Introduction

Have you ever looked at a complex machine—a robotic arm on an assembly line, a cutting-edge medical device, or a high-performance engine—and wondered not just who *designed* it, but who brought that design to life? Who tested it, tweaked it, and ensured it could actually be built and function in the real world? If your passion lies in that critical space between theoretical design and tangible reality, a career as a Mechanical Engineering Technologist might be your calling. It's a field built for problem-solvers, tinkerers, and practical thinkers who want to get their hands dirty.

This career is not only intellectually stimulating but also financially rewarding. The national median salary for Mechanical Engineering Technologists and Technicians hovers around $65,000 per year, with seasoned professionals in high-demand sectors easily commanding salaries well over $90,000 to $100,000 annually. The query "mechanical technology engineering salary" often leads here, to the world of the Mechanical Engineering Technologist (MET), the hands-on expert who makes innovation possible.

I'll never forget a tour of an advanced manufacturing facility where I met a senior MET named Clara. While engineers in a separate office were running complex digital simulations, Clara was on the floor with a prototype, using a combination of high-tech sensors and an almost intuitive sense of mechanics to diagnose a vibration issue that the simulations had missed. She explained, "The computer tells you what *should* happen. My job is to understand what *is* happening and bridge that gap." That moment perfectly encapsulated the indispensable value of this profession.

This comprehensive guide will illuminate every facet of a Mechanical Engineering Technologist's salary, career path, and future outlook. We will dissect the data, explore the influencing factors, and provide a clear roadmap for you to start your journey.

### Table of Contents

- [What Does a Mechanical Engineering Technologist Do?](#what-they-do)

- [Average Mechanical Engineering Technology Salary: A Deep Dive](#salary-deep-dive)

- [Key Factors That Influence Your Salary](#key-factors)

- [Job Outlook and Career Growth for METs](#job-outlook)

- [How to Get Started in Mechanical Engineering Technology](#how-to-start)

- [Conclusion: Is This Career Your Future?](#conclusion)

What Does a Mechanical Engineering Technologist Do?

While a Mechanical Engineer is primarily focused on the theoretical, research, and design phases of a project, the Mechanical Engineering Technologist (MET) is the master of application and implementation. They are the essential bridge connecting the drawing board to the factory floor, the lab bench to the finished product. Their work is fundamentally hands-on, practical, and oriented toward solving immediate, real-world challenges.

An MET's core mission is to assist mechanical engineers in the design, development, testing, and manufacturing of mechanical devices and systems. They take the concepts and blueprints created by engineers and figure out how to make them work efficiently, safely, and cost-effectively. They are the experts in "how" things are made and "if" they work as intended.

Core Responsibilities and Daily Tasks:

The day-to-day work of an MET is dynamic and varied, often involving a mix of computer-based work and hands-on lab or floor activities. Key responsibilities include:

- Prototyping and Fabrication: Building functional prototypes of new designs using a variety of tools, from traditional lathes and mills to advanced 3D printers and CNC machines.

- Testing and Data Acquisition: Designing and conducting experiments to test the performance, durability, and safety of products and components. This involves setting up sensors, using data acquisition software (like LabVIEW), and meticulously recording results.

- CAD/CAM Operations: Creating and modifying detailed 2D and 3D models using Computer-Aided Design (CAD) software like SolidWorks, AutoCAD, or CATIA. They may also use Computer-Aided Manufacturing (CAM) software to prepare these designs for production.

- Quality Control and Inspection: Ensuring that manufactured parts and final products meet precise engineering specifications. This often involves using advanced measurement tools like Coordinate Measuring Machines (CMMs), calipers, and micrometers.

- Analysis and Reporting: Analyzing test data to identify problems, suggest design improvements, and prepare detailed technical reports for the engineering team.

- Equipment Maintenance and Calibration: Maintaining, troubleshooting, and calibrating the complex machinery and testing equipment used in a lab or manufacturing environment.

