Are you fascinated by the intersection of technology and healthcare? Do you have a knack for problem-solving and a desire for a career that makes a tangible, life-saving impact every single day? If so, you might be looking at your future as a Biomedical Equipment Technician (BMET). Behind every successful diagnosis, every life-sustaining treatment, and every critical surgery, there is a complex web of medical technology that must function flawlessly. The unsung heroes ensuring that reliability are the BMETs.

But a fulfilling mission is only one part of a great career. You also need to know if it's a financially viable and secure path. That’s why understanding the details of a biomedical equipment technicians salary is so crucial. The earning potential in this field is strong and stable, with median salaries comfortably above the national average for all occupations and significant room for growth. A typical salary can range from an entry-level of around $45,000 to well over $95,000 for experienced specialists in high-demand areas.

I once interviewed a senior clinical engineering manager for a large hospital network who shared a powerful story. He recounted an emergency call in the middle of the night for a malfunctioning infant incubator in the NICU. His quick diagnosis and repair of a faulty sensor under immense pressure didn't just fix a machine; it ensured the survival of a premature baby. That story has always stuck with me as the perfect illustration of a BMET's profound importance—a role that blends deep technical expertise with a direct, human impact.

This guide will provide a comprehensive, data-driven look at everything you need to know about a BMET's salary, career outlook, and the steps required to enter and excel in this vital profession.

### Table of Contents

- [What Does a Biomedical Equipment Technician Do?](#what-does-a-bmet-do)

- [Average Biomedical Equipment Technicians Salary: A Deep Dive](#average-bmet-salary-a-deep-dive)

- [Key Factors That Influence a BMET's Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth for BMETs](#job-outlook-and-career-growth)

- [How to Get Started as a Biomedical Equipment Technician](#how-to-get-started)

- [Conclusion: Is a Career as a BMET Right for You?](#conclusion)

What Does a Biomedical Equipment Technician Do?

At its core, a Biomedical Equipment Technician—often called a BMET or Medical Equipment Repairer—is a highly skilled professional responsible for the maintenance, repair, and management of the vast array of electronic, electromechanical, and hydraulic equipment used in healthcare facilities. Think of them as the doctors and engineers for medical devices. When a ventilator, EKG machine, infusion pump, or surgical laser malfunctions, the BMET is the first responder who diagnoses the problem and brings it back to life.

Their work is a critical component of patient safety and clinical efficacy. A miscalibrated device can lead to an incorrect diagnosis or improper treatment, making the BMET's role foundational to quality healthcare delivery.

The responsibilities of a BMET are diverse and require a unique blend of technical knowledge, analytical thinking, and hands-on skill.

Core Daily Tasks and Responsibilities:

- Installation and Setup: Assembling, installing, and testing new medical equipment to ensure it meets manufacturers' specifications and safety regulations before it is used on patients.

- Preventive Maintenance (PM): Performing routine checks, cleaning, calibrations, and parts replacements on a scheduled basis to prevent breakdowns. This proactive work is a massive part of the job and is essential for hospital accreditation and safety.

- Troubleshooting and Repair: Responding to emergency and routine repair calls. This involves using specialized testing equipment (like multimeters, oscilloscopes, and pressure gauges), reading complex schematics, and methodically diagnosing issues to identify faulty components.

- Calibration: Adjusting medical devices to ensure their quantitative outputs (e.g., radiation dose, blood pressure readings, anesthetic gas flow) are accurate and within safe limits.

- Documentation: Meticulously documenting every single action taken on a piece of equipment—from routine PMs to complex repairs. This record-keeping is vital for regulatory compliance, equipment history, and safety audits.

- User Training: Instructing nurses, doctors, and other clinical staff on the proper and safe use of medical equipment.

- Inventory and Parts Management: Maintaining an inventory of spare parts and ordering new ones as needed to ensure repairs can be completed quickly.

