Behind every flick of a light switch, every clean glass of water from the tap, and every product manufactured in a factory, there is a team of highly skilled professionals working diligently behind the scenes. These are the plant operators—the unseen guardians of our modern infrastructure. If you're drawn to a career that combines technical skill, immense responsibility, and offers a stable, rewarding livelihood, becoming a plant operator might be the perfect path for you. This career is not just a job; it's a commitment to ensuring the seamless operation of the systems that power our daily lives, and it comes with a compensation package that reflects its critical importance.

A common question for those considering this field is, "What is a typical plant operator salary?" The answer is encouragingly robust, with the median salary for many operator roles comfortably exceeding the national average for all occupations. While the exact figure can vary significantly, many experienced operators find themselves earning in the $70,000 to over $100,000 range, especially in high-demand sectors like power generation. I once had the opportunity to tour a combined-cycle natural gas power plant, and I was struck by the calm, focused intensity of the control room. The lead operator explained that his job was like being the "brain of a billion-dollar machine," a statement that perfectly captures the weight and value of this profession.

This comprehensive guide will illuminate every facet of a plant operator's career, with a special focus on salary potential and the factors that drive it. We will explore the day-to-day responsibilities, dissect compensation data from authoritative sources, analyze the job outlook for the next decade, and provide a clear, step-by-step roadmap for how you can get started.

### Table of Contents

- [What Does a Plant Operator Do?](#what-is-a-plant-operator)

- [Average Plant Operator Salary: A Deep Dive](#average-salary)

- [Key Factors That Influence a Plant Operator's Salary](#key-factors)

- [Job Outlook and Career Growth for Plant Operators](#job-outlook)

- [How to Become a Plant Operator: Your Step-by-Step Guide](#how-to-start)

- [Conclusion: Is a Plant Operator Career Right for You?](#conclusion)

What Does a Plant Operator Do?

At its core, a plant operator is a highly trained technician responsible for monitoring, controlling, and maintaining the machinery and equipment within an industrial facility or plant. They are the human interface for complex, often automated systems, ensuring everything runs safely, efficiently, and in compliance with strict regulations. The term "plant" is broad and can refer to a variety of facilities, including:

- Power Plants: Generating electricity from sources like natural gas, coal, nuclear energy, hydroelectric dams, or solar farms.

- Water and Wastewater Treatment Plants: Purifying drinking water and treating sewage to protect public health and the environment.

- Chemical Plants: Manufacturing chemicals, pharmaceuticals, and other products through controlled chemical processes.

- Manufacturing Plants: Overseeing the machinery involved in producing goods, from automobiles to food products.

- Gas and Oil Refineries: Processing crude oil and natural gas into usable fuels and other petroleum products.

While the specific equipment varies, the core responsibilities of a plant operator share a common thread. They are the first line of defense against system failures and operational disruptions.

### Daily Tasks and Core Responsibilities

An operator's day is a blend of routine monitoring and the readiness to respond to unexpected events. Their duties typically include:

- System Monitoring: Using sophisticated control panels, computer systems (like SCADA - Supervisory Control and Data Acquisition), and gauges to monitor pressure, temperature, flow rates, and other critical variables.

- Equipment Control and Adjustment: Starting and stopping generators, pumps, and turbines; opening and closing valves; and adjusting controls to optimize the process based on demand, safety protocols, and efficiency targets.

- Inspections and Maintenance: Performing routine rounds to visually inspect equipment, listen for unusual noises, check fluid levels, and perform minor preventive maintenance tasks. They work closely with maintenance mechanics and electricians to report and diagnose larger issues.

- Safety and Compliance: Adhering to strict safety procedures, including lockout/tagout (LOTO) protocols, to ensure a safe working environment. They are responsible for understanding and complying with all environmental and industry regulations.

- Record Keeping and Reporting: Meticulously logging all operational data, readings, maintenance activities, and any incidents that occur during their shift. This documentation is crucial for analysis, compliance, and shift handovers.

- Emergency Response: Acting swiftly and decisively to troubleshoot problems, respond to alarms, and execute emergency shutdown procedures if necessary to prevent accidents or equipment damage.

