If you're exploring a hands-on, technically challenging career path, industrial maintenance is a field bursting with opportunity. These skilled professionals are the backbone of modern manufacturing, energy, and logistics, ensuring the complex machinery that powers our world runs smoothly. But beyond job security, what is the earning potential? This career is not only essential but also financially rewarding, with average salaries comfortably exceeding the national median and top earners commanding figures well over $95,000 annually.

This guide will break down the key factors that determine an industrial maintenance salary, providing a clear roadmap for your potential earnings in this dynamic and critical profession.

What Does an Industrial Maintenance Technician Do?

Before diving into the numbers, it's important to understand the role. An Industrial Maintenance Technician (often called an Industrial Machinery Mechanic) is a highly skilled problem-solver responsible for the installation, repair, and preventative maintenance of industrial equipment and machinery.

Their daily responsibilities are diverse and demanding, often including:

- Diagnosing and troubleshooting mechanical, electrical, pneumatic, and hydraulic systems.

- Reading blueprints, schematics, and technical manuals.

- Performing routine preventative maintenance to minimize downtime.

- Installing new equipment and machinery.

- Welding, fabricating parts, and using a wide range of tools.

- Working with Programmable Logic Controllers (PLCs) and robotic systems.

They are the essential personnel who keep production lines moving, power plants generating, and distribution centers operating efficiently.

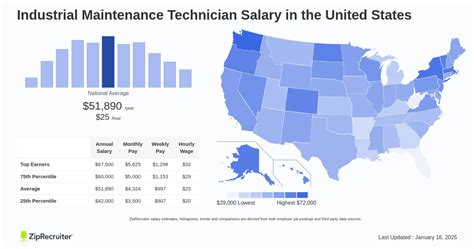

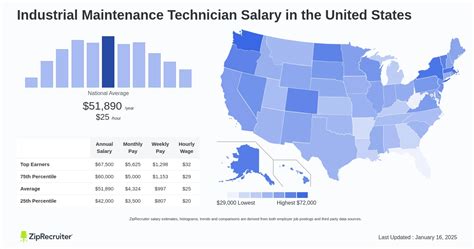

Average Industrial Maintenance Salary

The salary for an industrial maintenance professional is competitive and reflects the high level of skill required.

According to the most recent data from the U.S. Bureau of Labor Statistics (BLS), the median annual wage for industrial machinery mechanics was $63,900 in May 2023. This translates to approximately $30.72 per hour.

However, a "median" salary only tells part of the story. The full salary spectrum reveals the significant growth potential within the field:

- The lowest 10% of earners, typically entry-level positions, made less than $41,920.

- The highest 10% of earners, representing senior technicians with specialized skills, commanded salaries exceeding $95,200.

Data from reputable salary aggregators reinforces these findings. Payscale.com reports an average base salary of around $62,500 per year, while Salary.com places the median for an experienced Industrial Maintenance Technician (Technician III) closer to $68,300, with a common range between $60,400 and $76,200. This variance highlights how specific factors can significantly impact your paycheck.

Key Factors That Influence Salary

Your specific salary as an industrial maintenance technician isn't a single number; it's a range determined by a combination of critical factors. Understanding these drivers is the key to maximizing your earning potential.

### Level of Education and Certification

While a high school diploma or GED is the minimum entry point, formal education and professional certifications are a direct path to higher pay.

- Associate of Applied Science (A.A.S.): A two-year degree in fields like Industrial Maintenance Technology, Mechatronics, or Advanced Manufacturing provides a deep theoretical and practical foundation. Graduates with an A.A.S. are often fast-tracked into higher-level roles and can command a higher starting salary.

- Certifications: Industry-recognized credentials prove your expertise. The Certified Maintenance & Reliability Technician (CMRT) certification, for example, is a highly respected credential that validates your skills in preventative, predictive, and corrective maintenance, often leading to a salary bump and better job prospects.

### Years of Experience

Experience is arguably the most significant factor in salary growth. As you gain hands-on expertise, your value to an employer skyrockets.

