Welcome to the definitive guide on a career in metal fabrication. If you're drawn to the idea of transforming raw metal into the essential components that build our world—from soaring skyscrapers and life-saving medical devices to the cars we drive every day—you're exploring a profession that is both deeply rewarding and financially stable. The clang of a hammer, the hiss of a welder, and the precision of a laser cutter are the sounds of progress, and skilled fabricators are the conductors of this powerful symphony.

But passion and purpose, while essential, must be paired with practicality. You need to know: what is the real earning potential? A career in metal fabrication offers a robust salary that rewards skill, experience, and specialization. While the national median salary provides a solid benchmark, the true potential for a high metal fabrication salary lies in the details—your location, your specific skills, and your commitment to growth.

I remember touring a large-scale manufacturing plant a few years ago. Amidst the noise and machinery, I watched a senior fabricator meticulously interpreting a complex blueprint, then seamlessly moving between a press brake and a TIG welder to create a custom component for an aerospace project. It was a masterful display of technical skill, problem-solving, and artistry, a tangible reminder that these are not just jobs; they are highly skilled crafts that form the backbone of modern industry.

This guide is designed to give you the clarity and confidence to pursue this path. We will dissect every factor that influences your potential earnings, explore the job outlook for the next decade, and provide a clear, step-by-step roadmap to get you started.

### Table of Contents

- [What Does a Metal Fabricator Do?](#what-is-a-metal-fabricator)

- [Average Metal Fabrication Salary: A Deep Dive](#average-salary)

- [Key Factors That Influence Salary](#key-factors)

- [Job Outlook and Career Growth](#job-outlook)

- [How to Get Started in Metal Fabrication](#how-to-start)

- [Conclusion: Is a Career in Metal Fabrication Right for You?](#conclusion)

What Does a Metal Fabricator Do?

A metal fabricator is a skilled trades professional who creates parts and structures from raw metallic materials. They are the artisans and engineers of the industrial world, blending manual dexterity with technical knowledge to cut, bend, shape, and assemble metal into finished products. Their work is project-based and incredibly varied, ranging from producing a single, custom-designed gate for a luxury home to manufacturing thousands of identical brackets for an automotive assembly line.

The core of a fabricator's job is transformation. They take initial designs, whether as a complex 3D CAD model or a traditional 2D blueprint, and execute a series of processes to bring that design to life. This is not simply manual labor; it's a discipline that requires precision, foresight, and a deep understanding of how different metals behave under stress, heat, and pressure.

Core Responsibilities and Daily Tasks:

A fabricator's day-to-day work is a dynamic mix of planning, execution, and quality control. Common tasks include:

- Blueprint and Specification Interpretation: The first step is always understanding the plan. Fabricators must be adept at reading and interpreting technical drawings, blueprints, and computer-aided design (CAD) files to understand dimensions, material requirements, and assembly instructions.

- Layout and Marking: Before any cutting occurs, the fabricator marks the workpiece. Using tools like scribers, protractors, and squares, they lay out the precise lines for cuts, bends, and holes directly onto the sheet metal or structural steel.

- Cutting and Shaping: This is where the raw material begins to take form. Fabricators use a wide array of tools and machinery for this, including:

- Saws: Band saws and cold saws for cutting thick profiles.

- Shears: Guillotine-style machines for making long, straight cuts in sheet metal.

- Plasma and Laser Cutters: High-tech, computer-numerical-controlled (CNC) machines that use superheated gas or focused light to make intricate and precise cuts.

- Press Brakes: Machines that bend sheet metal to specific angles.

- Rolls: Equipment used to curve metal sheets into cylinders or arcs.

- Joining and Assembly: Once individual components are formed, they must be assembled. This is often the most recognizable part of the job and typically involves:

- Welding: Using processes like MIG (Gas Metal Arc Welding), TIG (Gas Tungsten Arc Welding), or Stick (Shielded Metal Arc Welding) to fuse metal parts together.

- Fastening: Using bolts, rivets, and other mechanical fasteners to join components.

- Finishing: After assembly, the product often requires finishing touches to meet aesthetic and functional requirements. This can include grinding welds smooth, sandblasting surfaces for painting, or polishing for a clean appearance.

- Quality Control: Throughout the entire process, fabricators constantly check their work against the original specifications using precision measuring instruments like calipers, micrometers, and gauges to ensure accuracy and quality.

