Behind every flawlessly functioning power plant, every precisely mixed pharmaceutical, and every safely operated oil rig, there's a team of highly skilled professionals ensuring the silent, critical systems are running perfectly. These are the Instrumentation and Control (I&C) Technicians and Technologists, the masters of measurement and control who form the technological nervous system of modern industry. If you are a problem-solver who enjoys hands-on work, is fascinated by technology, and seeks a career with exceptional stability and financial rewards, you may have just found your calling. The field of instrumentation technology offers a direct path to a robust middle-class and even upper-middle-class income, often without the need for a four-year university degree. The national median salary for experienced technicians frequently lands in the $75,000 to $90,000 range, with top earners in high-demand industries pushing well into six figures.

I once spoke with a senior I&C technician at a massive water treatment facility, and his perspective has stuck with me ever since. He said, "People turn on their taps and never think about the science, engineering, and automation that deliver safe, clean water. My job is to make sure they don't *have* to think about it." That profound sense of quiet responsibility, of being an essential yet unseen guardian of our modern infrastructure, is at the very heart of this career. It's a profession that blends the hands-on skill of a master craftsperson with the analytical mind of an engineer, creating a unique and deeply satisfying career path.

This guide is designed to be your definitive resource for understanding the true financial potential of a career in instrumentation technology. We will dissect salary expectations, explore the factors that can maximize your earnings, and lay out a clear, step-by-step roadmap to get you started.

### Table of Contents

- [What Does an Instrumentation Technologist Do?](#what-does-an-instrumentation-technologist-do)

- [Average Instrumentation Technology Salary: A Deep Dive](#average-instrumentation-technology-salary-a-deep-dive)

- [Key Factors That Influence Your Salary](#key-factors-that-influence-your-salary)

- [Job Outlook and Career Growth in Instrumentation](#job-outlook-and-career-growth-in-instrumentation)

- [How to Get Started in an Instrumentation Career](#how-to-get-started-in-an-instrumentation-career)

- [Conclusion: Is a Career in Instrumentation Right for You?](#conclusion-is-a-career-in-instrumentation-right-for-you)

---

What Does an Instrumentation Technologist Do?

An Instrumentation and Control (I&C) Technologist or Technician is a specialized professional responsible for the installation, maintenance, calibration, troubleshooting, and repair of the instruments and control systems used in industrial and commercial processes. Think of them as the doctors and neurosurgeons for the machinery and systems that run our world.

If a manufacturing plant were a human body, the pipes and tanks would be the skeleton, the pumps and motors would be the muscles, and the engineers would be the brain designing the overall system. The instrumentation technologists would be responsible for the entire nervous system. They ensure that the brain (the control system) receives accurate information from the senses (the instruments) and can effectively command the muscles (the valves, motors, and heaters) to perform their tasks precisely.

These instruments measure critical process variables, including:

- Pressure: The force exerted by a fluid or gas in a pipe or vessel.

- Flow: The rate at which a liquid or gas moves through a system.

- Temperature: The degree of heat in a process, crucial for chemical reactions and safety.

- Level: The height of a substance in a tank or silo.

- pH and Conductivity: The chemical properties of a liquid.

- Position: The physical location of a valve or robotic arm.

- Vibration: The operational health of a large motor or turbine.

The core responsibility is to ensure these instruments are providing accurate and reliable data to the central control system, which is often a Programmable Logic Controller (PLC) or a Distributed Control System (DCS). When an instrument fails or provides faulty data, the entire process can be compromised, leading to product loss, equipment damage, or, in the worst-case scenario, a major safety incident.

Typical Daily Tasks and Projects:

- Calibration: Using highly accurate test equipment to verify that an instrument's measurement is correct and adjusting it if necessary. This is a primary and constant duty.

- Troubleshooting: Diagnosing and resolving issues when a control loop, sensor, or final control element (like a valve) is malfunctioning. This requires a deep understanding of electronics, mechanics, and process logic.

