Introduction

In the intricate dance of modern industry, where raw materials are transformed into the marvels of our daily lives, the bright, intense arc of a welder’s torch is the creative spark. It’s a craft that fuses metal and ambition, building everything from the skyscrapers that pierce the clouds to the vehicles that connect our world. If you're drawn to the tangible satisfaction of creating something real with your own hands, a career as a MIG welder offers a direct path to a stable, respectable, and surprisingly lucrative profession. But beyond the sparks and steel, what does that path truly look like in terms of financial reward?

A career in MIG welding isn't just a job; it's an entry into a world of skilled trades where expertise is a currency more valuable than any degree. The national average salary for a MIG welder typically hovers around $48,000 to $55,000 per year, but this figure is merely the starting point of our story. With the right skills, certifications, and experience, a dedicated MIG welder can easily earn $75,000, $85,000, or even break the six-figure mark in specialized, high-demand sectors.

I remember visiting a custom automotive shop years ago and watching a master fabricator at work. He wasn't just joining metal; he was sculpting it. With the low hum of the MIG welder and a steady hand, he laid down a bead so perfect it looked like a stack of dimes, transforming a simple sheet of steel into a work of art. It struck me then that this craft is a powerful blend of technical science and artistic precision, and those who master it are the unsung architects of our physical world.

This guide is designed to be your blueprint for that mastery. We will dissect every component of a MIG welder’s salary, explore the factors that can dramatically increase your earnings, and lay out a clear, step-by-step plan to launch and advance your career.

### Table of Contents

- [What Does a MIG Welder Do?](#what-does-a-mig-welder-do)

- [Average MIG Welder Salary: A Deep Dive](#average-mig-welder-salary-a-deep-dive)

- [Key Factors That Influence a MIG Welder's Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Become a MIG Welder: A Step-by-Step Guide](#how-to-get-started-in-this-career)

- [Conclusion: Forging Your Future in Welding](#conclusion)

---

What Does a MIG Welder Do?

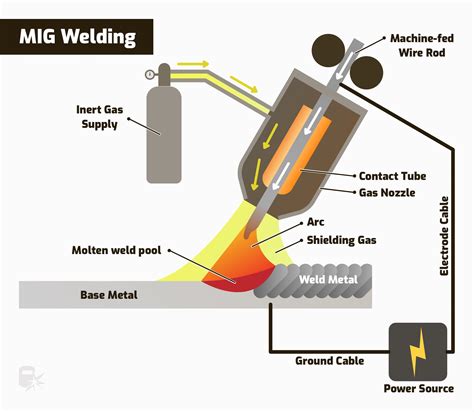

At its core, MIG welding, or Gas Metal Arc Welding (GMAW), is a process that uses a continuously fed solid wire electrode and a shielding gas to join pieces of metal. The MIG welder is the skilled professional who controls this process, wielding a "MIG gun" to create strong, clean, and durable seams—or "beads"—that are the backbone of countless manufactured goods and structures.

While the fundamental task is joining metal, the day-to-day responsibilities of a MIG welder are far more diverse and demanding than simply pulling a trigger. They are interpreters of technical plans, metallurgists in practice, and meticulous quality control inspectors, all rolled into one.

Core Roles and Responsibilities:

- Blueprint and Schematic Interpretation: A welder's first task is often to read and understand complex blueprints, technical drawings, and welding procedure specifications (WPS). This requires a strong understanding of welding symbols, measurements, and project requirements to ensure the final product is built to exact standards.

- Equipment Setup and Calibration: Before a single spark flies, a MIG welder must meticulously set up their equipment. This involves selecting the correct wire type (e.g., steel, stainless steel, aluminum), wire diameter, shielding gas (like argon, CO2, or a mix), voltage, and wire feed speed. Calibrating these settings perfectly is crucial for achieving a strong and clean weld.

- Material Preparation: "A great weld starts with great prep." Welders spend significant time preparing the metal surfaces. This includes cleaning away rust, paint, and oil, as well as cutting, grinding, and beveling edges to ensure proper fusion and penetration of the weld.

