Table of Contents

- [What Does an Industrial Engineer Do?](#what-does-an-industrial-engineer-do)

- [Average Industrial Engineer Salary: A Deep Dive](#average-industrial-engineer-salary-a-deep-dive)

- [Key Factors That Influence an Industrial Engineer's Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth for Industrial Engineers](#job-outlook-and-career-growth)

- [How to Become an Industrial Engineer: Your Step-by-Step Guide](#how-to-get-started-in-this-career)

- [Conclusion: Is a Career in Industrial Engineering Right for You?](#conclusion)

---

Are you the kind of person who looks at a chaotic process—be it a crowded airport security line, a disorganized factory floor, or even the inefficient way a coffee shop handles morning orders—and immediately starts redesigning it in your head? If you're driven by a desire to eliminate waste, optimize performance, and make complex systems work more smoothly, a career as an industrial engineer might be your calling. This field is not just about tinkering with machinery; it's about being the strategic architect of efficiency, a role that is becoming increasingly critical in every industry imaginable.

As a career analyst who has guided countless professionals, I've seen firsthand how a career in industrial engineering offers a rare blend of intellectual challenge, tangible impact, and significant financial reward. The demand for professionals who can streamline operations and save companies millions of dollars is immense, and this is directly reflected in compensation. The average industrial engineer salary is highly competitive, with the U.S. Bureau of Labor Statistics reporting a median pay of $99,410 per year as of May 2023. But this figure is just the starting point of a much larger story about earning potential.

I once consulted for a mid-sized medical device manufacturer that was bleeding money due to production bottlenecks. They brought in a senior industrial engineer who, within six months, completely reconfigured their assembly line, implemented a new inventory system, and retrained the staff on lean principles. The result was a 30% increase in output and a drastic reduction in defects, saving the company from a potential crisis. It was a powerful, real-world demonstration that industrial engineers aren't just a cost center; they are a profound source of value and innovation.

This guide is designed to be your definitive resource on a career in industrial engineering. We will dissect salary expectations, explore the factors that can maximize your earnings, analyze the robust job outlook, and provide a clear, actionable roadmap for how you can enter and thrive in this dynamic profession. Whether you are a student choosing a major, a professional considering a career change, or an existing engineer looking to advance, this article will provide the in-depth insights you need to build a successful and lucrative career.

What Does an Industrial Engineer Do?

At its core, industrial engineering (IE) is the branch of engineering that focuses on the optimization of complex processes, systems, or organizations. While other engineers might design a new circuit board, a stronger bridge, or a more powerful engine, the industrial engineer designs the *system* that produces, manages, or delivers those things efficiently, safely, and cost-effectively. They are the "big picture" thinkers of the engineering world, integrating workers, machines, materials, information, and energy to make a product or provide a service.

Think of them as "efficiency experts" or "systems integrators." Their work is less about nuts and bolts and more about flow, logic, and human-computer interaction. They ask critical questions like:

- How can we reduce the time it takes to manufacture this product without sacrificing quality?

- What is the most effective layout for a new hospital emergency room to minimize patient wait times?

- How can a logistics company redesign its distribution network to reduce fuel costs and delivery times?

- What is the safest and most ergonomic way to design a workstation to prevent employee injuries?

#### Core Responsibilities and Daily Tasks

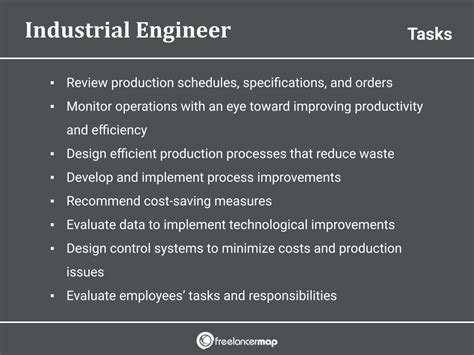

The day-to-day work of an industrial engineer is incredibly varied and depends heavily on the industry and specific project. However, some common responsibilities thread through the profession:

- Process Analysis and Improvement: Using methodologies like Six Sigma and Lean Manufacturing, IEs meticulously study existing processes to identify waste, bottlenecks, and inefficiencies. They use tools like time studies, value stream mapping, and statistical process control to gather data.

