In a world driven by production, where millions of products—from the smartphone in your pocket to the life-saving medical devices in hospitals—are made every day, one role stands as the crucial guardian of excellence: the Quality Control (QC) Technician. If you are a meticulous, detail-oriented individual who finds satisfaction in ensuring things are done *right*, this career path may not only be fulfilling but also financially rewarding. The national average quality control technician salary offers a stable foundation, with significant potential for growth for those who master the craft.

I once had the opportunity to tour an aerospace manufacturing facility where components for commercial airliners were being forged. Amidst the roar of machinery, I saw a QC Technician working in a climate-controlled, glass-enclosed lab, using a sophisticated Coordinate Measuring Machine (CMM) to verify a turbine blade's dimensions down to the micron. It struck me then that this individual's focus and precision were a direct link in the chain of safety for hundreds of passengers on every single flight. This isn't just a job; it's a profound responsibility.

This guide is designed to be your comprehensive roadmap to understanding the financial landscape of a Quality Control Technician career. We will delve deep into salary expectations, the factors that can dramatically increase your earning potential, the long-term career outlook, and a step-by-step plan to get you started.

### Table of Contents

- [What Does a Quality Control Technician Do?](#what-does-a-qc-technician-do)

- [Average Quality Control Technician Salary: A Deep Dive](#average-qc-salary)

- [Key Factors That Influence Salary](#key-factors)

- [Job Outlook and Career Growth](#job-outlook)

- [How to Get Started in This Career](#how-to-get-started)

- [Conclusion: Is a QC Technician Career Right for You?](#conclusion)

What Does a Quality Control Technician Do?

At its core, a Quality Control Technician is the hands-on enforcer of quality standards. While a Quality Engineer might design the testing protocols and a Quality Manager might oversee the entire system, the QC Technician is on the front lines, actively inspecting, measuring, and testing products to ensure they conform to a precise set of specifications. They are the detectives of the manufacturing world, searching for deviations, defects, and non-conformities before a product ever reaches the consumer.

Their work is essential across virtually every industry, including:

- Manufacturing: Automotive parts, electronics, machinery, consumer goods.

- Aerospace & Defense: Aircraft components, navigation systems, military hardware.

- Pharmaceuticals & Medical Devices: Medications, surgical tools, implants, diagnostic equipment.

- Food & Beverage: Ensuring safety, consistency, and compliance with health regulations.

- Software & Technology: Testing applications for bugs and user experience issues (often called a QA, or Quality Assurance, Tester).

- Construction & Materials: Testing the strength and composition of concrete, steel, and other building materials.

Core Responsibilities and Daily Tasks:

A QC Technician's day is a blend of meticulous hands-on work, data analysis, and communication. Common tasks include:

- Inspection and Testing: Performing visual inspections, running automated tests, and using precise measuring instruments (like calipers, micrometers, and CMMs) to check product dimensions and features against blueprints and technical drawings.

- Documentation: Accurately recording test results, logging defects, and creating detailed inspection reports. This documentation is critical for compliance, traceability, and process improvement.

- Root Cause Analysis: When a defect is found, technicians often assist engineers in identifying the source of the problem—whether it's a faulty machine, an incorrect process, or a subpar raw material.

- Calibration: Ensuring that all testing and measurement equipment is properly calibrated and functioning accurately.

- Following Protocols: Adhering strictly to established quality standards, such as those from the International Organization for Standardization (ISO 9001) or specific industry regulations like Good Manufacturing Practices (GMP) in the pharmaceutical sector.

- Communication: Collaborating with production staff to provide feedback on quality issues and working with engineers to resolve problems.

### A Day in the Life: "Maria, a QC Tech at an Electronics Plant"

To make this role more tangible, let's imagine a typical day for Maria, a mid-level QC Technician.

- 8:00 AM - Morning Huddle & First Article Inspection: Maria starts her day in a brief meeting with the production supervisor to discuss the day's schedule. Her first task is a "First Article Inspection" (FAI). The production line has just been set up to produce a new batch of 10,000 circuit boards. Maria takes the very first board off the line and brings it to the QC lab. She spends the next hour meticulously comparing it against the engineering drawing, using a digital microscope to check solder points and a vision system to verify component placement.