- Entry-Level (0-2 years): Technicians just starting can expect to earn in the range of $42,000 to $55,000 as they learn the ropes and prove their abilities.

- Mid-Career (3-9 years): With solid experience, technicians can comfortably earn within the median range of $58,000 to $70,000. They can work more independently and troubleshoot complex issues.

- Senior/Experienced (10+ years): A seasoned technician with a decade or more of experience becomes a leader and a go-to expert. These professionals, especially those with supervisory responsibilities or specialized skills, regularly earn $75,000 to $95,000+.

### Geographic Location

Where you work matters. Salaries for industrial maintenance technicians vary significantly by state and even by metropolitan area, largely due to demand and cost of living. According to BLS data, the top-paying states for this profession include:

- Alaska: High demand in resource extraction industries.

- Wyoming: Driven by the mining and energy sectors.

- Hawaii: High cost of living and specialized needs.

- District of Columbia: Government and infrastructure-related maintenance.

- Nevada: Driven by large-scale manufacturing and logistics hubs.

Conversely, states with a lower cost of living may offer salaries below the national median, but the purchasing power could still be very strong.

### Company Type and Industry

The industry you work in has a massive impact on your salary. Industries with highly complex, expensive, or mission-critical equipment pay a premium for top talent to ensure minimal downtime. The BLS identifies the following as top-paying industries for industrial mechanics:

- Natural Gas Distribution

- Electric Power Generation, Transmission, and Distribution

- Aerospace Product and Parts Manufacturing

- Pipeline Transportation

- Automotive Manufacturing

Working for a large, multinational corporation in one of these sectors will almost always yield a higher salary than working for a small, local manufacturing plant.

### Area of Specialization

Modern industrial environments are increasingly automated and high-tech. Developing a specialized skill set in a high-demand area is one of the fastest ways to increase your salary.

- PLC and Automation: Technicians who can program and troubleshoot Programmable Logic Controllers (PLCs)—the brains behind most automated systems—are in extremely high demand.

- Robotics: As more companies integrate robotic arms and systems into their production lines, technicians who can install, maintain, and repair them are invaluable.

- Hydraulics and Pneumatics: Expertise in fluid power systems remains a core, high-value skill for heavy machinery.

- CNC Machinery: Specializing in the maintenance and repair of Computer Numerical Control (CNC) machines used in precision manufacturing commands a premium.

- Multi-skilled/Mechatronics: A technician who is truly multi-skilled—possessing strong knowledge in mechanical, electrical, and programming disciplines—is the most sought-after and highest-paid professional in the field.

Job Outlook

The future for industrial maintenance technicians is bright. According to the U.S. Bureau of Labor Statistics, employment in this field is projected to grow 5 percent from 2022 to 2032, which is faster than the average for all occupations.

This steady growth is driven by two main forces:

1. Increasing Automation: As factories and plants adopt more complex machinery and robotic systems, the need for skilled technicians to maintain them will only increase.

2. Retiring Workforce: A significant portion of the current skilled trades workforce is approaching retirement age, creating a skills gap and high demand for new talent to fill these crucial roles.

Conclusion: A Rewarding Path Forward

A career in industrial maintenance offers a powerful combination of job security, engaging work, and excellent earning potential. While a starting salary is respectable, the path to a six-figure income is clear and attainable through strategic career choices.

For anyone considering this field, the key takeaways are:

- Invest in Education: Pursue an associate's degree or targeted certifications to start ahead.

- Embrace Specialization: Focus on high-demand areas like PLCs, robotics, or mechatronics to become indispensable.

- Be Strategic About Industry: Target high-paying sectors like energy, aerospace, or automotive manufacturing.

- Gain Experience: Commit to continuous learning on the job, as experience is the ultimate salary driver.

For those with a knack for technology and a passion for problem-solving, the industrial maintenance career path offers a clear and rewarding journey toward financial stability and professional achievement.