Introduction

In the intricate and powerful engine of the global economy, few roles are as fundamental as that of the factory worker. These are the individuals who transform raw materials into the finished goods that define our daily lives—from the cars we drive to the smartphones we use and the food we eat. If you're considering a career in manufacturing, you're looking at a path that offers stability, tangible results, and a surprising potential for growth and specialization. But a crucial question stands at the forefront of this decision: What can you expect to earn? Understanding the nuances of a factory worker salary is the first step toward building a successful and rewarding career in this essential field.

The financial landscape for a factory worker is far more complex and promising than many assume. While entry-level positions provide a solid starting wage, the potential for significant salary growth is tied directly to skill, specialization, and experience. A general production worker might start with a median pay of around $38,000 per year, but a skilled CNC (Computer Numerical Control) machinist or a robotics technician can easily command salaries exceeding $60,000 or even $75,000 annually. This guide is designed to be your definitive resource, navigating you through every factor that influences your earning potential, from your geographic location to the specific industry you choose.

I remember visiting a high-tech automotive plant with my uncle, a longtime maintenance supervisor. I was struck not by the noise or the scale, but by the symphony of precision—the seamless dance between human expertise and robotic automation. He told me, "We don't just build cars here; we build the future, one perfectly welded seam at a time," a sentiment that captures the profound pride and importance of this profession.

This article will provide a comprehensive, data-driven analysis of factory worker salaries, job outlook, and the strategic steps you can take to maximize your income and advance your career.

### Table of Contents

- [What Does a Factory Worker Do?](#what-does-a-factory-worker-do)

- [Average Factory Worker Salary: A Deep Dive](#average-factory-worker-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

What Does a Factory Worker Do?

The term "factory worker" is an umbrella that covers a vast array of roles and responsibilities within a manufacturing or production environment. At its core, the job involves participating in the creation, assembly, finishing, or packaging of goods. However, the specific tasks can vary dramatically based on the industry, the level of automation in the facility, and the worker's specialization. These environments range from food processing plants and textile mills to advanced electronics manufacturing and heavy industrial assembly lines.

The modern factory is a far cry from the assembly lines of the early 20th century. Today's facilities are often clean, highly organized, and technologically advanced, requiring a blend of manual dexterity and technical know-how.

Core Responsibilities and Daily Tasks:

A factory worker's duties are typically hands-on and require a strong focus on safety, quality, and efficiency. Common tasks include:

- Operating Machinery: Setting up, operating, and tending to production machines. This can range from simple conveyor belts to complex CNC machines, robotic arms, or industrial mixers.

- Assembling Products: Following blueprints, schematics, or work orders to manually assemble components and subassemblies. This requires precision and excellent hand-eye coordination.

- Quality Control and Inspection: Visually inspecting products for defects, using gauges and measuring tools to ensure they meet exact specifications, and reporting any issues to supervisors.

- Material Handling: Moving raw materials to the production line and transporting finished goods to storage or shipping areas. This often involves operating forklifts, pallet jacks, or cranes.

- Packaging and Shipping: Preparing finished products for shipment by boxing, crating, labeling, and palletizing them according to company and customer requirements.

- Maintaining a Safe and Clean Workspace: Adhering to strict safety protocols (like wearing Personal Protective Equipment - PPE), keeping work areas clean and organized, and participating in routine safety drills.

- Record Keeping: Documenting production numbers, tracking machine performance, and logging quality control data.

### A Day in the Life: An Electronics Assembler

To make the role more tangible, let's walk through a typical day for an electronics assembler working the first shift (7:00 AM - 3:30 PM) at a mid-sized company that manufactures circuit boards.

- 6:45 AM: Arrive at the plant, change into steel-toed boots, and put on an anti-static wrist strap. Grab a coffee and join the brief team huddle led by the shift supervisor. The supervisor reviews the day's production targets and highlights a quality alert from the previous shift.

- 7:00 AM: Head to a designated workstation. The first task is to set up the selective soldering machine for a new batch of circuit boards, referencing a digital work order on a nearby tablet.

- 8:30 AM: With the machine running, the assembler moves to a manual assembly station to meticulously place tiny components onto a different set of boards, using tweezers and a magnifying lamp for precision.

