Table of Contents

- [What Does a Production Technician Do?](#what-does-a-production-technician-do)

- [Average Production Technician Salary: A Deep Dive](#average-production-technician-salary-a-deep-dive)

- [Key Factors That Influence Your Salary](#key-factors-that-influence-your-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Become a Production Technician](#how-to-become-a-production-technician)

- [Conclusion: Is a Career as a Production Technician Right for You?](#conclusion-is-a-career-as-a-production-technician-right-for-you)

In the intricate and powerful engine of the global economy, some roles operate quietly behind the scenes, yet their impact is monumental. These are the positions that transform raw materials into life-saving medicines, innovative electronics, and the vehicles that connect our world. If you are a problem-solver, a hands-on doer, and someone who finds satisfaction in the tangible results of your work, a career as a Production Technician might be your calling. This role is not just a job; it's the very heartbeat of modern manufacturing and innovation.

But passion and purpose must be paired with practicality. You want to know if this career can provide a stable and prosperous life. The answer is a resounding yes. A production technician salary is competitive and offers significant growth potential, with a typical range in the United States falling between $45,000 and $75,000 per year, and top earners in specialized fields exceeding $90,000.

I’ve spent over two decades analyzing career trajectories, and I once had the opportunity to tour a major biopharmaceutical manufacturing facility. While the scientists in their lab coats received much of the fanfare, it was a senior production technician, Maria, who truly ran the show on the floor. With an almost intuitive understanding of the complex bioreactors, she noticed a minuscule pressure fluctuation that computer monitors missed, preventing a batch contamination that would have cost the company over a million dollars. Her expertise was the invisible shield protecting the company's bottom line and, more importantly, its life-changing product.

Maria’s story is a testament to the critical nature of this profession. This guide is designed to be your comprehensive roadmap to understanding and achieving success in this field. We will delve into the nitty-gritty of the role, dissect every component of your potential salary, explore the factors that can maximize your earnings, and provide a step-by-step plan to launch your career. Whether you're just starting to explore your options or looking to advance in your current role, this article will equip you with the knowledge to build a rewarding and lucrative career.

What Does a Production Technician Do?

At its core, a Production Technician is a skilled professional responsible for setting up, operating, monitoring, and maintaining the equipment and machinery used in a manufacturing or production process. They are the frontline experts who ensure that production lines run efficiently, safely, and produce high-quality products according to precise specifications. Think of them as the skilled operators and guardians of the manufacturing process, bridging the gap between engineering designs and finished goods.

While the specific industry—be it automotive, pharmaceutical, electronics, or food and beverage—shapes the fine details of the job, the core responsibilities remain remarkably consistent. They are the masters of the "how," ensuring the "what" gets made correctly.

Breakdown of Core Responsibilities and Daily Tasks:

- Equipment Setup and Calibration: Before a production run begins, technicians meticulously set up machinery, calibrate instruments, and load raw materials. This requires a keen eye for detail and the ability to interpret technical manuals and blueprints.

- Operation and Monitoring: During production, technicians operate the equipment, often through complex control panels or computer interfaces (HMIs - Human-Machine Interfaces). They constantly monitor the process, watching for warning lights, listening for unusual sounds, and checking gauges to ensure everything is running within optimal parameters.

- Quality Control and Inspection: Quality is paramount. Technicians perform regular in-process checks and inspections on products. This can involve visual inspections, taking precise measurements with tools like calipers and micrometers, or running samples through laboratory equipment. They are the first line of defense against defects.

- Troubleshooting and Maintenance: When a machine malfunctions or a process deviates from the norm, the production technician is the first responder. They use their diagnostic skills to identify the root cause of the problem—be it mechanical, electrical, or pneumatic—and perform necessary repairs or adjustments. This can range from clearing a simple jam to assisting maintenance engineers with more complex repairs.

- Documentation and Record-Keeping: Precision industries, especially pharmaceuticals and aerospace, require meticulous documentation. Technicians are responsible for maintaining accurate production logs, recording data, tracking batch numbers, and documenting any deviations or maintenance activities. This data is crucial for regulatory compliance and process improvement.