### A "Day in the Life" of a Control Room Operator

To make this role more tangible, let's walk through a hypothetical shift for an operator at a power plant:

- 6:45 AM: Arrive at the plant. The first order of business is the shift change briefing. The outgoing operator provides a detailed report on the plant's status, any issues encountered during the night, and the expected operational plan for the day.

- 7:15 AM: After the handover, the operator begins their own review of the system on the main control board. They check key parameters: Is the generator output matching the grid's demand? Are all temperatures and pressures within their normal operating bands?

- 9:00 AM: An auxiliary operator (or "outside operator") conducts a physical walkthrough of the plant, and radios in their findings. They report a slight vibration on a secondary cooling pump. The control room operator logs this and schedules a maintenance work order to have it investigated.

- 11:30 AM: An alarm sounds on the control panel—a pressure sensor in the boiler feed system is reading erratically. The operator immediately cross-references it with a backup sensor, identifies it as a faulty instrument, and dispatches a technician to replace it, all while ensuring the system remains stable.

- 1:00 PM: Lunch, often taken in the control room to maintain constant oversight.

- 2:30 PM: The grid operator requests a ramp-up in power generation to meet peak afternoon demand. The operator carefully adjusts the controls to increase the fuel flow and turbine speed, monitoring dozens of variables to ensure a smooth and stable increase in output.

- 4:00 PM: The operator begins compiling the shift log, detailing all activities, adjustments, and communications. This detailed record is essential for tracking performance and for the next shift's handover.

- 6:50 PM: The night shift operator arrives. The process repeats, with a detailed briefing to ensure a seamless and safe transition of control.

This example highlights the immense responsibility and technical acumen required. Plant operators are not just watching screens; they are actively managing dynamic and powerful systems.

Average Plant Operator Salary: A Deep Dive

Now, let's address the central question: how much can you expect to earn as a plant operator? The compensation for this career is a significant draw, reflecting the high level of skill, training, and responsibility involved. We'll examine data from the U.S. Bureau of Labor Statistics (BLS) and leading salary aggregators to build a complete picture.

It's important to note that "plant operator" is a broad category. For the most accurate data, we will look at specific operator roles. The BLS Occupational Outlook Handbook is the gold standard for this information.

- According to the latest BLS data (May 2022), the median annual wage for Power Plant Operators, Distributors, and Dispatchers was $95,340. This means half of all operators in this field earned more than this amount, and half earned less.

- For Water and Wastewater Treatment Plant and System Operators, the median annual wage was $52,150 in May 2022.

- For Chemical Plant and System Operators, the median annual wage was $68,910 in May 2022.

These figures immediately highlight a key theme: specialization matters immensely. An operator in the power generation sector, particularly in nuclear or complex fossil fuel plants, generally has a much higher earning potential than an operator in a municipal water facility.

Salary aggregator websites like Salary.com, Payscale, and Glassdoor provide a wider range and more real-time data. For instance, Salary.com reports that the typical Plant Control Room Operator salary in the United States ranges from $68,521 to $92,027 as of late 2023, with the median sitting around $81,595. This range often excludes significant overtime and bonuses.

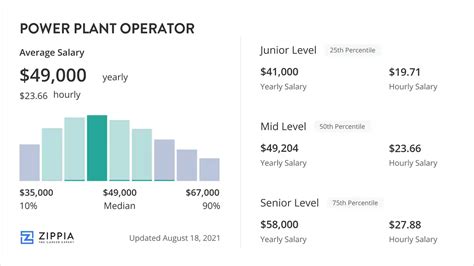

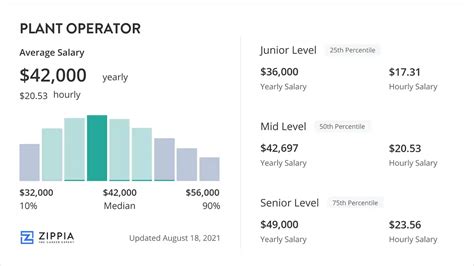

### Salary Brackets by Experience Level

Like any profession, salary grows with experience. An entry-level operator is learning the systems and requires supervision, while a senior operator is a trusted expert capable of managing the most critical situations.