- 10:00 AM - In-Process Audits: The FAI passed. Now, Maria heads to the factory floor to perform in-process audits. Every hour, she pulls a random sample of five boards from the line. She performs a series of pre-defined checks on each, recording the results in the company's Quality Management System (QMS) software.

- 12:30 PM - Lunch.

- 1:00 PM - Investigating a Non-Conformance: A machine operator flags an issue—a batch of boards is showing minor discoloration. Maria isolates the affected batch and begins her investigation. She documents the issue with photos, runs a few additional tests, and reviews the machine's logs from that production run. She works with the operator and a process engineer to trace the problem back to a slight temperature fluctuation in a curing oven.

- 3:00 PM - Data Entry & Reporting: Back in the lab, Maria finalizes her non-conformance report, detailing the problem, its root cause, and the corrective action taken (the oven was recalibrated). She also analyzes the data from her hourly audits, noting a very slight, but consistent, drift in a resistor's placement. She flags this for the engineering team as a potential area for process improvement.

- 4:30 PM - Final Checks: Before leaving, Maria ensures her workstation is clean and her measurement tools are properly stored. She sends a summary email of the day's quality metrics to the Quality Manager, highlighting the resolved oven issue and the potential resistor drift.

This example illustrates how a QC Technician's role is not just about finding flaws, but about being an integral part of a continuous improvement cycle that enhances product quality and company efficiency.

Average Quality Control Technician Salary: A Deep Dive

Understanding the earning potential is a critical step in evaluating any career. A quality control technician salary can vary significantly, but we can establish a clear baseline and progression using data from authoritative sources.

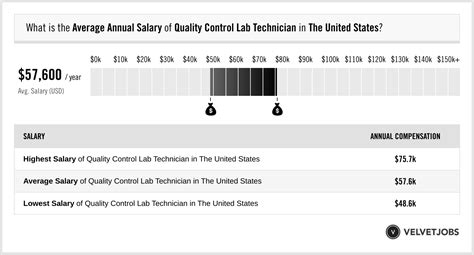

According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for quality control inspectors was $43,770 as of May 2023. This means half of all QC inspectors earned more than this amount, and half earned less. The BLS also reports a wide salary spectrum, with the lowest 10 percent earning less than $30,220 and the highest 10 percent earning more than $73,790.

However, the BLS often groups various skill levels and industries together. For a more granular view, we can turn to leading salary aggregators that differentiate by experience.

- Salary.com provides a more detailed breakdown, reporting the median salary for a Quality Control Technician II (a mid-career role) to be around $54,236 as of May 2024. Their data suggests a typical range between $47,944 and $60,948.

- Payscale.com reports a similar average base salary of approximately $49,600 per year, with a common range falling between $37,000 and $69,000.

- Glassdoor.com, which aggregates self-reported salaries, shows a total pay estimate (including bonuses and other compensation) of around $58,405 per year in the United States.

Key Takeaway: While the BLS provides a conservative median, real-world data from multiple sources suggests that a competent QC Technician can expect to earn in the $48,000 to $60,000 range, with significant room for growth beyond that figure.

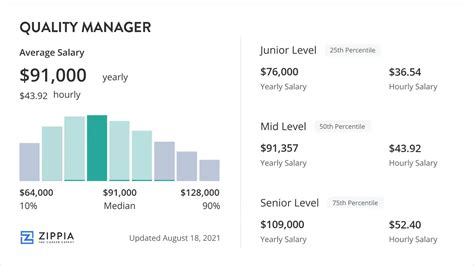

### Salary by Experience Level

Your earnings will directly correlate with your experience, skill level, and the complexity of your responsibilities. The career path typically follows three main stages, each with its own salary bracket.

