Introduction

Imagine an office where the walls are the deep blue of the ocean, your commute is a descent into another world, and your daily tasks involve harnessing the power of a welding arc against the immense pressure of the sea. This is the reality for an underwater welder, a career that exists at the intersection of extreme skill, immense courage, and critical global infrastructure. It's a profession that consistently ranks among the most dangerous, yet also one of the most financially rewarding skilled trades on the planet. For those with the right blend of technical aptitude, physical resilience, and a spirit of adventure, it offers a life less ordinary.

The allure of this career is often tied to its legendary earning potential. While stories of six-figure salaries abound, the reality is nuanced. An underwater welding starting salary can be substantial, often beginning in the range of $55,000 to $80,000, but the ceiling can stretch to well over $200,000 or even $300,000 for elite divers working in the most demanding conditions. This vast range is what we will explore in detail, breaking down every factor that separates a novice's pay from a seasoned veteran's windfall.

I once spoke with a retired saturation diver who had spent decades in the Gulf of Mexico. He didn't talk about the money first; he talked about the silence, the focus, and the immense satisfaction of completing a perfect weld on a pipeline support hundreds of feet below the surface, knowing that the safety and energy supply for thousands of people depended on his steady hand. It was a powerful reminder that while the salary is a significant motivator, the work itself is a unique and profound responsibility.

This guide is designed to be your comprehensive briefing on entering this demanding field. We will submerge ourselves in the details of the job, conduct a deep dive into salary data, analyze the factors that control your earning potential, and chart a course for you to begin your own journey.

### Table of Contents

- [What Does an Underwater Welder Do?](#what-they-do)

- [Average Underwater Welder Salary: A Deep Dive](#salary-deep-dive)

- [Key Factors That Influence an Underwater Welder's Salary](#key-factors)

- [Job Outlook and Career Growth for Underwater Welders](#job-outlook)

- [How to Become an Underwater Welder: Your Step-by-Step Guide](#how-to-start)

- [Conclusion: Is a Career in Underwater Welding Right for You?](#conclusion)

What Does an Underwater Welder Do?

At its core, an underwater welder is a highly skilled commercial diver who is also a certified welder. This dual-specialty is what makes the role so unique and valuable. They don't just swim; they perform complex construction, inspection, repair, and maintenance tasks in submerged environments. Their "office" can be the hull of a supertanker, the base of an offshore oil rig, the interior of a dam's intake pipe, or the foundation of a subsea bridge.

The work is broadly divided into two categories based on the environment:

1. Inland/Onshore Diving: This involves working in freshwater environments like rivers, lakes, dams, reservoirs, and nuclear power plant facilities. Projects often include repairing bridge pilings, maintaining water intake systems, salvaging submerged vehicles, and inspecting or repairing dam structures.

2. Offshore Diving: This is the sector most associated with high earnings and takes place in saltwater environments, primarily in support of the oil and gas industry, but increasingly for offshore wind farms. Tasks include welding and cutting on pipelines, installing and repairing components on drilling rigs, and performing complex subsea construction and salvage operations.

### A Day in the Life of an Underwater Welder

The daily routine of an underwater welder is anything but routine and varies dramatically based on the project. However, a typical day often follows a structured, safety-oriented procedure.

Example: An Offshore Surface-Supplied Air Diver

- 05:00 - Wake Up & Briefing: The day starts early on the rig or dive support vessel (DSV). The entire dive team, including the dive supervisor, divers, and tenders, meets for a "toolbox talk." They review the day's specific task (e.g., "perform a fillet weld on a bracing strut at 120 feet"), the environmental conditions (currents, visibility), the equipment to be used, and the comprehensive safety and emergency procedures.

- 06:30 - Equipment Checks: The diver and their tender meticulously inspect every piece of gear. This includes the dive helmet (like a Kirby Morgan), the umbilical cord (which supplies breathing gas, communications, and power), the hot water suit (if in cold water), and all welding equipment (stinger, electrodes, grounding clamp). Every seal, valve, and connection is checked and double-checked.

- 08:00 - The Dive Begins: The diver, now fully geared up (weighing over 200 lbs with equipment), is lowered into the water via a dive stage or basket. The tender, on the surface, manages the umbilical, ensuring it doesn't snag and pays out slack as needed. Communication with the supervisor is constant.