### A Day in the Life of a BMET

To make this tangible, let’s imagine a day for "Maria," a mid-career BMET (a BMET II) at a regional hospital:

- 8:00 AM: Maria starts her day by checking the service request system. She sees a new ticket for a telemetry monitor on the cardiac floor that isn't transmitting data correctly. She also reviews her list of scheduled Preventive Maintenance tasks for the day, which includes ten infusion pumps and two defibrillators.

- 8:30 AM: She heads to the cardiac floor. After speaking with the charge nurse, she diagnoses the telemetry monitor issue as a faulty network connection. She reconfigures the network settings, tests the device, and confirms with the nursing staff that it’s now working perfectly. She documents the repair in the hospital's computerized maintenance management system (CMMS).

- 10:00 AM: Maria moves on to her scheduled PMs. She systematically works through the infusion pumps, cleaning them, testing their alarms, and verifying their flow rate accuracy using a specialized analyzer.

- 12:30 PM: Lunch break.

- 1:00 PM: While working on a defibrillator PM, she receives an urgent "stat" call from the Operating Room. An electrosurgical unit (ESU) is "faulting out" mid-procedure.

- 1:10 PM: Maria rushes to the OR. Using her diagnostic skills, she quickly identifies a frayed grounding pad cable as the culprit. She replaces the cable from her stock, runs a full safety and output test, and gets the unit back online, allowing the surgery to continue with minimal delay.

- 3:00 PM: Back in the biomed shop, she finishes her defibrillator PMs, which involves testing the energy output and charging time. She carefully logs all her work.

- 4:00 PM: Maria spends the last hour of her day ordering a replacement ESU cable to replenish her stock, following up on a part order for a different repair, and preparing her tools and schedule for the next day.

This example highlights the dynamic nature of the role—a mix of planned, meticulous maintenance and high-pressure, reactive problem-solving that directly impacts patient care.

Average Biomedical Equipment Technicians Salary: A Deep Dive

Now for the central question: What can you expect to earn as a BMET? The salary for a biomedical equipment technician is competitive and reflects the specialized skills and critical importance of the role. It's influenced by a combination of experience, location, specialization, and the type of employer.

To provide the most accurate picture, we will pull data from several authoritative sources, including the U.S. Bureau of Labor Statistics (BLS), Salary.com, and Payscale.

### National Salary Benchmarks

According to the most recent data from the U.S. Bureau of Labor Statistics (BLS) Occupational Outlook Handbook, the median annual wage for medical equipment repairers was $58,740 in May 2023. The "median" wage is the midpoint—half of all BMETs earned more than this amount, and half earned less.

However, the median only tells part of the story. The full range of salaries is much wider:

- Lowest 10%: Earned less than $37,860

- Highest 10%: Earned more than $98,150

This significant range highlights the substantial opportunity for salary growth throughout a BMET's career.

Data from salary aggregators, which often use real-time, user-submitted data, provides further granularity.

- Salary.com reports that as of late 2023, the median salary for a Biomedical Equipment Technician II (an experienced, non-entry-level role) in the United States is $67,619, with a typical range falling between $59,629 and $76,334.

- Payscale.com shows an average base salary of approximately $62,000 per year, with a reported range from $44,000 to $88,000.

- Glassdoor.com estimates the total pay for a BMET to be around $75,446 per year on average in the U.S., which includes base salary and additional pay like bonuses and profit sharing.

Key Takeaway: While the BLS provides a conservative and highly reliable median, other sources suggest that with a few years of experience, a salary in the $65,000 to $75,000 range is very attainable, with top earners approaching six figures.

### Salary by Experience Level

One of the most significant drivers of a BMET's salary is experience. The industry often uses a tiered system to classify technicians, which directly correlates with compensation.

