For individuals with a passion for precision, problem-solving, and hands-on craftsmanship, a career as a tool and die maker offers a stable and rewarding path. These highly skilled professionals are the backbone of modern manufacturing, creating the specialized tools, dies, jigs, and fixtures that make mass production possible. But beyond job satisfaction, what is the earning potential?

A career as a tool and die maker provides a competitive salary that rewards technical expertise and experience. While entry-level positions offer a solid starting wage, seasoned professionals with specialized skills can command impressive incomes, often earning between $50,000 and over $85,000 annually.

This guide will provide a detailed breakdown of a tool and die maker's salary, exploring the key factors that influence your pay and the long-term outlook for this essential profession.

What Does a Tool and Die Maker Do?

Often described as the elite machinists of the manufacturing world, tool and die makers are responsible for producing and maintaining the precision tools that shape metal and plastic parts. They are master craftspeople who can transform raw blocks of steel into complex, functional devices with microscopic accuracy.

Their core responsibilities include:

- Reading and interpreting complex blueprints and technical drawings.

- Operating a wide range of machinery, including computer numerically controlled (CNC) machines, lathes, milling machines, and grinders.

- Using advanced measurement tools like micrometers and calipers to ensure components meet exacting specifications (often within ten-thousandths of an inch).

- Assembling, fitting, and testing newly created tools and dies.

- Troubleshooting and repairing existing dies and tooling to keep production lines running smoothly.

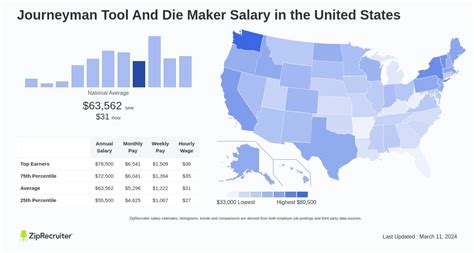

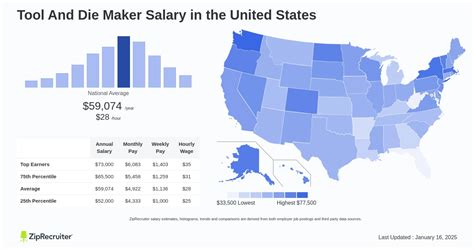

Average Tool and Die Maker Salary

Compensation for tool and die makers is strong, reflecting the high level of skill and training required.

According to the most recent data from the U.S. Bureau of Labor Statistics (BLS), the median annual wage for tool and die makers was $61,540 in May 2023. This means that half of all tool and die makers earned more than this amount, and half earned less. The median hourly wage was approximately $29.59.

However, this median figure is just the middle point. The salary spectrum is wide and depends heavily on experience and other factors:

- The lowest 10% of earners, likely apprentices or entry-level workers, made less than $40,680.

- The highest 10% of earners, typically senior-level experts with specialized skills, earned more than $83,860.

Reputable salary aggregators provide a similar picture. Salary.com reports a typical range for a tool and die maker in the United States falls between $57,014 and $76,172, with a median around $65,850. This data underscores that earning potential well above the national median is highly achievable.

Key Factors That Influence Salary

Your specific salary as a tool and die maker isn't determined by a single number. It’s a dynamic figure influenced by a combination of your skills, location, and career choices. Here are the most critical factors.

### Level of Education and Training

While a four-year university degree is not required, the path to becoming a tool and die maker demands extensive training. The gold standard in this field is a formal apprenticeship program, which typically lasts 4 to 5 years. These programs combine paid, on-the-job training with classroom instruction.

Completing an apprenticeship and earning a "journeyman" certificate is the single most important educational credential for maximizing your earnings. Some candidates bolster their prospects with an associate's degree in machine tool technology or a related field before starting an apprenticeship, which can lead to higher starting pay and faster advancement.

### Years of Experience

Experience is a primary driver of salary growth in this trade. The progression is clear and directly tied to proficiency.

- Apprentice/Entry-Level (0-2 years): Apprentices earn a percentage of a journeyman's wage, which increases incrementally throughout their training. Their focus is on learning the fundamental skills under close supervision.

- Journeyman (3-10 years): Upon completing an apprenticeship, you become a journeyman. At this stage, you can expect a significant salary jump. You are considered a fully qualified professional capable of working independently on complex projects.

- Senior/Master Level (10+ years): With a decade or more of experience, you become a top earner. Senior tool and die makers often take on leadership roles, such as shop foreman, or specialize in the most complex tasks, like die design, prototyping, or troubleshooting difficult production issues.

### Geographic Location

Where you work has a major impact on your paycheck. States with a high concentration of manufacturing, automotive, and aerospace industries typically offer the highest wages to attract top talent.

According to BLS data, some of the top-paying states for tool and die makers include:

- Michigan

- Indiana

- Wisconsin

- Ohio

- Washington

It’s important to balance salary data with the local cost of living. A high salary in an expensive metropolitan area may not have the same purchasing power as a slightly lower salary in a more affordable region.

### Company Type

The type of company you work for is another crucial factor. Larger corporations, particularly those in high-stakes industries, often have more structured pay scales and offer higher wages.

- Aerospace and Defense: Companies manufacturing aircraft and defense components demand extreme precision and reliability, and they pay a premium for the skills to deliver it.

- Automotive Manufacturing: The auto industry is a major employer of tool and die makers for creating the dies that stamp vehicle body panels and other parts.

- Medical Device Manufacturing: This growing sector requires incredibly precise molds and tools for creating surgical instruments and implants, making it a high-paying field.

- Small, Independent Job Shops: While these shops may offer slightly lower starting salaries, they can provide excellent opportunities to gain a broad range of experience on diverse projects.

### Area of Specialization

Within the trade, certain high-demand specializations can significantly boost your earning potential. According to Payscale, skills in Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are strongly correlated with higher pay.

Other lucrative specializations include:

- Mold Making: Creating complex injection molds for the plastics industry is a highly sought-after and well-compensated skill.

- CNC Programming and Operation: Expertise in programming and operating multi-axis CNC machines is essential for modern manufacturing and is a key driver of higher wages.

- Die Design: Moving beyond fabrication into the design of tools and dies using software like SolidWorks or AutoCAD is a path to a much higher salary bracket.

Job Outlook

The BLS projects that employment for tool and die makers will see a slight decline of 1% from 2022 to 2032. However, this statistic doesn't tell the whole story.

The field is experiencing a significant "skills gap" as a large number of experienced professionals are reaching retirement age. This means that despite the flat growth projection, there will be a stable demand for new, highly skilled tool and die makers to replace those leaving the workforce.

Prospects will be best for those who embrace modern technology, especially those with strong skills in computer-aided manufacturing and CNC programming.

Conclusion

A career as a tool and die maker is an excellent choice for those seeking a stable, challenging, and financially rewarding profession without the need for a traditional four-year degree. While the median salary hovers around an impressive $61,540, your earning potential is directly in your hands.

To maximize your salary, focus on these key takeaways:

1. Complete a formal apprenticeship: It is the most respected and valuable credential in the industry.

2. Gain diverse experience: Work your way from apprentice to journeyman and beyond, building your skills and reputation.

3. Embrace technology: Master CNC programming and CAD/CAM software to become an indispensable asset.

4. Consider high-paying industries: Look for opportunities in the aerospace, automotive, or medical device sectors.

For the right individual, the path of a tool and die maker is not just a job—it's the foundation for a prosperous and fulfilling lifelong career.