You unbox your new smartphone. The satisfying pull of a tab, the perfect fit of the device in its molded tray, the minimalist design—it all feels effortless. Or consider the last package that arrived at your door; its contents perfectly intact despite a long journey. Behind this seemingly simple experience lies the complex, creative, and highly technical work of a packaging engineer. This is a field where science meets art, logistics meets marketing, and sustainability meets supply chain.

For professionals navigating the middle stages of their careers, the role of a packaging engineer offers a potent combination of stability, intellectual challenge, and significant financial reward. A mid-level packaging engineer in the United States can expect to earn a competitive salary, often ranging from $90,000 to $125,000 annually, with top earners in high-demand sectors and locations pushing that figure even higher. This guide is designed to be your definitive resource, unpacking every facet of this dynamic career.

As a career analyst who has guided countless professionals, I once worked with a client at a major food and beverage company. By re-engineering the secondary packaging for a single product line to be lighter and stack more efficiently, her team saved the company over $4 million in annual freight costs and removed the equivalent of 500 cars' worth of carbon emissions from the atmosphere. That’s the tangible, high-impact world of a packaging engineer—it’s not just about the box; it’s about the bottom line and the planet.

This article will provide a comprehensive look at the packaging engineer mid-level career salary in the USA, exploring the factors that drive compensation, the long-term career outlook, and a step-by-step guide to advancing in this essential field.

### Table of Contents

- [What Does a Mid-Level Packaging Engineer Do?](#what-does-a-mid-level-packaging-engineer-do)

- [Average Mid-Level Packaging Engineer Salary: A Deep Dive](#average-mid-level-packaging-engineer-salary-a-deep-dive)

- [Key Factors That Influence a Packaging Engineer's Salary](#key-factors-that-influence-a-packaging-engineers-salary)

- [Job Outlook and Career Growth for Packaging Engineers](#job-outlook-and-career-growth-for-packaging-engineers)

- [How to Become a Top-Earning Packaging Engineer](#how-to-become-a-top-earning-packaging-engineer)

- [Conclusion: Is a Career as a Packaging Engineer Right for You?](#conclusion-is-a-career-as-a-packaging-engineer-right-for-you)

---

What Does a Mid-Level Packaging Engineer Do?

While an entry-level engineer might focus on executing specific tasks like running lab tests or drafting basic specifications, a mid-level packaging engineer takes on significantly more responsibility, autonomy, and strategic input. They are the engine of the packaging development process, bridging the gap between junior execution and senior-level strategy. They own projects from concept to commercialization and are expected to navigate complex technical and business challenges independently.

The core of the role revolves around a central mission: to design, test, and implement packaging solutions that protect a product, delight the consumer, and meet business objectives for cost, efficiency, and sustainability. They are multi-disciplinary experts, blending principles from mechanical engineering, materials science, industrial design, and logistics.

Core Responsibilities of a Mid-Level Packaging Engineer:

- Project Management: Leading packaging development projects for new product launches or existing product renovations. This includes creating timelines, managing budgets, and coordinating with cross-functional teams (Marketing, R&D, Supply Chain, Procurement, Quality Assurance).

- Material Selection and Qualification: Researching, selecting, and testing packaging materials (e.g., polymers, paperboard, glass, aluminum, sustainable alternatives) to ensure they meet performance, cost, and regulatory requirements.

- Structural Design and Prototyping: Using Computer-Aided Design (CAD) software like ArtiosCAD or SolidWorks to create 2D and 3D structural designs. They oversee the creation of prototypes for testing and stakeholder review.

- Performance and Quality Testing: Designing and executing rigorous testing protocols to ensure packaging can withstand the hazards of the supply chain. This includes drop tests, vibration tests, compression tests, and climate conditioning, often following standards from organizations like ISTA (International Safe Transit Association).

- Supplier Collaboration: Working closely with packaging suppliers and contract manufacturers to source materials, troubleshoot production issues, conduct plant trials, and ensure quality control.

