For individuals with a passion for precision, technology, and creating tangible, mission-critical components, a career as a machinist can be incredibly rewarding. When that career is with an aerospace giant like Boeing, the potential for professional growth and financial stability is even greater. But what can you realistically expect to earn?

A career as a machinist at Boeing offers a competitive salary that reflects the high level of skill required. While entry-level positions are well-compensated, experienced and specialized machinists can see their annual earnings climb well into six figures, often ranging from $70,000 to over $125,000 per year.

This article will break down the salary expectations for a Boeing machinist, explore the key factors that influence your pay, and provide a look at the future of this vital profession.

What Does a Boeing Machinist Do?

Before diving into the numbers, it's essential to understand the role. A Boeing machinist is a highly skilled professional who fabricates, modifies, and repairs precision mechanical parts for aircraft. This is not a typical manufacturing job; it involves working with advanced materials and to infinitesimal tolerances where there is no room for error.

Key responsibilities include:

- Operating Complex Machinery: Using and programming Computer Numerical Control (CNC) machines, lathes, mills, and grinders to shape metal and composite materials into aircraft components.

- Reading Blueprints: Interpreting detailed technical drawings and schematics to produce parts that meet exact specifications.

- Ensuring Quality: Performing rigorous quality control checks using precision measuring instruments like calipers, micrometers, and gauges to ensure every component is flawless.

- Collaboration: Working closely with engineers, and quality assurance teams to troubleshoot issues and optimize manufacturing processes.

Every part a Boeing machinist creates is a critical component of a system that ensures the safety of millions of passengers. This immense responsibility is a primary reason for the role's professional standing and competitive compensation.

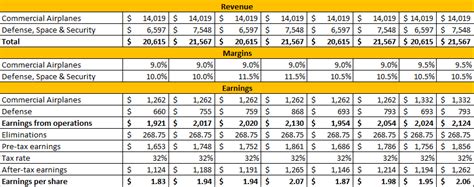

Average Boeing Machinist Salary

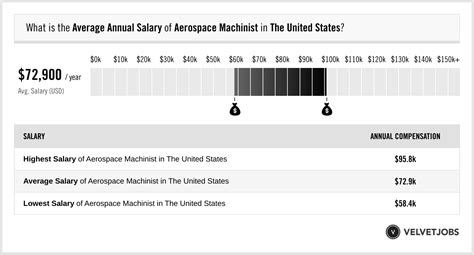

The salary for a machinist at Boeing significantly outpaces the national average for the profession. The U.S. Bureau of Labor Statistics (BLS) reports that the median annual wage for all machinists was $52,680 as of May 2022.

In contrast, a machinist at Boeing can expect a much higher figure. Based on an analysis of data from reputable salary aggregators:

- Average Base Salary: Most sources, including Glassdoor and Payscale, place the average base salary for a Boeing machinist between $85,000 and $92,000 per year, which translates to an hourly rate of approximately $41 to $44.

- Typical Salary Range: The overall salary range is wide, reflecting differences in experience, location, and specialization. A typical range spans from around $68,000 for entry-level or apprentice roles to $128,000 or more for senior, lead, or highly specialized machinists.

It is also important to note that these figures often represent base pay. Overtime opportunities, shift differentials, and a comprehensive benefits package—often negotiated by unions like the International Association of Machinists and Aerospace Workers (IAM)—can substantially increase the total compensation package.

Key Factors That Influence Salary

Your specific salary as a Boeing machinist isn't a single number but a reflection of several key variables. Understanding these factors is crucial for maximizing your earning potential.

### Level of Education

While a four-year university degree is not required, a strong technical education is non-negotiable. Most Boeing machinists have a high school diploma or GED followed by specialized training. Higher earning potential is linked to:

- Associate's Degree: An associate's degree in machine tool technology or a related field provides a strong theoretical and practical foundation.

- Vocational/Technical School Certificate: Programs focused on CNC operation, programming, and precision machining are highly valued.

- Apprenticeships: A formal apprenticeship, often lasting several years, is one of the most respected pathways, as it combines paid on-the-job training with classroom instruction.

Certifications from organizations like the National Institute for Metalworking Skills (NIMS) can also validate your expertise and potentially lead to higher pay.