- 10:00 AM: A quality control inspector stops by to randomly sample a few boards from the soldering machine's output. They work together to verify that all solder joints are perfect.

- 12:00 PM: Lunch break in the company cafeteria with colleagues.

- 12:30 PM: Return to the workstation. The afternoon is dedicated to "potting"—a process of filling electronic assemblies with a solid compound to protect them from shock and moisture. This requires careful mixing of chemical compounds and precise application.

- 2:30 PM: The production quota for the day is met. The final hour is spent cleaning the workstation, properly storing tools and materials, and completing a digital log of the day's output, noting any machine downtime or material issues.

- 3:30 PM: Shift ends. The assembler clocks out, leaving the clean and prepped workstation ready for the second-shift employee.

This example illustrates that the role is structured, detail-oriented, and a blend of machine operation and skilled manual work, with a constant emphasis on quality and safety.

Average Factory Worker Salary: A Deep Dive

Determining a single "average" salary for a factory worker can be challenging due to the vast range of roles the title encompasses. However, by looking at data from authoritative sources for common production and manufacturing roles, we can establish a clear and reliable baseline.

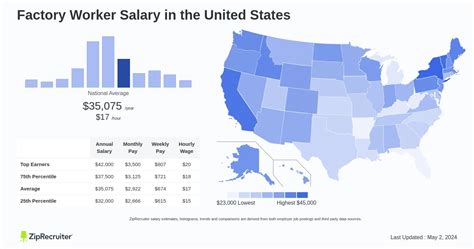

According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for Assemblers and Fabricators was $40,330 in May 2023. This means that half of the workers in this occupation earned more than this amount, and half earned less. The lowest 10 percent earned less than $29,910, and the highest 10 percent earned more than $62,150.

For a broader perspective, the BLS reports that the median annual wage for all Production Occupations combined was $42,860 in May 2023. This category includes everything from general laborers to highly skilled machinists.

Salary aggregators, which collect real-time, user-reported data, often provide a slightly different but complementary picture.

- Payscale.com reports the average hourly wage for a Production Worker is $16.89 per hour, which translates to an annual salary of approximately $35,131 (as of early 2024). Their data shows a typical range from $13.00/hour to $23.00/hour.

- Salary.com places the median salary for a generic "Factory Worker" at $38,206 per year (as of May 2024), with a common range falling between $34,310 and $42,308.

- Glassdoor estimates the total pay for a Factory Worker in the United States is around $46,957 per year, which includes a base salary of approximately $41,000 and additional pay (bonuses, profit sharing) of around $6,000.

The key takeaway is that a typical salary for a general or entry-level factory role falls within the $35,000 to $45,000 range. However, this is just the starting point. Experience, skill, and specialization can dramatically increase this figure.

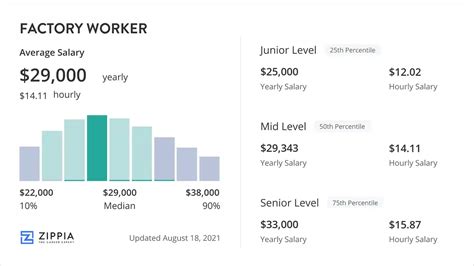

### Salary by Experience Level

Like any profession, experience is a primary driver of income growth in manufacturing. As workers gain proficiency, master new machinery, and demonstrate reliability, their value—and pay—increases.

Here is a typical salary progression, compiled from various data sources like Payscale and Salary.com:

| Experience Level | Years of Experience | Typical Hourly Wage Range | Typical Annual Salary Range | Description |

| :--- | :--- | :--- | :--- | :--- |

| Entry-Level | 0-1 years | $14.00 - $18.00 | $29,000 - $37,500 | New to the field, learning basic machine operation, safety protocols, and assembly techniques. Requires close supervision. |

| Mid-Career | 2-9 years | $17.00 - $24.00 | $35,000 - $50,000 | Proficient in several machines or processes. Can work independently, troubleshoot minor issues, and may help train new employees. |

| Experienced/Senior | 10-20+ years | $22.00 - $30.00+ | $46,000 - $62,000+ | Master of multiple complex processes or machinery (e.g., CNC programming). Acts as a team lead, troubleshoots significant problems, and contributes to process improvement. |

Important Note: These ranges are for general production roles. Specialized roles, which we will explore later, have significantly higher earning potential at all experience levels.

