Table of Contents

- [What Does a Mechanical Technician Do?](#what-does-a-mechanical-technician-do)

- [Average Mechanical Technician Salary: A Deep Dive](#average-mechanical-technician-salary-a-deep-dive)

- [Key Factors That Influence a Mechanical Technician's Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth for Mechanical Technicians](#job-outlook-and-career-growth)

- [How to Become a Mechanical Technician: A Step-by-Step Guide](#how-to-get-started-in-this-career)

- [Conclusion: Is a Career as a Mechanical Technician Right for You?](#conclusion)

Are you the person who has always been fascinated by how things work? Do you find satisfaction not just in understanding complex machinery, but in building, testing, and repairing it? If you're driven by a hands-on approach to problem-solving and innovation, a career as a mechanical technician could be your calling. This profession is the critical bridge between engineering theory and real-world application, placing you at the heart of technological progress across countless industries. But beyond the satisfaction of the work itself, a crucial question remains: is it a financially rewarding path?

The answer is a resounding yes. A skilled mechanical technician commands a solid, competitive salary with significant potential for growth. According to the most recent data from the U.S. Bureau of Labor Statistics (BLS), the median annual wage for mechanical engineering technicians was $65,550 in May 2023. This figure places the role comfortably above the median for all occupations, with top earners in the field exceeding $99,190 per year.

I once had the opportunity to tour a state-of-the-art medical device R&D facility. While the engineers in their pristine offices were impressive, the true magic was happening on the lab floor. There, a senior mechanical technician was meticulously assembling a prototype for a new surgical robot, a device that could one day save lives. Her expertise was palpable; she wasn't just following a schematic, she was anticipating stress points, suggesting material changes, and providing real-time feedback that would be invaluable to the final design. It was a powerful reminder that mechanical technicians are not just support staff; they are essential collaborators and innovators who make progress tangible.

This comprehensive guide is designed to be your definitive resource for understanding the financial landscape of a mechanical technician career. We will dissect salary data from authoritative sources, explore the crucial factors that can increase your earning potential, analyze the long-term job outlook, and provide a clear, step-by-step roadmap to get you started. Whether you are a high school student planning your future, a professional considering a career change, or a current technician aiming for advancement, this article will equip you with the knowledge to build a successful and lucrative career.

What Does a Mechanical Technician Do?

At its core, a mechanical technician is an expert practitioner who applies the principles of mechanical engineering to build, test, evaluate, repair, and maintain mechanical devices, equipment, and systems. They are the hands-on specialists who translate the complex blueprints and digital models created by engineers into functioning, real-world products and machinery. Their work is essential in a vast array of sectors, including manufacturing, research and development (R&D), aerospace, automotive, energy, and robotics.

While the specific duties can vary significantly based on the industry and specialization, the core responsibilities of a mechanical technician generally revolve around a few key areas:

- Assembly and Fabrication: They meticulously assemble new machines and equipment based on detailed diagrams, schematics, and computer-aided design (CAD) models. This can range from constructing a small prototype for an R&D lab to helping install a massive industrial press on a factory floor.

- Testing and Data Collection: A crucial part of the role is conducting rigorous tests on new or modified equipment to ensure it meets quality and performance specifications. They set up test apparatus, operate machinery, and use precision measuring instruments to collect data on factors like stress, wear, vibration, and efficiency.

- Troubleshooting and Repair: When a machine malfunctions, mechanical technicians are the first line of defense. They use their deep understanding of mechanical, hydraulic, and pneumatic systems to diagnose the root cause of a problem and perform the necessary repairs, which might involve disassembling equipment, replacing worn parts, and recalibrating components.

- Maintenance and Inspection: To prevent costly breakdowns, technicians perform routine preventive maintenance. This includes lubricating parts, cleaning components, monitoring performance, and conducting regular inspections to identify potential issues before they become critical failures.

- Supporting Engineering Design: Technicians work in close collaboration with mechanical engineers. They provide practical feedback on designs, pointing out potential manufacturing difficulties or suggesting modifications that could improve a product's performance, reliability, or cost-effectiveness. They often create initial sketches or build proof-of-concept models.

- Documentation and Reporting: Precision and detail extend to paperwork. Technicians are responsible for maintaining detailed records of maintenance schedules, repair work, test results, and inventory of spare parts. This documentation is vital for quality control, regulatory compliance, and future engineering efforts.