- Adherence to Safety and Regulatory Protocols: Technicians must be experts in safety procedures, including Lockout/Tagout (LOTO) and the use of Personal Protective Equipment (PPE). In regulated industries like food and medicine, they must strictly follow protocols like Current Good Manufacturing Practices (cGMP).

### A "Day in the Life" of a Production Technician

To make this tangible, let's imagine a day for a Production Technician at a medical device company:

7:00 AM: Arrive and gear up. This includes putting on specialized gowning (bunny suit, booties, mask, gloves) to enter the cleanroom environment.

7:15 AM: Shift handoff meeting. The outgoing shift technician briefs you on the status of the production line, any issues encountered overnight, and the production targets for the day. You review the production schedule and logbooks.

7:45 AM: Line setup. You are tasked with setting up the automated assembly line for a new batch of diagnostic catheters. You load the correct components into the feeders, pull up the specific program on the PLC control panel, and run a few test cycles to ensure the robotic arms are perfectly calibrated.

9:30 AM: Production run begins. You initiate the full production run, closely monitoring the entire process. Your eyes scan across multiple screens showing pressure, speed, and temperature, while you also physically watch the machines for any sign of a jam or misalignment.

11:00 AM: Quality check. Every 90 minutes, you pull five finished catheters from the line for a quality inspection. You use a digital microscope to check for any microscopic flaws and a laser micrometer to ensure the diameter is within a tolerance of just a few microns. You log your results in the digital batch record.

12:30 PM: Lunch break.

1:00 PM: Minor troubleshooting. An alarm sounds—a sensor on one of the adhesive dispensers is failing to read properly. You pause the line, follow safety protocols to access the machine, clean the sensor, and reboot the station. The line is back up and running within 10 minutes, preventing significant downtime.

3:00 PM: Material changeover. The spool of a critical polymer tubing is running low. You execute a seamless changeover, splicing the new spool in without stopping the main line, ensuring continuous production. You document the lot number of the new material.

4:45 PM: End of shift duties. You clean your workstation, complete all required documentation for the day's production run, and prepare a detailed handoff report for the incoming evening shift technician.

5:00 PM: Degown and head home, leaving behind a full day's work of perfectly manufactured, life-saving medical devices.

This example highlights the blend of technical knowledge, attention to detail, and problem-solving skills that define the role.

Average Production Technician Salary: A Deep Dive

Understanding the financial landscape is a critical step in evaluating any career path. For production technicians, the salary is not just a single number but a spectrum influenced by a variety of factors, which we'll explore in the next section. Here, we will establish a solid baseline by looking at national averages, typical ranges, and the different components that make up a technician's total compensation.

It's important to note that government data from sources like the Bureau of Labor Statistics (BLS) often groups various technician roles, so it's beneficial to cross-reference this information with real-time data from salary aggregators for a more complete picture.

### National Averages and Salary Ranges

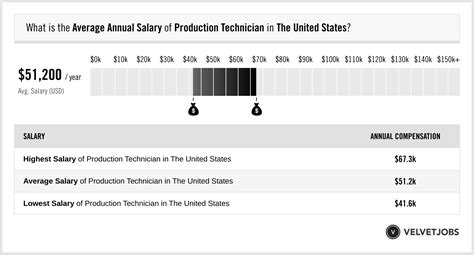

According to the most recent data, here’s a look at what production technicians can expect to earn across the United States:

- U.S. Bureau of Labor Statistics (BLS): The BLS groups many production roles. For example, the category "Assemblers and Fabricators" had a median annual wage of $40,990 in May 2023. However, this includes very basic assembly line work. A more comparable category might be "Chemical Technicians," who had a median annual wage of $55,900, or "Semiconductor Processing Technicians" with a median wage of $47,260. This highlights that the specific industry heavily influences the official data.

- Salary.com: This platform, which collects employer-reported data, provides a more targeted view. As of early 2024, they report the median salary for a "Production Technician I" (entry-level) to be around $46,944, with a typical range falling between $41,617 and $53,491. For a more experienced "Production Technician III" (senior), the median jumps to $64,482, with a range of $56,664 to $73,639.

- Payscale: This aggregator, which uses user-reported data, shows the average base salary for a Production Technician is approximately $52,100 per year (as of early 2024). Their reported range is typically between $38,000 and $74,000.