Here is a typical salary progression, combining data from sources like Payscale and industry observations:

| Experience Level | Typical Annual Base Salary Range | Key Characteristics & Responsibilities |

| :--- | :--- | :--- |

| Entry-Level / Apprentice (0-2 years) | $45,000 - $65,000 | Learning systems as an "outside operator" or trainee. Performing routine checks, minor maintenance, and assisting senior operators. Often involves a formal apprenticeship program. |

| Mid-Career Operator (3-9 years) | $65,000 - $95,000 | Qualified to work in the control room. Can independently manage a shift, respond to normal operational changes, and troubleshoot common issues. Possesses key certifications. |

| Senior / Lead Operator (10+ years) | $90,000 - $125,000+ | Expert-level knowledge of all plant systems. Responsible for training junior operators, leading responses to major emergencies, and coordinating with management and maintenance. May hold a Shift Supervisor title. |

*Note: These ranges are for base salary and can be significantly higher in certain industries (e.g., nuclear power) and high-cost-of-living areas. Senior operators in specialized fields can easily surpass $130,000 or more with overtime.*

### Beyond the Base Salary: A Look at Total Compensation

A plant operator's W-2 is often much more than just their base salary. The total compensation package is a major part of the career's appeal.

- Overtime Pay: This is arguably the most significant addition to an operator's income. Plants run 24/7/365, which means shift work is standard. Operators are often required to work nights, weekends, and holidays, all of which come with shift differential pay (an extra hourly rate). Furthermore, when a colleague is sick or on vacation, operators are called upon to work overtime shifts, which are paid at 1.5x (time-and-a-half) or even 2.0x (double-time) their regular hourly rate. It is not uncommon for an operator's overtime pay to add 20-40% to their annual base salary.

- Bonuses: In private industry (e.g., investor-owned utilities, chemical companies), annual bonuses are common. These are typically tied to plant performance metrics, such as safety record, uptime (the percentage of time the plant is operational), and production efficiency. These can range from a few thousand dollars to over 15% of an operator's base salary.

- Profit Sharing: Some private companies offer profit-sharing plans, where a portion of the company's profits is distributed among employees, further boosting total earnings.

- Benefits and Pension: This is a major differentiator, especially in government/municipal roles and established utility companies. Plant operators often receive excellent benefits packages, including high-quality health, dental, and vision insurance with low employee premiums. Furthermore, many still have access to traditional defined-benefit pension plans, a rarity in today's job market. These plans guarantee a monthly income for life upon retirement, providing incredible long-term financial security. They also typically offer robust 401(k) or 403(b) plans with generous employer matching.

When you combine a strong base salary with significant overtime potential, performance bonuses, and a top-tier benefits and retirement package, the true value of a plant operator's compensation becomes clear.

Key Factors That Influence a Plant Operator's Salary

While the national averages provide a good starting point, an individual operator's salary is determined by a confluence of factors. Understanding these variables is crucial for anyone looking to maximize their earning potential in this field. This is the most critical section for strategic career planning.

###

1. Area of Specialization or Industry

As we've already seen, this is the single most powerful factor. The complexity, risk, and economic value of the plant's output directly correlate with operator pay.

- Nuclear Power Reactor Operators: This is the pinnacle of the profession in terms of compensation. The training is incredibly rigorous, requiring years of study and passing an intense licensing exam administered by the Nuclear Regulatory Commission (NRC). The immense responsibility of safely operating a nuclear reactor commands the highest salaries. It is common for licensed senior reactor operators to earn $120,000 to $160,000+ in base salary alone.

- Power Plant Operators (Fossil Fuel, Hydro, Geothermal): These roles are also at the high end of the scale. Operating a large natural gas, coal, or hydroelectric plant requires a deep understanding of thermodynamics, electrical theory, and complex machinery. BLS data confirms their median pay is near the six-figure mark, with significant overtime potential.

- Oil and Gas Plant Operators (Refineries, LNG Plants): Working in a refinery or a liquefied natural gas (LNG) facility is both complex and hazardous, leading to high compensation. These operators manage the process of converting raw materials into valuable fuels and can earn salaries comparable to or even exceeding those in traditional power plants, often in the $80,000 to $115,000 range.