### Beyond the Paycheck: A Look at Total Compensation

The annual salary or hourly wage is only one part of the financial equation. Manufacturing jobs, especially those at larger companies or unionized facilities, often come with a robust compensation package that significantly increases the overall value of the position.

Key Components of Total Compensation:

- Overtime Pay: This is a major factor. Manufacturing often runs on tight deadlines, and overtime is common. Non-exempt hourly employees are legally entitled to "time and a half" (1.5 times their regular hourly rate) for any hours worked over 40 in a week. Consistent overtime can boost annual earnings by 10-25% or more.

- Shift Differentials: Many factories operate 24/7, running second (evening) and third (overnight) shifts. To compensate for the less desirable hours, companies offer a "shift differential"—an extra amount added to the base hourly wage. This can range from an additional $0.50 to several dollars per hour, making these shifts financially attractive.

- Bonuses and Profit Sharing: Companies may offer several types of bonuses:

- Performance Bonuses: Awarded for meeting or exceeding production targets, quality metrics, or safety goals.

- Annual/Holiday Bonuses: A lump-sum payment given to employees, often at the end of the year.

- Profit Sharing: The company shares a portion of its annual profits with its employees, directly linking their hard work to the company's success.

- Health and Wellness Benefits: Comprehensive health insurance (medical, dental, vision) is a standard offering from most reputable employers. Many also provide life insurance, disability insurance, and employee assistance programs (EAPs) for mental health support.

- Retirement Savings Plans: The most common plan is a 401(k), where employees contribute a portion of their pre-tax income. A crucial benefit is the company match. A typical match might be 50% of the employee's contribution up to 6% of their salary—this is essentially free money for retirement.

- Paid Time Off (PTO): This includes paid vacation days, sick leave, and holidays. The amount of PTO usually increases with tenure at the company.

- Tuition Reimbursement: Forward-thinking companies invest in their workforce by offering to pay for or reimburse the cost of courses, certifications, or even college degrees related to the field. This is a powerful benefit for career advancement.

When evaluating a job offer, it's essential to look beyond the hourly wage and consider the full value of the compensation package. A job offering $18/hour with excellent benefits and a 401(k) match may be far more valuable than a job offering $20/hour with no benefits.

Key Factors That Influence a Factory Worker Salary

The difference between earning a starting wage and a top-tier salary in manufacturing lies in a combination of factors. Understanding and strategically leveraging these elements is the key to maximizing your income. This is the most critical section for anyone serious about building a high-earning career in this field.

### `

`Level of Education and Certification`

`While a four-year college degree is not required for most factory jobs, education and specialized training are powerful levers for increasing pay.

- Baseline Education (High School Diploma/GED): This is the standard entry requirement for most general production jobs. It provides the foundational literacy and numeracy skills needed to follow instructions and perform basic calculations.

- *Salary Impact:* Qualifies you for entry-level roles in the $30,000 - $38,000 range.

- Vocational School or Technical College (Certificates/Diplomas): This is a major step up. Programs in Welding Technology, Precision Machining, Industrial Maintenance, or Mechatronics provide hands-on, job-ready skills that are in high demand. A one-year certificate program can be a game-changer.

- *Salary Impact:* Graduates can often bypass general labor roles and start in semi-skilled positions, with starting salaries frequently in the $40,000 - $50,000 range.

- Associate's Degree (A.A.S.): A two-year Associate of Applied Science degree in fields like Manufacturing Technology, Advanced Manufacturing, or Engineering Technology provides a deeper theoretical and practical understanding. It prepares workers for more complex roles like CNC programming, quality assurance technology, or robotics maintenance.

- *Salary Impact:* This level of education opens doors to technician-level roles and supervisory tracks, with potential starting salaries of $45,000 - $60,000. It's a strong foundation for future management positions.

- Key Certifications: Certifications validate specific skills and knowledge, making you a more valuable and often higher-paid employee.

- OSHA 10/30: Safety certifications that are highly valued (and sometimes required) by employers. They demonstrate a commitment to a safe work environment.

- MSSC Certified Production Technician (CPT): A nationally recognized credential that certifies an individual's core competencies in manufacturing production. It covers safety, quality, manufacturing processes, and maintenance awareness.