- 08:30 - At the Worksite: Reaching the designated depth, the diver orients themselves at the underwater worksite. Visibility might be near-zero, requiring them to work entirely by feel. They clean the metal surface to be welded using hydraulic grinders or wire brushes, preparing a clean "parent metal" for the weld.

- 09:30 - The Welding Process: The dive supervisor, watching via a camera on the diver's helmet, gives the command to "make it hot." The surface team energizes the welding circuit. The diver strikes an arc with a special waterproof electrode and performs the weld. This requires immense concentration and a steady hand to maintain the correct angle, travel speed, and arc length while currents try to push them off balance.

- 12:00 - Return to Surface & Decompression: After the task is complete (or the diver's bottom time is reached), they return to the surface. Depending on the depth and duration of the dive, they may need to spend time in a deck decompression chamber (DDC) to safely off-gas nitrogen from their body, preventing decompression sickness ("the bends").

- 14:00 - Post-Dive & Debrief: Once out of the chamber, the diver debriefs with the supervisor, detailing the work completed and any issues encountered. The rest of the afternoon is spent cleaning and maintaining equipment, preparing for the next day's dive, and assisting other members of the dive team.

This cycle of meticulous preparation, intense execution, and rigorous safety protocols defines the profession. It's a physically and mentally demanding job where a single mistake can have catastrophic consequences.

Average Underwater Welder Salary: A Deep Dive

Analyzing the salary for an underwater welder is complex because it's not a standard 9-to-5 job with a fixed annual paycheck. Compensation is a multifaceted package influenced by the project, location, depth, and risk. However, we can establish reliable benchmarks using data from government agencies and industry aggregators.

The U.S. Bureau of Labor Statistics (BLS) groups underwater welders under the broader category of "Commercial Divers." According to the most recent BLS data from May 2023, the outlook is as follows:

- Median Annual Wage: $72,740 per year, which translates to approximately $34.97 per hour.

- Salary Range: The lowest 10 percent earned less than $41,260, while the top 10 percent earned more than $117,110.

It's crucial to understand that the BLS figure represents the *median* for all commercial divers, including those who perform less specialized (and lower-paying) tasks like golf ball retrieval or simple inspections. Highly skilled welder-divers, especially those working offshore, consistently earn in the upper echelons of this range and often far exceed it.

Data from salary aggregators provides a more granular view, often reflecting the specialized nature of welding:

- Payscale.com: Reports an average salary for Underwater Welders of around $79,891 per year. The reported range is vast, from $51,000 to $178,000, explicitly noting that factors like depth pay and specialization cause significant variance.

- Salary.com: Places the average salary for a "Diver/Welder" slightly higher, often in the $80,000 to $95,000 range, with top earners pushing past $115,000.

- Glassdoor: Lists an average total pay (including bonuses and additional compensation) for an Underwater Welder at approximately $96,554 per year, based on user-submitted data.

These figures paint a clear picture: while a solid median exists around the $70k-$80k mark, the potential to earn a six-figure income is very real and relatively common for experienced professionals in the right sectors.

### Salary by Experience Level

The career and salary trajectory for an underwater welder follows a distinct path, moving from surface support to complex subsea work.

| Career Stage | Years of Experience | Typical Salary Range (Annual) | Key Responsibilities |

| :--- | :--- | :--- | :--- |

| Tender / Apprentice Diver | 0 - 2 years | $45,000 - $65,000 | Surface support, equipment maintenance, managing diver's umbilical, learning procedures. Does not typically perform underwater welding. |

| Entry-Level Underwater Welder | 1 - 3 years | $55,000 - $80,000 | Performing basic wet welding tasks, inspections, and light construction in inland or shallow offshore environments. |

| Mid-Career Underwater Welder | 3 - 8 years | $80,000 - $150,000+ | Handling complex welding projects, working at greater depths, leading small dive teams, proficient in various welding/cutting techniques. |

| Senior / Saturation Diver | 8+ years | $150,000 - $300,000+ | Elite specialization in saturation or deep hyperbaric welding, managing major projects, working for extended periods at extreme depths. |

| Dive Supervisor / Superintendent | 10+ years | $120,000 - $250,000+ | Manages all dive operations, responsible for safety and project execution, extensive experience, and leadership skills. Does less "in-water" work. |

*Note: These ranges are estimates and can be significantly influenced by the factors discussed in the next section.*

### Deconstructing the Paycheck: Beyond the Base Salary

An underwater welder's income is rarely a simple hourly wage or annual salary. The total compensation package is a mosaic of different pay types:

- Base Pay/Day Rate: This is the foundational rate for being part of the crew, whether you dive that day or not. Offshore rates are significantly higher than inland rates.

