Introduction

Imagine the controlled roar of a GE90 engine, the intricate dance of hydraulics and fly-by-wire systems, and the immense responsibility of ensuring the safety of hundreds of souls at 35,000 feet. For the elite professionals known as Aircraft & Powerplant (A&P) Mechanics, this is not a scene from a movie; it's the daily reality of their high-stakes, high-reward career. If you're drawn to complex machinery, possess an unwavering attention to detail, and seek a career that offers both profound satisfaction and exceptional financial stability, then understanding the Delta A&P mechanic salary and the world it represents is your first step toward an extraordinary future.

This career is one of the most critical and respected in the world. While pilots are the visible heroes of aviation, A&P mechanics are the silent guardians, the technical wizards who work tirelessly on the ground to make every flight possible and, above all, safe. The path to becoming an A&P mechanic for a major airline like Delta Air Lines is demanding, but the compensation reflects the immense skill and trust placed in these individuals. Entry-level mechanics at top-tier companies can start in the high five figures, with experienced, senior technicians often commanding salaries well into the six-figure range, complemented by some of the best benefits in any industry. I once had a flight delayed for a technical issue, and rather than feeling frustrated, I was mesmerized watching the ground crew—a team of Delta mechanics—work with focused precision under the wing of a 767. It was a powerful, real-time demonstration of expertise ensuring our safety, a moment that cemented my respect for this profession.

This guide will serve as your definitive resource, a comprehensive flight plan for understanding and achieving a top-tier salary as a Delta A&P Mechanic. We will dissect every component of compensation, explore the factors that drive salary growth, outline the robust job outlook, and provide a clear, step-by-step roadmap to launch your own career.

### Table of Contents

- [What Does an A&P Mechanic Actually Do?](#what-does-an-ap-mechanic-actually-do)

- [Average Delta A&P Mechanic Salary: A Deep Dive](#average-delta-ap-mechanic-salary-a-deep-dive)

- [Key Factors That Influence Your Salary](#key-factors-that-influence-your-salary)

- [Job Outlook and Career Growth in Aviation Maintenance](#job-outlook-and-career-growth-in-aviation-maintenance)

- [How to Become an A&P Mechanic and Get Hired at Delta](#how-to-become-an-ap-mechanic-and-get-hired-at-delta)

- [Conclusion: Is a Career as a Delta A&P Mechanic Right for You?](#conclusion-is-a-career-as-a-delta-ap-mechanic-right-for-you)

What Does an A&P Mechanic Actually Do?

An A&P Mechanic, more formally known as an Aircraft Maintenance Technician (AMT), is a highly trained and FAA-certified professional responsible for the inspection, maintenance, repair, and overhaul of aircraft. The "A&P" designation stands for Airframe and Powerplant, the two primary certifications an AMT must hold to work on the vast majority of aircraft components. At a major airline like Delta, these mechanics are the backbone of Delta TechOps, one of the world's largest and most respected Maintenance, Repair, and Overhaul (MRO) organizations.

Their role is far more than simply "fixing what's broken." It's a proactive, highly regulated, and data-driven discipline focused on preventative maintenance to ensure that issues never arise in the first place. Every task they perform is meticulously documented and must comply with strict Federal Aviation Administration (FAA) regulations, as well as the manufacturer's specifications.

Core Responsibilities and Daily Tasks:

- Inspections: AMTs perform routine checks (line maintenance) between flights, as well as more intensive, scheduled inspections (A, B, C, and D checks) that can take an aircraft out of service for days or even weeks. These inspections involve examining everything from the landing gear and control surfaces to the internal structures of the fuselage and wings.

- Diagnostics and Troubleshooting: When a pilot reports an issue or a system flags a fault, mechanics use sophisticated diagnostic equipment, technical manuals, and their own deep knowledge of the aircraft to pinpoint the root cause of the problem.

- Repair and Replacement: This is the hands-on work of the job. It can range from replacing a tire on the tarmac to performing a complete engine change in a hangar. They repair hydraulic lines, patch composite structures, fix avionics systems, and replace worn-out components.

- Documentation (The Paper Trail): Every single action taken on an aircraft must be logged. This meticulous record-keeping is a legal requirement and creates a complete history of the aircraft's maintenance life. An AMT's signature on a logbook is a legal declaration that the work was performed correctly and the aircraft is airworthy.