- Glassdoor: Combining user-reported salaries and job listings, Glassdoor estimates the total pay for a Production Technician in the U.S. to be around $59,850 per year, with a likely range between $48,000 and $75,000.

Consolidated View: Taking all sources into account, a realistic national average base salary for a skilled Production Technician is in the $50,000 to $60,000 range. Entry-level positions start in the low $40,000s, while highly skilled, experienced technicians in specialized industries can earn well into the $70,000s and beyond.

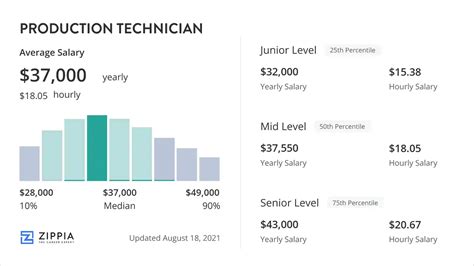

### Salary Progression by Experience Level

Your value—and therefore your salary—grows significantly as you gain hands-on experience and prove your ability to manage more complex tasks with greater autonomy. Here’s a typical salary progression you can expect:

| Experience Level | Years of Experience | Typical Annual Salary Range | Key Responsibilities & Skills |

| :--- | :--- | :--- | :--- |

| Entry-Level Production Technician | 0-2 Years | $40,000 - $50,000 | Following instructions, basic machine operation, routine quality checks, learning safety protocols, assisting senior technicians. |

| Mid-Career Production Technician | 3-8 Years | $50,000 - $65,000 | Independent operation of complex machinery, basic troubleshooting and maintenance, training junior technicians, process monitoring, data entry. |

| Senior/Lead Production Technician| 9+ Years | $65,000 - $80,000+ | Overseeing a production line or shift, advanced troubleshooting, process improvement projects, calibrating complex instruments, leading training efforts, working with engineers. |

*Note: These are national averages and can be significantly higher in high-cost-of-living areas or high-demand industries.*

### Beyond the Base Salary: Understanding Total Compensation

Your annual salary is only one piece of the puzzle. Total compensation includes other valuable financial benefits that can significantly increase your overall earnings and financial well-being. When evaluating a job offer, be sure to consider the entire package.

- Overtime Pay: Manufacturing often operates on tight deadlines and can run 24/7. This means overtime opportunities are common. For non-exempt employees (which includes most technicians), work beyond 40 hours a week is paid at 1.5 times the regular hourly rate. This can add a substantial amount—often 10-25%—to your annual income.

- Shift Differentials: Many facilities operate multiple shifts. Working the second (evening), third (overnight), or weekend shifts almost always comes with a pay premium, known as a shift differential. This can range from an extra $1-$5 per hour, adding thousands of dollars to your yearly pay.

- Bonuses:

- Performance/Production Bonuses: Many companies offer quarterly or annual bonuses tied to meeting or exceeding production targets, quality metrics, or safety goals.

- Sign-On Bonuses: In high-demand fields or regions, companies may offer a sign-on bonus of several thousand dollars to attract skilled technicians.

- Profit Sharing: Some companies, particularly established, profitable ones, offer a profit-sharing plan. A percentage of the company's annual profits is distributed among employees, directly rewarding you for the company's success.

- Retirement Benefits (401k/403b): A strong retirement plan is a crucial part of compensation. Look for employers that offer a 401(k) plan with a generous company match. A common match is 50% of your contributions up to 6% of your salary—this is essentially free money and a key component of long-term wealth building.

- Health and Wellness Benefits: Comprehensive health, dental, and vision insurance is a major financial benefit. A good employer plan can save you thousands of dollars per year in premiums and out-of-pocket costs compared to private insurance.

- Paid Time Off (PTO): Generous vacation, sick leave, and holiday policies are also part of your compensation, providing work-life balance without sacrificing income.

- Tuition Reimbursement: Many forward-thinking companies will invest in their employees by offering tuition reimbursement for relevant coursework, certifications, or even a full associate's or bachelor's degree. This is an incredibly valuable perk that allows you to increase your future earning potential on the company's dime.

