In the high-tech world of modern manufacturing, CNC Programmers are the essential link between digital design and physical creation. It's a career that demands precision, technical skill, and problem-solving—and it offers significant financial rewards and stability in return. If you're considering this dynamic field, you're likely asking a critical question: "What is a typical CNC Programmer salary?"

The answer is encouraging. While starting salaries are competitive, the path to a six-figure income is well within reach for skilled and experienced professionals. A typical CNC Programmer in the United States can expect to earn a median salary between $65,000 and $75,000 per year, with top earners in high-demand sectors exceeding $95,000 annually.

This guide will break down everything you need to know about CNC Programmer salaries, the factors that drive them, and how you can maximize your earning potential in this vital profession.

What Does a CNC Programmer Do?

Before diving into the numbers, it's important to understand the role. A CNC (Computer Numerical Control) Programmer is a highly skilled technician who writes and optimizes the code that guides manufacturing machinery. They are the digital craftspeople of the 21st century.

Their primary responsibilities include:

- Translating Designs: They take 2D or 3D computer-aided design (CAD) blueprints and translate them into a set of instructions, known as G-code, that a CNC machine can understand.

- Using CAM Software: They use sophisticated computer-aided manufacturing (CAM) software to generate and simulate toolpaths, ensuring the machine cuts, drills, or mills a part efficiently and accurately.

- Optimization and Troubleshooting: They refine programs to reduce cycle times, improve surface finishes, and extend tool life. When a machine produces a faulty part, they are the first line of defense in diagnosing and fixing the code.

- Setup and Collaboration: They often work closely with CNC Machinists and Setup Specialists to ensure the machines are configured correctly with the right tools and work-holding fixtures.

Average CNC Programmer Salary

Salary data shows a strong and stable earning potential for CNC Programmers. While figures vary slightly between sources due to different methodologies, they all point to a robust compensation package.

- The U.S. Bureau of Labor Statistics (BLS) classifies this role under "Numerical Tool and Process Control Programmers." As of May 2023, the median annual wage was $63,050, with the top 10% of earners bringing in more than $89,640.

- Reputable salary aggregator Salary.com reports a higher median salary for a CNC Programmer II (a mid-level role) at around $72,135 per year, with a typical range falling between $64,099 and $79,835. Their data shows senior-level programmers often earn well into the $80,000s and $90,000s.

- Payscale notes an average base salary of approximately $65,000 per year, but highlights that total pay can increase significantly with bonuses and profit-sharing, which are common in productive manufacturing environments.

A realistic salary spectrum looks like this:

- Entry-Level (0-2 years): $50,000 - $62,000

- Mid-Career (3-9 years): $63,000 - $78,000

- Senior/Specialist (10+ years): $80,000 - $95,000+

Key Factors That Influence Salary

Your specific salary is not just a single number; it's influenced by a combination of critical factors. Understanding these levers is the key to navigating your career and maximizing your income.

### Level of Education

While a four-year degree is uncommon and often unnecessary for this role, formal training is a significant asset. Employers highly value candidates who have a foundational understanding of manufacturing principles.

- High School Diploma/GED: A basic requirement, but will typically place you in an entry-level position, often starting as a machine operator before moving into programming.

- Vocational Certificate or Associate's Degree: This is the sweet spot. A certificate in CNC Machining or an Associate of Applied Science (A.A.S.) in Manufacturing Technology gives you a major advantage. It proves you understand shop math, blueprint reading, G-code, and CAM software fundamentals, often leading to a higher starting salary and a faster path to a mid-level role.

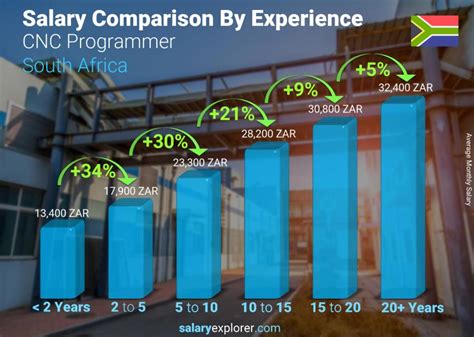

### Years of Experience

Experience is arguably the single most important factor in a CNC Programmer's salary. In this field, time on the job translates directly to expertise in efficiency, troubleshooting, and handling complex projects.

