In a world dominated by e-commerce, intricate supply chains, and the powerful "unboxing experience," a silent yet indispensable professional stands at the intersection of design, engineering, and marketing: the Packaging Engineer. If you're a detail-oriented problem-solver with a knack for both science and creativity, this career doesn't just offer a stable and engaging profession—it provides a significant and rewarding financial path. But what does that path truly look like, especially once you've moved past the entry-level phase? What is the real earning potential of a packaging engineer mid-level career salary?

This guide is designed to be your definitive resource. We will move beyond simple salary averages and dive deep into the nuanced factors that shape your income, from your specific industry and location to the high-value skills that can add thousands to your annual compensation. The national average for a mid-level Packaging Engineer hovers impressively between $90,000 and $115,000 per year, but as you'll soon discover, this is merely a starting point.

I'll never forget the first time I truly appreciated the genius of packaging engineering. It wasn't a sleek Apple product box, but a simple, frustration-free package for a child's toy. The clever perforations, the lack of plastic-welded shells, and the intuitive design that allowed it to be opened without tools was a small moment of manufactured delight, a testament to an engineer who deeply understood the end-user's journey. This is the tangible impact you can have in this field—blending physics, material science, and human empathy into the physical objects that millions of people interact with every single day.

Whether you're an aspiring student, an early-career professional planning your next move, or a seasoned engineer looking to maximize your earnings, this in-depth analysis will provide the data, insights, and actionable advice you need to build a prosperous and fulfilling career.

### Table of Contents

- [What Does a Packaging Engineer Do?](#what-does-a-packaging-engineer-do)

- [Average Packaging Engineer Salary: A Deep Dive](#average-packaging-engineer-salary-a-deep-dive)

- [Key Factors That Influence Your Salary](#key-factors-that-influence-your-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Become a Packaging Engineer](#how-to-become-a-packaging-engineer)

- [Conclusion: Is a Career in Packaging Engineering Right for You?](#conclusion-is-a-career-in-packaging-engineering-right-for-you)

What Does a Packaging Engineer Do?

At its core, a Packaging Engineer is a multidisciplinary problem-solver responsible for designing, developing, and testing packaging for a vast range of products. They are the masterminds ensuring that a product—be it a fragile vial of life-saving medicine, a complex electronic device, a bag of potato chips, or a luxury cosmetic—survives the journey from the factory to the consumer's hands safely, efficiently, and cost-effectively.

Their work is a delicate balance of science, art, and business acumen. They must consider:

- Product Protection: The primary function. The package must protect the contents from shock, vibration, temperature changes, moisture, and contamination.

- Material Science: Selecting the right materials—from corrugated cardboard and molded pulp to advanced polymers, glass, and aluminum—based on performance, cost, and sustainability goals.

- Logistics & Supply Chain: How will the packaged product be stacked on a pallet? How will it fit in a truck or shipping container? The design must optimize for space and transportation efficiency to reduce costs.

- Cost-Effectiveness: Developing solutions that meet all performance requirements without being prohibitively expensive. This involves constant negotiation between material costs, manufacturing processes, and shipping expenses.

- Regulatory Compliance: Ensuring packaging meets industry-specific standards, such as FDA regulations for food and drug packaging, or ISTA (International Safe Transit Association) standards for shipping.

- Sustainability: A rapidly growing area of focus. Engineers are challenged to reduce waste, use recycled or renewable materials, and design for recyclability or compostability.

- Brand Experience: Collaborating with marketing and design teams to create packaging that is aesthetically pleasing, easy for the consumer to open ("the unboxing experience"), and reinforces the brand's image.

### A Day in the Life of a Mid-Level Packaging Engineer

Imagine you're a mid-level Packaging Engineer at a large consumer-packaged goods (CPG) company. Your day might look something like this:

- 9:00 AM - 9:30 AM: Start the day by checking emails and responding to urgent queries from the manufacturing plant in another state. They're having a minor issue with a sealing machine on a new snack bag line you helped develop. You provide some initial troubleshooting advice and schedule a call with the machine vendor.

- 9:30 AM - 11:00 AM: You head to the R&D lab for a drop test. You're working on a new e-commerce shipper for a glass jar of pasta sauce. Using high-speed cameras, you and a lab technician conduct a series of controlled drops from various heights and angles to simulate the harsh realities of the shipping environment. You analyze the footage and the post-test package to see if your new molded pulp insert prevented breakage.

- 11:00 AM - 12:00 PM: Project meeting with the marketing team for a new line of organic soaps. They present their vision for an "earthy, premium" look. You provide initial feedback on material possibilities—perhaps a textured, uncoated paperboard with soy-based inks—and caution them that certain delicate designs might not hold up well during transport without a protective overwrap, which could conflict with their plastic-free goals. You agree to create three different structural prototypes for review next week.