- NIMS or MMSC Machining Credentials: Certifications for CNC machinists that prove proficiency in specific machine operations and programming.

- AWS Certified Welder: The American Welding Society (AWS) certification is the industry standard for welders and can significantly increase earning potential.

- Lean Six Sigma (Yellow/Green Belt): These process improvement methodologies are highly sought after. A worker with a Green Belt certification can help identify and eliminate waste, a skill that directly impacts the company's bottom line and justifies higher pay.

### `

`Years of Experience`

`Experience is perhaps the most straightforward path to a higher salary. As you transition from a novice to an expert, your efficiency, problem-solving ability, and leadership potential grow, all of which are compensated.

- Entry-Level (0-2 Years): The focus is on learning and reliability. Pay is typically at the lower end of the scale for a given role. At this stage, your greatest asset is a strong work ethic and a willingness to learn. *Salary Example (General Assembler): $32,000 - $38,000.*

- Mid-Career (3-9 Years): You are now a proficient and independent contributor. You've mastered several machines or assembly processes and can troubleshoot common issues without supervision. You might be asked to train new hires. Your pay reflects this reliability and expanded skill set. *Salary Example (General Assembler): $39,000 - $48,000.*

- Senior/Lead Worker (10+ Years): You are a subject matter expert. You can operate the most complex machinery, handle non-routine problems, lead a small team or production line, and contribute to process improvement initiatives. This level of experience is highly valued and commands the highest pay for non-supervisory roles. *Salary Example (Lead Assembler): $50,000 - $65,000+.*

- Supervisor/Manager (Promotion): With significant experience, the next step is often a promotion to a salaried supervisor role. This involves managing a team, scheduling production, ensuring safety and quality compliance, and reporting to upper management. This move represents a significant jump in both responsibility and compensation. *Salary Example (Production Supervisor): $60,000 - $85,000+.*

### `

`Geographic Location`

`Where you work matters immensely. Salaries are heavily influenced by the local cost of living and the concentration of manufacturing jobs in a particular area. A factory worker in a high-cost urban center with a thriving industrial sector will earn significantly more than someone in a low-cost rural area.

Top-Paying States for Production Occupations (According to BLS Data):

States with a heavy presence in high-tech or specialized manufacturing (like aerospace or automotive) and/or high costs of living tend to offer the best pay.

1. Alaska: High cost of living and specialized industries like oil and gas processing drive up wages.

2. Washington: A hub for aerospace manufacturing (e.g., Boeing).

3. Wyoming: Strong presence in mining and resource extraction/processing.

4. California: High cost of living and a diverse manufacturing base from electronics in Silicon Valley to food processing in the Central Valley.

5. Massachusetts: A center for medical device and biotech manufacturing.

Top-Paying Metropolitan Areas:

Specific cities, often manufacturing hubs, offer even higher wages. According to BLS data, metropolitan areas like:

- Seattle-Tacoma-Bellevue, WA

- San Jose-Sunnyvale-Santa Clara, CA

- Anchorage, AK

- Detroit-Warren-Dearborn, MI (for automotive roles)

...frequently report some of the highest average wages for production workers in the nation. For example, an assembler in the Seattle area might earn a median salary closer to $48,000 - $55,000 compared to the national median of $40,330.

Lower-Paying States:

Conversely, states in the Southeast and parts of the Midwest with a lower cost of living tend to have salaries below the national average. States like Mississippi, Arkansas, and South Dakota often fall into this category. However, the lower pay is offset by significantly cheaper housing, food, and transportation costs.

### `

`Company Type & Size`

`The type of company you work for is a major determinant of your salary and benefits package.

- Large Corporations (e.g., Ford, Procter & Gamble, Boeing): These companies typically offer the highest wages and most comprehensive benefits packages. They often have structured pay scales, regular performance reviews, and clear paths for advancement. Many are also unionized, which can lead to higher base pay, better benefits, and more job security through collective bargaining agreements.

- Small to Medium-Sized Enterprises (SMEs): Local or regional manufacturers may offer slightly lower base salaries than large corporations. However, they can provide other advantages, such as a more tight-knit work environment, more cross-training opportunities, and potentially greater flexibility. Some may also offer unique perks like profit sharing that can be very lucrative in a good year.