- Facility and System Design: They design the physical layout of factories, warehouses, and even service environments like amusement parks or government offices to optimize the flow of people and materials.

- Quality Control and Assurance: IEs develop and implement quality control systems to ensure products and services meet consistent standards, reducing defects and rework.

- Supply Chain Management and Logistics: They work on optimizing the entire supply chain, from sourcing raw materials to final product distribution, ensuring everything happens on time and within budget.

- Ergonomics and Safety: A key part of the role is designing work environments that are safe and comfortable for employees, which improves morale and productivity while reducing workplace injuries.

- Data Analysis and Simulation: Modern IEs are data wizards. They use computer simulation software (like Arena or Simio) and data analysis tools (like Python or R) to model, test, and predict the outcomes of proposed changes before implementation.

- Project Management: IEs often lead cross-functional teams to implement their proposed improvements, requiring strong communication, leadership, and organizational skills.

#### A "Day in the Life" of an Industrial Engineer

To make this more concrete, let's imagine a day for "Maria," a mid-career industrial engineer at a large automotive parts manufacturing plant.

- 8:00 AM: Maria arrives and starts her day by reviewing the production dashboards from the previous day's shifts. She notices a 5% increase in a specific type of defect on Assembly Line 3.

- 9:00 AM: She heads to the factory floor. She spends an hour observing Line 3, speaking with the line operators and the quality control inspector. She uses a tablet to record her observations and take videos of the process in question.

- 10:30 AM: Back at her desk, she pulls the raw sensor data from the machines on Line 3. She uses a statistical software package to analyze the data, looking for correlations between machine settings, cycle times, and the occurrence of the defect.

- 12:00 PM: Lunch meeting with the production manager and the lead technician for Line 3. Maria presents her initial findings and hypotheses. They decide to run a small, controlled experiment in the afternoon to test a potential solution.

- 1:30 PM: Maria works with the technician to slightly adjust a robotic arm's calibration on the line. They run a batch of 100 parts with the new setting, carefully monitoring the process.

- 3:00 PM: The test is complete. Maria and the quality inspector examine the new batch and find the defect rate has dropped to nearly zero. This is a promising result.

- 3:30 PM: Maria begins drafting a formal report. She documents the problem, her analysis, the experiment, and the results. She includes a cost-benefit analysis showing the potential savings from permanently implementing this change across all similar assembly lines.

- 5:00 PM: Before leaving, she sends the draft report to the production manager and schedules a follow-up meeting to discuss a full-scale implementation plan.

This example highlights the blend of hands-on observation, data-driven analysis, and collaborative problem-solving that defines the role of an industrial engineer.

Average Industrial Engineer Salary: A Deep Dive

Now for the central question: what can you expect to earn as an industrial engineer? The financial prospects are a significant draw for the profession, offering a high starting salary and substantial growth potential throughout one's career. The compensation reflects the immense value IEs bring to organizations by driving efficiency, cutting costs, and improving quality.

#### The National Snapshot: Median and Typical Ranges

When analyzing salary data, it's crucial to look at multiple reputable sources to get a well-rounded picture.

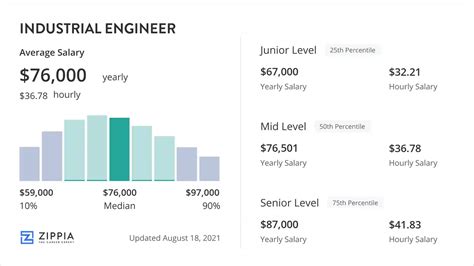

- The U.S. Bureau of Labor Statistics (BLS) is the gold standard for occupational data. In its May 2023 report, the BLS stated that the median annual wage for industrial engineers was $99,410. The median represents the midpoint—half of all industrial engineers earned more than this amount, and half earned less.

- The BLS also provides a range: the lowest 10 percent earned less than $66,480, and the highest 10 percent earned more than $146,860. This wide range hints at the many factors that can influence your paycheck, which we will explore in the next section.

- Salary.com, as of late 2023, reports a slightly different but comparable median salary for an Industrial Engineer I (entry-level) at around $77,910, while an Industrial Engineer III (senior) has a median of $105,790. Their data shows the typical range for all IEs falls between $88,487 and $111,296.