### A Day in the Life of a Mechanical Technician

To make this role more tangible, let's imagine a day for "Maria," a mid-career mechanical technician working in the R&D department of a consumer electronics company.

- 8:00 AM: Maria starts her day by reviewing the test plan for a new drone prototype. She syncs with the lead mechanical engineer to clarify the objectives for today's stress test: to determine the failure point of a newly designed propeller mount.

- 8:30 AM: She heads to the workshop to prepare the test rig. This involves mounting the drone chassis securely, attaching sensors to measure vibration and strain, and setting up a high-speed camera to capture the test.

- 10:00 AM: The test begins. Maria operates the control console, gradually increasing the rotational speed of the propellers. She closely monitors the data streaming from the sensors onto her computer, looking for any anomalies.

- 11:15 AM: The propeller mount fractures, precisely as predicted by the engineering simulations, but at a slightly lower RPM. The test is a success. Maria carefully saves all the sensor data and the high-speed camera footage.

- 12:00 PM: Lunch break with her team, where they casually discuss the initial results.

- 1:00 PM: Maria meticulously disassembles the damaged prototype, taking detailed photographs of the fracture points. She uses calipers and a digital microscope to measure the deformation of the surrounding components.

- 2:30 PM: She begins compiling her test report. She graphs the strain and vibration data, annotates the key photos, and writes a clear, concise summary of the test procedure, observations, and results. She includes a recommendation to reinforce a specific section of the mount based on the fracture pattern she observed.

- 4:00 PM: Maria meets with the engineering team to present her findings. Her hands-on observations provide crucial context that the simulation data alone could not. Her recommendation is adopted into the next design iteration.

- 4:45 PM: She cleans her workstation, inventories the parts used, and plans her tasks for the next day, which will involve fabricating the newly redesigned propeller mount using the lab's 3D printer.

This example illustrates how the role is a dynamic blend of technical skill, analytical thinking, and collaborative problem-solving.

Average Mechanical Technician Salary: A Deep Dive

Understanding the financial potential is a primary motivator for anyone exploring a new career path. For mechanical technicians, the compensation is robust, reflecting the specialized skills and critical importance of the role. While a single "average" salary provides a useful benchmark, a deeper analysis reveals a wide spectrum of earnings influenced by experience, location, and specialization.

To provide the most accurate and comprehensive picture, we will synthesize data from the U.S. Bureau of Labor Statistics (BLS), the gold standard for government occupational data, alongside top salary aggregator sites like Salary.com, Payscale, and Glassdoor, which collect real-time, user-reported and employer-reported data.

### National Salary Benchmarks

According to the U.S. Bureau of Labor Statistics (BLS) Occupational Employment Statistics, the most recent data (May 2023) shows the following for "Mechanical Engineering Technologists and Technicians":

- Median Annual Wage: $65,550 (This means 50% of workers in the occupation earned more than this amount and 50% earned less.)

- Mean Annual Wage: $67,610

- Bottom 10% Earned: Less than $43,890 (Typical for entry-level positions or in lower-paying regions/industries).

- Top 10% Earned: More than $99,190 (Typical for senior technicians, specialists, or those in high-paying industries).

Data from leading salary aggregators provides a slightly different but complementary view, often updated more frequently:

- Salary.com reports that as of late 2023, the median salary for a Mechanical Technician II (a mid-level role) in the United States is $66,973, with a typical range falling between $60,286 and $74,543.

- Payscale.com indicates a similar average base salary of around $61,000, with a total pay range (including bonuses and overtime) spanning from $44,000 to $88,000.

- Glassdoor.com estimates the total pay for a mechanical technician in the U.S. to be around $73,500 per year, which includes a base salary of approximately $62,000 and additional pay (bonuses, profit sharing) of around $11,500.

Why the difference? The BLS provides a broad, comprehensive survey, while aggregator sites use a mix of user-submitted and employer-posted data, which can sometimes capture more dynamic elements like bonuses and reflect more recent market trends. The key takeaway is that the mid-$60,000s is a very solid median figure, with a clear path to earning well over $80,000 or $90,000 with the right experience and skills.

