In a world increasingly dominated by digital careers and office jobs, the skilled trades stand as the bedrock of our physical reality. They build our cities, power our homes, and move our world forward. Among these vital professions, welding is a cornerstone—a craft that fuses art with science, strength with precision. If you're drawn to the idea of creating tangible, lasting work with your own hands, a career in welding offers not just deep personal satisfaction but also a significant and often underestimated financial reward. The conversation often starts with a simple question: What is the average annual salary for welders? While the national median hovers around a respectable figure, the full story of a welder's earning potential is far more dynamic, with pathways leading to six-figure incomes for those who master their craft.

Many people see the finished product—the towering skyscraper, the sprawling bridge, the sleek pipeline—without ever considering the intense heat and focused skill required to join its individual steel bones. I once had the opportunity to tour a naval shipyard and watched a team of welders working deep inside the hull of a new destroyer. The air was thick with the scent of ozone and hot metal, but the focus in their eyes was absolute; they were the modern-day sculptors responsible for the integrity of a vessel that would protect thousands. It was a profound reminder that this trade is about more than just a paycheck; it’s about strength, safety, and building the infrastructure of our lives.

This guide is designed to be your definitive resource on that journey. We will move beyond the simple averages to dissect every factor that influences a welder's salary. We will explore the day-to-day realities of the job, the landscape of career growth, and provide a clear, step-by-step roadmap for getting started. Whether you are a high school student considering your options, an adult looking for a career change, or a current welder aiming to maximize your income, this article will provide the data-driven insights and expert guidance you need to forge a successful and lucrative career.

### Table of Contents

- [What Does a Welder Do?](#what-does-a-welder-do)

- [Average Welder Salary: A Deep Dive](#average-welder-salary-a-deep-dive)

- [Key Factors That Influence a Welder's Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth for Welders](#job-outlook-and-career-growth)

- [How to Become a Welder: Your Step-by-Step Guide](#how-to-get-started-in-this-career)

- [Conclusion: Is a Career in Welding Right for You?](#conclusion)

What Does a Welder Do? The Art and Science of Fusing Metal

At its core, a welder is a skilled artisan who uses intense heat and specialized equipment to permanently join or cut metal parts. While this description is accurate, it barely scratches the surface of the complexity and critical thinking involved in the profession. Welders are the architects of connection, working on everything from microscopic components in electronic devices to the massive structural beams of bridges and stadiums. Their work is the invisible force holding much of our modern world together.

The primary responsibility of a welder is to fuse materials according to highly detailed blueprints, schematics, or work orders. This requires not only a steady hand but also a deep understanding of metallurgy, geometry, and physics. A welder must know how different metals like steel, aluminum, stainless steel, and exotic alloys react to heat, what type of filler material to use, and which welding process is appropriate for the job.

The main welding processes a professional must master include:

- Shielded Metal Arc Welding (SMAW): Often called "stick welding," this is one of the oldest and most versatile methods, commonly used in construction and repair due to its portability and effectiveness outdoors.

- Gas Metal Arc Welding (GMAW): Popularly known as "MIG" (Metal Inert Gas) welding, this process uses a continuously fed wire and a shielding gas. It's known for its speed and ease of use, making it a staple in manufacturing and fabrication shops.

- Gas Tungsten Arc Welding (GTAW): Widely known as "TIG" (Tungsten Inert Gas) welding, this is a highly precise and clean process. It requires immense skill and is used for critical welds on thin or delicate materials like stainless steel, aluminum, and titanium, especially in the aerospace, nuclear, and high-end automotive industries.

- Flux-Cored Arc Welding (FCAW): Similar to MIG welding but uses a special tubular wire filled with flux. It's highly effective for heavy-duty welding in outdoor, windy conditions, common in heavy equipment manufacturing and shipbuilding.

### A Day in the Life of a Structural Welder

To make this tangible, let’s follow a day in the life of "Maria," a mid-career structural welder working on a new commercial high-rise building.