- Manufacturing Process Improvement: Working on the assembly line or factory floor to optimize production processes, improve efficiency, and reduce waste.

### A Day in the Life of an MET

To make this more concrete, let's follow "Jordan," a mid-career MET working in the R&D department of an automotive parts supplier.

- 9:00 AM: Jordan starts the day in a team huddle with mechanical engineers. They discuss the results from yesterday's stress test on a new brake caliper bracket. The bracket failed sooner than predicted in the computer simulations.

- 9:30 AM: Back at their workstation, Jordan uses SolidWorks to review the 3D model of the failed bracket, comparing it to the physical part to look for discrepancies. They hypothesize that a specific sharp corner created a stress concentration point.

- 11:00 AM: Jordan heads to the machine shop. Using a CNC mill, they fabricate a new version of the bracket with a filleted (rounded) corner, a modification they suggested in the meeting.

- 1:00 PM: After lunch, Jordan sets up the new prototype on the hydraulic fatigue testing rig. They carefully attach strain gauges and connect them to the data acquisition system, ensuring everything is calibrated perfectly.

- 2:30 PM: The test begins. Jordan monitors the real-time data on their computer, watching the stress levels and looking for any signs of premature failure. The test is scheduled to run for several hours.

- 4:00 PM: While the test runs, Jordan works on a technical report for a different project, summarizing the performance of a new polymer material they tested last week, complete with graphs and statistical analysis.

- 5:00 PM: Before leaving, Jordan checks on the ongoing test. The new bracket is holding up perfectly, already surpassing the failure point of the previous design. They set the system to alert them if anything changes overnight and head home, feeling accomplished.

This example highlights the MET's unique blend of analytical thinking, software proficiency, and hands-on mechanical aptitude. They are the indispensable problem-solvers who ensure that great ideas become great products.

Average Mechanical Engineering Technology Salary: A Deep Dive

Understanding the financial potential is a critical step in evaluating any career path. For Mechanical Engineering Technologists and Technicians, the compensation is competitive and reflects the high-demand, skilled nature of the work. It's important to look at a variety of sources to get a complete picture, from government statistics to real-time, user-reported data.

The term you may have searched for, "mechanical technology engineering salary," points directly to the earnings in this field. Let's break down the numbers in detail.

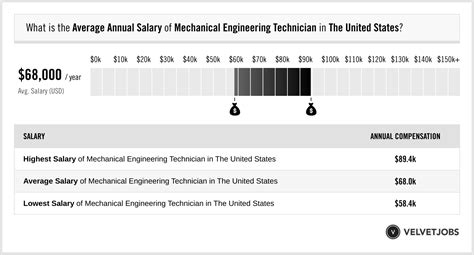

### National Averages and Salary Ranges

The most reliable starting point for salary data is the U.S. Bureau of Labor Statistics (BLS), which provides a broad, national overview. Other salary aggregators like Payscale, Salary.com, and Glassdoor offer more dynamic, real-time data based on user-submitted profiles, which can provide a different and equally valuable perspective.

- U.S. Bureau of Labor Statistics (BLS): As of May 2023, the BLS reports the median annual wage for Mechanical Engineering Technologists and Technicians was $65,060. This means half of the workers in the field earned more than this amount, and half earned less. The BLS data also shows a wide range: the lowest 10 percent earned less than $41,960, and the highest 10 percent earned more than $97,630.

- *Source: BLS Occupational Outlook Handbook, Mechanical Engineering Technologists and Technicians (Accessed 2024).*

- Payscale.com: This platform provides a more granular look. As of early 2024, Payscale reports the average salary for a Mechanical Engineering Technologist to be around $68,000 per year. Their typical range spans from $49,000 to $94,000.

- *Source: Payscale.com, Mechanical Engineering Technologist Salary Profile (Accessed 2024).*

- Salary.com: This site often reports slightly higher figures due to its data sources, which are heavily weighted toward HR-reported compensation data from companies. As of 2024, Salary.com places the median salary for a Mechanical Engineering Technologist II (a mid-level role) at approximately $74,500, with a common range falling between $66,900 and $82,500. Their data for a senior-level Technologist (Level III) pushes the median to over $85,000.

