Imagine a career that isn't confined to a 9-to-5 schedule or the four walls of the same workshop, day in and day out. Picture a profession where your office view changes from the vast plains of a West Texas oil field to the intricate superstructure of a new skyscraper in a bustling metropolis, or even the belly of a naval warship in a coastal drydock. This is the reality for a traveling welder—a skilled tradesperson who takes their craft on the road, tackling critical projects that form the backbone of our modern world. This path is not just one of adventure and variety; it's a route to significant financial reward, with a traveling welder salary often soaring into the six-figure range for those with the right skills and tenacity.

I once spoke with a seasoned rig welder during a shutdown at a refinery in Louisiana. Covered in the honest grime of a hard day's work, he explained that his custom-outfitted truck wasn't just a vehicle; it was his mobile business, his toolbox, and his ticket to earning over $200,000 a year. He told me, "They don't pay me for the eight hours I'm here. They pay me for the ten years it took to learn how to do this job right, in any weather, with no excuses." That conversation solidified my understanding of this profession: it's a demanding, high-stakes career built on expertise, and it is compensated accordingly.

This comprehensive guide is designed to illuminate every facet of the traveling welder career path. We will dissect the salary expectations, explore the factors that drive earning potential, and provide a clear, actionable roadmap for anyone aspiring to join the ranks of these elite, mobile craftspeople.

### Table of Contents

- [What Does a Traveling Welder Do?](#what-does-a-traveling-welder-do)

- [Average Traveling Welder Salary: A Deep Dive](#average-traveling-welder-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion: Is a Traveling Welder Career Right for You?](#conclusion)

What Does a Traveling Welder Do?

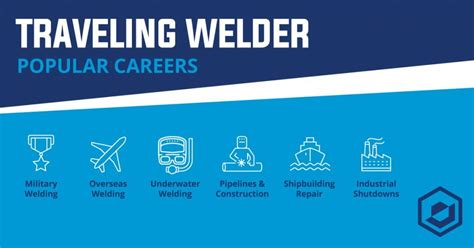

At its core, a traveling welder, often called a "journeyman welder," "combo welder," or "rig welder," is a highly skilled professional who fabricates and assembles metal structures and equipment through the use of various welding techniques. What sets them apart from their stationary counterparts is their nomadic work life. They travel to diverse job sites, often for extended periods, to work on specific, time-sensitive, and frequently complex projects.

Their responsibilities go far beyond simply laying a bead of molten metal. They are problem-solvers who must adapt to new environments, materials, and challenges on every job. Their work is critical to the integrity and safety of the structures they help build, from pipelines carrying essential energy resources to power plants that light up our cities.

Core Responsibilities and Daily Tasks:

A traveling welder's duties are project-dependent but generally include:

- Blueprint and Specification Analysis: Reading and interpreting complex technical drawings, schematics, and welding procedure specifications (WPS) to understand the project requirements.

- Material Preparation: Cleaning, cutting, and shaping metal components using tools like grinders, plasma cutters, and saws to prepare them for welding.

- Welding and Fabrication: Fusing metal parts together using specific welding processes such as Shielded Metal Arc Welding (SMAW/Stick), Gas Metal Arc Welding (GMAW/MIG), Gas Tungsten Arc Welding (GTAW/TIG), or Flux-Cored Arc Welding (FCAW).

- Quality Control and Inspection: Visually inspecting their own welds for defects like cracks, porosity, or lack of fusion. They may also use non-destructive testing (NDT) methods to ensure the weld meets stringent quality and safety standards.

- Equipment Maintenance: Maintaining their welding equipment, including their welding machine, power sources, and personal protective equipment (PPE). For rig welders, this extends to their entire truck-mounted setup.

- Adherence to Safety Protocols: Strictly following all safety procedures, which are often rigorous in industrial, construction, and energy sector environments.

### A Day in the Life: Shutdown Welder on a Power Plant Project

To make this role more tangible, let's walk through a typical day for a traveling welder, "Maria," on a 6-week shutdown project at a natural gas power plant.

