

- Robotics and Automation: Overseeing the implementation of automated storage and retrieval systems (AS/RS) in warehouses and robotic process automation (RPA) for administrative tasks.

- Focus on Resilience and Agility: The COVID-19 pandemic was a brutal lesson in the fragility of lean, globalized supply chains. The new mandate is to build resilient supply chains that can withstand shocks. This involves a shift away from pure cost-efficiency towards strategies like:

- Dual-sourcing and diversifying the supplier base to avoid over-