Introduction

In the intricate, humming heart of modern industry—from sprawling automated warehouses to sterile semiconductor fabrication plants—exists a critical and often unsung hero: the electromechanical technician. If you're drawn to the elegant intersection of electrical circuits and mechanical machinery, and you find satisfaction in diagnosing and solving complex, tangible problems, then a career as an electromechanical technician could be your calling. This isn't just a job; it's a role that places you at the very core of the technological revolution, ensuring the systems that power our world run flawlessly.

But beyond the intellectual satisfaction lies a crucial question for anyone considering this path: What is the real earning potential? A career needs to be both fulfilling and financially rewarding. The good news is that the demand for skilled electromechanical technicians translates directly into a competitive salary and robust career prospects. Nationally, the median salary for these professionals hovers around $67,830 per year, with seasoned experts in high-demand industries earning well over $95,000 annually.

I once had the opportunity to tour a state-of-the-art electric vehicle manufacturing facility. I was mesmerized by the ballet of robotic arms and the seamless flow of the assembly line. Suddenly, an alarm blared, and a critical section ground to a halt. Within minutes, a technician was on the scene, laptop in one hand and a multimeter in the other, methodically diagnosing the issue. She was the calm in the storm, the human intelligence directing the automated beast. In that moment, I saw firsthand that these technicians aren't just "fixers"; they are the indispensable guardians of modern productivity.

This comprehensive guide is designed to be your definitive resource on the electromechanical technician salary and career path. We will dissect every factor that influences your pay, explore the job outlook, and provide a clear, step-by-step roadmap to help you launch or advance your career in this dynamic field.

### Table of Contents

- [What Does an Electromechanical Technician Do?](#what-does-an-electromechanical-technician-do)

- [Average Electromechanical Technician Salary: A Deep Dive](#average-electromechanical-technician-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

What Does an Electromechanical Technician Do?

An electromechanical technician, sometimes called a mechatronics technician, is a specialized professional who operates, tests, maintains, and calibrates unmanned, automated, robotic, or electromechanical equipment. They are the essential bridge between the world of mechanics (gears, levers, pneumatics, hydraulics) and the world of electronics (circuits, controls, sensors, computer programming). Where one system ends and the other begins, the electromechanical technician thrives.

Their primary objective is to ensure that complex machinery and automation systems operate safely, efficiently, and reliably. They are expert problem-solvers, combining the hands-on skills of a mechanic with the diagnostic and analytical mind of an electronics technician. Their work prevents costly downtime in manufacturing, ensures precision in scientific research, and keeps the wheels of logistics turning.

Core Responsibilities and Daily Tasks:

The day-to-day duties of an electromechanical technician are varied and dynamic. They rarely have a "boring" day. Key responsibilities include:

- Installation and Commissioning: Setting up new automated equipment, connecting electrical wiring, installing sensors, and ensuring all mechanical components are aligned and functioning correctly before the system goes live.

- Preventive Maintenance: Performing scheduled checks, lubrication, cleaning, and calibration on machinery to prevent failures before they happen. This is a proactive and critical part of the role.

- Troubleshooting and Repair: This is the reactive heart of the job. When a machine malfunctions, they use diagnostic tools like multimeters, oscilloscopes, and PLC (Programmable Logic Controller) software to identify the root cause—be it a faulty sensor, a frayed wire, a jammed gear, or a software glitch—and perform the necessary repairs.

- Testing and Analysis: Running diagnostic programs and tests to evaluate the performance of equipment, often documenting the results and making recommendations for improvements.

- Reading and Interpreting Schematics: De-coding complex blueprints, electrical diagrams, and technical manuals to understand how a system is supposed to work and to guide their maintenance and repair efforts.

- Collaboration: Working closely with engineers, machine operators, and plant managers to discuss system performance, schedule maintenance, and collaborate on upgrades or modifications.

- Documentation: Meticulously logging all maintenance activities, repairs, and part replacements. This data is crucial for tracking equipment history, managing inventory, and ensuring compliance with safety regulations.