| Career Stage | Typical Years of Experience | Common Responsibilities | Average Salary Range (Annual) | Data Source & Context |

| :--- | :--- | :--- | :--- | :--- |

| Entry-Level Quality Control Technician | 0-2 Years | Following established procedures, performing basic visual inspections, using simple measurement tools (calipers, rulers), data entry. | $37,000 - $48,000 | Based on the 10th-25th percentile data from Salary.com (for a QC Tech I) and Payscale.com. |

| Mid-Career Quality Control Technician | 3-8 Years | Working with more complex blueprints, operating advanced equipment (CMM, optical comparators), identifying non-conformances, assisting in root cause analysis, training junior technicians. | $48,000 - $61,000 | Based on median salary data from Salary.com (QC Tech II) and Glassdoor. |

| Senior/Lead Quality Control Technician | 9+ Years | Leading inspection teams, developing inspection plans, calibrating complex equipment, analyzing quality data (SPC), authoring quality reports, driving process improvements. | $61,000 - $75,000+ | Based on the 75th-90th percentile data from Salary.com (QC Tech III) and Payscale for highly experienced individuals. |

*Note: These are national averages. Your specific salary will be heavily influenced by the factors discussed in the next section.*

### Beyond the Base Salary: Understanding Total Compensation

Your paycheck is more than just your base salary. A comprehensive compensation package for a QC Technician often includes several other valuable components. When evaluating a job offer, be sure to consider the entire package.

- Bonuses: Many manufacturing and technology companies offer annual or quarterly bonuses tied to individual performance, team goals, or company profitability. These can range from a few hundred dollars to several thousand, potentially adding 5-10% to your annual earnings.

- Profit Sharing: Some companies, particularly privately-held ones, distribute a portion of their profits to employees. This is a powerful incentive that directly links your work to the company's success.

- Overtime Pay: As a non-exempt role under the Fair Labor Standards Act (FLSA), most QC Technicians are eligible for overtime pay (1.5x their hourly rate) for any hours worked over 40 in a week. During busy production cycles, this can significantly boost income.

- Shift Differentials: Technicians working second or third shifts often receive a "shift differential"—an increase in their hourly pay rate (typically 10-15%) as compensation for working non-standard hours.

- Health and Wellness Benefits: This includes medical, dental, and vision insurance. A strong benefits package can be worth thousands of dollars a year.

- Retirement Savings: Look for a 401(k) or similar retirement plan, especially one with a company match. A company match is essentially free money and a critical component of long-term financial health.

- Paid Time Off (PTO): This includes vacation days, sick leave, and paid holidays.

- Tuition Reimbursement: Many employers will invest in their employees by helping to pay for further education, such as an Associate's degree or professional certifications, which can lead to higher pay in the long run.

A job offer with a base salary of $52,000 but a strong bonus structure, excellent health benefits, and a 401(k) match could be far more valuable than a flat $55,000 offer with minimal benefits.

Key Factors That Influence a Quality Control Technician Salary

Two technicians with the same job title can have vastly different salaries. Why? Because compensation is a complex equation influenced by a multitude of factors. Mastering these variables is the key to maximizing your earning potential throughout your career. This section provides an exhaustive breakdown of what truly drives a quality control technician salary.

### 1. Level of Education and Certification

While you can enter the field with a high school diploma, your educational background and professional certifications create a clear ladder for salary advancement.

- High School Diploma or GED: This is the minimum requirement for most entry-level positions. At this level, you can expect a salary at the lower end of the spectrum, likely in the $37,000 to $42,000 range. The focus will be on on-the-job training.

- Associate's Degree: Earning a two-year Associate of Applied Science (A.A.S.) degree in a relevant field like Manufacturing Technology, Industrial Technology, or Quality Assurance can be a significant advantage. It provides a formal understanding of metrology (the science of measurement), blueprint reading, and quality systems. Graduates with an Associate's degree can often command starting salaries $5,000 to $8,000 higher than those with only a high school diploma and may advance more quickly.

- Bachelor's Degree: While not typically required for a *technician* role, a four-year degree in a field like Industrial Engineering, Mechanical Engineering, or Operations Management positions you for higher-level roles. Individuals with a bachelor's degree may start as a QC Technician to gain hands-on experience but are on a fast track to becoming a Quality Engineer, a role with a significantly higher salary (often starting in the $70,000s).

- Professional Certifications: This is arguably the most impactful way to increase your salary without pursuing a full degree. Certifications from respected bodies like the American Society for Quality (ASQ) are the gold standard.