- Cost Analysis and Optimization: Continuously seeking opportunities to reduce packaging costs through material reduction (light-weighting), design efficiency, or process improvements without compromising quality or performance.

- Sustainability Initiatives: Playing a critical role in helping companies meet their sustainability goals by designing for recyclability, incorporating post-consumer recycled (PCR) content, and reducing the overall carbon footprint of packaging systems.

### A Day in the Life of a Mid-Level Packaging Engineer

To make this tangible, let's follow "Alex," a mid-level packaging engineer at a consumer electronics company.

- 8:30 AM: Alex starts the day reviewing overnight emails from a supplier in Asia regarding a new molded pulp tray. They're seeing minor cosmetic defects on the production line. Alex drafts a technical response with revised quality standards and schedules a video call for later in the evening to resolve it.

- 9:30 AM: Alex leads a project meeting for an upcoming headphone launch. The team includes members from Marketing, Industrial Design, and Logistics. Marketing wants a "premium unboxing experience," while Logistics is concerned about the package size increasing shipping costs. Alex presents three design concepts via a slideshow, detailing the pros and cons of each in terms of cost, user experience, and supply chain impact.

- 11:00 AM: Time to get hands-on. Alex heads to the packaging lab to conduct drop testing on a prototype for a new wireless speaker. Using a high-speed camera, Alex records the package's impact to analyze potential failure points, ensuring the product inside remains pristine.

- 1:00 PM: After lunch, Alex uses CAPE Pack software to run a pallet pattern analysis for the new headphone box. The goal is to maximize the number of units per pallet, a key factor in reducing shipping costs and carbon emissions. The software shows that a 5mm reduction in box depth could increase pallet efficiency by 8%.

- 2:30 PM: Alex connects with a polymer supplier to discuss a new type of film with 30% post-consumer recycled content. Alex requests material specifications and samples for upcoming qualification testing, aligning the project with the company's 2025 sustainability roadmap.

- 4:00 PM: Alex spends the last hour updating project documentation, including component specifications and cost-tracking spreadsheets. They prepare a summary report for their manager on the headphone project's progress, highlighting the potential cost savings from the pallet pattern optimization.

This example illustrates the dynamic nature of the role—a constant blend of technical analysis, creative problem-solving, and cross-functional collaboration.

---

Average Mid-Level Packaging Engineer Salary: A Deep Dive

The salary for a packaging engineer is not a single number but a spectrum influenced by a host of factors we'll explore in the next section. However, by aggregating data from authoritative sources, we can build a clear picture of the compensation landscape in the United States.

It is important to note that the U.S. Bureau of Labor Statistics (BLS) does not have a dedicated category for "Packaging Engineer." They are often classified under broader categories like "Industrial Engineers" or "Materials Engineers." While the BLS provides a solid baseline for engineering salaries in general, for role-specific data, we turn to reputable salary aggregators that collect real-world, self-reported data.

According to Salary.com, as of late 2023, the median salary for a Packaging Engineer II (representing a mid-level professional) in the United States is $92,670. The typical salary range falls between $85,027 and $103,277.

Payscale.com reports a similar average base salary for a Packaging Engineer at $79,891, but this figure aggregates all experience levels. When looking at their career path data, professionals with 5-9 years of experience (a key mid-level bracket) see a significant increase in earning potential, pushing well into the $90,000+ range.

Glassdoor, which incorporates user-submitted salary reports, shows the average total pay (base plus additional compensation) for a Packaging Engineer in the U.S. to be $103,554 per year, with a likely range between $84,000 and $129,000. This "total pay" figure is crucial as it begins to account for bonuses and other incentives.