- 6:00 AM - Safety Briefing & Prep: Maria arrives on site. The first order of business is the daily safety meeting with the site foreman. They discuss the day's tasks, potential hazards (like working at height or in tight spaces), and review safety protocols. Afterward, Maria gathers her Personal Protective Equipment (PPE)—her helmet, flame-resistant jacket, steel-toed boots, gloves, and respirator.

- 7:00 AM - Blueprint Review & Equipment Setup: At her designated work area on the 15th floor, Maria reviews the structural blueprints for the steel frame connections she's assigned. She needs to understand the specific type of weld required (e.g., a full penetration groove weld), the dimensions, and the quality standards. She then inspects and sets up her equipment, which today is a portable FCAW machine, ensuring the wire feed speed and voltage are perfectly calibrated for the thick structural steel.

- 8:30 AM - The First Welds: The ironworkers have positioned a massive I-beam. Maria's job is to weld it to a vertical column. The process is physically demanding and requires intense focus. She positions herself securely, strikes the arc, and lays down a "root pass"—the critical first weld that sets the foundation for the joint. She meticulously chips away the slag (a hardened protective layer) and cleans the weld with a wire brush before laying subsequent "filler" and "cap" passes.

- 12:00 PM - Lunch & Inspection: After a well-deserved break, Maria’s morning work is inspected by the site's Certified Welding Inspector (CWI). The inspector uses visual checks and sometimes ultrasonic testing equipment to ensure the weld is free of defects like cracks or porosity. A failed inspection means grinding out the weld and redoing it—a costly and time-consuming process, so Maria’s initial precision is paramount.

- 1:00 PM - Tackling Complex Joints: The afternoon presents a more complex challenge: a multi-joint connection in a tight corner. This requires welding in different positions—horizontal, vertical, and overhead. Overhead welding is particularly difficult, as Maria must fight against gravity to ensure the molten metal deposits correctly into the joint.

- 4:00 PM - Cleanup and Shutdown: As the workday winds down, Maria completes her final welds. She cleans her work area, properly stores her equipment, and completes her daily work log, noting the joints she completed and any issues encountered.

- 4:30 PM - Departure: Maria leaves the site, physically tired but with the satisfaction of knowing her work has made a skyscraper a little bit taller and a whole lot stronger.

This example illustrates that a welder's job is a dynamic mix of technical knowledge, physical skill, problem-solving, and unwavering attention to safety and detail.

Average Welder Salary: A Deep Dive into National Earnings

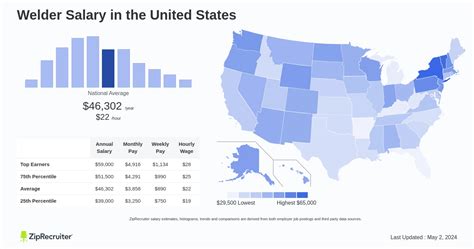

When considering a career, the bottom line often dictates the decision. Fortunately, for welders, the financial outlook is solid and offers substantial room for growth. While a single "average" number provides a starting point, it's the full range of earnings—from apprentice to master specialist—that reveals the true potential of this trade.

### The National Benchmark

According to the most recent data from the U.S. Bureau of Labor Statistics (BLS) Occupational Outlook Handbook, the median annual wage for welders, cutters, solderers, and brazers was $50,560 in May 2023. This translates to a median hourly wage of $24.31.

The "median" wage is the midpoint—half of all welders earned more than this amount, and half earned less. However, this single figure doesn't capture the full spectrum. The BLS also provides a more detailed breakdown:

- Lowest 10%: Earned less than $37,550 per year ($18.05/hour)

- Lower 25% (Q1): Earned less than $42,750 per year ($20.55/hour)

- Median (50%): Earned $50,560 per year ($24.31/hour)

- Upper 75% (Q3): Earned more than $60,860 per year ($29.26/hour)

- Highest 10%: Earned more than $73,060 per year ($35.13/hour)

This data shows a typical entry-level welder might start in the low $40,000s, while a highly experienced and skilled welder working in a standard industry can command over $73,000. It's crucial to note that these BLS figures represent the broad base of the profession. As we'll explore in the next section, top-tier specialists can earn significantly more, often breaking the six-figure barrier.