### A Day in the Life: "Maria, Mid-Career Fabricator"

- 7:00 AM: Maria arrives at the fabrication shop, clocks in, and joins the morning safety briefing. The shop foreman outlines the day's priorities: completing a batch of stainless steel frames for a restaurant kitchen and starting a new custom staircase project.

- 7:15 AM: Maria reviews the blueprints for the stainless steel frames. She verifies the material type (304 stainless steel), thickness, and all critical dimensions.

- 8:00 AM: She programs the CNC plasma cutter with the cutting pattern for the frame components. While the machine runs, she gathers the necessary TIG welding equipment and sets up her welding station.

- 10:00 AM: The components are cut. Maria deburrs the sharp edges with a grinder and cleans them to prepare for welding.

- 10:30 AM: She carefully tacks the frame components together in a jig to ensure they are perfectly square. She then proceeds with the final TIG welding, laying down clean, precise beads as required for food-grade equipment.

- 12:30 PM: Lunch break.

- 1:00 PM: Maria finishes welding the last of the frames. She inspects each one, checking for squareness and weld quality.

- 2:30 PM: She moves to the finishing department. Using a series of grinders and polishing pads, she grinds the welds flush and gives the frames a brushed finish to match the client's specifications.

- 4:00 PM: With the frame project complete and passed to the shipping department, Maria pulls the blueprints for the new staircase. She spends the last part of her day reviewing the complex design, planning her cutting list, and laying out the stringers on a large piece of structural steel, ensuring she's ready to hit the ground running tomorrow.

- 4:30 PM: Maria cleans her work area, stores her tools, and clocks out, leaving with the satisfaction of having created tangible, high-quality products.

Average Metal Fabrication Salary: A Deep Dive

Understanding the earning potential is a critical step in evaluating any career path. For metal fabricators, the salary landscape is promising and multifaceted, with significant room for growth based on skill, experience, and specialization. Compensation is not just a single number but a package that often includes a solid base wage, opportunities for overtime, and valuable benefits.

To provide the most accurate picture, we'll draw data from several authoritative sources, including the U.S. Bureau of Labor Statistics (BLS), which provides robust government-collected data, and reputable salary aggregators like Payscale and Salary.com, which compile real-world, user-submitted data.

National Averages and Salary Ranges

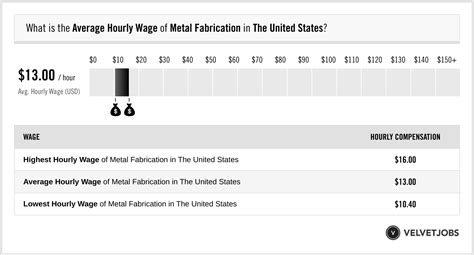

The BLS groups metal fabricators within broader categories like "Welders, Cutters, Solderers, and Brazers" and "Sheet Metal Workers." This is a good starting point for understanding the general market.

- According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for Welders, Cutters, Solderers, and Brazers was $50,460 in May 2022, which translates to approximately $24.26 per hour. The salary spectrum is wide: the lowest 10 percent earned less than $37,020, while the top 10 percent earned more than $72,970. (Source: BLS OOH, published September 2023)

- For Sheet Metal Workers, the BLS reports a higher median annual wage of $58,690 in May 2022 ($28.22 per hour). The range for this specialization is also significant, with the top 10 percent earning over $99,990.

Salary aggregators, which often capture more specific job titles like "Metal Fabricator," provide a complementary view:

- Payscale.com reports the average base salary for a Metal Fabricator is approximately $21.49 per hour, which equates to an annual salary of around $52,000. Their data shows a total pay range (including potential overtime and bonuses) from $38,000 to $79,000 per year. (Data retrieved October 2023)

- Salary.com places the median salary for a "Fabricator I" (entry-level) at $48,935, with a typical range falling between $43,446 and $55,626. For a more experienced "Fabricator III," the median jumps to $64,424, with a range of $57,750 to $72,254. (Data retrieved October 2023)

Key Takeaway: A realistic starting point for a new fabricator is in the $40,000 to $50,000 range, with the national median hovering around $50,000 to $58,000. However, with experience, specialization, and strategic career moves, top-tier fabricators can easily push their earnings into the $70,000 to $100,000+ bracket.