- Compliance: They must stay constantly updated on Airworthiness Directives (ADs) issued by the FAA—mandatory modifications or inspections required to correct an unsafe condition.

### A "Day in the Life" of a Delta Line Maintenance AMT

Let's walk through a hypothetical shift to make the role more tangible:

4:30 AM: Your alarm goes off. A career in aviation maintenance often means working unconventional hours, including nights, weekends, and holidays, to keep the fleet flying. You grab your coffee and head to the airport.

5:30 AM: You arrive at the Delta TechOps maintenance office at Hartsfield-Jackson Atlanta International Airport (ATL). The shift briefing begins. The lead mechanic reviews the overnight logs, discusses any aircraft that are "out of service" (AOG - Aircraft on Ground), and assigns tasks for the morning. You're assigned to Gate C35, where a Boeing 757 is scheduled for a 7:15 AM departure to Los Angeles.

6:00 AM: You head to the gate. The first task is the "walk-around" inspection. You meticulously check the tires for wear, the brakes for hydraulic leaks, the wings and fuselage for any signs of damage, and the engine nacelles for security. You check fluid levels and ensure all external lights are operational.

6:30 AM: You review the pilot's logbook from the previous flight. There's a write-up: "Cabin temperature fluctuations in the aft section." You head into the cockpit, power up the relevant systems, and access the maintenance diagnostic computer. The system points to a faulty temperature sensor.

6:45 AM: You consult the Aircraft Maintenance Manual (AMM) on your tablet to confirm the part number and the correct procedure for replacement. You radio the parts department to have the new sensor delivered to the gate.

7:00 AM: The part arrives. You access the aft electronics bay, remove the faulty sensor, install the new one, and perform a system test. The temperature control now operates perfectly.

7:10 AM: The crucial final step: documentation. You make a detailed entry in the aircraft's logbook, describing the problem, the corrective action taken, the part number of the new sensor, and the successful test. You then sign your name and A&P certificate number. Your signature legally certifies that the aircraft is airworthy and safe to fly.

7:15 AM: The boarding process is complete. You give the "thumbs up" to the flight crew as the jet bridge retracts. As the aircraft pushes back, you feel a profound sense of pride and responsibility, knowing your work just enabled a safe journey for nearly 200 people. The rest of your day will be filled with similar tasks on different aircraft, a constant cycle of vigilance, problem-solving, and precision.

Average Delta A&P Mechanic Salary: A Deep Dive

The compensation for an A&P Mechanic at a major airline like Delta is one of the most compelling aspects of the career. It's a testament to the high level of skill, knowledge, and responsibility the job demands. Unlike many other professions, salary growth is often rapid and highly structured, governed by union contracts that reward experience and expertise.

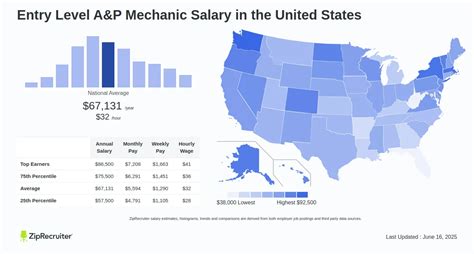

First, let's establish a baseline. According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for all Aircraft and Avionics Equipment Mechanics and Technicians was $70,010 in May 2022. The top 10 percent in the profession earned more than $107,690. However, it's crucial to understand that these figures represent the entire industry, including smaller repair stations, cargo carriers, and regional airlines. Major legacy carriers like Delta Air Lines are at the top end of this pay scale.

For Delta specifically, salaries are significantly higher than the national average. While Delta does not publicly list its pay scales, data from reputable salary aggregators and industry insiders provide a clear picture. According to Salary.com, the average base salary for an Aircraft Mechanic (A&P) at Delta Air Lines is approximately $98,016 as of late 2023, with a typical range falling between $85,913 and $110,039. Similarly, data from Glassdoor places the total pay (including bonuses and other compensation) for a Delta AMT in a similar range, often exceeding $100,000 for experienced technicians.

The journey to a six-figure salary is well-defined. Here's a breakdown of the typical salary progression based on experience level at a major airline like Delta.