### Salary Progression by Experience Level

A welder's salary is not static; it grows substantially with experience, skill acquisition, and proven reliability. Data from salary aggregators like Salary.com, which categorizes positions by skill level, provides a clear picture of this trajectory.

| Experience Level | Typical Title(s) | Typical Years of Experience | Average Annual Salary Range (2024) | Key Responsibilities |

| :--- | :--- | :--- | :--- | :--- |

| Entry-Level | Welder I, Apprentice Welder | 0-2 years | $40,100 - $55,600 | Basic welding tasks, material prep, shop cleanup, works under direct supervision. Focus on learning core processes (MIG/Stick). |

| Mid-Career | Welder II, Journeyman Welder | 3-7 years | $50,500 - $68,300 | Works independently from blueprints, performs more complex welds in multiple positions, may have some certifications (e.g., AWS D1.1). |

| Senior/Lead | Welder III, Master Welder, Lead Welder | 8+ years | $60,200 - $81,100 | Handles the most complex and critical welds (e.g., pipe, TIG), inspects work of others, mentors junior welders, troubleshoots equipment. |

| Specialist/Inspector | CWI, Pipe Welder, Aerospace Welder | 10+ years | $75,000 - $150,000+ | Highly specialized work (e.g., underwater, nuclear), quality control and inspection, advanced certifications, works with exotic materials. |

*Source: Data compiled and synthesized from Salary.com (Welder I, II, III), Payscale, and BLS percentile data as of early 2024.*

This table clearly demonstrates that consistent work and skill development can nearly double a welder's base salary over the course of a career, even before considering high-paying specializations.

### Beyond the Paycheck: A Look at Total Compensation

The annual salary is only one piece of the compensation puzzle. For welders, especially those in industrial, construction, or travel-based roles, other forms of payment can significantly boost total earnings.

- Overtime Pay: Many welding jobs, particularly in manufacturing, construction, and shutdowns (plant maintenance periods), offer abundant overtime opportunities. Paid at 1.5 times the base hourly rate ("time and a half") or even double time, overtime can add tens of thousands of dollars to a welder's annual income.

- Per Diem Allowances: Traveling welders, known as "road warriors" or "rig welders," often receive a daily allowance (per diem) to cover food and lodging expenses while on a job away from home. This allowance is typically tax-free and can range from $100 to $200 per day, adding a significant amount of untaxed income.

- Bonuses and Profit Sharing: In profitable manufacturing or energy companies, welders may be eligible for performance bonuses or a share of the company's profits, rewarding them for their role in the company's success.

- Union Benefits: Welders who are members of a union (like the UA Plumbers and Pipefitters or the Boilermakers) often have a comprehensive benefits package negotiated on their behalf. This typically includes excellent health insurance, a defined-benefit pension plan, and annuity funds, which are powerful long-term wealth-building tools that go beyond the hourly wage.

- Rig Pay: A "rig welder" who owns their own truck equipped with a welding machine and tools can charge a premium rate. Part of their pay is for their labor, and another part is a rental fee for their equipment, which can dramatically increase their earning potential.

When evaluating a welding job offer, it's essential to look at the total compensation package—the hourly wage plus overtime potential, benefits, and any allowances—to understand the true financial opportunity.

Key Factors That Influence a Welder's Salary

The difference between a welder earning $45,000 and one earning $145,000 is not luck; it's a combination of strategic choices, continuous learning, and positioning oneself in the most lucrative sectors of the industry. Understanding these influencing factors is the key to maximizing your income.

### Level of Education and Certification

While a four-year university degree is not required to become a welder, education and certification are arguably the most important drivers of initial hiring and long-term salary growth.

- High School Diploma / GED: This is the minimum entry point. A welder with only a high school diploma and on-the-job training will typically start at the lower end of the salary spectrum.