### A Day in the Life: Maria, a Technician at an Automated Distribution Center

- 7:00 AM: Maria arrives, clocks in, and attends the morning huddle with the maintenance team and shift supervisors. They review the previous shift's report. A specific sorter on Conveyor Line 7 was reporting intermittent faults overnight. This becomes her top priority.

- 7:30 AM: She heads to Line 7. Instead of just replacing the sensor that faulted, she first connects her laptop to the line's PLC. She analyzes the fault logs and notices the sensor is failing at the exact moment a high-torque motor engages upstream.

- 9:00 AM: Her diagnostic hunch is that an electrical noise or voltage sag from the motor is interfering with the sensor's signal. Using an oscilloscope, she confirms a significant voltage fluctuation when the motor starts. This is the root cause.

- 10:30 AM: After following safety lockout/tagout procedures to de-energize the equipment, she installs a signal conditioner and better shielding on the sensor's communication cable. She also inspects the motor's power connections for any signs of wear.

- 12:00 PM: Lunch break.

- 12:30 PM: She brings Line 7 back online and monitors it for an hour. The intermittent faults have vanished. She documents the problem, her diagnosis, and the fix in the aintenance management system (CMMS).

- 2:00 PM: With her priority task complete, she moves to her scheduled preventive maintenance. Today, it's the robotic palletizer in the outbound shipping area. This involves checking gearboxes for lubricant levels, cleaning photo-eye sensors, and verifying the robot's positional accuracy.

- 3:30 PM: An engineer stops by to discuss a planned upgrade. They want to install a new vision system on one of the robotic arms. Maria provides practical feedback on the best mounting locations and cable routing to avoid mechanical interference.

- 4:00 PM: She cleans up her tools, finalizes her daily report, and briefs the incoming evening shift technician on the status of Line 7 and the other equipment she worked on.

Average Electromechanical Technician Salary: A Deep Dive

Understanding the financial landscape of this career is paramount. The salary for an electromechanical technician is not a single, static number; it's a dynamic range influenced by a multitude of factors we'll explore in the next section. However, by examining data from authoritative sources, we can establish a clear and reliable baseline.

According to the most recent data from the U.S. Bureau of Labor Statistics (BLS), the median annual wage for Electro-mechanical and Mechatronics Technologists and Technicians was $67,830 in May 2023. This is the midpoint—meaning half of all technicians earned more than this amount, and half earned less.

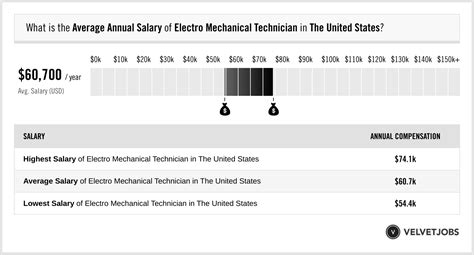

The BLS data also reveals the broader salary spectrum:

- The lowest 10 percent earned less than $44,190. These are typically entry-level positions or roles in lower-paying regions or industries.

- The highest 10 percent earned more than $99,920. These top earners are senior technicians with extensive experience, specialized skills (like robotics or PLC programming), and often work in high-paying industries and locations.

Reputable salary aggregators provide a similar, and often more granular, view of the compensation landscape.

- Salary.com (as of late 2023) reports the median salary for an Electromechanical Technician I (entry-level) at $59,497, while a more experienced Electromechanical Technician III has a median of $79,849. The typical range for all technicians generally falls between $55,602 and $85,263.

- Payscale.com shows an average base salary of around $65,000 per year. Their data is particularly useful for visualizing the impact of experience on pay.

- Glassdoor, which incorporates user-submitted data, reports a total pay average of approximately $71,500 per year, which includes base salary and additional compensation like bonuses.