- Certified Quality Technician (CQT): This certification demonstrates a thorough understanding of quality concepts, tools, and techniques. According to ASQ's own salary survey, professionals holding the CQT certification report higher average salaries than their non-certified peers.

- Certified Quality Inspector (CQI): This is another highly respected certification focused specifically on inspection and measurement techniques. It validates your hands-on skills.

- Six Sigma Belts (Yellow, Green, Black): While more focused on process improvement, Six Sigma certifications are highly valued in quality departments. A QC Technician with a Green Belt certification is seen as a valuable asset who can not only find defects but also participate in projects to prevent them, commanding a higher salary.

### 2. Years of Experience

As shown in the previous section, experience is a primary driver of salary. However, it's not just the number of years that matters, but the *quality* and *progression* of that experience.

- 0-2 Years (The Learner): In this phase, your value is in your ability to learn quickly and execute instructions reliably. Your salary will be at the entry-level range. The goal is to absorb as much as possible and become proficient with basic tools and procedures.

- 3-8 Years (The Problem-Solver): Here, you move from just following instructions to actively solving problems. You should be able to work independently, troubleshoot common issues, and operate advanced equipment. This is where you'll see the most significant jump in salary, moving firmly into the mid-career range of $48,000 to $61,000. Employers are paying for your proven competence and efficiency.

- 9+ Years (The Leader & Expert): Senior technicians become mentors and subject matter experts. They may not have direct reports but are often responsible for training others, leading complex inspections, and validating new processes or equipment. They have a deep understanding of the "why" behind the quality standards. This level of expertise commands salaries at the top end of the spectrum, often exceeding $65,000 and pushing into the $70,000s, especially with specialized skills.

### 3. Geographic Location

Where you work matters—a lot. Salaries for QC Technicians are heavily influenced by the local cost of living and the concentration of high-paying industries. A salary that feels comfortable in one state might be difficult to live on in another.

Top-Paying States and Metropolitan Areas:

States with a high concentration of aerospace, medical device, semiconductor, and high-tech manufacturing tend to offer the highest salaries.

- California: Particularly in areas like Silicon Valley and Southern California's aerospace corridor, salaries can be 15-25% above the national average to compensate for the high cost of living.

- Washington: Home to Boeing and a thriving tech scene, the Seattle-Tacoma area is another high-paying region.

- Massachusetts: The Boston area is a hub for biotechnology, pharmaceuticals, and medical devices, driving up demand and wages for skilled QC technicians.

- Texas: Major manufacturing hubs like Dallas-Fort Worth and Houston offer competitive salaries, especially in the oil & gas and electronics sectors.

- Maryland & Virginia: The proximity to government and defense contractors creates a high-demand, high-salary environment.

Lower-Paying Regions:

Conversely, salaries tend to be lower in states with a lower cost of living and a less-developed high-tech manufacturing base. This often includes more rural areas in the Southeast and parts of the Midwest, where salaries might be 5-15% below the national average. However, the reduced cost of living can often offset the lower wage.

### 4. Industry and Company Size

The industry you work in is one of the most powerful salary determinants. Industries with high-risk, high-regulation, and high-precision requirements pay a premium for quality.

- Top-Tier Industries (Highest Paying):

- Aerospace & Defense: The consequence of failure is catastrophic, so quality is paramount. Technicians must be experts in complex metrology and non-destructive testing (NDT). Salaries here are often at the absolute top of the pay scale.

- Pharmaceuticals & Medical Devices: These are heavily regulated by the FDA. Technicians must be experts in GMP, documentation, and sterile processes. This expertise commands a significant salary premium.

- Semiconductor Manufacturing: Working in a cleanroom environment with incredibly complex and expensive equipment requires specialized skills that are well-compensated.

- Mid-Tier Industries (Competitive Pay):

- Automotive: With a strong focus on safety and efficiency (Lean/Six Sigma), the auto industry pays competitively, especially for technicians with skills in automation and SPC.

- Heavy Machinery & Industrial Equipment: Precision and durability are key, leading to solid, reliable salaries.