- Chemical Plant Operators: The salary here varies based on the product being manufactured. An operator at a specialty pharmaceutical or complex polymer plant will earn significantly more than one at a bulk fertilizer plant. The median of around $69,000 reflects this wide range, with top earners in specialized facilities easily clearing $90,000+.

- Water/Wastewater Treatment Plant Operators: While absolutely essential for public health, these roles typically have the most modest salaries in the operator family. This is often because they are municipally funded, and the direct revenue generation is less obvious than in a power plant. However, they often come with exceptional job security and government benefits, including strong pensions. The path to a comfortable, stable middle-class career is very clear here.

###

2. Geographic Location

Where you work matters. Salaries for plant operators vary significantly by state and even by metropolitan area, driven by cost of living, local demand, and the presence of high-value industries.

According to BLS data for Power Plant Operators, the highest-paying states are often on the West Coast or in areas with high energy production costs or infrastructure.

Top-Paying States for Power Plant Operators (Annual Mean Wage, May 2022):

1. Washington: $119,770

2. California: $116,910

3. New Jersey: $111,940

4. Oregon: $110,610

5. Maryland: $109,790

Conversely, states with a lower cost of living and less dense industrial infrastructure tend to have lower average salaries. For example, some states in the Southeast and Midwest may have median salaries closer to the $70,000-$80,000 range. However, the purchasing power in these areas can still be very high. A plant operator earning $85,000 in a low-cost-of-living area may have a higher quality of life than one earning $110,000 in a very expensive coastal city.

###

3. Years of Experience and Career Progression

Experience is directly tied to salary growth. The journey from an apprentice to a lead operator is a structured path of increasing competence and compensation.

- Apprentice/Trainee (0-2 years): Focus is on learning safety protocols and basic system functions. Salary is lower but represents an investment in training.

- Junior Operator (2-5 years): Qualified on some systems, but not yet a control room expert. Salary sees a significant jump from the trainee level as they become a more productive team member.

- Control Room Operator (5-10 years): This is the benchmark role. Fully qualified and trusted to run the plant from the control room. This is where salaries reach and exceed the national median for the profession.

- Lead Operator / Shift Supervisor (10+ years): Manages an entire shift of operators. This is a leadership role with a commensurate salary increase. They are the ultimate authority on shift.

- Plant Management / Operations Superintendent (15+ years): Some operators leverage their deep technical knowledge to move into salaried management roles, overseeing the entire plant's operations. These roles can command salaries well into the $150,000+ range.

###

4. Education and Certifications

While a four-year degree is rarely required, specific education and certifications are powerful salary boosters.

- High School Diploma / GED: This is the minimum entry requirement.

- Associate's Degree: A two-year degree in Process Technology (PTEC), Power Plant Technology, or a related engineering technology field is highly valued. It provides a strong theoretical foundation that can lead to a higher starting salary and a faster promotion track. Many community colleges located near industrial centers offer excellent PTEC programs.

- Certifications: These are non-negotiable in many sectors and directly impact pay.

- NERC Certification: For power plant operators working on the bulk electric system, a certification from the North American Electric Reliability Corporation (NERC) is often mandatory. Achieving a credential like the Reliability Coordinator (RC) or Balancing, Interchange, and Transmission Operator (BITO) certification is a major career milestone and salary driver.

- State Water/Wastewater Licenses: Operators in this sector must obtain state-issued licenses, which are graded by class (e.g., Class I, II, III, IV or A, B, C, D). Each higher-level license requires more experience and passing a more difficult exam, and it directly unlocks eligibility for higher-paying, more responsible positions.

- Nuclear Regulatory Commission (NRC) License: As mentioned, obtaining an NRC Reactor Operator or Senior Reactor Operator license is the most intensive certification process and leads to the highest salaries in the field.

###

5. Company Type and Size

The type of entity that owns the plant also plays a role.

- Investor-Owned Utilities (IOUs): Large, publicly-traded utility companies (e.g., Duke Energy, NextEra Energy) are often the top-paying employers in the power sector. They have the revenue to support high salaries, bonuses, and extensive training programs.

- Municipal/Government-Owned Utilities: This includes city water departments, public utility districts (PUDs), and federal entities like the Tennessee Valley Authority (TVA). While their base salaries may sometimes be slightly lower than top IOUs, they are famous for offering exceptional job security and incredible government pension plans, making their total long-term compensation package extremely attractive.

