In the intricate world of modern manufacturing and production, Industrial Maintenance Technicians are the indispensable heroes who keep the engines of industry running. This vital, hands-on career offers not only stability but also significant earning potential for skilled professionals. If you're considering this path, you're likely asking a critical question: "What is a typical Industrial Maintenance Technician salary?"

The answer is promising. While a national average provides a strong benchmark, your actual earnings can range from approximately $45,000 for an entry-level position to over $85,000 for experienced specialists in high-demand areas. This guide will break down the salary you can expect and explore the key factors that will drive your earning potential to the top of that range.

What Does an Industrial Maintenance Technician Do?

Often called the "doctors of the factory floor," Industrial Maintenance Technicians are multi-skilled problem solvers responsible for the installation, troubleshooting, repair, and preventative maintenance of industrial machinery and production equipment. Their work is critical for minimizing downtime and ensuring operational efficiency and safety.

Key responsibilities include:

- Diagnosing mechanical, electrical, pneumatic, and hydraulic issues.

- Performing routine preventative maintenance to ensure machinery runs smoothly.

- Repairing or replacing defective parts using hand tools, power tools, and industrial equipment.

- Reading and interpreting blueprints, schematics, and technical manuals.

- Installing new equipment and ensuring it operates correctly.

It's a dynamic role that requires a sharp mind, excellent mechanical aptitude, and a commitment to continuous learning.

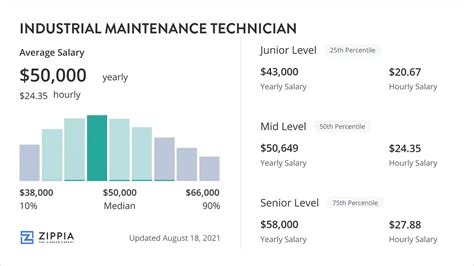

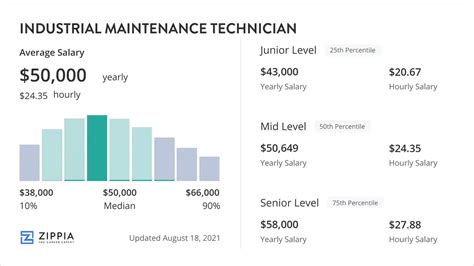

Average Industrial Maintenance Technician Salary

To understand the earning landscape, we look to data from authoritative sources.

According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for the broader category of "Industrial Machinery Mechanics" was $61,770 in May 2023. The median wage is the point at which half the workers in the occupation earned more than that amount and half earned less. The BLS also notes that the lowest 10 percent earned less than $41,210, and the highest 10 percent earned more than $84,400.

Reputable salary aggregators provide a more granular look:

- Salary.com reports that the median salary for an Industrial Maintenance Technician in the United States is approximately $65,391 as of early 2024. The typical salary range falls between $56,238 and $74,863.

- Payscale shows a similar average base salary of around $62,100 per year, with a total pay range (including potential bonuses and overtime) stretching from $44,000 to $88,000.

These figures confirm that a career as an Industrial Maintenance Technician is financially rewarding, with a strong median income and significant room for growth.

Key Factors That Influence Salary

The national average is just a starting point. Your personal compensation will be influenced by a combination of factors. Understanding these levers is key to maximizing your earning potential throughout your career.

### Level of Education

While a high school diploma combined with extensive on-the-job training is a viable path, formal education can significantly boost your starting salary and long-term prospects.

- Vocational Certificates: A postsecondary certificate in industrial maintenance technology or a related field demonstrates foundational knowledge and can make you a more attractive candidate than someone with no formal training.

- Associate's Degree: An Associate of Applied Science (A.A.S.) in Industrial Maintenance Technology is highly valued by employers. These programs provide in-depth, hands-on training in electronics, PLCs, hydraulics, and motor controls, often leading to higher starting pay and faster advancement to senior or specialist roles.

### Years of Experience

Experience is one of the most significant drivers of salary growth in this profession. Employers pay a premium for technicians who have a proven track record of solving complex problems and working independently.