| Experience Level | Typical Title | Average Salary Range (Annual) | Key Responsibilities |

| :--- | :--- | :--- | :--- |

| Entry-Level (0-2 years) | BMET I, Apprentice Technician | $45,000 - $58,000 | Performing basic preventive maintenance, safety testing, and minor repairs under supervision. Focus on learning and documentation. |

| Mid-Career (2-5 years) | BMET II, Journeyman Technician | $58,000 - $72,000 | Working independently on a wide range of general medical equipment. Troubleshooting complex issues and assisting with installations. May mentor junior technicians. |

| Senior/Experienced (5+ years)| BMET III, Senior Technician | $70,000 - $85,000 | Handling the most complex and critical equipment. Leading projects, training clinical staff, and specializing in high-tech modalities like anesthesia or imaging. |

| Specialist/Lead (8+ years) | Imaging Specialist, Lead BMET | $80,000 - $98,000+ | Subject matter expert in a specific field (e.g., MRI, CT scanners, linear accelerators). May have supervisory duties, manage budgets, and lead departmental strategy. |

*Sources: Synthesized data from BLS, Salary.com, and industry job postings.*

As you can see, a dedicated BMET can realistically expect to nearly double their starting salary over the course of their career through skill development and specialization.

### Beyond the Base Salary: Understanding Total Compensation

Your annual salary is just one piece of the puzzle. Total compensation for a BMET can include several other valuable components:

- On-Call Pay: Many BMETs, especially those working in hospitals, are required to be "on-call" for after-hours or weekend emergencies. They typically receive a small stipend for each hour they are on-call, and a higher hourly rate (often 1.5x) if they are actually called in to work. This can add several thousand dollars to an annual income.

- Overtime Pay: As non-exempt employees, most BMETs are eligible for overtime pay for any hours worked beyond the standard 40-hour week. This is common during large-scale equipment installations or when dealing with significant backlogs.

- Bonuses: While less common in non-profit hospital settings, BMETs working for third-party service organizations (ISOs) or original equipment manufacturers (OEMs) may be eligible for performance-based bonuses tied to service contract renewals, customer satisfaction, or team efficiency.

- Health and Retirement Benefits: This is a significant part of total compensation. Most full-time BMETs receive comprehensive benefits packages, including health, dental, and vision insurance; paid time off (PTO); and access to retirement savings plans like a 401(k) or 403(b), often with an employer match.

- Professional Development: Many employers will pay for certification exams, ongoing training courses, and attendance at industry conferences. This is an investment in your skills that also has immense financial value.

When evaluating a job offer, it's essential to look at the entire compensation package, as strong benefits and opportunities for overtime or on-call pay can make a lower base salary more attractive than a higher one with fewer perks.

Key Factors That Influence a BMET's Salary

Beyond the national averages, your specific salary as a BMET will be determined by a powerful combination of factors. Understanding these variables is key to maximizing your earning potential throughout your career. This is where you can move from an average earner to a top-tier professional.

###

1. Level of Education and Certification

While a four-year bachelor's degree isn't typically required to enter the field, your educational background and professional certifications lay the foundation for your career trajectory and salary.

- Associate of Applied Science (A.A.S.) in Biomedical Equipment Technology: This is the most common and direct educational pathway. A two-year A.A.S. degree provides the essential theoretical knowledge and hands-on lab experience needed for an entry-level BMET I position.

- Military Training: The U.S. Department of Defense (DoD) Biomedical Equipment Technician training program is highly respected in the civilian world. Veterans with this training are sought after for their discipline, extensive hands-on experience, and ability to work under pressure. Their starting salaries are often on the higher end of the entry-level spectrum.

- Bachelor's Degree: A four-year degree in Biomedical Engineering Technology (BSET) or a related field can provide a higher starting salary and, more importantly, can fast-track you for leadership positions. Individuals with a B.S. are often better positioned to move into roles like Clinical Engineer, Department Manager, or Director of Healthcare Technology Management.

- Professional Certifications: This is arguably the most impactful factor in this category for boosting pay. Certifications from the Association for the Advancement of Medical Instrumentation (AAMI) are the industry gold standard.

- Certified Biomedical Equipment Technician (CBET): This is the cornerstone certification. Achieving CBET status demonstrates a broad-based knowledge of the field and a commitment to the profession. Many employers offer an immediate salary increase or a one-time bonus upon certification, and it is often a prerequisite for promotion to a BMET II or III level. Payscale data suggests that holding a CBET can increase salary potential by several thousand dollars per year.