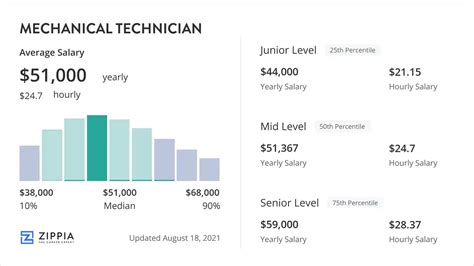

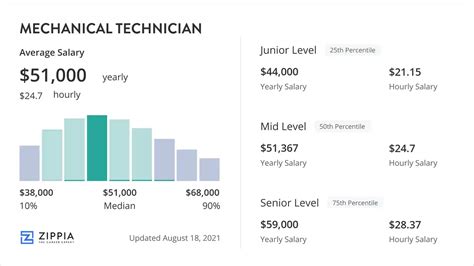

### Salary by Experience Level

One of the most significant factors determining your salary is your level of experience. As you progress in your career, your ability to work independently, troubleshoot complex problems, and mentor others increases your value exponentially.

Here is a typical salary progression, synthesized from BLS, Salary.com, and Payscale data:

| Experience Level | Years of Experience | Typical Salary Range (Annual) | Key Characteristics & Responsibilities |

| :--- | :--- | :--- | :--- |

| Entry-Level Mechanical Technician | 0-2 Years | $44,000 - $58,000 | Works under direct supervision. Focuses on basic assembly, routine maintenance, data collection, and following established test procedures. Learning core skills like reading blueprints and using measurement tools. |

| Mid-Career Mechanical Technician | 3-8 Years | $59,000 - $75,000 | Works more independently on complex projects. Can troubleshoot common equipment failures, set up and run standard tests, and may contribute to design improvements. May begin to specialize in a specific area (e.g., hydraulics, robotics). |

| Senior/Lead Mechanical Technician | 9+ Years | $76,000 - $99,000+ | A subject matter expert. Manages complex projects, diagnoses novel and difficult problems, and designs custom test fixtures. Often responsible for training junior technicians, managing the workshop/lab, and collaborating directly with senior engineers on R&D. |

### Beyond the Base Salary: Understanding Total Compensation

Your annual salary is only one piece of the puzzle. A comprehensive compensation package for a mechanical technician often includes several other valuable components that significantly boost your overall earnings and financial well-being.

- Overtime Pay: This is a very common and significant component, especially in manufacturing, field service, and R&D environments with tight deadlines. Technicians are often classified as non-exempt employees, meaning they are legally entitled to overtime pay (typically 1.5 times their hourly rate) for any hours worked over 40 in a week. This can add thousands, or even tens of thousands, of dollars to an annual income.

- Bonuses: Many companies offer annual or quarterly performance-based bonuses. These can be tied to individual performance, team goals (e.g., completing a project on time), or overall company profitability.

- Profit Sharing: Some companies, particularly in the manufacturing sector, have profit-sharing plans where a portion of the company's profits is distributed among employees. This provides a direct incentive to improve efficiency and quality.

- Benefits Package: The value of a strong benefits package cannot be overstated. This includes:

- Health Insurance: Medical, dental, and vision coverage. A good employer plan can be worth over $10,000 per year.

- Retirement Savings Plan: Access to a 401(k) or 403(b) plan, often with a generous employer match (e.g., matching 50% of your contributions up to 6% of your salary). This is essentially free money for your retirement.

- Paid Time Off (PTO): Includes vacation days, sick leave, and paid holidays.

- Tuition Reimbursement: Many employers will help pay for further education, such as completing a bachelor's degree or earning a valuable certification. This is a powerful benefit for career advancement.

- Tool Allowance: Some employers provide an annual stipend for technicians to purchase or upgrade their personal tools.

When evaluating a job offer, it's crucial to look at the total compensation package, not just the base salary. A job with a slightly lower base salary but excellent overtime potential, a strong bonus structure, and a premium benefits package could be far more lucrative in the long run.

Key Factors That Influence a Mechanical Technician's Salary

While the national averages provide a great starting point, your personal earning potential as a mechanical technician is not set in stone. It is a dynamic figure heavily influenced by a combination of your qualifications, choices, and the market you work in. Mastering these factors is the key to maximizing your income throughout your career. This section provides an in-depth analysis of the six primary drivers of a mechanical technician's salary.

### 1. Level of Education and Certifications

Your educational foundation is the first major determinant of your starting salary and long-term growth potential. While it's possible to enter the field with just a high school diploma and on-the-job training, formal education significantly accelerates your career.