- Payscale.com provides a total pay estimate (including bonuses and profit sharing) with an average base salary of around $78,000 per year, but with a total pay range extending from $59,000 to $112,000.

- Glassdoor reports a national average salary of approximately $88,500 in base pay, with "total pay" (including additional compensation) averaging around $96,000.

Key Takeaway: While the exact number varies slightly between sources, a consensus emerges: the median salary for a typical industrial engineer in the United States is firmly in the $95,000 to $100,000 range. Entry-level professionals can expect to start in the $70,000s, with top earners and senior specialists easily commanding salaries well into the six figures.

#### Salary by Experience Level

Experience is arguably the single most significant factor in salary growth for an industrial engineer. As you accumulate skills, manage larger projects, and demonstrate a track record of successful improvements, your value—and compensation—will rise accordingly.

Here is a typical salary progression based on aggregated data from sources like Payscale and Salary.com:

| Career Stage | Years of Experience | Typical Salary Range (Base Pay) | Key Responsibilities & Skills |

| :--- | :--- | :--- | :--- |

| Entry-Level Industrial Engineer | 0-2 years | $70,000 – $85,000 | Applying academic knowledge, data collection, supporting senior engineers, learning specific company processes, time studies, creating process maps. |

| Mid-Career Industrial Engineer | 3-8 years | $85,000 – $110,000 | Leading small to medium-sized projects, performing complex data analysis and simulation, mentoring junior engineers, specializing in an area like logistics or quality. |

| Senior Industrial Engineer | 8-15 years | $110,000 – $135,000 | Managing large-scale, cross-functional projects, developing strategic initiatives, setting departmental goals, managing budgets, deep expertise in a chosen specialization. |

| Principal / Lead Engineer / IE Manager| 15+ years | $130,000 – $160,000+ | Setting long-term strategy for entire plants or divisions, managing a team of engineers, high-level stakeholder management, driving enterprise-wide innovation and efficiency programs. |

*Note: These are national averages. Your actual salary will be heavily influenced by location, industry, and other factors discussed below.*

#### Beyond the Base Salary: A Look at Total Compensation

An industrial engineer's earnings are not limited to their base salary. Total compensation is a critical part of the financial picture and often includes several lucrative components.

- Annual Bonuses: This is a very common component. Bonuses are typically tied to individual performance, team performance, and overall company profitability. They can range from 5% to 20% or more of your base salary, especially at senior levels. A senior IE with a $120,000 base salary might receive a $18,000 bonus in a good year, bringing their total cash compensation to $138,000.

- Profit Sharing: Some companies, particularly in manufacturing, offer profit-sharing plans where a portion of the company's profits is distributed among employees. This directly ties your compensation to the success of the efficiency improvements you help create.

- Stock Options and RSUs (Restricted Stock Units): More common in publicly traded companies, especially in the tech and advanced manufacturing sectors. This gives you an ownership stake in the company, which can be extremely valuable if the company performs well over the long term.

- Retirement Plans (401k/403b): Virtually all large employers offer retirement plans. A key benefit is the "company match," where the employer contributes a certain amount to your account based on your own contributions (e.g., matching 100% of your contribution up to 5% of your salary). This is essentially free money and a vital part of long-term wealth building.

- Health and Wellness Benefits: Comprehensive health, dental, and vision insurance is standard. Other benefits can include generous paid time off (PTO), life insurance, disability insurance, and wellness stipends.

- Tuition Reimbursement: Many companies will invest in their IEs by paying for advanced degrees (like a Master's in Engineering Management or an MBA) or expensive certifications (like a Six Sigma Master Black Belt), which in turn increase your future earning potential.

When evaluating a job offer, it is crucial to look beyond the base salary and consider the full value of the total compensation package.

Key Factors That Influence an Industrial Engineer's Salary

While the national averages provide a useful benchmark, your individual salary as an industrial engineer will be determined by a combination of factors. Understanding these levers is key to maximizing your earning potential throughout your career. This is the most critical section for anyone looking to strategically build a high-income career in this field.

### Level of Education and Certifications

Your educational foundation sets the stage for your starting salary and long-term growth.