- *Source: Salary.com, Mechanical Engineering Technologist Salary Profiles (Accessed 2024).*

- Glassdoor.com: Glassdoor's data, which aggregates user-submitted salaries and job postings, shows an estimated total pay for a Mechanical Engineering Technologist in the United States to be around $77,000 per year, with a likely range between $62,000 and $97,000. This "total pay" figure includes base salary as well as other forms of compensation like bonuses.

- *Source: Glassdoor.com, Mechanical Engineering Technologist Salary Profile (Accessed 2024).*

Key Takeaway: While the figures vary slightly, a clear consensus emerges. A typical MET can expect to earn somewhere in the $65,000 to $75,000 range, with significant upward mobility. Entry-level positions may start closer to $50,000, while experienced, highly-skilled technologists in premium industries can easily surpass the $100,000 mark.

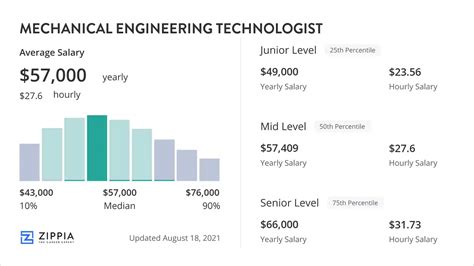

### Salary by Experience Level

Your earning potential grows significantly as you accumulate experience and expertise. Companies pay a premium for technologists who can work independently, lead projects, and solve complex problems without extensive supervision.

Here is a breakdown of typical salary brackets based on years of experience, compiled from aggregate data:

| Experience Level | Years of Experience | Typical Annual Salary Range | Description |

| :--- | :--- | :--- | :--- |

| Entry-Level Technologist | 0-2 Years | $48,000 - $62,000 | Recently graduated with an Associate's or Bachelor's degree. Focuses on learning systems, assisting senior staff, and performing well-defined tasks like basic testing, CAD drafting, and data collection. |

| Mid-Career Technologist | 3-9 Years | $63,000 - $80,000 | Has developed a strong skill set and can work more independently. Manages smaller projects, refines testing procedures, performs more complex analysis, and may begin to specialize in a specific area (e.g., hydraulics, thermal analysis). |

| Senior Technologist | 10-19 Years | $78,000 - $95,000 | A seasoned expert in their field. Often leads complex R&D projects, designs sophisticated testing apparatuses, mentors junior technologists, and acts as a key liaison between the engineering and manufacturing teams. |

| Lead / Principal Technologist | 20+ Years | $90,000 - $115,000+ | At the pinnacle of the technical track. Manages the lab or a team of technologists. Serves as the top technical expert for a department or facility. Consults on the most challenging technical problems and strategic decisions. |

*Note: These are national averages. Your specific salary will be heavily influenced by the factors discussed in the next section.*

### Beyond the Base Salary: Understanding Total Compensation

Your salary is just one part of your overall earnings. A comprehensive compensation package for an MET often includes several other valuable components:

- Bonuses: Annual or quarterly performance-based bonuses are common, especially in manufacturing and corporate environments. These can range from a few thousand dollars to 10-15% of your base salary, tied to individual, team, and company performance.

- Profit Sharing: Many manufacturing and engineering firms offer profit-sharing plans, where a portion of the company's profits is distributed among employees. This directly ties your financial success to the company's success.

- Overtime Pay: As non-exempt employees under the Fair Labor Standards Act (FLSA), many METs are eligible for overtime pay (time-and-a-half) for any hours worked over 40 in a week. This can significantly boost income during busy project cycles.

- Health and Retirement Benefits: Don't underestimate the value of a strong benefits package. This includes medical, dental, and vision insurance, as well as a 401(k) or 403(b) retirement plan. A good employer match on your retirement contributions is essentially free money and a critical part of your long-term financial health.