- Installation and Commissioning: Installing new instruments and control systems, connecting them to the process and the PLC/DCS, and verifying they operate as designed.

- Preventive Maintenance (PM): Performing scheduled checks, cleaning, and testing of instruments to prevent failures before they happen.

- Reading Schematics and Blueprints: Interpreting Process and Instrumentation Diagrams (P&IDs), loop diagrams, and electrical drawings to understand how systems are supposed to work.

- Documentation: Meticulously recording all calibration data, maintenance work, and changes made to the system. This is critical for regulatory compliance (e.g., FDA, EPA) and future troubleshooting.

- Working with PLCs and DCSs: Interfacing with the control system to diagnose problems, monitor data, and sometimes make minor programming adjustments.

### A "Day in the Life" of an I&C Technician

7:00 AM: Arrive at the chemical plant, change into flame-retardant clothing (FRC) and steel-toed boots. Attend the morning toolbox talk with the maintenance team to discuss the day's priorities and safety permits.

7:30 AM: Pick up your work orders. The first task is an urgent call: a temperature transmitter on a critical reactor is showing erratic readings, threatening to cause a batch to be rejected.

8:00 AM: After getting the necessary work permits, you head to the reactor. You connect your HART communicator (a specialized handheld device) to the transmitter. The device diagnostics show an internal fault. You check the wiring and power supply—both are good. The issue is the transmitter itself.

9:15 AM: You go to the warehouse, sign out a new, pre-configured temperature transmitter, and return to the field. You safely de-energize the circuit, remove the faulty instrument, install the new one, and re-energize it.

10:30 AM: You verify the new transmitter is communicating correctly with the DCS in the control room. The operator confirms the reading is now stable and accurate. You close out the work order, documenting the failure and the fix.

11:00 AM: Time for your scheduled PMs. You spend the next hour performing calibrations on three critical pressure sensors on a pipeline, using a high-precision digital pressure calibrator. You record the "as found" and "as left" data in the plant's calibration management software.

1:00 PM: Lunch with the team.

2:00 PM: You join a project team to assist engineers with the commissioning of a new automated mixing system. Your role is to perform "loop checks"—verifying every wire from every new instrument is landed correctly in the PLC cabinet and that the signal travels from the sensor to the PLC and from the PLC to the final control valve without issue.

4:30 PM: You finish your loop checks for the day, update the project lead on your progress, and clean your tools.

5:00 PM: You complete your final paperwork, log your hours, and head home, knowing the plant is running safely and efficiently because of your work.

---

Average Instrumentation Technology Salary: A Deep Dive

The financial compensation for an instrumentation technology career is one of its most compelling attributes. The salary reflects the high level of skill required, the responsibility of the role, and the critical impact technicians have on an organization's safety and profitability. Unlike many professions, salary data in this field is fairly consistent across various aggregators, painting a clear picture of earning potential.

It is important to note that the U.S. Bureau of Labor Statistics (BLS) does not have a single, perfect category for this role. Instrumentation Technicians are often grouped under broader categories. The two most relevant are:

1. Electrical and Electronics Repairers, Commercial and Industrial Equipment (SOC 49-2094): This is often the best fit for technicians focused on maintenance and repair in plant environments.

2. Electrical and Electronic Engineering Technologists and Technicians (SOC 17-3023): This category may include technicians who are more involved in design, development, and testing, often working more closely with engineers.

For the most accurate picture, we will synthesize data from the BLS with real-world salary data from professional aggregators that survey individuals with the specific job title "Instrumentation Technician."

### National Salary Averages and Ranges

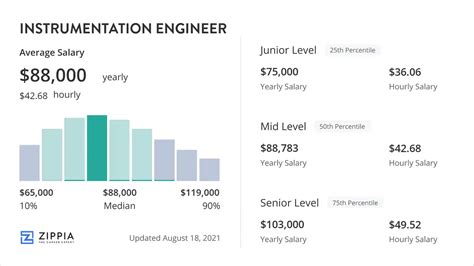

Based on a comprehensive review of current data, here is a snapshot of the national salary landscape for an Instrumentation and Control Technician in the United States:

- Median Salary: Most sources place the median national salary—the midpoint of all salaries—between $74,000 and $80,000 per year.

