Have you ever walked into a massive industrial plant, a state-of-the-art hospital, or a towering skyscraper and marveled at the sheer complexity of it all? Behind the clean walls and beneath the polished floors lies a hidden world—a complex circulatory system of pipes that carries everything from water and air to volatile chemicals and high-pressure steam. This is the world of the pipefitter, the highly skilled tradesperson who designs, builds, and maintains the arteries of our modern infrastructure. If you're looking for a career that combines mental acuity with hands-on skill, offers exceptional job security, and provides a significant income, then understanding the journeyman pipefitter salary and career path is your first step toward a powerful future.

This isn't just a job; it's a foundational profession with earnings that can rival, and often surpass, those of many four-year-degree holders. A journeyman pipefitter commands a respectable salary that can climb well into the six-figure range with experience, specialization, and strategic career moves. I once had the opportunity to tour a newly constructed semiconductor fabrication plant, and the guide pointed out the "high-purity" piping system. The level of precision, the flawless orbital welds, and the sheer scale of the network were breathtaking. He told me the pipefitting team was on-site for over two years, and their work was as critical as any engineer's design—a testament to the immense skill and value these professionals bring to our most advanced industries. This guide is designed to give you that same sense of clarity, breaking down everything you need to know about this lucrative and essential trade.

We will dissect every facet of a pipefitter's career, from daily duties to the long-term financial outlook. This is your blueprint for success in the pipefitting trade.

### Table of Contents

- [What Does a Journeyman Pipefitter Do?](#what-is-a-pipefitter)

- [Average Journeyman Pipefitter Salary: A Deep Dive](#salary-deep-dive)

- [Key Factors That Influence a Journeyman Pipefitter's Salary](#key-factors)

- [Job Outlook and Career Growth for Pipefitters](#job-outlook)

- [How to Become a Journeyman Pipefitter: A Step-by-Step Guide](#how-to-get-started)

- [Conclusion: Is a Pipefitting Career Right for You?](#conclusion)

What Does a Journeyman Pipefitter Do?

A journeyman pipefitter is a skilled trades professional who has completed a formal apprenticeship program and is certified to work independently in the trade. They are experts in planning, installing, assembling, maintaining, and repairing the mechanical piping systems that are essential for countless industrial, commercial, and residential facilities.

Unlike plumbers, who primarily work with low-pressure pipes for water and drainage in residential and commercial settings, pipefitters work with high-pressure and high-temperature systems designed to transport chemicals, gases, steam, and other fluids. Their work is often on a much larger and more complex scale, found in places like power plants, oil refineries, pharmaceutical manufacturing facilities, food processing plants, and semiconductor fabs.

The core responsibilities of a journeyman pipefitter are demanding and diverse, requiring a unique blend of technical knowledge, physical skill, and problem-solving ability.

Core Responsibilities and Daily Tasks:

- Blueprint and Specification Interpretation: A pipefitter's day almost always begins with a plan. They must be able to read and interpret complex isometric drawings, blueprints, and schematics to understand the layout of the piping system, the materials required, and the precise measurements needed.

- Pipe Fabrication and Preparation: They measure, cut, thread, and bend pipes to the required configuration. This can be done using a variety of hand and power tools, including pipe threaders, benders, and saws.

- System Assembly: Pipefitters assemble and join pipe components using various methods, including threading, welding, brazing, soldering, and cementing. The joining method depends entirely on the type of material being transported and the pressure it's under.

- Welding: Welding is a critical and often highly specialized skill for pipefitters. They may need to be proficient in various welding processes like Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (TIG), and Gas Metal Arc Welding (MIG) on different types of metals like carbon steel, stainless steel, and other alloys.

- Installation and Support: They install pipes, valves, and other fixtures, securing them with hangers, brackets, and clamps to ensure the system is stable and safe.

- Testing and Inspection: After installation, pipefitters must rigorously test the system for leaks. This is a critical safety step, often involving filling the system with water or inert gas and pressurizing it to check for any drops in pressure.

- Maintenance and Repair: In industrial settings, pipefitters are crucial for ongoing maintenance. They inspect systems, perform preventative maintenance, troubleshoot issues, and repair or replace worn or damaged pipes and components.