- Private Industrial Companies: This covers chemical, manufacturing, and oil/gas companies. Salaries can be very high, especially in profitable sectors like pharmaceuticals or oil refining, and are often supplemented by significant performance bonuses and profit-sharing.

- Smaller Cooperatives: Rural electric cooperatives or smaller water districts may offer more modest salaries, but often provide a great work-life balance and a strong sense of community.

###

6. In-Demand Technical Skills

Beyond formal qualifications, specific hands-on skills can make an operator more valuable. Candidates who can demonstrate proficiency in these areas on their resumes are more competitive and can command higher pay.

- SCADA/DCS Proficiency: Deep knowledge of Supervisory Control and Data Acquisition (SCADA) or Distributed Control Systems (DCS) is fundamental. This is the software brain of the plant.

- Programmable Logic Controllers (PLCs): The ability to troubleshoot, if not program, PLCs is a highly valuable skill that bridges the gap between operations and maintenance.

- Mechanical and Electrical Aptitude: While not a mechanic or electrician, a strong understanding of how pumps, motors, valves, and circuits work is essential for effective troubleshooting.

- Troubleshooting and Analytical Skills: The ability to logically diagnose a problem based on system data is perhaps the most important day-to-day skill.

- Safety Protocols: Expertise in safety procedures like Lockout/Tagout (LOTO), confined space entry, and handling of hazardous materials is non-negotiable and highly valued.

Job Outlook and Career Growth for Plant Operators

When considering a long-term career, salary is only one part of the equation. Job security and the potential for advancement are equally important. The job outlook for plant operators is a nuanced story of decline in some areas, stability in others, and a massive wave of impending retirements creating significant opportunities.

### A Tale of Two Outlooks

The BLS projects different futures for different types of operators over the next decade (2022-2032):

- Power Plant Operators: The BLS projects a 6 percent decline in employment for this group. This sounds alarming, but it's crucial to understand the context. This decline is driven primarily by two factors:

1. Automation: Newer plants are more automated and require fewer operators to run.

2. Shifting Energy Mix: The closure of older coal-fired power plants will reduce the number of jobs in that specific sector.

However, this projection hides a critical opportunity. The BLS also notes that "despite declining employment, about 3,100 openings for power plant operators, distributors, and dispatchers are projected each year, on average, over the decade." Where do these openings come from? Retirements. A large portion of the current workforce is nearing retirement age, and these experienced operators will need to be replaced. This "great crew change" means that while the total number of jobs may shrink slightly, the number of available positions for qualified new entrants will remain steady and significant.

- Water and Wastewater Treatment Plant Operators: The outlook here is much more stable. The BLS projects employment to decline by 2 percent, but with about 10,600 openings projected each year, again, largely due to the need to replace workers who retire or leave the profession. The need for clean water and wastewater treatment is directly tied to population size and environmental regulations, both of which are not going away. This makes it one of the most stable "essential" careers available.

- Chemical Plant Operators: The BLS projects a 1 percent decline for this occupation. Much like the power sector, automation plays a role. However, the demand for manufactured chemicals remains strong, and the need for skilled operators to oversee these complex and potentially hazardous processes persists.

### Emerging Trends and Future Challenges

To thrive in the coming decades, operators must be aware of the trends shaping their industry:

- The Rise of Renewables: While some traditional power plant jobs may decline, new operator roles are emerging in renewable energy. This includes control center operators for large-scale solar farms and wind turbine fleets, as well as operators for battery storage facilities.

- Cybersecurity: As plants become more networked and automated, protecting control systems from cyber threats is a growing concern. Operators with an understanding of cybersecurity principles will be increasingly valuable.

- Data Analysis: Modern control systems generate vast amounts of data. Operators who can not only monitor this data but also help analyze it to identify trends, predict failures, and improve efficiency will have a competitive edge.

### How to Stay Relevant and Advance Your Career

The key to a long and prosperous career as a plant operator is a commitment to lifelong learning.

1. Embrace New Technology: Be the first to volunteer for training on new control systems or software.

2. Pursue Higher Certifications: Don't stop at the minimum required license.