- Vocational School or Community College Program: Completing a 9-18 month welding technology program is the most common and effective pathway. These programs provide foundational knowledge in metallurgy, blueprint reading, and safety, along with hundreds of hours of hands-on practice in various welding processes. Graduates enter the workforce with a higher level of skill and are more attractive to employers, often starting at a higher wage than someone with no formal training.

- Associate's Degree in Welding Technology: A two-year degree goes deeper, covering more advanced topics like robotic welding, destructive and non-destructive testing, and fabrication management. This credential can be a stepping stone to supervisory roles like a welding inspector or shop foreman, which come with higher salaries.

Certifications are the currency of the welding world. They are tangible proof of your ability to perform a specific type of weld to a defined standard. The American Welding Society (AWS) is the primary certifying body in the United States.

- AWS Certified Welder (CW): This is the foundational certification. It demonstrates your ability to perform a weld according to a specific code or standard. There are hundreds of different certifications for various processes, materials, and positions. Each one you earn adds to your versatility and value.

- Certified Welding Inspector (CWI): This is a high-level credential that allows you to inspect and approve the work of other welders. CWIs are in high demand and command significantly higher salaries, often in the $70,000 to $100,000+ range. Becoming a CWI requires several years of experience and passing a rigorous exam.

- Other Specialized Certifications: Industries like aerospace (e.g., NADCAP accreditation), military (e.g., NAVSEA certification for naval ships), and pipeline (e.g., API 1104 certification) have their own highly specific and lucrative certifications.

### Years of Experience

As highlighted in the salary deep dive, experience is a direct driver of income. The career path is a ladder, with each rung representing a new level of skill, responsibility, and compensation.

- 0-2 Years (Apprentice/Entry-Level): Focus is on learning and absorbing information. You'll likely be doing basic production welds, prepping materials, and assisting senior welders. Pay is at the lower end of the scale as you are essentially being paid to learn.

- 3-7 Years (Journeyman/Mid-Career): You are now a reliable, proficient welder. You can read complex blueprints, work independently, and produce high-quality welds in multiple positions. Your speed and efficiency have increased, making you more productive and valuable. This is where you'll see significant salary jumps.

- 8+ Years (Senior/Master Welder): You are a problem-solver and a leader. You're given the most critical, complex, or high-stakes welding jobs. You may be responsible for training apprentices, setting up difficult projects, or pioneering new techniques in the shop. Your reputation for quality work commands top-dollar pay within the standard welder classification.

### Geographic Location

Where you work matters—a lot. The demand for welders and the prevailing cost of living create vast salary disparities across the United States. High-demand industries like oil and gas, shipbuilding, and power generation are often concentrated in specific regions, driving wages up.

According to the BLS, the top-paying states for welders are often those with heavy industrial or energy sector activity:

| State | Annual Mean Wage (May 2023) | Why It Pays Well |

| :--- | :--- | :--- |

| Alaska | $77,950 | Oil and gas industry, remote work, high cost of living. |

| Wyoming | $71,110 | Energy sector (natural gas, mining), infrastructure. |

| North Dakota | $69,490 | Oil and gas extraction (Bakken formation). |

| District of Columbia | $68,640 | Federal construction projects, high cost of living. |

| Hawaii | $68,090 | Military bases, shipbuilding, high cost of living. |

Conversely, states with less heavy industry or a lower cost of living tend to have lower average salaries. The highest-paying metropolitan areas often follow a similar pattern, with cities like Anchorage, AK ($78,220), Bremerton-Silverdale, WA ($76,060 - naval shipyard), and Cheyenne, WY ($75,020) leading the pack.

A welder in a rural fabrication shop in the Southeast might earn $45,000, while a similarly skilled welder working on a pipeline in North Dakota could earn $85,000 plus overtime and per diem.

### Industry and Company Type

The industry you work in is a massive determinant of your salary. A welder's skills are transferable, but the value of those skills changes dramatically depending on the application.