- Depth Pay: This is a premium paid for every foot of water you work in. It's often calculated in brackets (e.g., $1 per foot from 50-100ft, $2 per foot from 101-200ft, and so on). This can add thousands of dollars to a single dive.

- "Delta P" Pay: A premium for working in differential pressure environments (like near a dam intake), which are extremely dangerous.

- Saturation Pay: This is the highest premium, paid to saturation divers who live in a pressurized habitat for up to 28 days at a time. They are paid for every hour they are "in saturation," whether they are working, eating, or sleeping. This is what drives salaries into the $200k-$300k+ range.

- Overtime: Long hours are standard, especially offshore where crews work 12-hour shifts for weeks at a time. Overtime pay can significantly boost earnings.

- International & Hardship Pay: Working in remote or politically unstable regions often comes with a significant pay bump.

- Bonuses: Project completion bonuses are common, especially for finishing ahead of schedule and under budget.

Key Factors That Influence an Underwater Welder's Salary

The difference between a $60,000 salary and a $250,000 salary is not arbitrary. It is a direct result of a specific set of factors that define a diver's value to an employer. This section provides an in-depth analysis of those critical variables.

###

1. Level of Education and Certification

In this field, "education" does not refer to a traditional four-year university degree. Instead, it encompasses highly specialized training and industry-recognized certifications that are non-negotiable requirements for employment.

- Commercial Diving School Diploma: This is the first and most critical gate. Graduating from an accredited commercial diving school is mandatory. These intensive programs (typically 4-10 months) teach everything from dive physics and medicine to underwater tools and safety protocols. The school's reputation matters. Institutions like the Divers Institute of Technology (DIT) in Seattle or the Commercial Diving Academy (CDA) in Florida are highly regarded and their graduates are sought after.

- Welding Certifications: Simply knowing how to dive isn't enough. A diver must prove their welding competency through rigorous testing. The most important certification is the American Welding Society (AWS) D3.6M, Specification for Underwater Welding. This standard certifies welders for different classes of welds (A, B, C, O) in either wet or dry (hyperbaric) environments.

- Class A: Intended for structural welds on critical components, often performed in a dry hyperbaric habitat. This is the highest level and commands the highest pay.

- Class B: For less critical applications where load-bearing is a factor but some defects are tolerable.

- Class O: Correlates to welds performed in a dry, atmospheric-pressure habitat, often inside a caisson.

- ADCI Certification: The Association of Diving Contractors International (ADCI) issues credentials that are the industry standard in the U.S. and many other parts of the world. Upon graduating from an accredited school, a diver receives an ADCI Entry-Level Tender/Diver certification. This is the passport to getting a job.

- Additional NDT Certifications: Non-Destructive Testing (NDT) skills dramatically increase earning potential. Certifications in Magnetic Particle Inspection (MPI), Ultrasonic Testing (UT), or Eddy Current Testing allow a welder to not just perform repairs, but also to inspect existing structures, a highly valuable service.

Impact on Salary: A diver with only a basic dive school diploma will start as a tender. A diver who also has top-tier welding certifications (like AWS D3.6M Class A) and NDT credentials can start at a significantly higher salary and will be eligible for more complex, higher-paying jobs from day one.

###

2. Years of Experience and Career Progression

Experience is perhaps the single most powerful driver of salary growth. In an industry where safety and judgment are paramount, a proven track record is invaluable.

- Tender (0-2 Years): A tender's salary is the lowest on the dive team because they don't enter the water to work. Their job is to learn the ropes, support the diver, and prove their reliability. It's a mandatory "apprenticeship."

- Entry-Level Diver (1-3 Years): Once a tender has proven themselves, they get their chance to "break out" as a diver. They start with shallower, less complex jobs, often inland. Each dive is meticulously logged in a personal logbook, which becomes their professional resume. An entry-level diver focused on gaining experience might earn $60,000 - $75,000, but this is highly dependent on the number of days they work.