- Lower-Tier Industries (Standard Pay):

- General Consumer Goods: While still important, the quality standards may be less stringent than in aerospace.

- Textiles and Apparel: Often involves more visual inspection and less complex metrology, leading to salaries on the lower end of the national average.

Company Size:

- Large Corporations (e.g., Johnson & Johnson, Boeing, General Motors): These companies typically have very structured pay bands, excellent benefits, and clear paths for advancement. Your starting salary might be standardized, but the long-term potential and benefits package are often superior.

- Small to Medium-Sized Enterprises (SMEs) & Startups: Salaries can be more variable. A well-funded startup in a high-tech space might offer a very competitive salary to attract top talent. A smaller, family-owned manufacturing shop might offer a lower base salary but could provide more flexibility or a better work-life balance.

### 5. In-Demand Skills and Specializations

The generic title "Quality Control Technician" can hide a wide range of specializations. Developing niche, high-value skills is the fastest way to become indispensable and increase your paycheck.

- Coordinate Measuring Machine (CMM) Programming & Operation: This is a top-tier skill. A CMM is a highly advanced device that measures the geometry of physical objects. Technicians who can not only operate but also program a CMM (using software like PC-DMIS or Calypso) are in high demand and can command salaries $10,000+ above the median.

- Geometric Dimensioning and Tolerancing (GD&T): This is the symbolic language used on engineering drawings to define the allowable deviation of feature geometry. A deep understanding of GD&T is critical for accurate inspection in precision manufacturing. Payscale.com data consistently shows that GD&T proficiency is one of the highest-paying skills for a QC Tech.

- Statistical Process Control (SPC): This involves using statistical methods to monitor and control a process. Technicians skilled in SPC can move beyond simply finding defects to analyzing trends and helping prevent them from occurring in the first place. This analytical skill is highly valued.

- Non-Destructive Testing (NDT): In industries like aerospace and welding, NDT methods (like ultrasonic testing, magnetic particle inspection, or X-ray) are used to evaluate the properties of a material or component without causing damage. NDT technicians require special certification and are very well compensated.

- Regulatory Compliance (GMP/FDA/ISO): Expertise in specific regulatory frameworks is essential in certain industries. A technician who deeply understands FDA 21 CFR Part 820 (for medical devices) or ISO 13485 is invaluable to their company and will be paid accordingly.

- Software Quality Assurance (QA): In the tech world, the QC role is a QA Tester or Analyst. While the principles are the same—finding defects against specifications—the tools are different (bug tracking software like Jira, automated testing scripts). Specializing in software testing opens up a different, often lucrative, career path.

By strategically developing skills in these high-demand areas, you can transform from a generalist inspector into a specialist expert, with a salary that reflects that advanced capability.

Job Outlook and Career Growth

While salary provides a snapshot of current earnings, the job outlook offers a glimpse into the future stability and growth potential of the career. Understanding the long-term trends is crucial for making an informed career decision.

According to the U.S. Bureau of Labor Statistics (BLS) Occupational Outlook Handbook, employment for quality control inspectors is projected to show little or no change from 2022 to 2032, which is slower than the average for all occupations. The BLS projects about 52,900 openings for quality control inspectors each year, on average, over the decade. Most of those openings are expected to result from the need to replace workers who transfer to different occupations or exit the labor force, such as to retire.

At first glance, "little or no change" might seem discouraging. However, it's vital to look beyond the headline number and understand the *why* behind it. This static projection is not due to a decreasing need for quality, but rather to a fundamental shift in how quality is managed.

Emerging Trends Shaping the Future of Quality Control:

1. The Rise of Automation and "Smart" Technology: The single biggest trend is the integration of automation into the inspection process. Automated Optical Inspection (AOI) systems, robotic arms with vision systems, and advanced CMMs can perform repetitive inspection tasks faster and often more accurately than humans. This means fewer technicians are needed for simple, manual inspection.

2. The Shift from Detection to Prevention: Modern quality philosophy (like Six Sigma and Lean Manufacturing) emphasizes building quality into the process rather than inspecting it at the end. The goal is to prevent defects from ever happening.

3. Data-Driven Quality (Industry 4.0): Quality control