- Salary.com, as of November 2023, reports a median salary for an "Instrumentation Technician III" (an experienced professional) at $87,830, with a typical range falling between $77,935 and $97,934.

- Payscale.com reports an average base salary for an "Instrumentation and Control Technician" at $74,481 per year, with a common range of $53,000 to $103,000.

- Glassdoor lists a total pay average of $84,657 per year for "Instrumentation Technicians," which includes base pay and additional compensation like bonuses.

- The U.S. Bureau of Labor Statistics (BLS), in its May 2022 data, reported a median annual wage for "Electrical and Electronics Repairers, Commercial and Industrial Equipment" of $68,150. The lowest 10 percent earned less than $40,650, and the highest 10 percent earned more than $99,920. The slight discrepancy between the BLS and salary aggregators can be attributed to the BLS's broader category definition and slightly older data set. The aggregators, which target specific job titles, often capture the higher pay associated with the specialized skills of I&C work.

### Salary by Experience Level

Your earnings will grow substantially as you move from an apprentice or entry-level technician to a seasoned, senior-level expert. The industry places a high premium on demonstrated, real-world experience.

| Experience Level | Typical Years of Experience | Typical Annual Base Salary Range | Key Responsibilities |

| :--- | :--- | :--- | :--- |

| Entry-Level / Apprentice | 0-2 years | $50,000 - $68,000 | Assisting senior technicians, performing basic calibrations, learning systems, running cables, following procedures. |

| Mid-Career / Journeyman | 3-8 years | $68,000 - $88,000 | Working independently, troubleshooting complex loop issues, performing advanced calibrations, leading small jobs. |

| Senior / Lead Technician | 8+ years | $85,000 - $115,000+ | Tackling the most complex problems, mentoring junior techs, system commissioning, PLC/DCS interface, project leadership. |

| Specialist / Supervisor | 10+ years | $100,000 - $140,000+ | Specializing in a high-demand area (e.g., analyzers, DCS), managing a team of technicians, planning maintenance schedules. |

*Source: Synthesized from Payscale, Salary.com, and industry job postings.*

### Beyond the Base Salary: Understanding Total Compensation

A crucial point for anyone considering this career is that base salary is only one part of the total compensation package. In instrumentation, additional pay can significantly increase your annual earnings.

- Overtime Pay: Many I&C Technicians work in facilities that run 24/7/365, such as power plants, refineries, and manufacturing sites. This means opportunities for overtime pay (typically 1.5x the base hourly rate) are abundant, especially during plant shutdowns (turnarounds), startups, or emergency call-outs. It is not uncommon for a technician with a base salary of $80,000 to earn over $100,000 with overtime.

- Bonuses and Profit Sharing: Many private-sector companies offer annual bonuses based on individual, team, and company performance. These can range from a few thousand dollars to 10-15% of your base salary. Some companies also offer profit-sharing plans.

- Per Diem and Uplifts: Technicians who travel for work, particularly those working for service companies or on remote projects, receive a "per diem"—a daily allowance to cover lodging and meals. Furthermore, working in hazardous or undesirable locations, such as an offshore oil rig or a remote arctic pipeline, comes with a significant "uplift" or pay premium that can increase base pay by 30-50% or more.

- Benefits Package: The value of benefits cannot be overstated. Most full-time positions offer comprehensive packages that include:

- Health, Dental, and Vision Insurance: Employer-sponsored plans can save you thousands of dollars a year compared to private insurance.

- Retirement Plans: A 401(k) or 403(b) with a company match is essentially free money. A common match is 50% or 100% of your contribution up to 3-6% of your salary. This is a powerful wealth-building tool.