### Salary Brackets by Experience Level at a Major Airline

| Experience Level | Years of Experience | Typical Base Salary Range (Annual) | Key Characteristics & Responsibilities |

| :--- | :--- | :--- | :--- |

| New Hire / Apprentice | 0 - 1 Year | $60,000 - $75,000 | Working under direct supervision, learning company procedures and specific aircraft systems. Performing basic tasks and inspections. |

| Mid-Career Mechanic | 2 - 7 Years | $75,000 - $95,000 | Fully independent, able to troubleshoot and resolve common issues. Qualified on multiple aircraft types. Eligible for overtime. |

| Senior / Journeyman Mechanic| 8 - 15 Years | $95,000 - $115,000+ | Expert on multiple complex systems. Can lead small teams on specific jobs. Often holds additional qualifications (e.g., engine run-up, taxi). |

| Lead / Master Mechanic | 15+ Years | $115,000 - $140,000+ | Technical expert and shift leader. Assigns tasks, mentors junior mechanics, and handles the most complex troubleshooting. Often has supervisory duties. |

*Note: These salary ranges are estimates based on aggregated data and industry reports. Actual salaries can vary based on the factors discussed in the next section.*

### Beyond the Base Salary: Understanding Total Compensation

A Delta A&P Mechanic's salary is only one piece of a much larger and more lucrative compensation package. The "total compensation" is what truly sets this career apart.

- Overtime Pay: Aviation is a 24/7 operation. Overtime is plentiful and paid at 1.5x (time-and-a-half) or even 2.0x (double-time) the standard hourly rate. It's common for ambitious mechanics to significantly increase their annual earnings through overtime, with many senior mechanics pushing their total income well past $150,000.

- Shift Differentials: Mechanics who work afternoon, night, or weekend shifts receive a pay premium per hour. This can add several thousand dollars to an annual salary.

- License Premiums: Holding an FAA A&P certificate automatically comes with an hourly pay premium. Additional certifications, such as an FCC license for avionics work or specific inspection authorizations, can add further premiums.

- Profit Sharing: This is a major benefit at Delta. For years, Delta has been renowned for its generous profit-sharing program, which distributes a significant portion of the company's annual profits back to its employees. In strong years, this can equate to a bonus of 10-20% or more of an employee's annual salary—a massive boost to total earnings.

- Comprehensive Benefits: Major airlines offer top-tier benefits packages that include:

- Health Insurance: Excellent medical, dental, and vision plans.

- Retirement: Robust 401(k) plans with significant company matching contributions.

- Paid Time Off: Generous vacation, holiday, and sick leave.

- Flight Benefits: One of the most famous perks—free or heavily discounted flights for the employee and their immediate family on the airline's global network.

- Tool Allowance: Many contracts include an annual allowance to help mechanics purchase and maintain their extensive collection of personal tools.

When all these components are combined, the total compensation for a mid-career or senior Delta A&P Mechanic can easily be 30-50% higher than their base salary, making it one of the most financially rewarding blue-collar professions in the world.

Key Factors That Influence Your Salary

While the pay scales at major airlines are highly structured, several key factors can significantly influence your earning potential and career trajectory. Understanding these variables is crucial for maximizing your income as an A&P mechanic.

###

1. Level of Education and Certifications

The foundation of this career is not a traditional four-year degree but the FAA-issued A&P certificate. This is the non-negotiable ticket to entry.

- FAA A&P Certificate: This is the baseline. Without it, you cannot work as an aircraft mechanic. Obtaining it immediately qualifies you for a license premium in your hourly wage.

- FAA-Approved Part 147 Schooling: The most common path to an A&P is graduating from an FAA-approved aviation maintenance technician school. While the diploma itself (often an Associate of Applied Science) is secondary to the A&P certificate it enables, graduating from a well-respected school with strong industry connections (like those that partner with Delta) can give you a significant advantage in the hiring process.

- Advanced Certifications: This is where you can truly differentiate yourself.

- Inspection Authorization (IA): This advanced certification allows a mechanic to perform annual inspections on smaller aircraft and approve major repairs and alterations. While more common in general aviation, holding an IA demonstrates a high level of expertise and regulatory knowledge that is valued everywhere.

- FCC General Radiotelephone Operator License (GROL): This is often required for avionics technicians who test and repair communication and navigation equipment. Holding this license can open doors to higher-paying specialized roles.

- Specialized Training Certificates: Delta provides extensive in-house training on its specific fleet (e.g., Airbus A350, Boeing 777). Earning these "Gen Fam" (General Familiarization) course certificates makes you more valuable and versatile to the company.

###

2. Years and Type of Experience

Experience is arguably the single most important factor driving salary growth in this field. Airline pay scales are explicitly tied to seniority.

