For those with a steady hand, a sharp eye for detail, and a passion for precision, a career in TIG welding offers a rewarding and financially stable path. As one of the most skilled and versatile welding processes, TIG welding is in constant demand across high-tech industries, leading to significant earning potential. But what can you realistically expect to make?

This in-depth guide will break down the salary of a TIG welder, exploring the key factors that influence your pay, the career outlook, and how you can maximize your income in this respected trade. While entry-level positions offer a solid starting wage, experienced specialists can earn salaries well into the $70,000 to $90,000+ range.

What Does a TIG Welder Do?

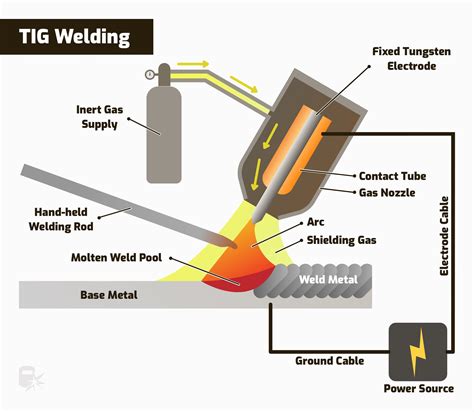

TIG (Tungsten Inert Gas) welding, also known as Gas Tungsten Arc Welding (GTAW), is a highly precise welding process that uses a non-consumable tungsten electrode to create the weld. The welder manually feeds a separate filler rod into the weld pool while controlling the arc with a foot pedal, requiring exceptional hand-eye coordination.

This process is renowned for producing extremely clean, strong, and aesthetically pleasing welds. Because of this precision, TIG welders are essential in industries where weld quality is paramount.

Key Responsibilities Include:

- Reading and interpreting blueprints and technical drawings.

- Welding thin and exotic materials like stainless steel, aluminum, titanium, and magnesium.

- Performing intricate welds on pipes, in aerospace components, and for sanitary applications (food/pharma).

- Maintaining equipment and ensuring a safe work environment.

- Inspecting welds for quality and adherence to strict specifications.

Average TIG Welder Salary

While the U.S. Bureau of Labor Statistics (BLS) groups all welders together, their data provides a solid baseline. According to the BLS, the median annual wage for "Welders, Cutters, Solderers, and Brazers" was $50,460 in May 2022, with the top 10% earning more than $72,970.

However, the specialized nature of TIG welding often places these professionals in a higher pay bracket. Data from reputable salary aggregators reflects this:

- Salary.com reports the median TIG welder salary in the United States is approximately $60,256 as of May 2024, with a typical range falling between $53,605 and $68,600.

- Payscale notes an average base hourly rate of $23.70, which translates to an annual salary of roughly $49,000. However, it also shows that hourly rates for experienced TIG welders can exceed $35/hour, pushing annual earnings over $72,000 before overtime.

This data reveals a clear picture: while a TIG welder can expect to earn more than the general median, your specific salary will be heavily influenced by several critical factors.

Key Factors That Influence Salary

Your paycheck is more than just a number; it's a reflection of your skills, experience, and the demand for your specific expertise. Here’s how various factors can impact your earning potential.

### Level of Education & Certifications

While a high school diploma is the minimum requirement, formal training and certifications are your ticket to higher pay. Graduating from a vocational school or community college welding program provides a structured foundation in theory and hands-on practice.

More importantly, certifications from the American Welding Society (AWS) are the industry standard. Holding a Certified Welder (CW) credential proves your skills have been tested and verified. Advanced certifications for specific materials (like titanium) or positions (like 6G pipe welding) are highly sought after and can significantly boost your income.

### Years of Experience

Experience is arguably the most significant driver of salary growth in welding. As you gain hands-on time, your speed, accuracy, and ability to troubleshoot complex projects increase exponentially.

- Entry-Level (0-2 years): In this phase, you are building foundational skills and proving your reliability. Expect a salary at the lower end of the range as you learn from senior welders.

- Mid-Career (3-9 years): With proven experience, you can tackle more complex jobs with less supervision. Your salary should climb steadily toward and beyond the median.

- Senior/Expert (10+ years): At this stage, you are a master of your craft. You may be working on the most critical components, supervising teams, or even moving into a Certified Welding Inspector (CWI) role, which carries its own high salary potential. These experts command the highest wages in the field.

### Geographic Location

Where you work matters. A TIG welder’s salary can vary dramatically based on the cost of living and the concentration of industries that rely on high-skill welding. States with a strong presence in aerospace, defense, energy, or shipbuilding tend to offer higher wages.

According to BLS data, the top-paying states for welders include:

1. Alaska: High demand from the oil and gas industry.

2. Wyoming: Strong energy and mining sectors.

3. District of Columbia: Government and infrastructure projects.

4. Hawaii: Driven by military and shipping needs.

5. North Dakota: Another state with a powerful energy sector.

Working in a major metropolitan area with significant industrial or manufacturing activity will generally yield a higher salary than a rural location, though this is often offset by a higher cost of living.

### Company Type & Industry

The industry you work in directly impacts your value. A weld on a decorative gate does not carry the same risk or require the same level of scrutiny as a weld on an airplane wing or a nuclear power plant pipe.

- Top Tier (Highest Paying): Aerospace & Defense, Oil & Gas (especially pipeline welding), Nuclear Energy, and Specialized Manufacturing (e.g., motorsports, semiconductors). These fields demand perfection and pay accordingly.

- Mid Tier: General Manufacturing, Commercial Construction, and Shipbuilding. These are stable, well-paying sectors that form the backbone of the welding industry.

- Lower Tier: Small, local fabrication shops or repair services. While essential, these operations typically have smaller budgets and cannot compete with the salaries offered by major industrial players.

### Area of Specialization

Within TIG welding, certain specializations are notoriously difficult and, therefore, extremely lucrative. Developing expertise in one of these areas is the fastest way to become an elite, high-earning professional.

- Pipe Welding: TIG pipe welders, especially those who can pass difficult 6G certification tests (welding a pipe in a fixed, 45-degree position), are among the highest-paid in the trade.

- Aerospace Welding: Working with materials like titanium and Inconel for aircraft and spacecraft components requires immense skill and adherence to zero-failure standards.

- Sanitary Welding: Used in the food, beverage, and pharmaceutical industries, this specialization requires creating perfectly smooth, crevice-free welds to prevent bacterial growth.

- Subsea/Underwater Welding: While often not TIG, this is a highly specialized and dangerous field that commands exceptionally high pay.

Job Outlook

The BLS projects a 2% decline for the overall welding profession from 2022 to 2032. It is crucial to understand the context behind this number. Much of this projection is tied to automation replacing routine, high-volume welding jobs in large manufacturing plants.

However, the outlook for highly skilled manual welders, especially TIG specialists, remains very strong. Automation cannot easily replicate the complex, custom, and repair work performed by expert TIG welders in fields like aerospace, energy, and custom fabrication.

Furthermore, a significant portion of the current welding workforce is nearing retirement, creating a persistent "skills gap." This means companies are actively competing for talented, well-trained welders to fill these essential roles, ensuring continued job security and strong wage potential for those entering the field.

Conclusion

A career as a TIG welder is far more than a job—it is a skilled craft that powers the world’s most advanced industries. While the national median provides a useful starting point, your earning potential is truly in your hands.

By investing in formal training, pursuing advanced certifications, and gaining experience in a high-demand industry or specialization, you can build a career that is both professionally fulfilling and financially rewarding. For individuals with a dedication to precision and a commitment to lifelong learning, the path of a TIG welder offers a clear route to a secure and prosperous future.