- Welding and Fabrication: This is the primary function. Using the MIG gun, the welder lays down beads in various positions—flat, horizontal, vertical, or overhead. This requires immense hand-eye coordination, a steady hand, and a deep understanding of how the molten weld puddle behaves.

- Quality Control and Inspection: A welder's job isn't done when the arc stops. They are their own first line of quality control, visually inspecting their work for defects like porosity (gas pockets), lack of fusion, cracks, or undercut. They may also use tools like calipers and gauges to ensure the weld meets dimensional specifications.

- Safety and Maintenance: Working with high temperatures, electricity, and compressed gases demands an unwavering commitment to safety. Welders must use appropriate Personal Protective Equipment (PPE) like helmets, gloves, and fire-resistant clothing. They are also responsible for the routine maintenance of their welding equipment to ensure it operates safely and effectively.

### A Day in the Life: Structural Steel Welder

To make this more tangible, let's walk through a typical day for a MIG welder working in a structural steel fabrication shop:

- 7:00 AM: Clock in, grab a coffee, and head to the morning safety briefing. The supervisor reviews the day's projects, highlighting any specific hazards or complex procedures for welding a series of large I-beams.

- 7:15 AM: Review the blueprints for the first beam assembly. You note the required weld types (fillet welds), sizes (1/4 inch), and locations.

- 7:45 AM: Head to your welding station. You inspect your MIG welder, check the gas levels, and ensure you have the correct wire loaded for structural steel. You calibrate your machine's voltage and wire speed based on the thickness of the steel and the WPS.

- 8:15 AM: The first set of precisely cut steel plates and an I-beam are brought to your workstation by a forklift. You use clamps and jigs to position and "tack weld" the pieces together, ensuring perfect alignment according to the blueprint.

- 9:00 AM - 12:00 PM: The real work begins. You don your helmet and systematically lay down the long, continuous fillet welds required to permanently join the plates to the beam. It's focused, physically demanding work, requiring you to maintain a consistent travel speed and gun angle to produce a flawless weld bead.

- 12:00 PM - 12:30 PM: Lunch break.

- 12:30 PM - 3:30 PM: You continue welding the remaining assemblies. One of the welds needs to be done in a vertical-up position, which is more challenging and requires adjusting your technique to fight gravity and ensure proper fusion. After each major weld, you use a chipping hammer and wire brush to clean off the slag and visually inspect your work.

- 3:30 PM - 4:15 PM: The welding for your assigned beams is complete. You use an angle grinder to smooth out any spatter and prepare the beams for the next stage: inspection by the Certified Welding Inspector (CWI) and then painting.

- 4:15 PM - 4:30 PM: Clean up your workstation, perform basic maintenance on your MIG gun, and store your tools. You've turned a pile of raw steel into a critical component of a future building—a satisfying and tangible end to the day.

This example showcases how a MIG welder's role is a dynamic mix of technical knowledge, hands-on skill, and rigorous attention to detail.

---

Average MIG Welder Salary: A Deep Dive

Understanding the earning potential is a critical step in evaluating any career path. For MIG welders, the salary landscape is not a single, flat number but a spectrum influenced by a multitude of factors. Here, we'll break down the national averages, typical ranges, and the complete compensation package you can expect.

It's important to note that the U.S. Bureau of Labor Statistics (BLS) groups all "Welders, Cutters, Solderers, and Brazers" into one category. While this provides a strong baseline, data from salary aggregators that specify "MIG Welder" can offer a more focused view.

National Averages and Salary Ranges

According to the most recent data from the U.S. Bureau of Labor Statistics (BLS), the median annual wage for welders, cutters, solderers, and brazers was $47,540 in May 2022. The median wage is the wage at which half the workers in an occupation earned more than that amount and half earned less. The BLS reports the following percentile breakdown:

- Lowest 10% earned less than: $37,130

- Median (50%) earned: $47,540

- Highest 10% earned more than: $72,970

However, these BLS numbers represent the entire spectrum of welding, including lower-paid production roles. Data specific to skilled MIG welders often shows a higher potential. Let's look at what leading salary aggregators report as of late 2023/early 2024:

- Payscale.com reports the average hourly rate for a MIG Welder is $20.47/hour, which translates to an annual salary of approximately $50,289. Their reported range spans from $16/hour to $29/hour.