- 12:00 PM - 1:00 PM: Lunch with a mentor from the senior engineering team.

- 1:00 PM - 3:00 PM: "Desk time." You use CAD software (like ArtiosCAD or SolidWorks) to refine the structural designs for the soap project. You also work on updating the specification documents for the pasta sauce shipper, detailing the exact material composition, dimensions, and assembly instructions for the supplier.

- 3:00 PM - 4:00 PM: Call with a plastics supplier to discuss a new type of post-consumer recycled (PCR) resin. You grill them on its technical properties, food-contact safety certifications, and cost per pound. You request samples to run your own internal validation tests.

- 4:00 PM - 5:00 PM: You finalize a report summarizing the drop test results from this morning, complete with data analysis and recommendations for minor design tweaks. You send it to your project manager and the quality assurance team, outlining the next steps for a full transportation simulation test.

This role is far from monotonous. It's a dynamic mix of hands-on testing, computer-based design, and cross-functional collaboration.

Average Packaging Engineer Salary: A Deep Dive

Now, let's get to the numbers. The salary for a Packaging Engineer is highly competitive and reflects the critical nature of the role. It scales significantly with experience, specialization, and location. We've compiled data from several authoritative sources to provide a comprehensive picture of your earning potential.

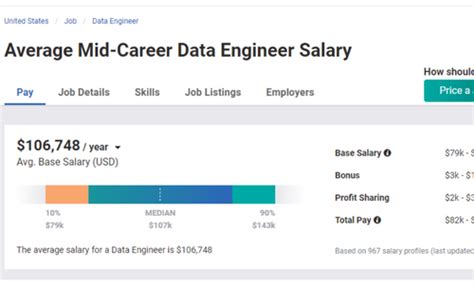

According to Salary.com (as of late 2023/early 2024), the median annual salary for a mid-level Packaging Engineer (classified as a Packaging Engineer II) in the United States is $94,013. However, the typical range for this experience level falls between $87,833 and $108,183.

Data from other top aggregators paints a similar, and sometimes even more optimistic, picture:

- Payscale.com reports an average base salary for a Packaging Engineer at $78,579, but notes that this average includes all experience levels. Their data shows a range from $59k at the 10th percentile (likely entry-level) to $114k at the 90th percentile (senior/lead roles).

- Glassdoor.com, which aggregates user-submitted data, shows an average total pay of $104,547 for Packaging Engineers in the US, with a base salary average of around $90,750 and additional pay (bonuses, profit sharing) making up the rest.

The key takeaway is that once you reach the mid-career stage (typically 3-7 years of experience), your base salary is very likely to be in the $90,000 to $115,000 range, with top performers in high-demand areas exceeding this.

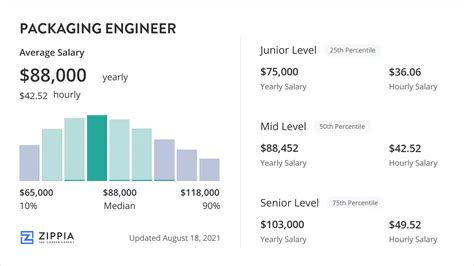

### Salary Progression by Experience Level

Your salary as a Packaging Engineer is not static; it's a journey. As you accumulate skills, lead more complex projects, and take on greater responsibility, your compensation will grow accordingly. Here is a typical salary progression, synthesized from data provided by Salary.com, which helpfully breaks down the role into distinct levels.

| Experience Level | Typical Years of Experience | Job Title Equivalent | Typical Salary Range (Base) | Key Responsibilities & Skills |

| :--- | :--- | :--- | :--- | :--- |

| Entry-Level | 0-2 Years | Packaging Engineer I | $70,000 - $85,000 | Assists on projects, runs standard tests, creates basic specs, learns CAD software and company processes. |

| Mid-Level | 3-7 Years | Packaging Engineer II | $88,000 - $115,000 | Manages small to medium projects independently, develops novel packaging solutions, works with suppliers, presents to cross-functional teams. |

| Senior-Level | 8-15 Years | Packaging Engineer III / Senior Packaging Engineer | $110,000 - $140,000+ | Leads large, complex projects, mentors junior engineers, develops strategic initiatives (e.g., sustainability roadmaps), manages key supplier relationships, has deep technical expertise. |

| Lead/Principal/Manager | 15+ Years | Principal Packaging Engineer / Packaging Engineering Manager | $135,000 - $180,000+ | Sets departmental strategy, manages a team of engineers, controls budgets, drives major innovation, interfaces with senior leadership. |