### Salary Progression by Experience Level

One of the most appealing aspects of a career in fabrication is the direct correlation between experience and income. As you transition from an apprentice to a master of the craft, your value—and your paycheck—grows accordingly.

Here is a typical salary progression based on data synthesized from Payscale and industry observations:

| Experience Level | Years of Experience | Typical Hourly Wage Range | Typical Annual Salary Range | Key Characteristics |

| :--- | :--- | :--- | :--- | :--- |

| Entry-Level | 0-1 Year | $17 - $22 / hour | $35,000 - $46,000 | Learning basic skills, assisting senior fabricators, performing simple cuts and assembly, focused on safety and process. |

| Early Career | 1-4 Years | $20 - $26 / hour | $41,000 - $54,000 | Works independently on standard projects, proficient with several key machines, developing welding and blueprint reading skills. |

| Mid-Career | 5-9 Years | $24 - $32 / hour | $50,000 - $67,000 | Can handle complex projects from blueprint to completion, proficient in multiple welding types, may train junior staff. |

| Experienced | 10-19 Years | $28 - $38 / hour | $58,000 - $79,000 | Master-level skills, specializes in high-value areas (e.g., TIG, exotic metals), leads projects, performs advanced layout. |

| Senior / Lead | 20+ Years | $35 - $45+ / hour | $73,000 - $95,000+ | Often in a foreman or shop supervisor role. Responsible for quoting, project management, quality control, and team leadership. |

### Beyond the Paycheck: Total Compensation

A metal fabrication salary is more than just the hourly wage. The total compensation package can significantly increase your overall earnings and job satisfaction. When evaluating an offer, consider these crucial components:

- Overtime Pay: Manufacturing and construction are often project-driven with tight deadlines. Overtime is very common and is paid at 1.5 times the regular hourly rate ("time-and-a-half"). For a fabricator earning $25/hour, each hour of overtime adds $37.50 to their check. Consistent overtime can boost annual earnings by 20-30% or more.

- Bonuses: Many companies offer performance-based bonuses. These can be tied to project completion (finishing ahead of schedule and under budget), shop profitability, or safety records.

- Profit Sharing: Some employers, particularly successful private companies, distribute a portion of their annual profits among employees. This can be a significant lump-sum payment at the end of the year, fostering a strong sense of ownership and teamwork.

- Health Insurance: Comprehensive health, dental, and vision insurance is a standard benefit. A good employer plan can save you thousands of dollars a year in premiums and out-of-pocket costs compared to buying insurance on the open market.

- Retirement Plans: Access to a 401(k) or similar retirement plan, especially one with an employer match, is a powerful tool for building long-term wealth. An employer match is essentially free money and should be maximized whenever possible.

- Paid Time Off (PTO): This includes paid vacation days, sick leave, and holidays, providing essential work-life balance.

- Tool and Gear Allowances: Some companies provide an annual allowance for purchasing new tools, work boots, and personal protective equipment (PPE).

When you combine a competitive base wage with ample overtime opportunities and a robust benefits package, the true value of a career in metal fabrication becomes exceptionally attractive.

Key Factors That Influence a Metal Fabrication Salary

While national averages provide a useful baseline, your individual salary as a metal fabricator will be determined by a specific set of variables. Understanding these factors is the key to maximizing your earning potential throughout your career. Think of them as levers you can pull to actively increase your income. This section provides an in-depth analysis of the six most critical factors that shape a metal fabrication salary.

###

1. Geographic Location

Where you work is one of the most significant determinants of your pay. The cost of living and the demand for skilled labor vary dramatically across the United States. A fabricator in a high-cost metropolitan area with a booming construction or manufacturing sector will almost always earn more than one in a rural area with a lower cost of living.

According to the BLS, the states and metropolitan areas with the highest annual mean wages for "Welders, Cutters, Solderers, and Brazers" offer a clear picture of this disparity.

Top-Paying States for Welders/Fabricators (Annual Mean Wage):

1. Alaska: $76,210

2. Wyoming: $70,710

3. District of Columbia: $70,360

4. Hawaii: $68,910

5. North Dakota: $66,660

*(Source: BLS Occupational Employment and Wages, May 2022)*

Top-Paying Metropolitan Areas (Annual Mean Wage):

1. Anchorage, AK: $79,270

2. Fairbanks, AK: $75,370

3. Honolulu, HI: $71,280

4. Casper, WY: $70,890

5. San Jose-Sunnyvale-Santa Clara, CA: $70,720

Conversely, states in the Southeast and parts of the Midwest tend to have lower average wages, but this is often balanced by a significantly lower cost of living. It's crucial to analyze not just the salary figure but its purchasing power in that specific location.