- Entry-Level (0-2 Years): Programmers at this stage are typically focused on 3-axis machines and simpler parts. They are learning the company's specific processes and building their CAM software skills.

- Mid-Career (3-9 Years): These programmers are trusted with more complex jobs, may work with multi-axis machines, and are proficient in optimizing code for speed and quality. They require less supervision and begin to mentor junior staff. Their salary reflects this increased responsibility.

- Senior-Level (10+ Years): A senior programmer is a master of their craft. They are often experts in 5-axis simultaneous machining, complex CAM software (like Siemens NX, Esprit, or Mastercam), and programming for exotic materials. They may lead a programming department, develop new processes, and are the go-to experts for the most challenging projects, commanding a premium salary.

### Geographic Location

Where you work matters. Salaries for CNC Programmers vary significantly based on the concentration of manufacturing industries and the regional cost of living. States with strong aerospace, defense, medical device, or automotive sectors tend to pay the most.

Top-Paying States (and Major Metro Areas):

- California: Driven by aerospace and tech manufacturing.

- Massachusetts & Connecticut: Hubs for defense, aerospace, and medical devices.

- Washington: Home to major aerospace companies.

- Texas: A growing center for manufacturing and technology.

Conversely, states with a lower cost of living and less concentrated high-tech manufacturing may offer lower baseline salaries, though the purchasing power can still be excellent.

### Company Type and Industry

The type of company you work for will have a direct impact on your paycheck.

- Small Job Shops: These companies are often the backbone of local manufacturing. While they provide excellent, hands-on experience, they may have tighter budgets and offer more modest salaries.

- Large Corporations (OEMs): Large-scale manufacturers in sectors like aerospace, medical devices, defense, and automotive have the highest demand for precision and reliability. They work with expensive materials and have zero tolerance for error, so they are willing to pay top dollar for elite programmers who can deliver that quality.

### Area of Specialization

As you advance in your career, specialization becomes a powerful tool for increasing your value.

- Multi-Axis Programming: A programmer proficient in 5-axis machining will earn significantly more than one who only programs 3-axis machines. 5-axis programming is far more complex and is required for creating intricate components like turbine blades or medical implants.

- CAM Software Proficiency: Expertise in high-end CAM software like Mastercam, Siemens NX, SolidCAM, Esprit, or GibbsCAM is a highly marketable skill. Companies often standardize on one platform and will pay a premium for a programmer who is already an expert.

- Material Expertise: Experience programming for difficult-to-machine materials like titanium, Inconel, composites, or hardened steels is extremely valuable, especially in the aerospace and medical industries.

Job Outlook

The future for skilled CNC Programmers is bright and stable. According to the U.S. Bureau of Labor Statistics, employment in this field is projected to remain steady, with an average of 1,400 job openings projected each year over the next decade.

While some worry about automation, the increasing complexity of manufacturing actually drives demand. As machines become more sophisticated, the need for highly skilled programmers to direct them, optimize their performance, and troubleshoot complex operations only grows. Many of these openings will arise from the need to replace workers who are retiring, creating excellent opportunities for a new generation to enter the field.

Conclusion

A career as a CNC Programmer is a rewarding choice for anyone with a passion for technology, precision, and making things. It offers a clear path for professional growth and a strong, data-backed salary potential that rewards expertise and continuous learning.

Key Takeaways:

- Strong Earning Potential: Expect a median salary in the $65,000 - $75,000 range, with the potential to earn over $95,000 with experience and specialization.

- Experience is King: Your salary will grow significantly as you move from entry-level to senior roles.

- Education Gives You an Edge: A formal certificate or associate's degree can fast-track your career and boost your starting pay.

- Specialize to Maximize: To reach the highest salary brackets, focus on mastering in-demand skills like 5-axis programming, high-end CAM software, and working with complex materials.

By investing in your skills and strategically navigating your career path, you can build a successful and financially rewarding future as a CNC Programmer.