*(Source: Data compiled and synthesized from Salary.com, Glassdoor, and Payscale, reflecting typical corporate structures. Ranges can vary significantly based on the factors discussed in the next section.)*

### Beyond the Base Salary: Understanding Total Compensation

Your salary is just one piece of the puzzle. Total compensation is a more accurate measure of your financial earnings. For a mid-level Packaging Engineer, this often includes:

- Annual Bonus: This is extremely common, especially in large corporations. Bonuses are typically tied to a combination of company performance, team goals, and individual performance. A bonus can range from 5% to 15% of your base salary. For a mid-level engineer earning $100,000, this could mean an extra $5,000 to $15,000 per year.

- Profit Sharing / Stock Options: Some companies, particularly publicly traded ones or successful startups, offer profit sharing or stock options/Restricted Stock Units (RSUs). This can significantly increase your total compensation over the long term and aligns your financial success with the company's.

- Comprehensive Benefits: Don't underestimate the value of a strong benefits package. This includes:

- Health Insurance: Medical, dental, and vision coverage. A premium plan can be worth over $10,000-$20,000 in value per year.

- Retirement Savings: A 401(k) or 403(b) plan with a company match is essentially free money. A common match is 50% of your contribution up to 6% of your salary.

- Paid Time Off (PTO): A generous vacation, holiday, and sick leave policy.

- Professional Development: Many companies will pay for certifications (like the CPP), conference attendance, and further education, which is a direct investment in your future earning potential.

When evaluating a job offer, always look at the total compensation package, not just the base salary figure. An offer with a $98,000 base salary and a 10% target bonus is better financially than a flat $105,000 salary with no bonus potential.

Key Factors That Influence Your Salary

Why does one mid-level Packaging Engineer earn $92,000 while another with similar experience earns $118,000? The answer lies in a combination of factors that create a complex and varied salary landscape. Mastering these variables is the key to maximizing your income.

### ### Level of Education

Your educational foundation sets the initial floor for your career.

- Bachelor's Degree (The Standard): The vast majority of Packaging Engineers hold a bachelor's degree. The most direct path is a B.S. in Packaging Science from a specialized program like those at Michigan State University, Rochester Institute of Technology (RIT), or Clemson. Graduates from these programs are highly sought after and often command top-tier entry-level salaries. Degrees in related fields like Mechanical Engineering, Industrial Engineering, or Materials Science are also very common and well-regarded gateways into the profession.

- Master's Degree (The Accelerator): While not required for most roles, a Master of Science (M.S.) in Packaging or a related engineering field can provide a significant advantage. It can lead to a higher starting salary (often $5,000-$10,000 more) and can fast-track you into more specialized R&D or leadership roles. An MBA, combined with an engineering undergrad, is a powerful combination for those aiming for senior management, as it blends technical knowledge with business strategy.

- Certifications (The Differentiator): For mid-level professionals, certifications are a powerful tool to validate expertise and boost earning potential. The most recognized certification is the Certified Packaging Professional (CPP) from the Institute of Packaging Professionals (IoPP). Earning your CPP designation demonstrates a broad and deep understanding of the field and is often a preferred qualification for senior and leadership roles. Many employers will financially support or even require this certification for advancement, and it can be a key bargaining chip during salary negotiations.

### ### Years of Experience

As shown in the salary progression table, experience is arguably the single biggest driver of salary growth. But it's not just about the number of years; it's about the *quality* of that experience.

- Early Career (0-2 years): Focus is on learning the fundamentals, supporting senior engineers, and mastering core skills like CAD and spec writing.

- Mid-Career (3-7 years): This is the sweet spot we're focused on. At this stage, you're expected to work with increasing autonomy. Your value (and salary) grows as you demonstrate the ability to:

- Lead your own projects from concept to launch.

- Manage budgets and timelines effectively.

- Solve complex, non-standard packaging problems.

- Communicate effectively with non-technical stakeholders (like marketing and sales).

- Begin mentoring interns or junior engineers.

- Senior/Lead (8+ years): At this level, your value shifts from just project execution to strategy. You are paid more for your ability to influence the business through innovation, cost-savings initiatives, and technical leadership. An engineer who saves the company $2 million a year by redesigning a shipper for a high-volume product line has a clear and quantifiable impact that directly justifies a higher salary.

### ### Geographic Location

Where you work matters—a lot. Salaries for Packaging Engineers can vary by as much as 25-30% based on the cost of living and the concentration of relevant industries in a particular region.