- Bachelor's Degree: A Bachelor of Science in Industrial Engineering (BSIE) from an ABET-accredited program is the standard entry requirement for the profession. This degree provides the fundamental knowledge in statistics, operations research, production systems, and ergonomics needed to succeed. Graduates with this degree can expect to land squarely in the typical entry-level salary range.

- Master's Degree: Pursuing a master's degree can provide a significant salary bump and open doors to more specialized or leadership-oriented roles. The salary premium for a master's degree is often 10-20% higher than for a bachelor's alone.

- Master of Science in Industrial Engineering (MSIE): This degree is ideal for those who want to deepen their technical expertise in a specific area, such as operations research, data analytics, or supply chain management. It qualifies you for R&D roles or highly specialized technical positions.

- Master of Engineering Management (MEM): This is a hybrid degree that blends engineering principles with business and management coursework. It is perfect for IEs who aspire to move into leadership roles, managing teams and large projects.

- Master of Business Administration (MBA): An MBA, especially from a top-tier school, can be a powerful accelerator for IEs aiming for executive-level positions in operations, consulting, or corporate strategy. The combination of deep process knowledge (IE) and broad business acumen (MBA) is highly sought after and commands a premium salary.

- Professional Certifications: In the world of industrial engineering, certifications are not just resume-boosters; they are validated proof of specific, high-value skills that companies will pay more for.

- Six Sigma (Green Belt, Black Belt, Master Black Belt): This is the most recognized certification family in process improvement. A Six Sigma Black Belt certification can add $10,000 to $20,000 to an engineer's annual salary, according to data from Payscale. It signifies expertise in a rigorous, data-driven methodology for eliminating defects and variation.

- Lean Certification: Focused on eliminating waste and maximizing value, Lean certifications (from organizations like SME, ASQ, or IISE) are also highly valued, particularly in manufacturing.

- Project Management Professional (PMP): As IEs often lead complex projects, a PMP certification is extremely valuable. It demonstrates proficiency in managing scope, schedule, and budget, a skill set essential for senior and management roles.

- Certified Professional in Engineering Management (CPEM): Offered by the American Society for Engineering Management, this certification is for experienced technical managers and validates leadership capabilities.

### Years of Experience

As detailed in the previous section, experience is a primary driver of salary growth. The career ladder is well-defined, and compensation grows in distinct steps.

- 0-2 Years (Entry-Level): Focus is on learning and execution. You're proving you can apply your academic skills to real-world problems. Salary: ~$70k - $85k.

- 3-8 Years (Mid-Career): You transition from executing tasks to owning projects. You begin to specialize and develop a reputation for your expertise in a specific area. This is where the most significant initial salary growth occurs. Salary: ~$85k - $110k.

- 8+ Years (Senior/Lead): You are now a strategic asset. You don't just solve problems; you identify opportunities for improvement that others might miss. You mentor others and may begin managing teams or large-scale programs. Your salary reflects this high level of responsibility and impact. Salary: ~$110k - $160k+.

The key to accelerating this progression is to proactively seek out challenging projects, take on leadership responsibilities, and continuously document your achievements in quantifiable terms (e.g., "Led a project that reduced production waste by 15%, saving $500,000 annually").

### Geographic Location

Where you work has a massive impact on your paycheck. Salaries are often adjusted to reflect the local cost of living and the concentration of companies that hire IEs.

High-paying states for industrial engineers often correspond to hubs of technology, aerospace, manufacturing, or defense contracting. According to the BLS, some of the top-paying states include:

| State | Annual Mean Wage (BLS, May 2023) | Why It Pays Well |

| :--- | :--- | :--- |

| Washington | $132,190 | Aerospace (Boeing), Tech (Amazon logistics), cloud data centers. |

| California | $124,560 | Tech (Apple, Google), defense, biotech, and massive logistics networks. |

| New Mexico | $121,950 | National labs (Sandia, Los Alamos), defense and aerospace industry. |

| Texas | $112,650 | Oil & gas, massive manufacturing sector, defense, and logistics hubs. |

| Massachusetts| $111,760 | Biotech, medical devices, defense, and a strong tech sector. |

Similarly, metropolitan areas offer higher salaries than rural regions. The top-paying metropolitan areas according to the BLS are often concentrated in California's Bay Area:

- San Jose-Sunnyvale-Santa Clara, CA: $149,040

- San Francisco-Oakland-Hayward, CA: $137,840

- Seattle-Tacoma-Bellevue, WA: $134,240

Crucial Caveat: A high salary in a city like San Jose must be weighed against its extremely high cost of living. A $130,000 salary in California might have the same or less purchasing power than a $100,000 salary in a city like Houston, Texas. Always use a cost-of-living calculator to compare offers in different locations.