###

2. Years of Experience and Career Progression

As detailed in the previous section, experience is king in the trades. A seasoned fabricator is exponentially more valuable than a novice for several reasons that directly translate into higher pay:

- Speed and Efficiency: An experienced worker can read a blueprint, plan the job, and execute the tasks in a fraction of the time it takes a beginner. This directly impacts project profitability.

- Reduced Error Rate: Senior fabricators make fewer mistakes, which saves immense costs in wasted material and rework. Their ability to anticipate problems before they occur is invaluable.

- Complex Problem-Solving: When unexpected issues arise—a design flaw, a material inconsistency—a veteran fabricator has the knowledge to troubleshoot and find a solution, whereas a junior employee would be stalled.

- Leadership and Mentorship: Experienced fabricators are often tasked with training apprentices and leading small teams, making them a force multiplier for the entire shop's productivity.

The salary trajectory reflects this. The jump from an entry-level wage (around $40,000) to a mid-career wage (around $60,000) is significant. The path to a lead or foreman position, which often pays $75,000 to $95,000+, is paved with years of dedicated, hands-on experience.

###

3. Industry of Employment

The industry you choose to work in has a profound impact on your salary. Fabricators are needed everywhere, but some sectors pay a premium for their skills due to the complexity, precision, and high-stakes nature of the work.

Here’s a comparison of mean wages for "Welders, Cutters, Solderers, and Brazers" across different industries:

| Industry | Annual Mean Wage | Why It Pays More/Less |

| :--- | :--- | :--- |

| Electric Power Generation, Transmission and Distribution | $84,910 | High-stakes work on critical infrastructure, often unionized, requires specialized certifications. |

| Natural Gas Distribution | $81,360 | Work on pipelines requires high-pressure welding certifications and often involves difficult field conditions. |

| Ship and Boat Building | $62,990 | Demands specialized skills for working on large, complex structures and often with aluminum. |

| Aerospace Product and Parts Manufacturing | $62,500 | Requires extreme precision, working with exotic alloys (titanium, Inconel), and strict quality control. |

| Automotive Repair and Maintenance | $54,990 | General repair work, less specialized than industrial or manufacturing roles. |

| Architectural and Structural Metals Manufacturing | $53,040 | A very common employer, representing the baseline for general fabrication work. |

*(Source: BLS Occupational Employment and Wages, May 2022)*

Choosing to work in a high-paying sector like energy, aerospace, or heavy industrial construction can add tens of thousands of dollars to your annual income compared to general job-shop fabrication.

###

4. Area of Specialization

Within the broad field of metal fabrication, specializing in a high-demand niche is one of the most effective ways to command a top-tier salary. Generalists are valuable, but specialists are rare and highly compensated.

- TIG (Tungsten Inert Gas) Welding: This is a highly precise welding process used on thin materials, stainless steel, and non-ferrous metals like aluminum and titanium. It is essential in aerospace, food-grade/sanitary fabrication, and custom automotive work. A skilled TIG welder can often earn a 15-25% premium over a general MIG welder.

- Pipefitting and Pipe Welding: Fabricating and welding pipe systems for power plants, refineries, and factories is a lucrative specialty. Pipe welders must often pass stringent certification tests (like ASME 6G) and can earn well over $100,000 annually, especially with travel and overtime.

- CNC Machine Programming and Operation: Fabricators who can not only operate but also program CNC equipment (laser cutters, plasma cutters, press brakes, mills) are incredibly valuable. This skill bridges the gap between the shop floor and the design office. A fabricator with strong CAD/CAM and CNC programming skills can easily move into higher-paying roles.

- Structural Steel and Ironworking: These specialists focus on the heavy-duty fabrication and erection of the steel skeletons for buildings and bridges. It's physically demanding work that often pays very well, especially in union environments.

- Custom and Artistic Fabrication: This niche involves creating one-of-a-kind items like elaborate gates, railings, sculptures, and custom furniture. While the business can be less predictable, elite fabricators in this space can charge premium rates for their unique skills and artistry.