- Startups: A manufacturing startup (e.g., in 3D printing or custom robotics) might offer lower initial salaries but could provide stock options or equity. These are higher-risk, higher-reward environments where you may have a greater impact on the company's growth.

- Temporary/Staffing Agencies: Many people start their manufacturing careers through temp agencies. While the initial pay might be on the lower end and benefits can be limited, it's an excellent way to get your foot in the door, gain experience at different facilities, and prove your worth. Many temp-to-hire positions can lead to permanent employment with better pay and full benefits after a probationary period.

### `

`Area of Specialization`

`This is arguably the most impactful factor on your earning potential. "Factory worker" is broad; "CNC Machinist" is specific and highly valuable. Moving from a generalist role to a specialist one is the fastest way to increase your salary.

Here’s a breakdown of different specializations and their typical salary ranges (data compiled from BLS, Salary.com, and Payscale):

| Specialization | Role Description | Typical Median Salary Range | Why It Pays More |

| :--- | :--- | :--- | :--- |

| General Assembler / Production Worker | Performs basic assembly, packaging, or machine tending. | $35,000 - $42,000 | The baseline role, requires the least amount of specialized training. |

| Welder, Cutter, Solderer, and Brazer | Joins metal parts using various welding techniques. Requires significant skill and certification. | $47,000 - $55,000 | Crucial for heavy industry, construction, and manufacturing. Skill and precision are paramount, and safety risks are higher. |

| Quality Control (QC) Inspector | Inspects materials and finished products to ensure they meet quality standards. Uses precision measuring tools. | $45,000 - $58,000 | Directly responsible for preventing defects and ensuring customer satisfaction. Requires high attention to detail and knowledge of standards. |

| Industrial Machinery Mechanic | Maintains and repairs factory equipment and machinery. Prevents costly downtime. | $58,000 - $70,000 | Every minute of machine downtime costs the company money. Skilled mechanics are essential and highly compensated. |

| CNC Machine Operator / Programmer | Sets up and operates computer-numerically controlled (CNC) machines to cut and shape materials. Programmers write the code. | Operator: $48,000 - $62,000

Programmer: $60,000 - $80,000+ | This is a highly technical, precision-oriented skill that is central to modern advanced manufacturing. Programming is a highly specialized skill. |

| Robotics Technician | Installs, maintains, and repairs the robotic systems used in automated manufacturing. | $55,000 - $75,000 | As automation increases, the need for skilled technicians who can keep the robots running grows. This is a future-proof specialization. |

| Chemical Plant and System Operator | Operates equipment that controls chemical processes or systems of machines. | $60,000 - $85,000+ | High-responsibility role, often in hazardous environments (e.g., oil & gas, pharmaceuticals), requiring extensive training and safety knowledge. |

### `

`In-Demand Skills`

`Beyond your job title, possessing a specific set of high-value skills can lead to higher pay, promotions, and job security.

High-Value Hard Skills:

- Blueprint and Schematic Reading: The ability to read and interpret technical drawings is fundamental for any role beyond basic labor.

- Precision Measurement: Proficiency with tools like calipers, micrometers, and gauges is essential for quality control and machining.

- CNC Programming (G-code, M-code): If you can not only operate but also program CNC machines, your value skyrockets.

- Robotics Operation and Maintenance: As factories become more automated, skills in operating and troubleshooting robotic arms and systems are in high demand.

- Lean Manufacturing / Six Sigma: Understanding and applying principles of waste reduction and process improvement makes you an asset to any team.

- Welding (TIG, MIG, Stick): Specialized welding skills, especially in TIG (Tungsten Inert Gas) welding for precision work, are always sought after.

- Forklift Operation (Certified): A simple but universally needed skill in any production or warehouse environment.

Critical Soft Skills:

- Attention to Detail: Manufacturing is a game of precision. A small error can lead to a large, costly defect.

- Problem-Solving: The ability to identify why a machine is malfunctioning or why a product is failing quality checks is crucial.

- Teamwork and Communication: Factories are collaborative environments. You must be able to work effectively with operators, mechanics, and supervisors.

- Adaptability: Technology and processes change. A willingness to learn new machines and new methods is key to long-term success.

Job Outlook and Career Growth

When