- Paid Time Off (PTO): Generous vacation, sick leave, and holiday policies contribute to a better work-life balance and are a key part of your total compensation.

- Tuition Reimbursement: Many tech-focused companies encourage continuous learning and may offer tuition assistance or reimbursement for employees pursuing further education (like a Bachelor's degree or advanced certifications), a massive financial benefit.

When evaluating a job offer, it's crucial to look beyond the base salary and consider the total compensation package to understand the true value of the opportunity.

Key Factors That Influence a Mechanical Engineering Technology Salary

Your "mechanical technology engineering salary" is not a single, fixed number. It's a dynamic figure influenced by a confluence of factors. Understanding these variables is the key to maximizing your earning potential throughout your career. This section provides an in-depth analysis of the six primary drivers of your salary.

###

1. Level of Education: The Foundation of Your Career

Your educational background is the first and most fundamental factor determining your starting salary and long-term career trajectory. In the world of engineering technology, there are two primary pathways.

Associate's Degree (A.S. or A.A.S.)

- Role: This degree typically prepares you for a role as a Mechanical Engineering Technician. Technicians often work under the direct supervision of technologists or engineers, focusing on tasks like drafting, operating equipment, conducting routine tests, and assembling components.

- Salary Impact: The starting salary for a technician with an associate's degree is generally lower than for a technologist with a bachelor's. The entry-level range is often in the $45,000 to $55,000 bracket. While experienced technicians can earn more, their ceiling is typically lower than that of their technologist counterparts.

- Key Advantage: A two-year degree is a faster and more affordable route into the workforce, allowing you to start earning and gaining practical experience quickly.

Bachelor's Degree (B.S. in Mechanical Engineering Technology - BSMET)

- Role: This degree prepares you for the role of a Mechanical Engineering Technologist. The curriculum is more advanced, incorporating higher-level math (calculus), physics, materials science, and engineering principles. This enables you to take on more complex responsibilities, including project management, advanced data analysis, and design modification.

- Salary Impact: Graduates with a BSMET degree command a higher starting salary, typically in the $58,000 to $68,000 range. The bachelor's degree provides a much higher long-term earning potential, as it is often a prerequisite for senior and lead technologist roles.

- ABET Accreditation: Crucially, ensure your program is accredited by the Accreditation Board for Engineering and Technology (ABET). ABET accreditation is the gold standard, signaling to employers that your education meets rigorous quality standards. Graduating from a non-accredited program can be a significant hindrance to your career and salary prospects.

Advanced Training & Certifications

Beyond your degree, professional certifications are a powerful way to increase your value. They validate your expertise in specific, high-demand skills.

- Software Certifications: Certified SolidWorks Associate/Professional (CSWA/CSWP), Autodesk Certified Professional in AutoCAD or Inventor.

- Industry Certifications: Certified Manufacturing Technologist (CMfgT) from the Society of Manufacturing Engineers (SME), certifications in Geometric Dimensioning and Tolerancing (GD&T).

- Salary Impact: Each relevant certification can add a few thousand dollars to your salary and make you a much more attractive candidate, especially for specialized roles.

###

2. Years of Experience: The Path to Mastery

As demonstrated in the "Salary by Experience Level" table, experience is arguably the single most powerful driver of salary growth. However, it's not just about the number of years; it's about the *quality* and *progression* of that experience.

- Entry-Level (0-2 years): Your primary value is your foundational knowledge and potential. You are paid to learn and execute tasks. Your salary reflects this learning phase.

- Mid-Career (3-9 years): You have moved from "learning" to "doing." You can work independently, troubleshoot common problems, and contribute meaningfully to projects. Your salary increases reflect your proven competence and growing autonomy. This is often where specialization begins to take hold.

- Senior/Lead (10+ years): You have transitioned from "doing" to "leading and solving." You are now an expert who can tackle the most complex challenges, mentor others, and manage projects or even entire labs. Your value is in your deep knowledge, problem-solving prowess, and leadership. This is where salaries reach their peak, often exceeding $100,000 for top performers in the right industries.