###

5. Education and Certifications

While a four-year degree is not required for a career in fabrication, the right education and industry-recognized certifications are a direct investment in your earning potential.

- Educational Pathways:

- High School Diploma / GED: The minimum entry point.

- Vocational/Technical School Certificate: A 9-12 month program focused on hands-on skills (e.g., a welding diploma) is the most common and effective entry path. It provides the foundational knowledge employers seek.

- Associate's Degree (A.A.S.): A two-year degree in Welding Technology or Manufacturing Technology provides deeper theoretical knowledge, including metallurgy, blueprint reading, and quality control. This can lead to faster advancement into supervisory or inspection roles.

- Crucial Certifications: Certifications are third-party verifications of your skills. They prove to an employer that you can perform a specific task to an established standard.

- American Welding Society (AWS) Certified Welder: This is the gold standard. A certification in a specific process and position (e.g., AWS D1.1 for structural steel) can be a prerequisite for high-paying jobs.

- Certified Welding Inspector (CWI): An advanced certification from the AWS, this allows you to move into a quality control role. CWIs command significantly higher salaries, often $70,000 to $100,000+.

- ASME (American Society of Mechanical Engineers) Certifications: Essential for high-pressure pipe and boiler welding.

- NCCER (National Center for Construction Education and Research) Certifications: Widely recognized in the construction industry.

###

6. In-Demand Skills (Technical and Soft)

Finally, your specific skill set—both on and off the machine—can set you apart and justify a higher salary.

High-Value Technical Skills:

- Advanced Blueprint Reading: The ability to read not just simple prints but complex assemblies, schematics, and geometric dimensioning and tolerancing (GD&T) symbols.

- CAD/CAM Software Proficiency: Skills in software like SolidWorks, AutoCAD, or Inventor. Being able to view, interpret, and even make minor edits to a digital model is a huge advantage.

- Welding Exotic Metals: Competency in welding aluminum, stainless steel, titanium, or Inconel is a highly paid skill due to the difficulty and expense of the materials.

- Metrology: The science of measurement. Mastery of precision tools like calipers, micrometers, height gauges, and CMMs (Coordinate Measuring Machines).

High-Value Soft Skills:

- Problem-Solving: The ability to diagnose and fix problems on the fly without constant supervision.

- Attention to Detail: Critical for ensuring quality and safety. A single misplaced decimal point on a measurement can ruin a project.

- Communication: Clearly communicating with supervisors, engineers, and other team members to ensure everyone is on the same page.

- Work Ethic and Reliability: Being dependable, punctual, and willing to put in the effort to meet deadlines is a trait every employer values and rewards.

By strategically developing these six areas, a metal fabricator can move from being a wage-earner to a highly compensated and indispensable professional.

Job Outlook and Career Growth

Choosing a career is not just about the starting salary; it's about long-term stability and the potential for advancement. For those considering metal fabrication, the future is bright and full of opportunity. Despite discussions about automation, the need for skilled, hands-on fabricators who can think critically and adapt to new technologies remains incredibly strong.

### The 10-Year Job Outlook

The U.S. Bureau of Labor Statistics (BLS) provides the most reliable projections for career fields. Their data paints a picture of steady and consistent demand for fabricators over the next decade.

- For Welders, Cutters, Solderers, and Brazers: The BLS projects a growth of 2 percent from 2022 to 2032, which is about as fast as the average for all occupations. While the percentage seems modest, it's crucial to look at the number of actual job openings. The BLS anticipates about 43,800 openings for these professionals *each year*, on average, over the decade.

- For Sheet Metal Workers: The outlook is similar, with a projected growth of 1 percent and about 13,200 openings each year, on average.

Why are there so many openings? The primary driver for these openings is not just new job creation, but the need to replace workers who are retiring or transitioning to different occupations. The manufacturing and skilled trades workforce is aging, creating a significant "skills gap." As experienced baby boomers retire, they leave behind a vacuum of talent that companies are desperate to fill with newly trained, ambitious fabricators. This creates a favorable job market for those entering the field.

The nation's aging infrastructure—from bridges and highways to power grids and water systems—will require extensive repair and replacement, all of which relies heavily on the skills of metal fabricators. Furthermore