- Specialty Certifications: For those looking to become high-earning experts, AAMI offers specialized certifications like CRES (Certified Radiology Equipment Specialist) and CLES (Certified Laboratory Equipment Specialist). These are rigorous exams that require deep knowledge of specific, high-tech modalities. A CRES-certified technician who can service MRI, CT, and X-ray equipment can command a salary significantly higher than a generalist BMET, often in the $85,000 to $100,000+ range.

###

2. Years of Experience

As illustrated in the previous section, experience is a primary driver of salary growth. However, it's not just about the number of years; it's about the *quality* and *diversity* of that experience.

- BMET I (Entry-Level): At this stage, you are primarily learning. Your value is in your potential and your ability to handle routine tasks, freeing up senior technicians. Salary is lower because you require significant supervision and training.

- BMET II (Mid-Career): You have become a reliable, independent resource. You can troubleshoot a wide variety of equipment with minimal supervision. Your salary increases to reflect your autonomy and productivity. You might be the "go-to" person for general equipment on several hospital floors.

- BMET III (Senior): You are now a mentor and a specialist. You've likely developed an expertise in a few complex systems (e.g., anesthesia machines, ventilators, dialysis units). You are trusted with the most critical equipment and high-stakes repairs. Your salary reflects your role as a key problem-solver and risk mitigator for the organization.

- Lead/Managerial Roles: After a decade or more of experience, technicians can move into leadership. A Lead BMET supervises a team, manages workflows, and handles administrative duties in addition to technical work. A Clinical Engineering Manager oversees the entire department, managing budgets, personnel, equipment purchasing strategies, and regulatory compliance. These roles come with a significant jump in salary, often exceeding $100,000 - $120,000+, depending on the size of the facility.

###

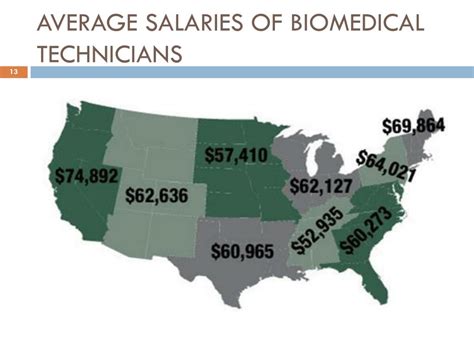

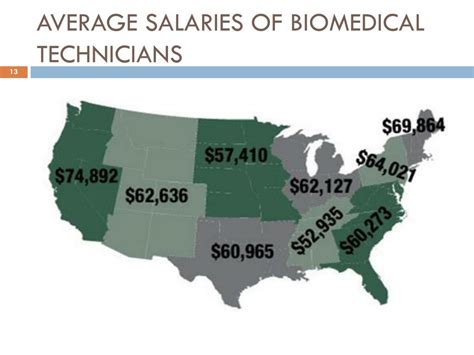

3. Geographic Location

Where you work has a massive impact on your paycheck. Salaries for BMETs vary significantly by state and even by metropolitan area, largely due to differences in cost of living and the concentration of healthcare facilities.

Top-Paying States for Medical Equipment Repairers (according to BLS May 2023 data):

| State | Annual Mean Wage |

| :--- | :--- |

| Washington | $80,210 |

| Oregon | $79,880 |

| California | $78,430 |

| Nevada | $75,370 |

| Connecticut | $73,610 |

Top-Paying Metropolitan Areas (according to BLS May 2023 data):

| Metropolitan Area | Annual Mean Wage |

| :--- | :--- |

| Portland-Vancouver-Hillsboro, OR-WA | $83,720 |

| San Francisco-Oakland-Hayward, CA | $83,430 |

| Sacramento-Roseville-Arden-Arcade, CA| $81,770 |

| Seattle-Tacoma-Bellevue, WA | $80,480 |

| San Jose-Sunnyvale-Santa Clara, CA | $80,310 |

Conversely, states in the Southeast and parts of the Midwest tend to have salaries closer to or slightly below the national median. However, the lower cost of living in these areas can often offset the lower nominal wage, meaning your purchasing power may be similar. When considering a job, always factor in the local cost of living to understand the true value of the salary being offered.