When you add these components together, a job with a base salary of $55,000 could easily have a total compensation value of $70,000 or more, making it essential to look beyond the initial salary figure.

Key Factors That Influence Your Salary

While national averages provide a useful benchmark, your personal production technician salary will be determined by a specific set of factors. Understanding these levers is the key to maximizing your earning potential throughout your career. By strategically focusing on your education, skills, and career choices, you can actively steer your compensation upward. This section provides a detailed breakdown of the six most critical factors that influence your pay.

###

1. Level of Education and Certification

While you can enter the field with a high school diploma, your educational background serves as the foundation upon which your career—and salary—are built. Higher levels of formal education and specialized certifications directly translate to higher starting salaries and faster advancement.

- High School Diploma or GED: This is the minimum requirement for most entry-level positions. With a diploma, you can expect a starting salary at the lower end of the spectrum, likely in the $40,000 - $45,000 range. Your initial focus will be on-the-job training.

- Vocational School or Certificate Programs: A post-secondary certificate in a field like Manufacturing Technology, Welding, or Industrial Maintenance (often a 6-12 month program) can make you a much more attractive candidate. It demonstrates commitment and foundational knowledge, potentially boosting your starting salary by 5-10% and allowing you to bypass more basic entry-level roles.

- Associate's Degree (A.S. or A.A.S.): This is often considered the sweet spot for ambitious production technicians. A two-year Associate of Science (A.S.) or Associate of Applied Science (A.A.S.) degree in Process Technology, Manufacturing Engineering Technology, or Electronics Technology provides a powerful combination of theoretical knowledge and hands-on lab experience. Graduates with an associate's degree can often command starting salaries in the $50,000 - $55,000 range and are placed on a faster track toward senior and lead technician roles.

- Industry Certifications: Certifications are a powerful way to validate your skills and command a higher salary at any stage of your career. They are tangible proof of your expertise.

- Certified Production Technician (CPT): Offered by the Manufacturing Skill Standards Council (MSSC), this is a nationally recognized credential that covers safety, quality, production processes, and maintenance. Holding this can give you a significant edge.

- Six Sigma (Yellow, Green Belt): Six Sigma is a data-driven methodology for process improvement. A technician with a Green Belt certification demonstrates they can identify and eliminate inefficiencies, a skill highly valued by employers and one that can add thousands to your salary.

- IPC Certification: For those in electronics manufacturing, IPC standards are globally recognized. Certifications like IPC-A-610 (Acceptability of Electronic Assemblies) are often required and come with a pay premium.

- ASQ Certifications: The American Society for Quality (ASQ) offers credentials like Certified Quality Technician (CQT), which are highly respected and can lead to specialized, higher-paying roles in quality assurance.

###

2. Years of Experience

Experience is arguably the single most significant factor in salary growth. In a hands-on role like this, there is no substitute for time spent on the production floor, solving real-world problems. Employers pay a premium for technicians who have "seen it all" and can work with minimal supervision.

- Entry-Level (0-2 years): Your primary value is your potential. Your salary (~$40k-$50k) reflects that you are still learning the specific equipment and processes. Your goal is to be a sponge, absorbing as much knowledge as possible.

- Mid-Career (3-8 years): You are now a reliable, independent contributor. You can handle most day-to-day operations and troubleshoot common issues. Your salary sees a significant jump (~$50k-$65k) as your proven competence reduces downtime and supports team productivity. You may begin training newer technicians.

- Senior/Lead (9+ years): You are a subject matter expert. You not only operate the equipment but understand *why* it works the way it does. You are called upon for the most difficult problems, lead process improvement initiatives, and work alongside engineers to implement new technologies. Your salary reflects this expertise (~$65k-$80k+), and you are a candidate for supervisory roles.

###

3. Geographic Location

Where you work matters—a lot. Salaries for production technicians can vary by as much as 30-40% depending on the state and metropolitan area. This variation is driven by two main factors: the local cost of living and the concentration of high-paying industries.

- Top-Paying States: States with a heavy presence of technology, aerospace, biopharmaceutical, or energy industries tend to offer the highest salaries. According to BLS and salary aggregator data, states like:

- California: (High tech, biotech, aerospace) - Averages can be 15-25% above the national average.