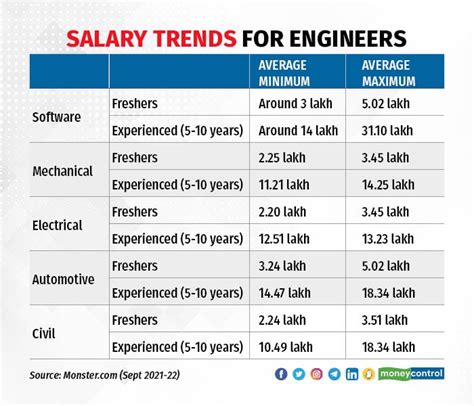

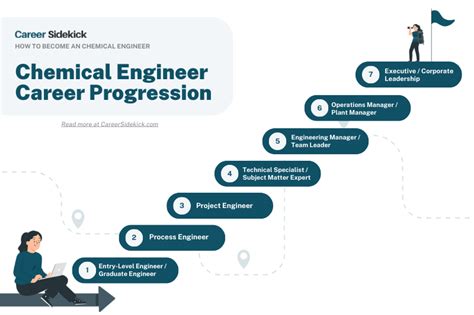

### Salary Progression by Experience Level

Salary growth in packaging engineering is strong and predictable. As engineers gain experience, master complex projects, and take on leadership responsibilities, their value—and compensation—rises accordingly.

Here is a typical salary progression, compiled from the sources above, reflecting base salary expectations in the U.S. market:

| Experience Level | Typical Years of Experience | Average Annual Base Salary Range | Key Responsibilities & Expectations |

| :--- | :--- | :--- | :--- |

| Entry-Level (Engineer I) | 0-2 years | $65,000 - $80,000 | Learning core skills, executing assigned tasks, running tests, drafting basic documents under supervision. |

| Mid-Level (Engineer II/III) | 3-8 years | $85,000 - $125,000 | Leading projects independently, managing suppliers, making technical decisions, mentoring junior engineers. |

| Senior / Principal Engineer| 8-15 years | $120,000 - $160,000+ | Subject matter expert, leading complex/high-impact projects, setting technical strategy, solving the toughest problems. |

| Packaging Manager / Director | 10+ years | $150,000 - $220,000+ | People management, budget ownership, departmental strategy, cross-functional leadership, reporting to VPs. |

*Note: These ranges are national averages and can be significantly higher in high-cost-of-living areas or specific high-paying industries.*

### Deconstructing Total Compensation

Base salary is only one piece of the puzzle. For a mid-level professional, the total compensation package is a critical part of their earnings.

- Annual Bonuses: This is the most common form of additional cash compensation. Bonuses are typically tied to a combination of individual performance (meeting project goals) and company performance (hitting revenue or profit targets). For a mid-level engineer, this can range from 5% to 15% of their base salary.

- Profit Sharing: More common in large, established consumer packaged goods (CPG) or manufacturing companies, profit-sharing plans distribute a portion of the company's profits to eligible employees. This can add another 3% to 10% to annual earnings.

- Stock Options / Restricted Stock Units (RSUs): In publicly traded companies, especially large tech or pharmaceutical firms, equity is a significant part of the compensation package. RSUs are grants of company stock that vest over time, providing a powerful long-term wealth-building tool.

- Benefits (The Hidden Salary): While not cash-in-hand, the value of a strong benefits package is immense. This includes:

- Health Insurance: Premium medical, dental, and vision plans. A good family plan can be worth over $20,000 per year.

- 401(k) Matching: Companies often match employee contributions up to a certain percentage (e.g., a 100% match on the first 6% of your salary). This is essentially free money for retirement.

- Paid Time Off (PTO): Generous vacation, sick leave, and holiday policies.

- Professional Development: A budget for attending conferences, workshops, and pursuing certifications like the Certified Packaging Professional (CPP).

When evaluating a job offer, a savvy mid-level engineer looks beyond the base salary and calculates the total value of the entire compensation and benefits package.

---

Key Factors That Influence a Packaging Engineer's Salary

A national average provides a useful benchmark, but your actual earning potential as a mid-level packaging engineer is determined by a unique combination of your background, skills, and where you choose to work. Understanding these levers is the key to maximizing your salary throughout your career. This section delves into the six most critical factors that dictate compensation.