- 4:30 AM: The alarm goes off in her extended-stay hotel room. Maria quickly gets ready, packs a lunch, and fills a large thermos with coffee. The workday starts early to maximize daylight and beat the worst of the heat.

- 5:30 AM: Maria arrives at the plant gate for the daily "toolbox talk." The entire crew gathers as the safety manager and foreman review the day's tasks, identify potential hazards (like working at heights or in confined spaces), and issue permits for specific jobs.

- 6:00 AM: After donning her flame-retardant clothing, hard hat, safety glasses, and steel-toed boots, Maria gathers her gear. Today, she's tasked with replacing a section of high-pressure steam piping. This requires TIG welding on stainless steel, a precision process. She inspects her TIG torch, tungsten electrodes, and argon gas supply.

- 7:00 AM: Maria is escorted to the work area. The old pipe section has already been removed by the pipefitters. Her job is to "fit up" the new section, ensuring the gap and alignment are perfect, and then perform the critical root pass weld, which is the most important layer of the weld.

- 12:00 PM: Lunch break. Maria and her colleagues find a spot away from the work zone to eat. The conversation is a mix of shop talk about the project and stories from past jobs in other states.

- 12:30 PM: Back to the pipe. Maria spends the afternoon meticulously completing the "fill" and "cap" passes of the weld, layering beads of metal to build the joint to its required thickness. The work is physically demanding, often done in an awkward position, requiring immense focus and a steady hand.

- 3:00 PM: The weld is complete. Now comes the inspection. A quality control inspector arrives to perform a visual check and then prepares the weld for radiographic testing (X-ray) to ensure there are no internal flaws. A failed X-ray means cutting the weld out and starting over, so the pressure to get it right the first time is immense.

- 4:30 PM: The weld passes inspection. Maria cleans up her work area, stores her equipment securely, and signs out for the day.

- 5:30 PM: Back at the hotel, she spends some time cleaning her gear and preparing for the next day. The evening is for dinner, a call home, and much-needed rest. This cycle will repeat, often 6-7 days a week, until the project is complete.

This example highlights the high-stakes, skill-intensive nature of the job. It's not just welding; it's precision engineering under pressure.

Average Traveling Welder Salary: A Deep Dive

The compensation for a traveling welder is one of the biggest draws to the profession. While the U.S. Bureau of Labor Statistics (BLS) provides a foundational number for all welders, the reality for a traveling specialist is significantly different and far more lucrative.

According to the BLS's Occupational Outlook Handbook, the median annual wage for all welders, cutters, solderers, and brazers was $47,540 in May 2022. The lowest 10 percent earned less than $36,830, and the highest 10 percent earned more than $65,580. It is crucial to understand that this figure represents the *entire* profession, including entry-level, stationary factory welders, and local repair shop workers.

A traveling welder's salary exists on a completely different scale. Due to the specialized skills required, the demanding travel schedule, overtime opportunities, and per diem allowances, their earning potential is substantially higher.

Based on data from reputable salary aggregators and real-world job postings, the salary landscape for a traveling welder looks more like this:

- Payscale reports that the average salary for a traveling welder is around $73,000 per year, with a typical range falling between $53,000 and $131,000.

- Glassdoor lists the estimated total pay for a traveling welder at $89,660 per year in the United States, with an average base salary of around $73,500 and additional pay (bonuses, overtime) of about $16,000.

- Indeed job postings frequently show hourly rates for skilled traveling welders ranging from $30 to $55+ per hour, plus per diem.

A more realistic all-in compensation range for a traveling welder is between $70,000 and $185,000 annually. Elite specialists, such as rig welders who own their own equipment or underwater welders, can easily surpass $200,000 to $300,000 in a good year.