### Years of Experience

Experience is arguably the most significant driver of salary growth for a machinist. Boeing, like many large manufacturers, has a structured progression path.

- Entry-Level (0-3 years): An apprentice or new machinist will focus on learning the fundamentals, operating basic machinery, and assisting senior colleagues. Salaries typically start in the $65,000 to $80,000 range.

- Mid-Career/Journeyman (4-10 years): A fully qualified journeyman machinist operates complex machinery independently, reads intricate blueprints, and handles more demanding projects. Earnings move firmly into the $80,000 to $105,000 range.

- Senior/Lead (10+ years): With a decade or more of experience, senior machinists often take on leadership roles, program complex multi-axis CNC machines, train junior staff, and troubleshoot the most difficult manufacturing challenges. Their salaries can easily exceed $105,000 and push towards $130,000 or higher.

### Geographic Location

Boeing has major manufacturing hubs across the United States, and salary levels are adjusted to reflect local market rates and cost of living. According to data from Salary.com, you can expect salary variations based on location:

- Puget Sound, Washington (Everett, Renton): This region is Boeing's historical hub for commercial aircraft. Due to a high concentration of aerospace talent and a higher cost of living, salaries here are often at the top end of the scale.

- St. Louis, Missouri: A major center for defense and space programs, this location offers competitive salaries with a more moderate cost of living compared to the West Coast.

- Charleston, South Carolina: As a newer major manufacturing site, salaries here are competitive for the region but may be slightly lower than in Washington state, reflecting the local economy.

### Company Type

Working for a prime aerospace contractor like Boeing typically yields a higher salary than working for a smaller, non-union machine shop. This is due to several factors:

- Union Representation: The IAM union negotiates robust contracts that stipulate wage scales, annual increases, and excellent benefits.

- Scale and Complexity: The sheer scale and complexity of aerospace manufacturing demand a higher level of skill and, therefore, higher pay.

- Resources: Large corporations have structured career ladders and more resources for training and development, leading to greater long-term earning potential.

### Area of Specialization

Within the machinist profession, certain specializations are in higher demand and command a premium wage.

- CNC Programming: Machinists who can not only operate but also program complex CNC machines using G-code and CAM software are highly sought after.

- 5-Axis Machining: Expertise in operating and programming 5-axis CNC machines, which are used for the most complex geometric parts, is a high-value skill.

- Tool and Die Makers: This specialized subset of machinists creates the tools, dies, and fixtures used in the manufacturing process and is often at the top of the pay scale.

- Quality Assurance/Inspection: Machinists who specialize in CMM (Coordinate Measuring Machine) programming and advanced inspection techniques are critical to maintaining safety and quality standards.

Job Outlook

According to the U.S. Bureau of Labor Statistics (BLS), the overall employment of machinists is projected to show little or no change from 2022 to 2032. However, this statistic requires context.

While automation may reduce the need for manual or routine machine operators, the outlook for *highly skilled* machinists is very strong. The increasing complexity of products in aerospace, defense, and medical manufacturing creates a sustained demand for professionals who can program, set up, and operate sophisticated CNC equipment.

For those considering a career at Boeing, the demand is tied to production rates and new aircraft programs. The need for skilled machinists to build and sustain the next generation of aircraft and space systems is expected to remain robust.

Conclusion

A career as a Boeing machinist offers a clear path to a stable, respectable, and high-earning profession. For individuals who possess mechanical aptitude, a keen eye for detail, and a commitment to continuous learning, the rewards are significant.

Key Takeaways:

- High Earning Potential: A Boeing machinist can expect to earn significantly more than the national average, with typical salaries ranging from $70,000 to over $125,000.

- Experience is King: Your salary will grow substantially as you move from an apprentice to a senior-level expert.

- Specialization Pays: Developing high-demand skills like CNC programming or 5-axis machining is the fastest way to increase your value and your paycheck.

- Strong Future for the Skilled: While the overall field may be stable, the demand for highly skilled, technologically adept machinists in the aerospace sector remains strong.

For those ready to build a career at the intersection of technology and manufacturing, the role of a Boeing machinist is not just a job—it's a high-flying opportunity.