Top-Paying States and Metropolitan Areas:

These areas typically have a high cost of living but also a high concentration of tech, biotech, pharmaceutical, or major CPG headquarters, driving up demand and wages.

- California: Particularly the San Francisco Bay Area (tech hardware, medical devices) and Southern California (CPG, entertainment). A mid-level engineer here could easily command $110,000 - $130,000+.

- Massachusetts: Centered around Boston and its suburbs, a major hub for biotechnology, pharmaceuticals, and medical devices. Salaries here are very competitive with California.

- Washington: The Seattle area, home to giants like Amazon and Microsoft, has a huge demand for engineers skilled in e-commerce and consumer electronics packaging.

- New Jersey / New York Metro Area: The "pharma corridor" of New Jersey and the CPG headquarters in the greater NYC area create a dense, high-paying market.

- Illinois: The Chicago metropolitan area is a massive hub for CPG companies (Kraft Heinz, Mondelez), food processing, and industrial manufacturing.

Average-Paying States:

These states offer a good balance of solid salaries and a more moderate cost of living. Think of major manufacturing hubs in the Midwest and Southeast.

- Michigan: Home to MSU's renowned packaging school and a strong manufacturing base.

- Ohio & Pennsylvania: Strong presence of CPG, industrial goods, and food manufacturing.

- Texas: Major hubs like Dallas and Houston have a growing number of corporate HQs and logistics centers.

- North Carolina: The Research Triangle Park area is a hotspot for life sciences and technology.

When considering a move, always use a cost-of-living calculator to compare a salary offer in a new city to your current location. A $115,000 salary in San Jose, CA is not the same as $115,000 in Grand Rapids, MI.

### ### Company Type & Size

The type of company you work for dramatically influences your role, work environment, and compensation.

- Large Corporations (e.g., Procter & Gamble, Johnson & Johnson, Apple, Amazon): These companies typically offer the highest base salaries, most robust benefits packages, and structured bonus programs. They provide clear career ladders, ample resources, and the chance to work on high-impact, global products. The work can be more specialized and sometimes more bureaucratic.

- Mid-Sized Companies: These can offer a great blend of stability and agility. Salaries are competitive, and you may have more visibility and a broader range of responsibilities than at a giant corporation.

- Startups: Base salaries may be lower than at large corporations. However, this is often offset by significant equity or stock options, which could lead to a massive financial windfall if the company is successful. The work is fast-paced, you'll wear many hats, and you'll have a huge influence on the product.

- Packaging Suppliers (e.g., WestRock, Berry Global): Working for a company that *makes* the packaging (as opposed to the company that buys it) offers a different experience. You might work in a customer-facing applications engineering role, helping many different clients solve their packaging challenges. Salaries are solid and often include sales-based commissions or bonuses.

- Consulting / Testing Labs: Working for a third-party consultancy or an ISTA-certified testing lab provides variety. You'll work on projects for a wide array of industries. Compensation can be very high, especially for experienced consultants, but may require more travel.

### ### Area of Specialization

Within packaging engineering, specializing in a high-demand or highly regulated niche can significantly increase your value.

- Pharmaceutical & Medical Device Packaging: This is one of the highest-paying specializations. The stakes are incredibly high—the packaging must maintain sterility, protect fragile and expensive products, and comply with stringent FDA and international regulations. Engineers with expertise in sterile barrier systems, validation (IQ/OQ/PQ), and materials like Tyvek and medical-grade polymers are in constant demand and command premium salaries.

- Sustainable Packaging: With intense corporate and consumer pressure to reduce environmental impact, this is the fastest-growing specialization. Engineers who are experts in life cycle analysis (LCA), compostable materials, PCR content, fiber-based solutions, and designing for the circular economy are highly sought after. This skill set is no longer a "nice-to-have"; it's a core strategic need for most companies.

- E-commerce & Logistics Packaging: The explosion of online shopping has created massive demand for engineers who can design packaging that survives the brutal "last mile" of single-parcel shipping. Expertise in ISTA testing protocols (especially 6-Amazon), cost-optimization for shipping rates (dimensional weight), and frustration-free design is a huge asset.

- Food & Beverage Packaging: A classic and stable field. Specialization in areas like aseptic packaging, modified atmosphere packaging (MAP) to extend shelf life, or high-speed bottling/canning line efficiency can make you a valuable asset.

- Packaging Machinery & Automation: This is a more systems-focused role. These engineers don't just design the package; they design or specify the machinery that will form, fill, seal, and palletize it. Expertise in robotics, automation, and optimizing manufacturing line efficiency is a highly technical and well-compensated skill set.

### ### In-Demand Skills

Beyond your degree and specialization, specific technical and soft skills can make you a more effective engineer and a more attractive candidate for a raise or a new job.