### A Day in the Life of a Journeyman Pipefitter

To make this tangible, let's follow a fictional journeyman pipefitter, Maria, working on a commercial construction project for a new hospital wing.

- 6:30 AM - Arrival and Safety Briefing: Maria arrives at the job site. The first order of business is the daily "toolbox talk" with her foreman and crew. They discuss the day's tasks, identify potential hazards (like working at heights or in tight spaces), and review safety protocols.

- 7:00 AM - Blueprint Review: Maria and her apprentice head to the mechanical room. They roll out the isometric drawings for the medical gas system they're installing. They verify the pipe routes, valve locations, and material specifications (e.g., Type K copper pipes for oxygen).

- 8:00 AM - Fabrication: They measure and cut sections of copper pipe using a specialized tubing cutter to ensure a clean, burr-free edge. Using a pro-press tool, they crimp fittings onto the pipes, creating a secure, flame-free joint required for this clean environment.

- 11:00 AM - Installation: Working on a scissor lift, Maria and her apprentice carefully route the fabricated pipe sections through the ceiling grid, securing them with hangers at intervals specified by the engineering plans and local codes. Precision is key; the pipes must have the correct slope and alignment.

- 12:00 PM - Lunch: A well-deserved break with the crew.

- 12:30 PM - Brazing and Purging: Maria moves to a section that requires a stronger, brazed joint. Donning her safety gear, she uses a nitrogen purge system to flow inert gas through the pipe while she heats the joint with a torch and applies the brazing alloy. This prevents oxidation inside the pipe, which is critical for medical gas purity.

- 3:00 PM - System Tie-In and Inspection: She connects the newly installed section to the main supply line. Her foreman comes by to inspect the work, checking the quality of the joints and ensuring all supports are correctly installed.

- 4:00 PM - Clean-up and Prep for Tomorrow: Maria cleans her work area, secures her tools, and reviews the blueprints for the next day's tasks. She gives her apprentice feedback and a few things to study overnight. She leaves the site tired but with the satisfaction of knowing her precise work will one day be part of a life-saving system.

This example highlights the blend of physical work, mental focus, and unwavering commitment to safety and quality that defines the role of a journeyman pipefitter.

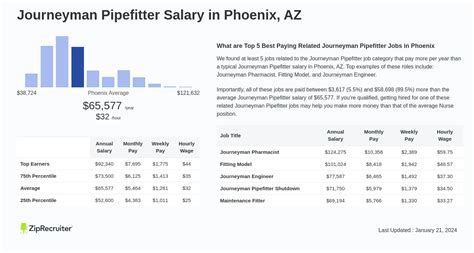

Average Journeyman Pipefitter Salary: A Deep Dive

Now, let's address the central question: what can you expect to earn? The journeyman pipefitter salary is one of the most compelling aspects of the trade, offering a robust income that rewards skill and experience. Compensation is not just a simple hourly wage; it's a package that often includes significant overtime opportunities, excellent benefits, and performance-based bonuses.

It's important to consult multiple authoritative sources to get a well-rounded picture of earnings.

National Averages and Salary Ranges

- The U.S. Bureau of Labor Statistics (BLS) groups pipefitters with plumbers and steamfitters. As of May 2023, the median annual wage for this group was $61,550, or $29.59 per hour. However, the BLS data includes plumbers, who often have a lower wage ceiling. Journeyman pipefitters, especially in industrial sectors, typically earn more. The top 10% in this category earned more than $103,480.

- Salary.com, which allows for more specific job title searches, reports that the median salary for a Journeyman Pipefitter in the United States is $68,893 as of May 2024. The typical salary range falls between $59,576 and $78,291, but this can extend significantly higher based on the factors we'll discuss below.

- Payscale.com provides a detailed breakdown based on user-reported data. As of June 2024, it shows the average journeyman pipefitter salary at $33.35 per hour, which translates to an annual salary of approximately $69,368 before overtime. The total pay range, including potential overtime and bonuses, is reported as $50,000 to $112,000 per year.