- Salary.com places the average MIG Welder salary in the United States slightly higher, at $51,601 per year, with a typical range falling between $45,958 and $59,102.

- Glassdoor estimates the total pay for a MIG Welder to be around $59,425 per year in the United States, which includes a base salary of approximately $51,101 and additional pay (like bonuses or overtime) of around $8,324.

Summary of Averages: A realistic national average for a competent MIG welder falls comfortably in the $48,000 to $55,000 range. However, as the data shows, entry-level positions may start in the high $30,000s, while the most experienced and specialized welders can push well past $70,000 on base salary alone.

### Salary by Experience Level

Experience is arguably the single most significant factor in a welder's pay. As you progress from an apprentice learning the ropes to a master fabricator leading projects, your value—and your paycheck—grows accordingly.

Here is a typical salary progression for a MIG welder in the United States:

| Experience Level | Years of Experience | Typical Hourly Rate | Typical Annual Salary Range | Description |

| :--- | :--- | :--- | :--- | :--- |

| Entry-Level / Apprentice | 0-2 years | $17 - $21 / hour | $35,000 - $44,000 | Learning basic techniques, performing simple welds under supervision, focusing on safety and material preparation. |

| Mid-Career / Journeyman | 2-5 years | $22 - $28 / hour | $45,000 - $65,000 | Works independently, reads blueprints, proficient in multiple positions, handles more complex projects. |

| Senior / Lead Welder | 5-10+ years | $29 - $38+ / hour | $65,000 - $85,000+ | Expert in the craft, troubleshoots complex welding problems, may lead small teams, trains junior welders, and holds multiple certifications. |

| Master Welder / Supervisor | 10+ years | Varies (often salaried) | $80,000 - $110,000+ | Top-tier technical skill combined with leadership. May hold CWI (Certified Welding Inspector) or management roles. Responsible for project outcomes, quality assurance, and team management. |

*Note: These are general estimates and can vary significantly based on the other factors discussed in the next section.*

### Beyond the Base Salary: Understanding Total Compensation

A welder's paycheck is often much more than just their hourly wage. The nature of the work, particularly in construction and industrial maintenance, creates opportunities for significant additional earnings.

- Overtime Pay: This is the most common and impactful addition to a welder's income. The standard is "time and a half" (1.5x the hourly rate) for any hours worked over 40 in a week. During busy project cycles, it's not uncommon for welders to work 50 or 60 hours a week, dramatically increasing their take-home pay. A welder earning $25/hour could make an extra $375 for a 50-hour week.

- Per Diem: For welders who travel for work ("road warriors"), companies provide a per diem—a daily allowance to cover lodging, food, and incidental expenses. This can range from $50 to $150+ per day, tax-free. A skilled welder on a long-term project can bank this entire allowance if they are frugal, adding thousands to their annual income.

- Bonuses and Profit Sharing: Manufacturing companies and fabrication shops often offer performance bonuses or profit-sharing plans. If the company has a profitable year, a portion of those profits is distributed to the employees, rewarding their hard work and efficiency.

- Union Benefits: Welders who are members of a union (like the Boilermakers, Ironworkers, or Pipefitters) typically receive an excellent benefits package negotiated on their behalf. This often includes:

- Comprehensive Health Insurance: Often fully or mostly paid for by the employer.

- Defined-Benefit Pension Plans: A major long-term financial advantage, providing a guaranteed retirement income.

- Annuity Plans: Additional retirement savings accounts funded by the employer.

- Non-Union Benefits: Non-union shops also offer benefits, which commonly include 401(k) retirement plans (often with an employer match), health insurance options, and paid time off.

When evaluating a job offer, it's crucial to look at the entire compensation package. A job with a slightly lower hourly wage but with guaranteed overtime, a strong 401(k) match, and excellent health insurance could be financially superior to a job with a higher hourly rate but no benefits.

---

Key Factors That Influence a MIG Welder's Salary

The difference between a MIG welder earning $40,000 and one earning $90,000 is not luck; it's a calculated combination of skill, strategy, and circumstance. Your earning potential is directly tied to the value you provide, and that value is measured by several key factors. Mastering these levers is the key to maximizing your income throughout your career.