### Salary by Experience Level

Like any profession, experience is a primary driver of income. The journey from a novice to a master welder is reflected in the paychecks.

| Experience Level | Typical Hourly Rate (Base) | Typical Annual Salary (All-In) | Characteristics |

| ----------------------- | -------------------------- | ------------------------------ | ------------------------------------------------------------------------------------------------------------ |

| Entry-Level/Apprentice (0-2 years) | $22 - $28/hour | $55,000 - $75,000 | Often works as a "welder's helper." Focuses on learning, basic welds, and assisting senior welders. |

| Mid-Career/Journeyman (3-9 years) | $28 - $45/hour | $75,000 - $140,000 | A certified, proficient welder capable of working independently on complex projects. Holds multiple certs. |

| Senior/Master Welder (10+ years) | $45 - $60+/hour | $140,000 - $250,000+ | An expert in multiple processes and materials. May be a CWI or a rig welder with a reputation for excellence. |

*Note: These are estimates and can vary significantly based on the other factors discussed in the next section.*

### Unpacking the Full Compensation Package

A traveling welder's income isn't just about the hourly rate. The total compensation package is a mosaic of different components that combine to create a high earning potential.

- Base Wage/Hourly Rate: This is the foundation of the welder's pay. It is determined by skill, experience, certifications, and the prevailing rate for the specific industry and location.

- Overtime (OT): This is a massive contributor to total earnings. Traveling jobs, especially shutdowns and time-critical infrastructure projects, often run on tight deadlines. It's common for welders to work 50, 60, or even 70+ hours a week. Overtime is typically paid at 1.5 times the base rate ("time and a half") and sometimes 2.0 times ("double time") for Sundays or holidays.

- Per Diem: This is a daily, tax-free allowance provided by the employer to cover lodging, meals, and incidental expenses while the welder is working away from home. Per diem rates can range from $75 to $150+ per day. A welder working 300 days a year on a $100/day per diem adds an extra $30,000 (tax-free) to their annual income. Frugal welders who find inexpensive lodging or share accommodations can bank a significant portion of their per diem.

- Bonuses and Incentives: Many projects offer bonuses for completing the job on or ahead of schedule ("completion bonus") or for maintaining a perfect safety record ("safety bonus").

- Travel Pay: Companies often pay for the welder's travel time to and from the job site at the beginning and end of a project, and sometimes provide a "travel-in" and "travel-out" allowance.

- Benefits: Reputable contracting firms and unions provide benefits packages that include health, dental, and vision insurance, as well as retirement contributions (e.g., 401(k) or a pension plan). This is a valuable part of the overall compensation that shouldn't be overlooked.

When you combine a high hourly rate (e.g., $40/hour) with significant overtime (e.g., 20 hours of OT per week) and a per diem (e.g., $120/day), the earning power becomes clear.

Key Factors That Influence Salary

The wide salary range for traveling welders exists because compensation is not a flat rate; it's a dynamic figure influenced by a confluence of critical factors. A welder who strategically develops their career by focusing on these areas can command a top-tier income.

### `

` Level of Education and Certifications `

`While a four-year university degree is not required, education in the form of specialized training and, most importantly, certifications is arguably the single most powerful lever for increasing a traveling welder's salary.

- Basic Education: A high school diploma or GED is the standard starting point.

- Vocational/Technical School: Graduating from a reputable welding program at a technical college or vocational school is highly advantageous. These programs provide foundational knowledge in metallurgy, blueprint reading, and hands-on training in various welding processes, making graduates more valuable and employable from day one.

- Certifications: This is where welders differentiate themselves and their paychecks. Certifications are proof of a welder's ability to produce a quality weld according to a specific code or standard.

- American Welding Society (AWS) Certifications: The AWS Certified Welder (CW) is the baseline credential. More advanced and lucrative are certifications to specific codes like AWS D1.1 (Structural Steel) or AWS D1.5 (Bridge Welding).

- American Petroleum Institute (API) 1104: This is the gold-standard certification for pipeline welders. Holding an API 1104 cert is often a non-negotiable requirement for high-paying jobs in the oil and gas sector.

- ASME Section IX: The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC) certification is essential for welders working on pressure vessels, power plant piping, and in nuclear facilities. This is a high-skill, high-pay credential.

- Certified Welding Inspector (CWI): An experienced welder can advance to become a CWI. These professionals are responsible for inspecting and verifying the work of other welders. CWIs are in high demand and command excellent salaries, often transitioning into quality control management roles.

A welder with only basic skills might earn $25/hour. A welder with multiple, in-demand certifications like API 1104 and ASME Section IX can easily demand $45/hour or more for the same project.