- Texas: (Energy, semiconductor, aerospace) - Strong salaries, particularly in hubs like Houston and Austin.

- Washington: (Aerospace, tech) - Driven by companies like Boeing and tech manufacturing.

- Massachusetts: (Biotech, medical devices) - Boston/Cambridge area is a major hub.

- Alaska: (Energy) - High cost of living and remote work drive up wages significantly.

- Lower-Paying States: States in the Southeast and parts of the Midwest with a lower cost of living and a focus on more traditional manufacturing (e.g., textiles, food processing) tend to have salaries closer to or slightly below the national average.

- Metropolitan vs. Rural Areas: Within any given state, salaries in major metropolitan areas will almost always be higher than in rural locations to account for a higher cost of living. A production technician in the San Francisco Bay Area might earn $75,000 for the same job that pays $55,000 in a smaller city in the Central Valley.

Example Salary Comparison by City (Annual Average Base):

- San Jose, CA: ~$72,000

- Boston, MA: ~$68,000

- Austin, TX: ~$62,000

- Raleigh, NC: ~$58,000

- St. Louis, MO: ~$54,000

- Orlando, FL: ~$51,000

*(Data compiled and averaged from various salary aggregators, early 2024)*

###

4. Company Type & Size

The type of company you work for has a direct impact on your compensation structure and overall earning potential.

- Large Corporations (Fortune 500): Companies like Johnson & Johnson, Intel, Procter & Gamble, or General Motors typically offer the most competitive and structured compensation. They generally provide:

- Higher base salaries.

- Robust benefits packages (excellent health insurance, generous 401k matching).

- Formal bonus structures and sometimes profit sharing or stock options.

- Clear, defined career ladders for advancement.

- Small to Medium-Sized Enterprises (SMEs): Smaller companies may offer a base salary that is at or slightly below the market rate of large corporations. However, they can sometimes offer more flexibility, a greater sense of ownership, and potentially faster opportunities for increased responsibility. The benefits packages might be less comprehensive.

- Startups: A manufacturing startup (e.g., in 3D printing, clean energy, or a new biotech field) is a higher-risk, potentially higher-reward environment. The base salary might be lower than at an established corporation, but this could be offset by equity or stock options, which could become extremely valuable if the company succeeds. The work environment is often fast-paced and less structured.

- Government/Defense Contractors: Working for a government agency or a major defense contractor like Lockheed Martin or Northrop Grumman often means excellent job security, fantastic benefits, and a pension plan (in some cases). Salaries are competitive and often follow a strict government pay scale (like the GS scale), ensuring transparent and predictable salary growth.

###

5. Area of Specialization (Industry)

The industry you choose to specialize in is a massive determinant of your salary. The more complex, regulated, and profitable the industry, the higher the pay for the technicians who make it run. While the prompt mentioned IT/marketing/finance, a production technician role is firmly rooted in physical production environments. The true specializations lie within different manufacturing sectors:

- Semiconductor/Microelectronics: (Highest Paying) This is often the pinnacle of production technician pay. Technicians work in highly controlled, expensive cleanroom environments, operating sophisticated photolithography, etching, and deposition equipment. The required precision is immense.

- *Average Salary Range:* $60,000 - $85,000+

- Pharmaceutical/Biotechnology: Technicians in this field must adhere to strict FDA regulations and cGMP. They operate bioreactors, purification systems, and aseptic filling lines. The critical nature of producing life-saving drugs commands a high salary.

- *Average Salary Range:* $55,000 - $75,000

- Aerospace & Defense: Building components for airplanes and defense systems requires zero defects. Technicians often work with advanced materials like composites, utilize precision CNC machining, and must maintain meticulous documentation for FAA and military compliance.

- *Average Salary Range:* $55,000 - $75,000

- Energy (Oil & Gas, Renewables): Technicians in the energy sector, particularly in oil and gas extraction and refining, can earn very high salaries, often supplemented by significant overtime and hardship pay for remote locations. Technicians in renewable energy (e.g., solar panel or wind turbine manufacturing) are also in growing demand.

- *Average Salary Range:* $60,000 - $90,000+

- Automotive Manufacturing: This is a classic field for production technicians. With the rise of electric vehicles (EV