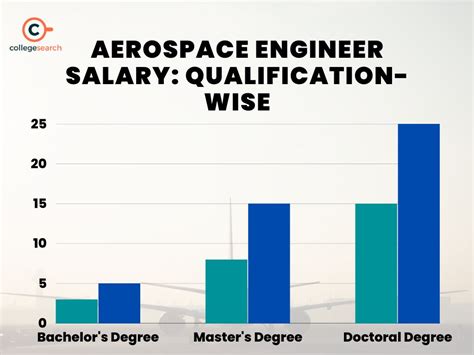

### 1. Level of Education and Certifications

Your educational foundation sets the initial floor for your salary, while advanced credentials can build a skyscraper on top of it.

- Bachelor's Degree: A Bachelor of Science is the standard entry requirement. The most direct path is a degree in Packaging Science from a specialized program like those at Michigan State University, Rochester Institute of Technology (RIT), Clemson University, or Cal Poly. These programs provide a tailored curriculum covering materials, processes, and design. However, degrees in Mechanical Engineering, Industrial Engineering, Chemical Engineering, or Materials Science are also highly valued and common in the field. There is generally minimal salary difference between these core engineering degrees at the mid-career level, as experience becomes the dominant factor.

- Master's Degree: Pursuing a Master of Science (M.S.) in Packaging or a related engineering field can provide a salary bump of 5% to 15%. An M.S. is particularly valuable for those wishing to specialize in highly technical R&D or materials science roles. An alternative and increasingly popular path is the Master of Business Administration (MBA). An engineer with an MBA is exceptionally well-positioned for leadership roles, as they can blend deep technical knowledge with financial acumen, strategic planning, and marketing insight. Engineers with an MBA who move into management can see salary increases of 20% or more.

- Professional Certifications: This is arguably the most impactful investment for a mid-level engineer. The premier credential in the industry is the Certified Packaging Professional (CPP), administered by the Institute of Packaging Professionals (IoPP). Earning the CPP designation demonstrates a broad, verified knowledge of the field and a commitment to professional excellence. According to IoPP's own salary survey, professionals holding the CPP designation earn, on average, 7% to 10% more than their non-certified peers. Other valuable certifications include a Project Management Professional (PMP) for those on a project management track, or a Lean Six Sigma Green or Black Belt for those focused on process optimization and manufacturing.

### 2. Years and Quality of Experience

Experience is the single most powerful driver of salary growth. At the mid-career stage (3-8 years), employers are not just looking for years on the job; they are evaluating the *quality* and *relevance* of that experience.

- Early Mid-Career (3-5 years): At this stage, you've moved beyond entry-level tasks and have likely managed smaller projects or significant workstreams within larger ones. You've proven your technical competence. Salaries typically fall in the $85,000 to $105,000 range. To advance, focus on taking ownership of a complete project from concept to launch.

- Peak Mid-Career (6-8 years): You are now a seasoned, independent engineer. You have a track record of successfully launched products and have likely navigated complex technical or supply chain challenges. You may have started mentoring junior engineers. This is where salaries push into the $100,000 to $125,000+ range. Your value is in your proven ability to deliver results with minimal supervision.

- Quality of Experience: Experience in a high-growth or highly regulated area is worth more. For example, three years of experience developing packaging for sterile medical devices is often valued more highly by employers in that sector than five years in a less-regulated CPG space. Similarly, experience leading a major sustainability initiative (e.g., transitioning a product line to 100% recycled materials) is a massive resume-builder and salary booster.

### 3. Geographic Location

Where you work has a dramatic impact on your paycheck. Salaries are closely tied to the cost of living and the concentration of industry in a particular region. A $100,000 salary in Greenville, South Carolina, provides a much different lifestyle than the same salary in San Jose, California.