- Mid-Career Diver (3-8 Years): With thousands of hours of bottom time logged, these divers are the workhorses of the industry. They are trusted with deeper dives, more complex welding and construction tasks, and work in more challenging offshore environments. Their daily rate increases substantially, and they are eligible for depth pay that can push their annual income well into the $90,000 - $150,000 range. They may also begin to lead small teams.

- Senior/Saturation Diver (8+ Years): This is the pinnacle of the profession. To qualify for saturation diving, a diver needs a flawless safety record and years of deep-diving experience. Because they work at extreme depths for weeks at a time, their pay is astronomical compared to surface-supplied divers. A single 28-day saturation rotation can net a diver $40,000 - $60,000 or more. Annually, these elite professionals can easily earn $180,000 - $300,000+.

###

3. Geographic Location

Where you work has a monumental impact on your paycheck. The demand for underwater welding is concentrated in specific regions tied to major industries.

- High-Paying Regions (U.S.): The Gulf of Mexico is the undisputed epicenter of offshore underwater welding in the United States. States like Louisiana, Texas, and Florida are hubs for companies supporting the offshore oil and gas industry. The abundance of high-paying offshore jobs, coupled with a high cost of living in some coastal areas, drives salaries up. A mid-career diver here can expect to be at the top end of the national average.

- Other Key U.S. Regions: The coasts of California and Washington also have significant commercial diving work related to shipping, port maintenance, and some offshore platforms. The East Coast has a growing demand related to bridge infrastructure and the burgeoning offshore wind farm industry.

- Lower-Paying Regions (U.S.): Inland states without significant coastlines or major waterways will have far fewer opportunities. The work that does exist is typically for smaller civil engineering firms on projects like local dams and bridges, and the pay is generally lower than the coastal offshore rates.

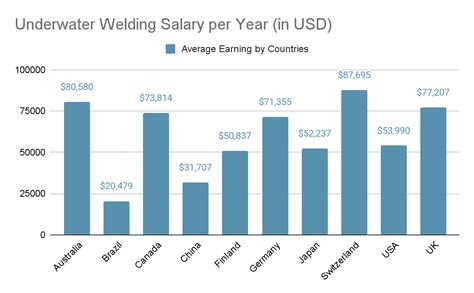

- International Hotspots: The highest salaries in the world are often found in major international oil and gas fields. The North Sea (UK, Norway), Southeast Asia (Singapore, Malaysia), West Africa, and the Middle East are all major employers of expatriate divers. These jobs often come with very high day rates, tax advantages (depending on the country and contract), and hardship pay, but require a willingness to travel and work in challenging conditions. An experienced saturation diver working internationally can potentially earn more than their U.S.-based counterparts.

###

4. Company Type and Industry

The type of company you work for dictates the type of projects, the working conditions, and the pay structure.

- Major Offshore Energy Contractors: Companies like Subsea 7, Oceaneering International, and McDermott are global giants in the offshore construction space. They handle the largest and most complex projects for oil and gas supermajors (like Shell, BP, ExxonMobil). They pay the highest rates, offer the most opportunities for saturation diving, and have structured career paths. However, the work is demanding, with long rotations offshore.

- Inland/Civil Engineering Firms: These are often smaller, regional companies that focus on public infrastructure projects. They might work for state Departments of Transportation to repair bridges or for utility companies to maintain dams. The pay is more modest and is often project-based, meaning there can be downtime between jobs. The work-life balance can be better, with less time away from home.

- Marine Salvage Companies: These specialists are called in to recover sunken vessels or clear wreckage. The work is unpredictable and can be extremely hazardous. Pay is often high but irregular, depending on the number and scale of salvage operations.

- Military/Government: The U.S. Navy employs elite underwater construction teams (the Seabee UCTs) and Navy Divers. While the base military pay is lower than in the private sector, it comes with unparalleled training, job security, and excellent benefits (healthcare, pension, education). This can be an excellent way to start a career and gain world-class experience.

###

5. Area of Specialization (The Biggest Differentiator)

This is the most crucial factor in determining an underwater welder's ultimate earning potential. All underwater welders are commercial divers, but not all are created equal in terms of their specialized skills.

- Surface-Supplied ("Air") Diving vs. Saturation ("Sat") Diving: This is the great divide in the industry.

- Surface-Supplied Diving: The diver's breathing gas is supplied from the surface via an umbilical. This is used for most inland work and for offshore work down to about 180-200 feet. While well-paid, it is the "standard" form of diving.