Here is a look at median annual salaries by top-paying industries, based on BLS data:

| Industry | Median Annual Salary (May 2023) | Reason for High Pay |

| :--- | :--- | :--- |

| Electric Power Generation, Transmission and Distribution | $90,120 | Critical infrastructure, high-skill/high-pressure work, often unionized. |

| Natural Gas Distribution | $80,430 | High-stakes pipeline work, safety-critical welds. |

| Support Activities for Mining | $71,480 | Repairing heavy, expensive equipment in harsh conditions. |

| Aerospace Product and Parts Manufacturing | $62,940 | Precision TIG welding on exotic, expensive materials (titanium, Inconel). |

| Ship and Boat Building | $60,860 | Large-scale, complex structural welding, often for military contracts. |

| Commercial and Industrial Machinery Repair | $57,010 | Specialized repair work requiring diagnostic skills. |

Working for a large corporation in the energy sector or a prime defense contractor will almost always pay more than working for a small, local fabrication shop. Government and union jobs often offer lower base hourly wages but compensate with exceptional benefits, job security, and pensions that can be more valuable in the long run.

### Area of Specialization

This is where welders can truly break away from the average and achieve elite-level earnings. Specializing in a difficult, dangerous, or highly technical niche creates massive demand for a very small pool of talent.

- Underwater Welding: The pinnacle of high-risk, high-reward welding. Underwater welders, also known as commercial diver-welders, work on offshore oil rigs, subsea pipelines, and dams. The work is physically grueling and extremely dangerous. Because of the risk and required dual skillset (master diver and expert welder), salaries can range from $100,000 to over $200,000 a year.

- Pipe Welding: Pipe welders, especially those who can pass a 6G certification test (welding a pipe in a fixed 45-degree position), are the aristocrats of the welding world. They are essential in power plants, refineries, and pipelines. A skilled "combo pipe welder" (proficient in both TIG and stick) working on the road can easily earn $80,000 to $150,000+ with overtime.

- Aerospace Welding (TIG): As mentioned, this involves extreme precision welding on high-consequence parts for aircraft and spacecraft. The tolerances are microscopic, and a single bad weld could be catastrophic. These TIG specialists are meticulously trained and highly compensated, often earning $70,000 to $95,000 or more.

- Nuclear Welding: Similar to aerospace, nuclear welding involves zero-defect work in an environment with the highest possible quality and safety standards. These welders work on reactor vessels and piping, and their salaries are among the highest for land-based welders due to the immense responsibility.

- Military Support Welding: Welders who are direct-hire or contractors for the military work on everything from tanks and armored vehicles to submarines and aircraft carriers. This work often requires security clearances and the ability to work on specialized alloys like armor plating, leading to premium pay.

### In-Demand Skills

Beyond broad specializations, possessing specific, high-value skills can add a significant premium to your hourly rate. According to data from Payscale, certain skills can increase a welder's pay by a notable percentage:

- TIG Welding (GTAW): Universally recognized as a high-skill process, proficiency in TIG is a major salary booster.

- Blueprint Reading: The ability to read and interpret complex technical drawings is non-negotiable for high-level work.

- Pipe Welding: A proven skill that immediately elevates a welder to a higher pay grade.

- Welding Inspection: Having knowledge of inspection techniques, even if not a full CWI, makes you a more valuable team member.

- Robotic Welding/Automation: As the industry evolves, welders who can program, operate, and maintain automated welding systems are becoming a new class of highly paid technicians.

By strategically combining these factors—getting certified, gaining experience in a high-paying industry, moving to a top-paying location, and developing a lucrative specialization—a welder can chart a course toward a very prosperous career.

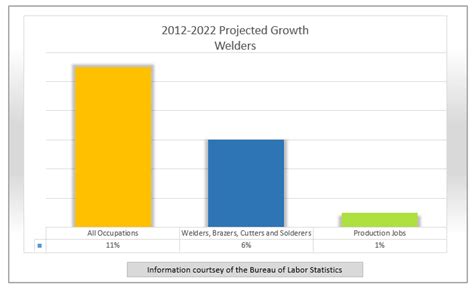

Job Outlook and Career Growth for Welders