Here's a look at how average mid-level packaging engineer salaries can vary across different U.S. metropolitan areas, based on data analysis from Salary.com and Glassdoor, adjusted for a mid-level role:

| Metropolitan Area | High/Medium/Low Cost of Living | Estimated Mid-Level Salary Range | Notes on Local Industry |

| :--- | :--- | :--- | :--- |

| San Jose, CA | Very High | $120,000 - $155,000+ | Tech, Consumer Electronics, Medical Devices |

| Boston, MA | Very High | $110,000 - $140,000+ | Biotech, Pharmaceuticals, Medical Devices |

| Chicago, IL | High | $95,000 - $125,000 | Food & Beverage, CPG, Medical Devices, Manufacturing |

| Minneapolis, MN | Medium-High | $90,000 - $120,000 | Medical Devices (Medical Alley), Food & Ag (General Mills, Cargill) |

| Atlanta, GA | Medium | $90,000 - $115,000 | CPG (Coca-Cola, Newell), Logistics Hub, Manufacturing |

| Cincinnati, OH | Medium | $88,000 - $110,000 | CPG giant Procter & Gamble (P&G) is a major employer |

| Grand Rapids, MI | Medium-Low | $85,000 - $105,000 | Strong manufacturing base, office furniture, proximity to packaging schools |

| Greenville, SC | Low | $80,000 - $100,000 | Major manufacturing hub (Michelin, BMW), CPG packaging plants |

Key Takeaway: The highest salaries are found in coastal tech and biotech hubs. However, the Midwest and Southeast offer strong salaries with a significantly lower cost of living, potentially increasing your real take-home buying power. The rise of remote and hybrid work is starting to flatten these differences slightly, but location remains a dominant factor for roles that require lab or manufacturing plant access.

### 4. Company Type, Size, and Industry

The context in which you work—the industry you serve and the size of your employer—creates distinct salary bands.

- Industry: This is a massive differentiator. The more complex, regulated, and profitable the industry, the higher the pay.

- Top Tier (Highest Paying): Pharmaceuticals, Biotechnology, and Medical Devices. These industries demand absolute precision, rigorous validation (IQ/OQ/PQ), and deep knowledge of FDA regulations and sterile packaging. The high stakes and high margins translate directly to higher salaries.

- Upper Tier: Consumer Electronics and Cosmetics. These fields compete on innovation and user experience. The "unboxing" experience is a key marketing tool, and engineers who can create premium, protective, and sustainable packaging for high-value goods are compensated accordingly.

- Middle Tier: Food & Beverage and Consumer Packaged Goods (CPG). These are the largest employers of packaging engineers. Salaries are very competitive, but the focus is often on high-volume, low-cost production and supply chain efficiency. Companies like P&G, PepsiCo, and Kraft Heinz are major players.

- Emerging Tier: E-commerce and Logistics. Companies like Amazon, Walmart, and third-party logistics (3PL) providers hire packaging engineers to optimize their entire fulfillment network. The focus is on damage reduction, dimensional weight (DIM) optimization, and developing frustration-free packaging.

- Company Size:

- Large Corporations (Fortune 500): These companies (e.g., Johnson & Johnson, Apple, Amazon, Procter & Gamble) typically offer the highest base salaries, structured bonus programs, excellent benefits, and stock options. The work is often more specialized.

- Startups and Small Companies: Base salaries may be slightly lower than at large corporations, but this can be offset by significant equity/stock options, which carry high risk but high potential reward. The roles are often broader, offering a chance to wear many hats and gain experience quickly.

- Packaging Suppliers: Working for a company that *makes* the packaging (e.g., WestRock, Berry Global, Amcor) offers a different experience. You might work in a customer-facing application development role, helping many different clients solve their packaging problems. Salaries are competitive and often include sales-based commissions or bonuses.

### 5. Area of Specialization

Within the field of packaging engineering, developing a deep expertise in a specific area can make you a highly sought-after—and highly paid—asset.

- Sustainability: This is currently the most in-demand specialization. Engineers who are experts in life cycle assessment (LCA), circular economy principles, biopolymers, chemical recycling, and navigating the complex landscape of local and global recycling regulations can command premium salaries.