- Entry-Level (0-2 years): Technicians just starting can expect a salary in the range of $44,000 to $55,000. The focus at this stage is on learning systems and proving reliability.

- Mid-Career (3-9 years): With several years of experience, technicians develop expertise and can handle more complex tasks. Salaries typically increase to the $58,000 to $70,000 range.

- Experienced/Senior (10+ years): Senior or lead technicians with over a decade of experience, particularly those who mentor junior staff or specialize in high-tech systems, can command salaries of $72,000 to $85,000+.

### Geographic Location

Where you work matters. Salaries vary based on local demand for skilled technicians and the regional cost of living. According to BLS data, states with heavy manufacturing, energy production, or advanced industrial sectors tend to pay more.

Top-Paying States for Industrial Machinery Mechanics (Annual Mean Wage, May 2023):

- Alaska: $80,430

- Wyoming: $73,590

- Washington: $73,540

- Nevada: $72,580

- District of Columbia: $71,760

Working in a major metropolitan area within any state will also generally yield a higher salary than working in a rural location.

### Company Type and Industry

The industry you work in has a direct impact on your paycheck. Industries with highly complex, expensive, or mission-critical machinery typically offer the best compensation.

Top-Paying Industries (BLS, May 2023):

- Electric Power Generation, Transmission and Distribution: $89,190

- Natural Gas Distribution: $87,410

- Aerospace Product and Parts Manufacturing: $79,890

- Pipeline Transportation of Crude Oil: $79,720

- Automobile Manufacturing: $76,730

Working for a large, unionized manufacturing plant or a government contractor will often pay more than a role at a small, non-union repair shop.

### Area of Specialization

As technology advances, specialization has become a powerful way to increase your value. Technicians who master in-demand systems are compensated accordingly.

- Programmable Logic Controllers (PLCs): Technicians who can program, troubleshoot, and integrate PLCs—the brains behind most automated systems—are in extremely high demand. This specialization can add a significant premium to your salary.

- Robotics Maintenance: With the rise of automation, technicians skilled in maintaining and repairing industrial robots are highly sought after in manufacturing, logistics, and warehousing.

- CNC Maintenance: Expertise in servicing Computer Numerical Control (CNC) machines is a lucrative skill, as these precise machines are the backbone of modern machining and fabrication.

- Hydraulics and Pneumatics: While a foundational skill, deep expertise in complex hydraulic and pneumatic systems remains a valuable and well-compensated specialty.

Job Outlook

The future for Industrial Maintenance Technicians is bright and stable. The BLS projects that employment for industrial machinery mechanics will grow 4 percent from 2022 to 2032, about as fast as the average for all occupations.

This growth will result in approximately 51,500 openings each year, on average, over the decade. Many of these openings will stem from the need to replace workers who are retiring or transferring to different occupations. As factories and plants continue to adopt more sophisticated technology, the demand for skilled technicians who can maintain this advanced machinery will remain strong.

Conclusion

A career as an Industrial Maintenance Technician is a rewarding choice for those who enjoy hands-on work, problem-solving, and technology. It offers a clear path to a comfortable, middle-class income with excellent financial security.

Key Takeaways:

- Solid Earning Potential: The national median salary hovers in the low-to-mid $60,000s, with experienced specialists earning upwards of $85,000.

- Experience is King: Your salary will grow significantly as you gain hands-on experience and prove your skills.

- Education Pays Off: A certificate or Associate's degree can give you a competitive edge and unlock higher pay.

- Location and Industry Matter: Targeting high-paying industries (like energy or aerospace) and regions can dramatically increase your income.

- Specialize to Maximize: Developing expertise in high-demand areas like PLCs, robotics, or CNC maintenance is the fastest way to become a top earner in the field.

For anyone looking for a stable, in-demand, and financially sound career, becoming an Industrial Maintenance Technician is an excellent path forward. By investing in your skills and strategically planning your career, you can build a prosperous future keeping the machinery of our world in motion.