- Paid Time Off (PTO): Includes vacation, sick leave, and holidays.

- Tuition Reimbursement: Many companies will pay for you to pursue further education or valuable certifications.

- Tool and Clothing Allowance: It is common for employers to provide an annual allowance for work boots, tools, and required personal protective equipment (PPE).

When evaluating a job offer, it's essential to look at the entire compensation structure. A job with a slightly lower base salary but excellent overtime opportunities, a generous bonus, and a strong 401(k) match could be far more lucrative than a job with a higher base salary and nothing else.

---

Key Factors That Influence Your Salary

While the national averages provide a solid baseline, your personal earning potential as an instrumentation technologist is not a fixed number. It is a dynamic figure influenced by a combination of your qualifications, choices, and skills. Mastering these factors is the key to maximizing your income and accelerating your career growth. This is the most critical section for understanding how to move from an average earner to a top-tier professional in the field.

###

Level of Education and Certification

Your educational foundation sets the stage for your entire career trajectory. While a four-year degree is not typically required to become a successful technician, formal training is non-negotiable.

- Associate of Applied Science (A.A.S.) Degree: This is the gold standard and the most common educational pathway. A two-year A.A.S. in Instrumentation Technology, Process Control, or a related field from a community college or technical school is highly valued by employers. These programs provide the perfect blend of theoretical knowledge (e.g., Ohm's law, digital electronics, fluid dynamics) and extensive hands-on lab experience with real-world equipment. Graduates of strong A.A.S. programs often start at a higher salary than those without a formal degree.

- Apprenticeships: A formal apprenticeship, often sponsored by a union (like the IBEW or UA) or a large industrial company, is another excellent route. This path combines on-the-job training with classroom instruction over a 3-5 year period. You earn while you learn, but the starting wage is lower. However, upon completion, a union journeyman technician often has a very high, collectively bargained wage and an excellent pension plan.

- Certifications: This is arguably the most powerful salary booster outside of experience itself. Certifications are third-party validations of your skills and knowledge. The premier certifying body is the International Society of Automation (ISA).

- ISA Certified Control Systems Technician (CCST®): This is the most recognized and respected certification for I&C technicians. It has three levels, each requiring a progressively higher level of experience and knowledge.

- CCST Level I: Demonstrates foundational knowledge. Achieving this early in your career can significantly boost your resume.

- CCST Level II: Requires more experience and shows you can work independently on complex systems.

- CCST Level III (Specialist): The highest level, marking you as a true expert and leader in the field. It often leads to senior, lead, or specialist roles.

- Holding a CCST certification can increase your salary by 5-15% and makes you a much more competitive candidate for high-paying jobs.

- Vendor-Specific Training: Certifications from major equipment manufacturers like Rockwell Automation (Allen-Bradley), Siemens, Emerson (DeltaV), or Honeywell are extremely valuable. If a plant primarily uses Rockwell PLCs, a technician with a Rockwell certification in PLC programming and maintenance is a highly sought-after asset and can command a higher wage.

###

Years of Experience

In a hands-on field like instrumentation, there is no substitute for experience. Your salary will and should grow in distinct stages as you progress from a novice to an expert.

- Entry-Level (0-2 years): Salary Range: $50,000 - $68,000. At this stage, you are learning the plant's specific systems, procedures, and safety protocols. You'll spend most of your time assisting senior technicians, performing basic calibrations, and learning to read schematics. Your primary value is your potential and your willingness to learn.

- Mid-Career (3-8 years): Salary Range: $68,000 - $88,000. You are now a reliable, independent technician. You can be assigned a complex troubleshooting task and be expected to see it through to completion. You understand the "why" behind the process, not just the "how" of the repair. You might begin to specialize and are trusted to work on critical systems without direct supervision. This is where you see the most significant salary jumps.

- Senior/Lead Technician (8+ years): Salary Range: $85,000 - $115,000+. You are the