- Glassdoor estimates the total pay for a Journeyman Pipefitter in the US to be around $80,265 per year, with a likely range of $64,000 to $101,000. This figure combines base pay with additional compensation like bonuses and profit sharing.

Summary of National Salary Data:

| Data Source | Median/Average Annual Salary | Typical Annual Salary Range |

| :--- | :--- | :--- |

| U.S. BLS (Plumbers, Pipefitters, Steamfitters) | $61,550 | $39,270 - $103,480+ |

| Salary.com (Journeyman Pipefitter) | $68,893 | $59,576 - $78,291 |

| Payscale.com (Journeyman Pipefitter) | $69,368 (base) | $50,000 - $112,000 (total) |

| Glassdoor (Journeyman Pipefitter) | $80,265 (total) | $64,000 - $101,000 (total) |

*(Note: Data is subject to change and reflects figures reported in mid-2024. Ranges can be wider depending on specific circumstances.)*

### Salary Progression by Experience Level

A pipefitter's salary grows steadily with experience. The journey from a new apprentice to a seasoned master pipefitter shows a clear and rewarding financial progression.

| Career Stage | Years of Experience | Typical Hourly Wage Range | Typical Annual Salary Range (Base) |

| :--- | :--- | :--- | :--- |

| Apprentice (1st Year) | 0 - 1 | $15 - $22/hour | $31,000 - $45,000 |

| Apprentice (Final Year) | 4 - 5 | $25 - $35/hour | $52,000 - $72,000 |

| Journeyman (Entry-Level) | 5 - 7 | $30 - $45/hour | $62,000 - $93,000 |

| Journeyman (Mid-Career) | 7 - 15 | $38 - $55/hour | $79,000 - $114,000 |

| Senior/Master Pipefitter / Foreman | 15+ | $45 - $70+/hour | $93,000 - $145,000+ |

*(Source: Aggregated data from Payscale, union wage scales, and industry job postings.)*

### Beyond the Hourly Wage: Total Compensation

A pipefitter's total compensation package is often much more than their base salary. These additional components can dramatically increase overall earnings.

- Overtime Pay: This is arguably the most significant factor. Industrial and construction projects often run on tight deadlines, requiring extensive overtime. Working over 40 hours a week is common, with pay at 1.5 times the base rate ("time and a half") and sometimes double time for Sundays or holidays. A pipefitter earning $40/hour could make $60-$80/hour for overtime work, adding tens of thousands to their annual income.

- Per Diem and Travel Pay: For jobs that require travel ("shutdowns," "turnarounds," or remote projects), companies provide a "per diem" – a daily allowance to cover lodging and food expenses. This is typically non-taxed and can add a significant amount of take-home pay.

- Union Benefits: For union members (e.g., through the United Association), the benefits package is a cornerstone of compensation. This often includes:

- Defined-Benefit Pension Plans: A retirement plan that guarantees a monthly payout, which is increasingly rare in the private sector.

- Excellent Health Insurance: Comprehensive medical, dental, and vision coverage for the member and their family, often fully paid for by the employer through contributions to a union fund.

- Annuity/401(k) Plans: Additional retirement savings vehicles.

- Bonuses and Profit Sharing: In non-union or corporate settings, pipefitters may be eligible for performance bonuses, project completion bonuses, or company-wide profit-sharing plans.

- Company Vehicle and Tools: Some employers, particularly those focused on service and maintenance, may provide a company truck, a fuel card, and a comprehensive set of expensive tools.

When you combine a strong base wage with overtime, benefits, and other perks, the total value of a journeyman pipefitter salary package is exceptionally competitive and financially secure.

Key Factors That Influence a Journeyman Pipefitter's Salary

While the national averages provide a good baseline, your actual earnings as a journeyman pipefitter will be determined by a combination of crucial factors. Understanding these variables is key to maximizing your income potential throughout your career. This is where you can be strategic and take control of your financial trajectory.

### 1. Geographic Location

Where you work is one of the single largest determinants of your salary. The demand for skilled pipefitters, the strength of local unions, the presence of major industries, and the cost of living all create significant wage disparities across the country.