The salary trajectory is steep in the first 5-10 years as you rapidly acquire skills. Afterwards, growth continues but may be more tied to taking on leadership responsibilities or developing a rare, specialized expertise.

###

3. Geographic Location: Where You Work Matters

Compensation for METs varies significantly across the United States, driven by two main forces: local cost of living and the concentration of relevant industries. A higher salary in a city like San Jose might not have the same purchasing power as a slightly lower salary in a city like Huntsville due to housing and living costs.

High-Paying States and Metropolitan Areas:

These locations typically have a high cost of living but also a dense concentration of high-tech industries like aerospace, defense, scientific R&D, and technology.

- Top Paying States (BLS Data, Annual Mean Wage for METs):

1. New Mexico: ~$85,000 (driven by national laboratories and defense)

2. Washington: ~$79,000 (aerospace hub - Boeing and its suppliers)

3. California: ~$78,000 (tech, aerospace, and R&D)

4. Alaska: ~$77,000 (oil and gas industry)

5. Maryland: ~$76,000 (defense contractors, federal agencies)

- Top Paying Metropolitan Areas:

- San Jose-Sunnyvale-Santa Clara, CA

- Albuquerque, NM

- Seattle-Tacoma-Bellevue, WA

- Washington-Arlington-Alexandria, DC-VA-MD-WV

- Boulder, CO

Lower-Paying States:

These states generally have a lower cost of living and fewer large-scale, high-tech employers.

- Examples of States with Lower Averages:

- Mississippi

- Arkansas

- South Dakota

- West Virginia

Key Strategy: When considering a job offer, always use a cost-of-living calculator to compare the purchasing power of the salary in that location versus your current location. A 15% salary increase might be completely negated by a 20% higher cost of living.

###

4. Company Type & Size: The Employer's DNA

The type of organization you work for has a profound impact on your salary, benefits, and work environment.

- Large Corporations (e.g., Fortune 500):

- Examples: Boeing, General Motors, Johnson & Johnson, General Electric.

- Salary & Benefits: Typically offer higher base salaries and comprehensive, well-structured benefits packages (excellent health insurance, generous 401(k) match). Pay scales are often rigid and defined by job "levels."

- Work Environment: More structured, specialized roles, and potentially more bureaucracy, but also more resources and stability.

- Startups and Small/Medium-Sized Enterprises (SMEs):

- Salary & Benefits: Base salaries may be slightly lower than at large corporations. Benefits can be less robust. However, they may offer stock options or other forms of equity, which could have a huge upside if the company is successful.

- Work Environment: Fast-paced, dynamic, and less structured. You'll likely wear many hats and gain a broader range of experience much faster.

- Government & Defense Contractors:

- Examples: NASA, Department of Defense, National Labs (e.g., Sandia, Los Alamos), Lockheed Martin, Raytheon.

- Salary & Benefits: Salaries are competitive and transparent, often following the General Schedule (GS) pay scale for federal jobs. The standout feature is exceptional job security and excellent government benefits, including pensions.

- Work Environment: Can be bureaucratic but offers work on unique, high-impact projects (e.g., space exploration, national defense). Security clearances are often required and can further increase your earning potential.

- Research & Development (R&D) Firms / Consulting:

- Salary & Benefits: Compensation can be very high, as these firms bill clients at a premium for their expertise. Pay is often heavily performance-based.

- Work Environment: Project-based, intellectually stimulating, and demanding. You will be exposed to a wide variety of technologies and industries.

###

5. Area of Specialization: Carving Your Niche

Generalist METs are always needed, but specializing in a high-demand niche is the fastest way to become an indispensable (and highly paid) expert.

- Robotics and Automation: This is a top-tier specialization. METs who can design, build, and maintain robotic systems for manufacturing and logistics are in extremely high demand. This often requires a blend of mechanical, electrical, and programming skills (PLCs