- High School Diploma / GED: This is the absolute minimum requirement. Entry-level opportunities might exist in assembly or basic maintenance roles, but salary potential will be at the lowest end of the spectrum, and advancement will be slow.

- Certificate Programs (1 year): Offered by community colleges and vocational schools, these programs provide foundational knowledge in areas like welding, machine tool technology, or industrial maintenance. They are a good step up from a high school diploma and can lead to entry-level technician roles, often starting in the $45,000 - $52,000 range.

- Associate's Degree (A.A.S.): The Associate of Applied Science in Mechanical Engineering Technology is considered the gold standard for entering this profession. This two-year degree provides a robust combination of theoretical knowledge (e.g., statics, materials science, thermodynamics) and intensive hands-on lab experience (e.g., CAD, machining, metrology). Graduates with an A.A.S. are highly sought after and can command starting salaries in the $50,000 to $60,000+ range. They are qualified for a much wider range of roles, including those in R&D and testing.

- Bachelor's Degree (B.S.): A four-year Bachelor of Science in Mechanical Engineering Technology (MET) or a related field positions you for higher-level "technologist" roles, which often blur the line with engineering. These positions involve more complex design work, project management, and analysis. A B.S. degree can lead to starting salaries approaching $65,000 or more and provides a much clearer path to management or engineering roles.

Professional Certifications: Beyond formal degrees, industry-recognized certifications are powerful salary boosters. They act as proof of your expertise in a specific, high-value skill.

- CAD Certifications: Proficiency in Computer-Aided Design is non-negotiable. Certifications in leading software like SolidWorks (CSWA/CSWP), AutoCAD, CATIA, or Creo can add thousands to your salary.

- American Society for Quality (ASQ) Certifications: Credentials like Certified Quality Technician (CQT) or Certified Mechanical Inspector (CMI) are highly valued in manufacturing and quality control, demonstrating a commitment to precision and standards.

- Lean Six Sigma: A Green Belt or Black Belt certification in this process improvement methodology is extremely attractive to employers in manufacturing, as it shows you can identify and eliminate waste, improving the bottom line.

- Welding Certifications (AWS): For technicians in fabrication or heavy industry, certifications from the American Welding Society are often required and command premium pay.

- HVAC-R Certifications (EPA 608, NATE): In the building systems and climate control sector, these certifications are essential for handling refrigerants and demonstrate a high level of competence.

### 2. Years of Experience

As detailed in the previous section, experience is arguably the most powerful driver of salary growth over a lifetime. However, it's not just the quantity of years but the *quality* of that experience that matters. A technician who has spent ten years proactively seeking out new challenges, learning new technologies, and taking on leadership responsibilities will earn significantly more than one who has performed the same repetitive tasks for a decade.

- 0-2 Years (The Learning Phase): Your primary goal is to absorb as much knowledge as possible. Focus on mastering the fundamentals, being reliable, and asking intelligent questions.

- 3-8 Years (The Specialization Phase): You have a solid foundation. Now is the time to develop a niche. Become the go-to person for the lab's 3D printer, the expert on the hydraulic press, or the most skilled CNC programmer. This specialized expertise is what begins to separate you from the pack and pushes your salary into the $60k-$75k range.

- 9+ Years (The Leadership/Expert Phase): At this stage, your value comes from solving the "unsolvable" problems and multiplying your impact. You should be training junior staff, leading complex projects, and acting as a key consultant to the engineering team. This is where salaries push past $80,000 and into the $90,000s, especially for those who formally move into lead technician or supervisory roles.

### 3. Geographic Location

Where you work has a dramatic impact on your paycheck. Salaries are typically higher in areas with a high cost of living and a high concentration of technology, manufacturing, or R&D companies. However, a higher salary doesn't always mean more take-home pay after accounting for expenses.

According to BLS data, the top-paying states for mechanical engineering technicians are:

1. New Mexico: ($83,290 mean salary) - Driven by national laboratories and defense/aerospace industries.

2. Maryland: ($81,040 mean salary) - Strong presence of government contractors and federal R&D facilities.

3. District of Columbia: ($79,930 mean salary)

4. Alaska: ($77,530 mean salary) - Often tied to the oil and gas industry.

5. California: ($76,010 mean salary) - Hub for tech, aerospace, and biotech.

Conversely, states with lower costs of living and less industrial concentration tend to have lower average salaries. It's crucial to research the salary norms in your target region and weigh them against the cost of housing, taxes, and other expenses.