High-Paying States and Regions:

States with heavy industrial activity, strong union presence, and major energy sectors consistently offer the highest wages. According to the BLS (May 2023 data for Plumbers, Pipefitters, and Steamfitters), the top-paying states are:

1. Illinois: Annual mean wage of $92,200

2. Alaska: Annual mean wage of $88,570

3. Massachusetts: Annual mean wage of $86,430

4. New Jersey: Annual mean wage of $83,670

5. Oregon: Annual mean wage of $81,540

Cities like Chicago, Boston, and areas within the New York/New Jersey metropolitan area often have union wage scales that push journeyman rates well over $50 or $60 per hour. Similarly, regions with major oil and gas operations, like the Gulf Coast (Texas, Louisiana) or remote locations in Alaska and North Dakota, offer exceptionally high wages, often supplemented by significant overtime and per diem to attract skilled labor for demanding projects.

Lower-Paying Regions:

Conversely, states in the Southeast and some parts of the Mountain West with lower costs of living, less union density, and fewer large-scale industrial projects tend to have lower average wages. States like Florida, Arkansas, and South Carolina fall into this category, with mean wages closer to the $50,000 - $55,000 range.

The Cost of Living Caveat: It is essential to balance high wages against the cost of living. A $90,000 salary in Chicago may not go as far as a $70,000 salary in a smaller Midwestern city. However, the sheer earning potential from overtime in high-wage areas can often outpace even a high cost of living, allowing for substantial savings.

### 2. Industry and Union Status

The type of industry you work in has a massive impact on your pay scale, work environment, and the skills you'll need.

Industrial vs. Commercial:

- Industrial Pipefitting: This is generally the highest-paying sector. It includes work in oil refineries, chemical plants, power generation (fossil fuels, nuclear, and renewables), pharmaceutical manufacturing, and food processing. The work is highly demanding, often involves hazardous materials and extreme temperatures/pressures, and requires an unwavering commitment to safety and precision. The wages reflect this high-stakes environment.

- Commercial Pipefitting: This involves work in buildings like hospitals, schools, airports, and office towers. The systems (HVAC, medical gas, fire sprinklers) are complex but generally less hazardous than in industrial settings. Pay is very good, but often a step below top-tier industrial rates.

- Residential Pipefitting: This is a much smaller niche, usually involving natural gas lines for homes. It is the lowest-paying sector for pipefitters.

Union vs. Non-Union (Open Shop):

This is perhaps the most significant fault line in compensation and benefits.

- Union Pipefitters: Members of a union, most commonly the United Association (UA), have their wages, benefits, and working conditions negotiated through a collective bargaining agreement (CBA).

- Pros: Significantly higher base wages (often called the "scale rate"), fully funded pension plans, exceptional family health insurance, structured training and advancement, and strong on-the-job protections. The total compensation package is typically far superior.

- Cons: Union dues are required, and work can sometimes be less steady between large projects, though a union hall helps place members in new jobs.

- Non-Union Pipefitters: They work for "open shop" contractors. Their wages and benefits are set by the individual employer.

- Pros: May offer more flexibility and potentially more consistent work if the company is well-established. Some workers prefer to avoid union rules and politics.

- Cons: Wages and benefits are almost always lower than union scale. Retirement is typically a 401(k) (often with a less generous match) instead of a pension, and workers often have to contribute more toward their health insurance premiums.

A union journeyman pipefitter in a major city could earn a total wage-and-benefit package worth over $100 per hour, while their non-union counterpart might earn $40 per hour with a less comprehensive benefits package.

### 3. Specialization and Certifications

Once you become a journeyman, you can further increase your value and salary by developing specialized skills and earning advanced certifications.

- Welding Certifications: This is paramount. A basic pipefitter may do some welding, but a certified pipe-welder is in a different league. Certifications from the American Welding Society (AWS), such as a 6G pipe certification, are highly sought after. Expertise in TIG welding for stainless steel or other exotic alloys can make you one ofthe highest-paid individuals on a job site.

- Orbital Welding: This automated welding process is used for high-purity piping in the semiconductor and pharmaceutical industries. Technicians trained in orbital welding are rare and command premium pay.