###

1. Certifications and Education

While a four-year degree is not required, education and certification are paramount in the welding world. They are the formal proof of your skills and your ticket to higher-paying jobs that require validated expertise.

- High School Diploma / GED: This is the foundational requirement for entry into any reputable training program or apprenticeship.

- Vocational School Certificate/Diploma: This is the most common educational path. Programs at community colleges and technical schools (like Lincoln Tech or Tulsa Welding School) provide intensive, hands-on training in MIG welding and other processes. Completing a 9-12 month program demonstrates commitment and foundational knowledge, making you a much more attractive candidate than someone with no formal training.

- Associate of Applied Science (A.A.S.) in Welding Technology: A two-year degree goes beyond the basics. It includes advanced welding theory, metallurgy, blueprint reading, destructive and non-destructive testing methods, and often business or management principles. Graduates with an A.A.S. degree are well-positioned for roles that lead to supervision, inspection (CWI), or technical sales, and they command a higher starting salary.

- The American Welding Society (AWS) Certifications: This is the gold standard. AWS certifications are performance-based tests where you must produce a high-quality weld that passes rigorous inspection. They prove you can perform to a specific code.

- AWS D1.1 (Structural Steel Welding Code): This is the most common and essential certification for welders in construction and structural fabrication. Having this cert is often a minimum requirement for high-paying structural jobs.

- Other AWS Certs: Depending on the industry, certifications like D1.5 (Bridge Welding), D1.2 (Aluminum), or D17.1 (Aerospace) can unlock elite, high-paying jobs.

- Certified Welder (CW): This is a portable credential that proves your ability to perform a specific type of weld. Companies often hire based on these specific certifications.

The Salary Impact: Simply put, more certs equal more money. An uncertified production welder might make $18/hour. The same welder who passes a 3G/4G (vertical and overhead position) D1.1 certification test could immediately command $25-$30/hour or more, as they are now qualified for more demanding and critical work.

###

2. Years of Experience and Skill Progression

Experience translates directly to speed, quality, and problem-solving ability—all of which are highly valuable to an employer. The salary trajectory detailed earlier shows a clear and consistent increase with time spent in the trade.

- Apprentice (0-2 Years): At this stage, you are paid to learn. Your value is in your potential and your ability to assist senior welders. Salary: ~$35k - $44k.

- Journeyman (2-5 Years): You are a reliable, proficient welder. You can work independently from a blueprint and produce consistent, quality welds. You are the workhorse of the shop floor or job site. Your pay reflects this competence. Salary: ~$45k - $65k.

- Senior/Master Welder (5-10+ Years): You are a problem-solver. When a complex joint, exotic material, or tricky repair comes up, you are the one they call. You can diagnose weld defects and fix them. You can fabricate complex assemblies from scratch. Your expertise minimizes costly errors and delays, making you worth a significant premium. Salary: ~$65k - $85k+.

The key to accelerating this progression is to actively seek out challenging projects. Don't just stay comfortable welding flat plates. Volunteer for the overhead welds, learn to weld different materials, and absorb as much knowledge as you can from the veterans around you.

###

3. Geographic Location

Where you work matters—a lot. Welding salaries can vary dramatically by state and even by metropolitan area, driven by demand, the cost of living, and the presence of high-paying industries.

Top-Paying States for Welders:

According to BLS data and industry analysis, states with heavy industrial, oil and gas, or major infrastructure projects tend to offer the highest wages.

| State | Average Annual Salary (for all welders) | Key Industries |

| :--- | :--- | :--- |

| Alaska | $70,860 | Oil & Gas, Pipeline Maintenance |

| North Dakota | $66,230 | Oil & Gas (Bakken Shale) |

| Wyoming | $63,080 | Mining, Oil & Gas |

| Hawaii | $62,180 | Military/Naval Shipyards, High Cost of Living |

| Washington | $61,020 | Aerospace (Boeing), Shipbuilding |

| Texas | $55,480 | Oil & Gas, Manufacturing, Petrochemical |

*Source: BLS Occupational Employment and Wage Statistics (May 2022)*

Conversely, states with less industrial activity and a lower cost of living tend to have lower average salaries. It's crucial to balance the higher wage against the cost of living. A $70,000 salary in North Dakota might give you more disposable income than an $80,000 salary in a high-cost area of California or New York.