- Linear Pay Progression: Most airline mechanic contracts feature a "top-out" pay scale. This means a new hire starts at a specific hourly rate and receives a guaranteed raise each year until they reach the "top of scale," which typically takes 5 to 10 years. For example, a new hire might start at $35/hour and top out at $60/hour or more, purely based on seniority.

- The Value of Heavy Jet Experience: Not all experience is created equal. An employer like Delta will place a much higher value on experience gained on large, complex transport category aircraft (like a Boeing 737 or an Airbus A321) than on experience with small, single-engine piston aircraft. Working for a regional airline or a cargo carrier like FedEx or UPS first is a common and highly effective way to gain the relevant experience needed to get hired by a major like Delta.

- Leadership Experience: Moving from a mechanic role to a Lead Mechanic or Supervisor position comes with a significant pay increase. This requires not only technical mastery but also strong leadership, communication, and organizational skills. The salary for a Maintenance Supervisor at a major hub can approach $150,000 or more with overtime and bonuses.

###

3. Geographic Location

While seniority-based pay scales are national, the cost of living and the concentration of maintenance operations in certain locations play a huge role. Delta's largest maintenance base is at its headquarters in Atlanta (ATL), a location with a relatively moderate cost of living, making the high salaries go even further.

- Major Maintenance Hubs: Airlines concentrate their heavy maintenance operations at a few key hubs. For Delta, these include Atlanta (ATL), Minneapolis-St. Paul (MSP), and Detroit (DTW). These locations have the highest concentration of AMT jobs and often offer the most opportunities for overtime and advancement.

- High Cost-of-Living Areas: Line maintenance positions exist at virtually every major airport Delta serves, including high-cost-of-living cities like New York (JFK/LGA), Los Angeles (LAX), and San Francisco (SFO). While the base pay scale is often the same, some union contracts may include a slightly higher locality pay for these cities. However, the purchasing power of your salary will be lower.

- The "Atlanta Advantage": Atlanta is widely considered one of the best locations for a Delta AMT. It hosts the airline's primary technical operations center, offering the widest range of job types (from line maintenance to engine overhauls to component repair) in a city where the cost of living is below that of many other major metropolitan areas. A $110,000 salary in Atlanta affords a significantly different lifestyle than the same salary in New York City.

###

4. Company Type & Size

Where you work in the aviation industry has a massive impact on your paycheck.

- Major "Legacy" Airlines (e.g., Delta, United, American): These are the top payers in the industry. They have the largest and most complex aircraft, the most extensive global networks, and strong union contracts that secure the highest wages and best benefits. This is the ultimate goal for most career-driven AMTs.

- Cargo Carriers (e.g., FedEx, UPS): These are also top-tier employers, with pay and benefits that are highly competitive with, and in some cases exceed, the major passenger airlines. They operate large fleets of wide-body aircraft and run massive, time-sensitive operations.

- Regional Airlines (e.g., SkyWest, Endeavor Air, Republic): These airlines operate smaller regional jets under contract for the major carriers. They are a fantastic place for new A&P graduates to gain their first one-to-three years of valuable turbine aircraft experience. However, their pay scales are significantly lower than the majors, often starting 30-40% below.

- MRO Facilities (Maintenance, Repair, and Overhaul): These are third-party shops that perform contract maintenance for various airlines. Pay can be competitive but may lack the profit-sharing and flight benefits of working directly for an airline.

- Corporate/Business Aviation: Maintaining private and corporate jets can be very lucrative, but it's a different world. It often requires a broader skill set and a more flexible, on-call schedule. Salaries can be very high, but benefits might not be as comprehensive as at a major airline.

###

5. Area of Specialization

Within the broad field of aircraft maintenance, specializing in a high-demand niche can lead to higher pay and greater job security.

- Avionics Technicians: These are the specialists who work on the "brains" of the aircraft—the complex electronic systems, including navigation, communication, autopilot, and flight control systems. As aircraft become more technologically advanced, the demand for skilled avionics technicians is skyrocketing. They often command a higher pay premium.

- Non-Destructive Testing (NDT) Technicians: NDT is a highly specialized field of inspection that uses techniques like ultrasonic, eddy current, and X-ray to inspect critical aircraft structures for cracks and flaws without taking them apart. NDT technicians require extensive training and additional certifications, and they are among the highest-paid specialists in the maintenance world.