- Saturation Diving: For work at extreme depths (typically 200 feet to over 1000 feet), it is not feasible to decompress after every dive. Instead, divers live in a pressurized chamber on a vessel or platform for up to 28 days. Their bodies become "saturated" with the inert gases in their breathing mix. They commute to the worksite each day in a pressurized diving bell. This is the most complex and dangerous form of commercial diving, and it commands the highest salaries in the industry by a wide margin. A diver who is "sat-qualified" is at the top of the food chain.

- Wet Welding vs. Hyperbaric Welding:

- Wet Welding: The welding is performed directly in the water with a waterproof electrode. It is fast and cost-effective but produces a lower-quality weld due to rapid quenching by the water. Used for less critical, temporary repairs.

- Hyperbaric (Dry) Welding: A rigid chamber or "habitat" is sealed around the area to be welded, and the water is purged out with gas. The welder-diver works inside this dry environment, producing welds of the same quality as those made on the surface. This is required for critical pipeline and structural connections and is a much higher-paying skill than wet welding.

A diver who is qualified for Saturation Diving and can perform Class A Hyperbaric Welds is the most valuable and highest-paid professional in the field.

###

6. In-Demand Technical Skills

Beyond the core competencies, a portfolio of ancillary skills can make a diver more versatile and thus more valuable.

- Advanced Cutting Techniques: Proficiency with tools like oxy-arc and ultrathermic cutting lances for underwater demolition and salvage.

- Inspection and NDT: As mentioned before, holding certifications in various non-destructive testing methods.

- Rigging and Heavy Lifting: Understanding how to safely rig and move heavy objects underwater.

- Hydraulics and Mechanics: The ability to operate and perform basic maintenance on underwater hydraulic tools (grinders, impact wrenches, etc.).

- ROV (Remotely Operated Vehicle) Piloting/Tending: As automation becomes more prevalent, divers who can also operate or assist with ROVs are increasingly in demand.

- Hazardous Materials (HAZMAT) Diving: Specialized training to work in contaminated water, which comes with a significant pay premium due to the increased risk.

Job Outlook and Career Growth

For those considering this challenging career, the future outlook is a critical piece of the puzzle. The demand for skilled underwater welders is closely tied to the health of several key global industries.

According to the U.S. Bureau of Labor Statistics' Occupational Outlook Handbook, employment for commercial divers (the category including underwater welders) is projected to grow 8 percent from 2022 to 2032, which is much faster than the average for all occupations. The BLS anticipates about 400 openings for commercial divers each year, on average, over the decade. Many of these openings are expected to result from the need to replace workers who transfer to different occupations or exit the labor force, such as to retire.

### Key Drivers of Job Growth

This positive outlook is not based on a single factor, but on a convergence of trends across infrastructure and energy sectors:

1. Aging Infrastructure: A significant portion of the bridges, dams, ports, and water systems in the U.S. and worldwide were built decades ago and are now in constant need of inspection, maintenance, and repair. Underwater welders are essential for reinforcing bridge pilings, repairing dam faces, and maintaining port facilities. This provides a steady stream of inland and coastal work.

2. Offshore Oil and Gas: While the world is transitioning towards renewable energy, the global demand for oil and gas remains strong. Existing offshore platforms and pipelines require continuous maintenance, inspection, and repair (IMR). Furthermore, new deepwater projects, which require the most highly skilled saturation divers, are still being developed. This sector will remain the primary employer of high-earning underwater welders for the foreseeable future.

3. The Rise of Offshore Wind Energy: This is a major emerging driver of growth. The construction of massive offshore wind farms requires extensive subsea work, including foundation installation, cable laying, and welding. As the U.S. and other nations invest heavily in this renewable source, the demand for commercial divers, including welders, is expected to surge. These professionals will be needed for both the construction phase and the long-term maintenance of the turbines.

4. Shipping and Marine Salvage: The global shipping industry relies on divers for hull inspections, propeller repairs, and other ship husbandry tasks that allow vessels to avoid costly dry-docking. The unpredictable but necessary field of marine salvage also provides a constant, if irregular, source of work.

### Future Challenges and Staying Relevant

Despite the strong outlook, the profession faces several challenges that aspiring welders must be aware of:

- Automation and ROVs: Remotely Operated Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs) are becoming more sophisticated. For simple, deepwater inspection