Urban vs. Rural: Large metropolitan areas with significant manufacturing or construction hubs (like Houston, TX, or Seattle, WA) often offer higher wages than rural areas. However, rural areas with specific industries, like mining or power plants, can become high-paying hotspots.

###

4. Industry and Company Type

The industry you apply your MIG welding skills to has a massive impact on your paycheck and work environment.

- General Manufacturing: This is a common entry point. Welding parts for machinery, appliances, or other goods. Work is often repetitive, indoors, and in a controlled environment. Pay is typically around the national average.

- Construction (Structural Steel): This involves erecting the steel skeletons of buildings, bridges, and other structures. The work is physically demanding, often outdoors, and at heights. The pay is significantly higher than general manufacturing due to the skill required and the challenging conditions. Union presence is strong in this sector.

- Automotive/Transportation: Welding frames, exhaust systems, and bodies for cars, trucks, and trailers. Can range from high-speed robotic MIG welding on an assembly line to highly skilled custom fabrication in specialty shops. Pay varies, with custom/racing fabrication paying a premium.

- Shipbuilding/Marine: Welding massive steel plates to construct and repair ships and submarines. This is heavy-duty, large-scale work, often requiring certifications for specific joint types and positions. These jobs are frequently unionized and offer excellent pay and benefits, especially at naval shipyards.

- Aerospace and Defense: This is an elite tier. MIG welding aluminum and other alloys for aircraft and military vehicles requires the utmost precision and quality. The standards are incredibly high, and so is the pay. These roles often require extensive background checks and specialized certifications.

- Oil and Gas / Pipeline: This is one of the most lucrative sectors. While pipeline welding is famous for Stick and TIG processes, MIG welding (specifically flux-cored arc welding, a type of MIG) is heavily used in fabricating the related infrastructure like skids, platforms, and pressure vessels. The work is in harsh environments and often involves long hours and travel, but the pay can be exceptional, with experienced welders earning well over $100,000 with overtime.

Company Size: Large corporations (e.g., General Dynamics, Caterpillar) and union shops often offer higher base wages and more robust benefits packages. Smaller, local fabrication shops might offer a lower starting wage but can provide more diverse experience and potentially profit sharing.

###

5. Specialization and In-Demand Skills

In the world of skilled trades, specialists earn more than generalists. While being a good MIG welder is valuable, being a welder with additional, in-demand skills makes you indispensable.

- Multi-Process / Combo Welder: A welder proficient in MIG (GMAW), TIG (GTAW), and Stick (SMAW) is far more versatile than a one-process welder. They can tackle any job that comes into the shop. TIG welding, in particular, is a skill that commands a high premium, especially for materials like stainless steel and aluminum.

- Pipe Welding/Fitting: While often associated with TIG/Stick, MIG welding is used for pipe in certain applications. The ability to not just weld pipe but also to read isometric drawings, cut, and fit the pipes together is a highly paid specialization. A pipefitter/welder is one of the highest-paid roles in the trade.

- Aluminum MIG Welding: Aluminum is notoriously difficult to weld compared to steel. It requires different techniques, specific equipment (like a spool gun), and a higher level of skill. Welders who master aluminum are in high demand in the marine, automotive, and aerospace industries.

- Robotic Welding Technician/Programmer: As automation increases, the demand for welders who can operate, program, and troubleshoot robotic welding cells is skyrocketing. Instead of being replaced by the robot, you become the person who controls the robot. This is a clear path to a six-figure income.

- Fabrication Skills: A "welder" just joins two pieces of metal. A "fabricator" can take a pile of raw stock and a blueprint and build the entire project from start to finish. This includes reading prints, measuring, cutting (with saws, plasma cutters, torches), bending, and assembling. Fabricators are project-solvers and earn significantly more.

- Certified Welding Inspector (CWI): After years of experience, a welder can pursue a CWI certification from the AWS. This transitions you from a hands-on role to a quality