### `

` Years of Experience `

`Experience directly correlates with skill, efficiency, and the ability to handle complex problems. Employers pay a premium for welders who have a proven track record of success.

- 0-2 Years (Apprentice/Helper): In this phase, the primary goal is learning. Pay is lower, but the experience gained is invaluable. They learn job site etiquette, safety protocols, and how to assist senior welders, gradually taking on more welding tasks.

- 3-9 Years (Journeyman): The journeyman is the workhorse of the industry. They have mastered one or more welding processes and can be trusted to work independently on critical tasks. Their salary increases steadily as they accumulate experience on different projects, materials, and in various industries. A five-year journeyman with a good reputation is highly sought after.

- 10+ Years (Master/Lead Welder): After a decade or more in the field, a welder has likely seen it all. They possess a deep understanding of metallurgy, can troubleshoot complex welding problems, and often take on leadership roles, mentoring younger welders or acting as a foreman. Rig welders who have spent years building a top-tier reputation and a fully-equipped truck fall into this category, commanding the highest rates.

### `

` Geographic Location `

`Where you work matters immensely. Salary variations are driven by a combination of regional demand, cost of living, and the concentration of specific industries.

- High-Paying States/Regions:

- Texas, North Dakota, Oklahoma: The heart of the U.S. oil and gas industry. The demand for skilled pipeline and rig welders here is immense, driving wages to the top of the national scale.

- Louisiana, Mississippi, Alabama: Major hubs for shipbuilding, petrochemical plants, and offshore oil platforms create a high concentration of high-paying welding jobs.

- Alaska: Due to the harsh conditions, remote locations, and the oil industry, welders in Alaska can earn some of the highest wages in the country.

- Virginia, California, Washington: These states have major naval shipyards and aerospace manufacturing facilities, which require highly specialized and well-compensated welders.

- Lower-Paying Regions: Areas with less heavy industry, construction, or energy production will naturally have lower demand and thus lower wages for welders. The key for a *traveling* welder is that they are not tied to their home region's pay scale; they go where the high-paying work is.

It's also important to note that a high salary in a high-cost-of-living area (e.g., California) might not have the same purchasing power as a slightly lower salary in a low-cost-of-living state (e.g., Texas). However, the per diem allowance helps to offset the high cost of living while on the job.

### `

` Industry and Company Type `

`The industry you serve dictates the complexity, risk, and profitability of the work, all of which are reflected in the salary.

- Oil & Gas (Upstream/Midstream): This is often the most lucrative sector. Welding on pipelines, offshore rigs, and refineries involves high-pressure, hazardous materials, and remote locations, all of which command premium pay.

- Power Generation (Especially Nuclear): Welding in a nuclear power plant is perhaps the most demanding specialty. It requires extensive background checks, rigorous certifications (like ASME Section IX), and flawless execution. The pay is exceptional.

- Military & Defense Contracting: Welding on naval ships (submarines, aircraft carriers) or military vehicles requires specialized skills and security clearances, leading to very high compensation.

- Aerospace: TIG welding on exotic alloys like titanium and aluminum for aircraft and spacecraft components is a precision art form that pays accordingly.

- Heavy Industrial Construction: Building factories, bridges, and skyscrapers requires skilled structural welders who are well-compensated, though typically not at the same level as the top-tier energy or aerospace sectors.

- Company Type: Working for a large, unionized contractor (like Bechtel or KBR) or a major energy company often provides higher wages, excellent benefits, and structured work environments. Working for a smaller, non-union contractor might offer more flexibility but potentially lower pay and fewer benefits. The ultimate step for many is becoming an owner-operator (rig welder), which turns them into a business owner with the highest earning potential but also all the risks and overhead costs.

### `

` Area of Specialization `

`"Welder" is a broad term. Specializing in a difficult, in-demand process or role is the fastest way to increase your value.

- Process Specialization:

- TIG (GTAW) Welder: TIG welding is a precise, clean, and difficult process used on thin materials and exotic alloys (stainless steel, aluminum, titanium). Pipe and aerospace TIG welders are among the highest-paid.