###

4. Company Type & Work Environment

The type of organization you work for is another critical salary determinant. There are three main employment models for BMETs:

- In-House (Hospital or Healthcare System): This is the most common path. You are a direct employee of the hospital.

- Pros: Stability, excellent benefits, strong sense of team/mission, less travel.

- Cons: Salaries can sometimes be slightly lower than OEM roles, and advancement may be tied to hospital budgets and bureaucracy.

- Salary: Tends to align closely with the national median ranges, with larger, more prestigious university hospitals often paying more.

- Third-Party ISO (Independent Service Organization): These companies are contracted by hospitals and clinics to manage their medical equipment service.

- Pros: Opportunity to work on a wider variety of equipment from different manufacturers, potentially faster career growth, and often more competitive salaries and bonuses to attract talent.

- Cons: Can involve more travel between different client sites, and job security is tied to service contracts. The work environment can be more fast-paced and sales-driven.

- OEM (Original Equipment Manufacturer): You work directly for the company that builds the equipment (e.g., GE Healthcare, Siemens Healthineers, Philips, Medtronic).

- Pros: This is often the highest-paying sector. You become a deep expert on a specific line of advanced technology and receive factory-level training.

- Cons: Usually involves extensive regional or national travel to customer sites. Your work is highly specialized, which could be seen as limiting if you prefer variety. The pressure to maintain customer satisfaction is very high.

- Salary: Field Service Engineers (the OEM title for BMETs) working on high-end imaging or therapeutic equipment can easily earn $90,000 to $120,000+ with experience.

###

5. Area of Specialization

Generalist BMETs are the backbone of any biomed shop, but specialists are the elite, high-earning experts. As medical technology becomes more complex, specialization is the most reliable path to a top-tier salary.

- General BMET: Focuses on a broad range of devices like infusion pumps, patient monitors, EKG machines, and defibrillators. This is the foundation of the career.

- Laboratory Equipment Specialist: Specializes in the complex analytical instruments found in clinical labs, such as blood gas analyzers, chemistry analyzers, and hematology analyzers. This requires knowledge of chemistry and fluidics. CLES certification is key.

- Radiology / Imaging Specialist: This is one of the most lucrative specializations. These technicians work on high-value, high-tech diagnostic imaging equipment like MRI machines, CT scanners, PET scanners, X-ray systems, and ultrasound machines. The training is extensive and often provided by the OEM. A senior imaging specialist with CRES certification is one of the highest-paid non-managerial roles in the field.

- Sterilization Equipment Specialist: Focuses on the equipment used in sterile processing departments (SPD), including autoclaves (steam sterilizers), washers/disinfectors, and low-temperature sterilizers. This is a critical role for infection control.

- Anesthesia and Respiratory Specialist: Works on life-support equipment like anesthesia delivery systems, ventilators, and heart-lung bypass machines. This is a high-stakes specialization where there is zero room for error, and the compensation reflects that responsibility.

###

6. In-Demand Skills

Finally, cultivating a specific set of high-value skills will directly translate into higher pay and better job opportunities.

- IT and Networking Skills: Modern medical devices are no longer standalone units; they are nodes on a hospital's network. They transmit data to Electronic Health Records (EHRs) and communicate with each other. BMETs who understand TCP/IP, network troubleshooting, and server architecture are invaluable. This is a major skills gap in the industry, and those who can bridge the worlds of biomed and IT are highly compensated.

- Cybersecurity: With network connectivity comes the risk of cyber threats. A BMET who understands how to secure medical devices, apply security patches, and respond to potential breaches is on the cutting edge of the profession. This is rapidly becoming a mandatory skill.

- Data Analysis: The ability to analyze equipment service histories from a CMMS to identify trends, predict failures, and make recommendations for equipment replacement is a high-level skill that transitions a BMET from a "repair person" to a "technology manager."

- Soft Skills: Technical acumen is not enough. The highest-paid BMETs are