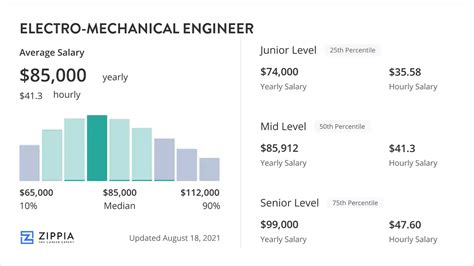

### Salary by Experience Level

Your earning potential will grow significantly as you accumulate experience, master new technologies, and prove your value. Here’s a typical salary progression you can expect:

| Experience Level | Years of Experience | Typical Salary Range | Key Characteristics |

| :--- | :--- | :--- | :--- |

| Entry-Level | 0-2 Years | $45,000 - $60,000 | Possesses an Associate's degree or certificate. Focuses on learning systems, performing routine maintenance, and assisting senior technicians with complex repairs. |

| Mid-Career | 3-8 Years | $60,000 - $78,000 | Works independently on most tasks. Can troubleshoot complex issues, read schematics proficiently, and may begin to specialize in specific systems (e.g., PLCs, robotics). |

| Senior/Experienced | 9+ Years | $78,000 - $95,000+ | Acknowledged expert on site. Leads complex projects, trains junior technicians, troubleshoots the most difficult problems, and may have supervisory responsibilities. |

*(Salary ranges are estimates compiled from BLS, Salary.com, and Payscale data and can vary based on the factors discussed below.)*

### Beyond the Paycheck: A Look at Total Compensation

Your annual salary is only one piece of the puzzle. Electromechanical technicians, especially those in industrial and manufacturing settings, often receive a comprehensive compensation package that significantly increases their overall earnings and job satisfaction.

- Overtime Pay: This is a major factor. Manufacturing facilities and other 24/7 operations often require technicians to work beyond their standard 40-hour week to handle emergencies or planned maintenance during shutdowns. Overtime is typically paid at 1.5 times the regular hourly rate and can add substantially to your annual income.

- Bonuses: Many companies offer annual or quarterly bonuses based on individual performance, team goals (e.g., meeting uptime targets), or overall company profitability. These can range from a few hundred to several thousand dollars.

- Profit-Sharing: Some companies, particularly employee-focused or smaller manufacturing firms, distribute a portion of their annual profits among employees.

- Shift Differentials: Technicians who work evening, overnight, or weekend shifts almost always receive a pay differential—an extra percentage or dollar amount added to their hourly wage—to compensate for the less desirable hours.

- Health and Wellness Benefits: A strong benefits package is standard, including medical, dental, and vision insurance. These are valuable components that reduce your out-of-pocket expenses.

- Retirement Plans: Access to a 401(k) or similar retirement plan, often with a company match, is a crucial part of long-term financial planning. A company matching 50% of your contributions up to 6% of your salary is effectively a 3% raise.

- Paid Time Off (PTO): This includes vacation days, sick leave, and paid holidays.

- Tuition Reimbursement and Professional Development: Many employers will pay for you to pursue further education, attend training seminars, or earn valuable industry certifications. This is an investment in your skills that pays dividends for both you and the company.

When evaluating a job offer, it's essential to look at the total compensation package, not just the base salary. A job with a slightly lower base salary but excellent overtime potential, a generous 401(k) match, and fully paid premium health insurance might be more lucrative in the long run.

Key Factors That Influence Salary

While the national average provides a useful benchmark, your personal earning potential as an electromechanical technician will be defined by a specific set of variables. Mastering these factors is the key to maximizing your income throughout your career. This section provides an in-depth analysis of the six primary drivers of your salary.

### 1. Level of Education and Certification

Your formal education forms the foundation of your knowledge and is a primary determinant of your starting salary and long-term career ceiling.

- High School Diploma / GED with Vocational Training: While it's possible to enter the field with just a high school diploma and significant on-the-job training, it is the most challenging path. Starting salaries will be at the lowest end of the spectrum, likely in the $40,000 - $48,000 range. This route often begins in an assembler or operator role, with a gradual transition into maintenance.

- Certificate Programs (1-Year): Many community colleges and technical schools offer focused certificate programs in electronics, industrial maintenance, or mechatronics. These are a step up and can qualify you for entry-level technician roles, with starting salaries typically in the $45,000 - $55,000 range.