High-paying metropolitan areas often include:

- San Jose-Sunnyvale-Santa Clara, CA (Silicon Valley)

- Boulder, CO

- Huntsville, AL (Aerospace hub)

- Seattle-Tacoma-Bellevue, WA

- Boston-Cambridge-Nashua, MA-NH

### 4. Industry, Company Type, and Size

The industry you choose to work in is a major salary differentiator. Some sectors require a higher degree of precision, operate with larger budgets, or face a greater shortage of skilled technicians, all of which drive up wages.

- Top-Paying Industries (BLS Data):

- Scientific Research and Development Services: This is often the highest-paying sector, as technicians are integral to innovation. Median salaries can be 10-20% higher than the national average.

- Aerospace Product and Parts Manufacturing: Requires extreme precision and adherence to safety standards, commanding premium pay.

- Federal Government / Defense Contracting: Offers competitive salaries, excellent benefits, and job security.

- Oil and Gas Extraction / Energy: Can be extremely lucrative, especially for field service technicians working in remote locations, but can also be cyclical.

- Standard-Paying Industries:

- Machinery and Automotive Manufacturing: The largest employer of mechanical technicians, offering solid, competitive wages in line with the national median.

- Semiconductor and Electronic Component Manufacturing: A high-tech field with strong pay and demand for clean-room experience.

Company Type and Size:

- Large Corporations (e.g., Boeing, General Motors, Johnson & Johnson): Typically offer higher base salaries, structured career paths, excellent benefits, and formal training programs. The work environment is more structured and specialized.

- Startups: May offer a lower base salary but could compensate with stock options, which have high potential upside. The work is often more varied and dynamic, offering the chance to wear many hats and learn quickly.

- Government Agencies (e.g., NASA, Department of Defense, National Labs): Salaries are set by formal pay scales (like the GS scale). While the base pay might not always be the absolute highest, the combination of job security, exceptional benefits (pensions, generous leave), and work-life balance can make this a very attractive option.

### 5. Area of Specialization

Generalist mechanical technicians are always in demand, but developing deep expertise in a high-value specialization can catapult your salary to the next level.

- Robotics and Automation: As industries increasingly automate, technicians who can install, program, maintain, and troubleshoot robotic systems (e.g., Fanuc, KUKA, ABB) are in extremely high demand and can command top-tier salaries.

- Field Service: These technicians travel to customer sites to install, repair, and service complex equipment. This role requires excellent troubleshooting skills, independence, and strong customer-facing communication. Because of the travel and high-stakes nature of the work, field service technicians are often among the highest-paid, frequently earning significant overtime.

- R&D / Prototyping: Working alongside engineers in a lab to build and test first-of-their-kind products requires creativity, precision, and a deep understanding of fabrication techniques (including 3D printing, machining, etc.). These roles are often in the highest-paying industries.

- HVAC-R (Heating, Ventilation, Air Conditioning, and Refrigeration): A highly specialized and consistently in-demand field. Commercial and industrial HVAC-R technicians have a unique, valuable skillset and strong earning potential.

- Quality Control / Metrology: Specialists in precision measurement using tools like Coordinate Measuring Machines (CMMs) are critical in aerospace, medical devices, and automotive manufacturing. This focus on quality assurance is highly valued.

### 6. In-Demand Technical Skills

Finally, your specific, demonstrable technical skills are what justify a higher salary during negotiations and performance reviews. The more of these you master, the more valuable you become.

- Advanced CAD/CAM: Moving beyond basic 2D drafting to expert-level 3D solid modeling (SolidWorks, Inventor) and CAM (Computer-Aided Manufacturing) for programming CNC machines is a huge value-add.

- CNC Programming and Operation: The ability to not just run a CNC mill or lathe, but to write and edit G-code, perform complex setups, and optimize tool paths is a highly paid skill.

- PLC Programming: Understanding and being able to troubleshoot Programmable Logic Controllers (PLCs) from manufacturers like Allen-Bradley or Siemens is essential for work in automation and manufacturing.

- GD&T (Geometric Dimensioning and Tolerancing): The ability to read and interpret complex engineering drawings that use GD&T is a marker of an advanced technician. The ability to apply it during inspection