- Packaging Automation and Machinery: These engineers work on the interface between the package and the machinery that fills, seals, and handles it. They are experts in specifying, installing, and qualifying high-speed packaging lines. This skill set is critical for improving efficiency and reducing labor costs, making it highly valuable.

- Supply Chain and Logistics Optimization: This specialization focuses on the "unseen" part of the package's journey. These engineers use software like CAPE or TOPS to optimize palletization, container loading, and reduce shipping costs by minimizing dimensional weight. In the age of e-commerce, this expertise is worth its weight in gold.

- Materials Science: The materials expert focuses on developing or qualifying novel packaging materials. This could involve anything from advanced barrier films for food preservation to new cushioning foams made from mycelium. This is a deeply technical, R&D-focused path.

### 6. In-Demand Skills (Technical and Soft)

Finally, your specific skill set can add thousands to your salary. A mid-level engineer who has cultivated a blend of advanced technical and polished soft skills is the ideal candidate.

- High-Value Technical Skills:

- CAD Software Proficiency: Mastery of industry-standard software like ArtiosCAD for structural design, and SolidWorks or AutoCAD for 3D modeling and integration.

- Palletization Software: Expertise in CAPE Pack or TOPS Pro to design efficient shipping patterns.

- Finite Element Analysis (FEA): The ability to use simulation software to predict how a package will perform under stress, reducing the need for physical prototypes.

- Regulatory Knowledge: Deep understanding of relevant standards from the FDA (food contact, pharmaceuticals), EPA (environmental claims), ISTA (transit testing), and ASTM (materials testing).

- High-Value Soft Skills:

- Project Management: The ability to lead a project from start to finish, on time and on budget. PMP certification is a huge plus.

- Cross-Functional Communication: The ability to clearly articulate complex technical concepts to non-technical stakeholders in Marketing, Sales, and Finance.

- Supplier Negotiation and Management: The skill to build strong relationships with suppliers and negotiate favorable costs and terms.

- Data Analysis and Storytelling: The ability to take test data, cost information, and market trends and weave them into a compelling business case for a recommended packaging change.

By strategically developing these six areas, a mid-level packaging engineer can move from the average salary bracket to the top percentile of earners in their field.

---

Job Outlook and Career Growth for Packaging Engineers

Choosing a career path requires not only understanding the current salary but also the long-term potential for growth and stability. For packaging engineers, the future is exceptionally bright, driven by powerful global trends that place their skills at the center of modern commerce and industry.

### Job Growth Projections

As mentioned, the U.S. Bureau of Labor Statistics (BLS) doesn't track packaging engineers as a distinct profession. However, we can look at closely related fields to establish a strong directional forecast. The BLS projects that employment for Industrial Engineers, a category that includes many packaging functions related to process efficiency and manufacturing, is expected to grow by 12 percent from 2022 to 2032. This is much faster than the average for all occupations. Similarly, Materials Engineers are projected to see steady growth.

Industry-specific data and anecdotal evidence suggest the outlook for packaging engineers is even more robust. The primary drivers of this high demand are:

1. The E-commerce Boom: The massive shift to online shopping has created an insatiable demand for packaging that is both protective and efficient. Every product sold online needs to be shipped, and packaging engineers are the ones who design the systems to do it without damage. They are on the front lines of solving the "last mile" delivery challenge, optimizing boxes for fulfillment centers, and creating frustration-free opening experiences for consumers. This trend shows no sign of slowing down.

2. The Sustainability Imperative: This is the single biggest transformation in the packaging industry in a generation. Consumers, regulators, and investors are all demanding that companies reduce their environmental impact. Packaging engineers are at the heart of this movement, tasked with:

- Replacing problematic plastics with recyclable or compostable alternatives.

- Increasing the use of post-consumer recycled (PCR) content.

- "Light-weighting" packages to use less material and reduce transport emissions.

- Designing for a circular economy where packaging can be