- Stick (SMAW) Welder: Stick welding is versatile and can be used in outdoor, windy, and dirty conditions, making it the go-to process for pipeline and heavy structural work. A skilled "downhill pipe" stick welder is a valuable asset.

- MIG (GMAW) Welder: While often seen as an easier process, a highly skilled MIG welder who can work with complex machinery or on specialty fabrication is still very valuable.

- Role Specialization:

- Combo Welder: A welder proficient in multiple processes (e.g., TIG and Stick) is a "combo welder." This versatility makes them extremely valuable as they can handle different parts of a complex project, like welding the TIG root pass and Stick fill passes on a pipe.

- Pipe Welder: This is a broad category of highly paid specialists who work on pipes in various industries. They must be able to weld in all positions (flat, horizontal, vertical, overhead), often using mirrors for joints they cannot see directly.

- Rig Welder: An owner-operator with a custom truck equipped with a high-end welding machine, tools, and supplies. They are independent contractors who bid on jobs and have the highest earning potential.

- Underwater Welder: A highly specialized, high-risk, and extremely high-paying career that combines commercial diving with welding to repair offshore platforms, pipelines, and ships.

### `

` In-Demand Skills `

`Beyond formal certifications, a set of practical skills can significantly boost a welder's employability and pay rate.

- Blueprint Reading Mastery: The ability to read and interpret complex blueprints and welding symbols without assistance is fundamental.

- Metallurgical Knowledge: Understanding how different metals and alloys react to heat and what filler materials to use is a sign of a true expert.

- Proficiency with Exotic Alloys: Welders who can expertly work with materials like stainless steel, Inconel, Monel, and titanium are rare and highly compensated.

- Mechanical Aptitude: The ability to perform basic fitting, cutting, and rigging makes a welder a more versatile and valuable member of the crew.

- Strong Safety Record: A demonstrated commitment to safety (often tracked by employers) makes a welder more attractive, as accidents are costly.

- Physical Fitness and Resilience: The ability to work long hours in extreme weather, confined spaces, or at heights is a physical requirement of the job.

- Professionalism and Reliability: Showing up on time, every time, with a good attitude and a willingness to work is a "soft skill" that builds a reputation and keeps you getting calls for the best jobs.

Job Outlook and Career Growth

When considering a long-term career, salary is only one part of the equation; job security and opportunities for advancement are equally important. The outlook for skilled welders—especially those willing to travel—is more nuanced and positive than general statistics might suggest.

The U.S. Bureau of Labor Statistics (BLS) projects that the overall employment of welders, cutters, solderers, and brazers is projected to grow 2 percent from 2022 to 2032, which is slower than the average for all occupations. The BLS anticipates about 41,600 openings for welders each year, on average, over the decade.

However, these headline numbers require deeper analysis. A significant portion of these openings will arise not from new job creation, but from the need to replace workers who are retiring or transferring to different occupations. The current welding workforce is aging, and as experienced welders retire, they will leave a skills vacuum that needs to be filled by a new generation of highly trained professionals.

This is where the opportunity lies for aspiring traveling welders. The demand isn't for just any welder; it's for the highly skilled, certified, and adaptable welder.

### Emerging Trends and Future Drivers of Demand

Several key trends are shaping the future of the welding profession and will drive demand for traveling specialists:

1. Aging Infrastructure: Much of the nation's infrastructure—bridges, pipelines, power plants, and dams—is decades old and requires significant repair, retrofitting, or replacement. Federal initiatives like the Bipartisan Infrastructure Law are injecting billions of dollars into these projects, all of which require massive amounts of skilled welding labor.

2. Energy Sector Evolution: While oil and gas will remain a major employer for the foreseeable future, the shift towards alternative energy also creates opportunities. The construction of wind turbine towers, solar panel support structures, and facilities for producing liquefied natural gas (LNG) all rely on expert welders.

3. Advanced Manufacturing and Aerospace: The growth in domestic manufacturing, particularly in high-tech sectors like aerospace, semiconductors, and defense, requires welders who can work with advanced materials and automated systems.

4. Automation and Technology: The rise of orbital welders and robotic welding systems is not eliminating