- Medical Gas Systems: Installing piping for oxygen, nitrous oxide, and medical air in hospitals requires a specific ASSE 6010 certification. This is a lucrative niche due to the life-or-death importance of the work.

- Steamfitting: Specializing in high-pressure steam systems for power plants and industrial heating is a traditional and high-paying branch of the trade.

- Instrumentation Fitting: This involves installing and connecting pneumatic and hydraulic control instruments to piping systems, blending pipefitting with elements of instrumentation technology.

- Safety Certifications: An OSHA 30 certification is often a minimum requirement for supervisors. Additional safety credentials can enhance your resume and qualifications for leadership roles.

### 4. Experience and Career Progression

As detailed in the salary table earlier, experience is directly correlated with pay. Your career doesn't stop at the journeyman level.

- Apprentice (0-5 years): You learn the trade while earning a progressively increasing wage, typically starting at 40-50% of the journeyman rate.

- Journeyman (5-15 years): You are a fully qualified, productive member of the workforce. Your salary will increase with proven skill, speed, and reliability.

- Foreman/General Foreman (10+ years): This is the first step into leadership. You'll lead a crew of pipefitters, plan work, ensure safety, and report to the superintendent. This role comes with a significant pay increase (often a "premium" of several dollars per hour above the journeyman rate).

- Superintendent/Project Manager (15+ years): You oversee the entire mechanical portion of a project, managing multiple crews, budgets, schedules, and client relations. These are salaried positions that can easily reach well into the six figures ($120,000 - $180,000+).

- Business Owner: Many experienced pipefitters eventually start their own mechanical contracting businesses, where the income potential is virtually unlimited.

### 5. In-Demand Skills (Hard and Soft)

Beyond formal certifications, a set of practical skills will make you more valuable and thus, better paid.

High-Value Hard Skills:

- Advanced Blueprint Reading: The ability to read not just basic layouts but also complex Process and Instrumentation Diagrams (P&IDs) and isometric drawings without assistance.

- Rigging and Signal Person Qualification: Safely moving and positioning heavy pipes and equipment is a crucial skill on large industrial sites.

- Knowledge of Codes and Standards: Deep familiarity with ASME (American Society of Mechanical Engineers) codes, particularly B31.1 (Power Piping) and B31.3 (Process Piping), is essential for quality control and inspection roles.

- Computer Skills: Familiarity with CAD software for viewing plans and even basic project management software can set you apart.

Crucial Soft Skills:

- Problem-Solving: The ability to troubleshoot a leaking system or figure out how to route a pipe through a congested area is invaluable.

- Communication and Teamwork: Effectively communicating with your foreman, apprentices, and other trades on site is critical for safety and efficiency.

- Work Ethic and Reliability: Simply showing up on time, every day, ready to work hard is a trait that foremen value above almost all else. A reliable pipefitter is never out of work for long.

By strategically focusing on these five areas, a motivated pipefitter can actively manage their career to move from a solid starting salary to a truly exceptional income.

Job Outlook and Career Growth

A high salary is attractive, but job security is what builds a stable life. For journeyman pipefitters, the future looks bright and stable. The skills they possess are fundamental to the nation's economy and infrastructure, making them less susceptible to the whims of economic bubbles or technological disruption that affect many white-collar professions.

BLS Projections: A Stable Foundation

The U.S. Bureau of Labor Statistics' Occupational Outlook Handbook projects that employment for plumbers, pipefitters, and steamfitters is expected to grow 2 percent from 2022 to 2032. While this may seem slower than the average for all occupations, it's crucial to understand the context. This projection still translates to approximately 45,300 job openings each year, on average, over the decade.

Why are there so many openings in a field with modest "growth"? The primary driver is workforce replacement. A significant portion of the current skilled trades workforce is at or nearing retirement age. As these experienced journeymen and masters hang up their tools, they leave a massive vacuum of skill and experience that must be filled by a new generation of trained professionals. This "silver tsunami" ensures a consistent, high demand for newly qualified apprentices and journeymen for years to come.

Emerging Trends Shaping the Future of Pipefitting

The world is changing, and the pipefitting trade is changing with it. Several key trends will provide new opportunities and require new skills.