### Company Type & Size

The type of organization you work for will also shape your compensation structure and overall earnings.

- Large Corporations (Fortune 500): Companies in sectors like automotive (Ford, GM), aerospace (Boeing, Lockheed Martin), consumer goods (Procter & Gamble), and technology (Amazon, Apple) are the largest employers of IEs. They typically offer:

- High base salaries and structured, predictable salary bands.

- Generous benefits packages and substantial annual bonuses.

- Clear career progression paths but potentially more bureaucracy.

- Consulting Firms: Firms like Deloitte, Accenture, and McKinsey hire IEs for their operations and supply chain practices. Consulting roles often come with:

- Extremely competitive salaries and performance bonuses, often exceeding corporate roles.

- High demands, long hours, and extensive travel.

- Rapid learning and exposure to a wide variety of industries.

- Startups and Tech Companies: A fast-growing area for IEs, especially in hardware or logistics-heavy startups.

- Potentially lower base salaries compared to large corporations.

- Significant equity/stock options, which can lead to a massive payday if the company succeeds.

- A fast-paced, less structured environment with more opportunities to wear multiple hats.

- Government and Defense Contractors: Working for federal agencies (like the Department of Defense) or contractors (like Northrop Grumman) offers:

- Good job security and excellent benefits, including pensions in some cases.

- Salaries that are competitive but may lag behind the top-tier private sector.

- A more structured and sometimes slower-paced work environment.

### Area of Specialization

Within the broad field of industrial engineering, certain specializations are in higher demand and command higher salaries.

- Supply Chain Management & Logistics: This has become one of the most lucrative specializations, especially after the global disruptions of recent years. Companies are desperate for experts who can design resilient, efficient, and technology-driven supply chains. Roles in logistics strategy, distribution network design, and inventory optimization are highly paid.

- Data Analytics and Operations Research: IEs who can blend traditional process improvement with advanced data science are at the top of the pay scale. Skills in Python, R, SQL, and machine learning to optimize complex systems are in extremely high demand. These roles often blur the line between industrial engineering and data science.

- Healthcare Systems Engineering: Applying IE principles to hospitals and healthcare networks is a rapidly growing field. IEs in this sector work to improve patient flow, reduce wait times, optimize operating room scheduling, and make healthcare safer and more efficient. As the healthcare industry continues to face cost pressures, this specialization is becoming increasingly valuable.

- Advanced Manufacturing & Automation (Industry 4.0): As factories become "smarter," IEs who specialize in integrating robotics, IoT (Internet of Things) sensors, and AI-driven manufacturing execution systems are essential. They design the automated factories of the future.

- Human Factors & Ergonomics: While sometimes seen as a niche, specialists who can design systems and products that are safe, comfortable, and intuitive for human use are critical in industries from consumer electronics to aerospace and defense, where human error can have catastrophic consequences.

### In-Demand Skills

Beyond your title, the specific skills you possess can directly impact your salary negotiations and career opportunities.

High-Value Technical Skills:

- Process Improvement Methodologies: Deep expertise in Six Sigma and Lean Manufacturing is non-negotiable for top earners.

- Simulation Software: Proficiency in discrete-event simulation packages like Arena, Simio, or AnyLogic allows you to model and test complex systems, a highly valued skill.

- Data Analysis Tools: Advanced skills in SQL for data extraction, Python or R for statistical analysis and modeling, and visualization tools like Tableau or Power BI.

- CAD and PLM Software: Familiarity with Computer-Aided Design (CAD) software like AutoCAD or SolidWorks and Product Lifecycle Management (PLM) systems is important in manufacturing environments.

- ERP Systems: Experience with Enterprise Resource Planning (ERP) systems, particularly SAP or Oracle, is crucial for IEs working in large