- Associate of Applied Science (A.A.S.) Degree (2-Years): This is the gold standard for entering the field and is preferred by the vast majority of employers. An A.A.S. in Electromechanical Technology or Mechatronics provides the ideal blend of theoretical knowledge (AC/DC circuits, digital electronics, fluid power) and hands-on lab experience (PLC programming, motor controls, robotics). Graduates with an Associate's degree command the highest entry-level salaries, typically starting between $52,000 and $62,000, and have the strongest foundation for future growth.

- Bachelor of Science (B.S.) Degree: A four-year degree in a field like Mechatronics Engineering, Electrical Engineering Technology, or Industrial Technology is less common for technician roles but can be a powerful differentiator. It often qualifies an individual for higher-level "technologist" or junior engineering roles right out of college, with starting salaries potentially exceeding $65,000 - $75,000. This path provides a direct route to future engineering and management positions.

The Power of Certifications:

Industry certifications are a potent tool for increasing your salary and proving your expertise. They are third-party validations of your skills in specific, high-value areas.

- PMMI Mechatronics Certifications: Offered by the Association for Packaging and Processing Technologies, these are highly respected in the manufacturing and packaging industries.

- ETA International Certifications: The Electronics Technicians Association offers a wide range of credentials, including the Certified Electronics Technician (CET) and various industrial electronics specializations.

- SACA Certifications: The Smart Automation Certification Alliance focuses on skills related to Industry 4.0, a critical area for future growth. Certifications in areas like Industrial Robot Operations can directly lead to higher pay.

- Vendor-Specific Certifications: Becoming certified by a major equipment manufacturer like Allen-Bradley/Rockwell Automation (for PLCs), FANUC or KUKA (for robotics) is extremely valuable. Companies that use this specific equipment will pay a premium for technicians who are already certified, saving them time and training costs.

### 2. Years of Experience

Experience is arguably the single most powerful factor in salary growth. Theoretical knowledge is essential, but the ability to quickly and accurately diagnose a real-world problem under pressure is a skill forged only through time and repetition.

- Entry-Level (0-2 years): As discussed, you are primarily learning. Your value is in your potential and your ability to execute well-defined tasks. Pay is at the lower end of the scale as the company invests in your training.

- Mid-Career (3-8 years): At this stage, you have become a reliable, independent contributor. You've seen a wide variety of failures and have developed a "sixth sense" for troubleshooting. You can handle almost any problem thrown your way and may start mentoring new hires. This is where you see the most significant salary jumps, moving firmly into the $60,000 - $78,000 range. Employers pay for your proven competence and efficiency.

- Senior/Expert (9+ years): You are now a "go-to" person. You tackle the intermittent, "impossible" problems that stump others. You might lead a maintenance team, manage large-scale installation projects, or specialize as the site expert in a critical technology like robotics or networked control systems. Your salary will be at the top of the range, from $78,000 to over $100,000 in some cases, reflecting your role as a knowledge leader and a critical asset to the operation.

### 3. Geographic Location

Where you work matters—a lot. Salaries can vary by 20-30% or more based on the state and metropolitan area due to differences in cost of living and the concentration of relevant industries.

High-Paying States and Metropolitan Areas:

These locations typically have a high cost of living but also a dense concentration of high-tech manufacturing, aerospace, or R&D industries that pay a premium for top talent.

- California: Particularly the San Jose-Sunnyvale-Santa Clara metro (Silicon Valley), where technicians working in semiconductor or electronics manufacturing can command top dollar. Median salaries here can easily exceed $85,000.

- Washington: The Seattle-Tacoma-Bellevue area, home to aerospace giants and a burgeoning tech/logistics sector, offers salaries well above the national average.

- Massachusetts: The Boston-Cambridge area is a hub for biotech, robotics, and R&D, creating high demand for skilled technicians.

- Alaska and Texas: While not always thought of as tech hubs, the oil and gas industry relies heavily on complex electromechanical systems and pays extremely well for technicians willing to work in demanding environments.