- Engine Shop Mechanics: These mechanics work in dedicated engine overhaul facilities, completely disassembling, inspecting, repairing, and reassembling the massive turbofan engines that power the fleet. This is highly specialized, precision work.

- Structures / Sheet Metal Technicians: These are the experts in repairing and fabricating metal and composite aircraft structures, from fixing minor skin damage to performing major structural repairs after an incident.

- Line Maintenance vs. Heavy Maintenance: Line maintenance mechanics are the "first responders" who work at the gate to get aircraft turned around quickly. Heavy maintenance mechanics work in large hangars on scheduled, in-depth checks that take planes out of service for extended periods. Both are critical, but they offer different work environments and lifestyles.

###

6. In-Demand Technical and Soft Skills

Beyond certifications, specific skills can make you a more valuable candidate and a higher earner over time.

- Troubleshooting and Diagnostics: The ability to logically and efficiently diagnose a complex, intermittent problem is perhaps the most valuable skill an AMT can possess. This is a mix of technical knowledge, experience, and critical thinking.

- Proficiency with New Technologies: Expertise in modern aircraft systems, such as advanced composite materials (found on the A350 and 787) and fly-by-wire flight controls, is in high demand.

- Data Interpretation: Modern aircraft generate vast amounts of data. Mechanics who can effectively use diagnostic software and interpret this data to predict and prevent failures are incredibly valuable.

- Leadership and Mentoring: As you gain seniority, the ability to train junior mechanics, lead a team, and communicate effectively with flight crews and management becomes essential for career advancement.

- Adaptability and Continuous Learning: The aviation industry never stands still. The best-paid mechanics are those who embrace lifelong learning and are always eager to get trained on the next new aircraft or system.

Job Outlook and Career Growth in Aviation Maintenance

The future for skilled A&P mechanics is exceptionally bright. The combination of a retiring workforce, steady growth in air travel, and increasingly complex aircraft has created a high-demand, high-security career field.

According to the U.S. Bureau of Labor Statistics (BLS) Occupational Outlook Handbook, employment for aircraft and avionics equipment mechanics and technicians is projected to grow 6 percent from 2022 to 2032, which is faster than the average for all occupations. This translates to about 12,500 openings projected each year, on average, over the decade. Most of these openings are expected to result from the need to replace workers who transfer to different occupations or exit the labor force, such as to retire.

This retirement wave is a critical factor. A large percentage of the current experienced AMT workforce is nearing retirement age, creating a "skills gap" that new, well-trained mechanics are perfectly positioned to fill. This isn't just a prediction; major airlines and MROs are actively and aggressively recruiting to build their talent pipeline for the coming years. For aspiring mechanics, this means greater job security and increased bargaining power.

### Emerging Trends and Future Challenges

The role of the A&P mechanic is evolving. To stay relevant and continue to advance, professionals must be aware of key industry trends:

1. Increasingly Complex Aircraft: Planes like the Airbus A350 and Boeing 787 Dreamliner are built with a majority of lightweight composite materials and feature incredibly sophisticated, integrated avionics suites. Mechanics must constantly update their skills to work with these new materials and digital systems.

2. The Rise of Predictive Maintenance: Airlines are leveraging big data and AI to move from a reactive or scheduled maintenance model to a predictive one. Onboard sensors monitor the health of thousands of components in real-time, allowing airlines to predict when a part will fail and replace it proactively. Mechanics of the future will need to be as comfortable with a data tablet as they are with a wrench.

3. Sustainable Aviation: While still in its infancy, the push toward more sustainable aviation—including Sustainable Aviation Fuel (SAF), and eventually, hybrid-electric and hydrogen-powered aircraft—will present entirely new challenges and learning opportunities for maintenance professionals in the long term.

4. The Need for Soft Skills: As teams become more collaborative and technology more complex, the ability to communicate clearly, work effectively in a team, and mentor junior technicians is becoming just as important as technical proficiency.

### Advancing Your Career: The Path Forward

The career ladder for an A&P mechanic at a company like Delta is long and full of opportunity. Here's a typical progression:

1. A&P Mechanic: Master the fundamentals, get qualified on multiple aircraft in the fleet, and build a reputation as a reliable, skilled technician.

2. Lead Mechanic: After gaining significant experience (typically 8-10+ years), you can promote to a Lead position. You'll guide a team on a specific shift or in a specific