High-Value Hard Skills:

- CAD Software: Proficiency is non-negotiable. ArtiosCAD is the industry standard for 2D/3D structural design of paperboard and corrugated. SolidWorks or AutoCAD are critical for designing plastic components, assemblies, and pallet patterns.

- Testing & Validation: Deep knowledge of ISTA and ASTM testing standards. The ability to not just run tests, but to design test plans, interpret results, and write formal validation reports.

- Materials Science: A deep understanding of the properties, costs, and manufacturing processes for a wide range of materials (polymers, paper, glass, metals).

- Project Management Software: Experience with tools like Jira, Asana, or Microsoft Project to manage complex timelines and deliverables.

- Data Analysis: Using tools like Excel or Minitab to analyze test data, perform statistical analysis, and make data-driven decisions.

Essential Soft Skills:

- Cross-Functional Communication: The ability to explain complex technical concepts to non-technical audiences like marketing, sales, and senior leadership.

- Project Management: Owning a project from start to finish, managing stakeholders, budgets, and timelines.

- Negotiation: Working with suppliers to get the best prices and terms for materials and tooling.

- Problem-Solving: A creative and analytical approach to overcoming unexpected challenges in design, manufacturing, or shipping.

- Business Acumen: Understanding how your packaging decisions impact the company's bottom line, from material costs to shipping fees and even sales lift from a better consumer experience.

Job Outlook and Career Growth

The future for Packaging Engineers is bright and stable. While the U.S. Bureau of Labor Statistics (BLS) does not have a dedicated category for "Packaging Engineers," they are often classified under related and larger professions like Industrial Engineers or Materials Engineers.

The BLS projects that employment for Industrial Engineers will grow by 12 percent from 2022 to 2032, which is much faster than the average for all occupations. They state, "The work of industrial engineers, in finding ways to reduce costs and increase efficiencies, is a key part of business competition." This directly mirrors the core function of a packaging engineer, who constantly works to optimize materials, reduce shipping costs, and improve manufacturing line efficiency. This strong projected growth indicates a healthy and expanding job market for the foreseeable future.

### Emerging Trends Shaping the Future of Packaging Engineering

The profession is not static. To remain relevant and continue to advance, mid-level engineers must stay ahead of the curve on several key trends that are transforming the industry:

1. The Sustainability Imperative: This is the single biggest force in packaging today. The focus is shifting from simply "reducing" to creating a fully circular economy. This includes:

- Designing for Recyclability: Creating mono-material packaging that can be easily sorted and processed by modern recycling facilities.

- Advanced Materials: The rise of compostable bioplastics, molded fiber alternatives to plastic, and chemically recycled polymers.

- Lightweighting: Aggressively reducing the amount of material used without compromising performance.

- Life Cycle Analysis (LCA): Using software to model the total environmental impact of a package, from raw material extraction to end-of-life.

2. The E-commerce Revolution: As more goods are shipped directly to consumers, the demands on packaging increase. Engineers must design for the "unboxing experience" while simultaneously protecting the product from the chaotic single-parcel shipping environment. This means more rigorous testing and a focus on right-sized, frustration-free designs.

3. Smart and Active Packaging: Technology is being integrated directly into packaging. This includes:

- Active Packaging: Components that actively help preserve the product, such as oxygen scavengers or moisture absorbers in food packaging.

- Smart/Connected Packaging: Using QR codes, NFC chips, or printed electronics to provide consumers with more information, verify authenticity, or track a package through the supply chain.

4. Digitalization and "Industry 4.0": The design and testing process is becoming more digital. This involves:

- Simulation Software: Using advanced software to simulate drop tests, compression strength, and vibration analysis, reducing the need for costly and time-consuming physical prototypes.

- 3D Printing: Rapidly creating prototypes of plastic components or even structural inserts for quick evaluation.

- Digital Specification Management: Using cloud-based systems to manage and share thousands of packaging specifications globally in real-time.

### How to Stay Relevant and Advance

For a mid-level professional, proactive career management is key to unlocking senior-level roles and compensation.

- Become the Sustainability Expert: Volunteer to lead a sustainability project. Take online courses on LCA or circular economy principles. Become the go-to person on your team for questions about recyclable materials.

- Embrace a New Specialization: If you work in CPG, seek out a project that involves e-commerce shipping to broaden your skill set. If you're in industrial goods, learn about the unique requirements of medical device packaging.

- Lead a Project: Don't just contribute—ask to lead. Take ownership of the budget, timeline, and communication with stakeholders. This is the most direct path to demonstrating your readiness for a senior role.

- **