- Arizona: With a massive and growing semiconductor manufacturing presence in the Phoenix area, demand and salaries are on a sharp upward trend.

States with Salaries Closer to or Below the National Average:

These locations often have a lower cost of living, which means your paycheck can go further. They typically have a more traditional manufacturing base.

- Midwestern States: Ohio, Indiana, Wisconsin, and Michigan have strong manufacturing sectors but salaries tend to be closer to the national median.

- Southeastern States: States like South Carolina, Tennessee, and Alabama have seen huge growth in automotive and other manufacturing, but wages have not always kept pace with the top-tier states.

When considering a move, always use a cost-of-living calculator to compare a salary offer in a new city to your current location. A $75,000 salary in Des Moines, Iowa, offers a significantly higher standard of living than the same salary in San Jose, California.

### 4. Industry of Specialization

The industry in which you apply your skills has a profound impact on your earning potential. Technicians who work on more complex, precise, or mission-critical equipment typically earn more.

- Semiconductor and Electronics Manufacturing: (Highest Paying) This industry operates on the cutting edge of technology. The equipment is extraordinarily complex and expensive, and any downtime is catastrophic. Technicians often work in highly controlled cleanroom environments and are compensated with top-tier salaries, often exceeding $80,000 - $90,000.

- Aerospace Product and Parts Manufacturing: Working on systems for aircraft and spacecraft demands an extremely high level of precision and adherence to strict safety and quality standards. Security clearances may be required. This results in salaries well above the national average.

- Scientific Research and Development: Technicians in this field support engineers and scientists in building and maintaining experimental apparatus. The work is often non-routine and highly technical, leading to strong compensation.

- Power Generation and Distribution: Working for utility companies on the equipment that keeps the electrical grid running is a critical role that offers high pay and excellent job security.

- Pharmaceutical and Medical Device Manufacturing: This is a highly regulated environment (by the FDA) where equipment must be perfectly calibrated and maintained. The high value of the products and the strict regulatory compliance lead to very competitive salaries.

- Automotive Manufacturing: A major employer of electromechanical technicians, especially with the rise of EV production and highly automated "gigafactories." Salaries are competitive, with excellent overtime potential.

- Food and Beverage or General Manufacturing: These roles are essential but may involve older or less complex technology compared to the industries above. Salaries are often closer to the national median but can still be very solid, especially in highly automated facilities.

### 5. Company Type and Size

The type of organization you work for influences not just your salary but also your work environment and career trajectory.

- Large Corporations (Fortune 500): Companies like Amazon, Tesla, Boeing, or Intel often offer the highest base salaries and the most comprehensive benefits packages. They have structured training programs and clear paths for advancement. The trade-off can be more bureaucracy and a less personal work environment.

- Original Equipment Manufacturers (OEMs): Working directly for a company that designs and builds automated machinery (e.g., a robotics company or a packaging machine manufacturer) can be very lucrative. These roles often involve travel to customer sites for installation and service and are known as Field Service Technician/Engineer positions. They often come with a company vehicle, travel per diems, and higher base pay, easily pushing earnings over $85,000.

- Small to Medium-Sized Enterprises (SMEs): A smaller manufacturing company or a family-owned business might offer a slightly lower base salary but can provide a more intimate work environment where you have a greater impact. You may have broader responsibilities and gain experience faster. They might also offer more flexible arrangements or profit-sharing plans.

- Government and Public Sector: Working for a government agency (e.g., Department of Defense), a national lab, or a public utility offers unparalleled job security and excellent government benefits, including pensions. Salaries may not reach the absolute peaks of the private sector but are very competitive and stable.

### 6. In-Demand Technical Skills

In the world of electromechanical technology, specific skills are golden tickets to a higher salary. The more you can do, and the more complex the systems you can manage, the more you are worth. Focusing on developing these high-value skills is the most direct way to increase your paycheck.

- Programmable Logic Controller (PLC) Programming and Troubleshooting: This is arguably the #1 most valuable skill. PLCs are the brains of most automated systems