---

Table of Contents

- [What Does a Welding Inspector Do?](#what-does-a-welding-inspector-do)

- [Average Welding Inspector Salary: A Deep Dive](#average-welding-inspector-salary-a-deep-dive)

- [Key Factors That Influence a Welding Inspector's Salary](#key-factors-that-influence-a-welding-inspectors-salary)

- [Job Outlook and Career Growth for Welding Inspectors](#job-outlook-and-career-growth-for-welding-inspectors)

- [How to Become a Welding Inspector: Your Step-by-Step Guide](#how-to-become-a-welding-inspector-your-step-by-step-guide)

- [Conclusion: Is a Career as a Welding Inspector Right for You?](#conclusion-is-a-career-as-a-welding-inspector-right-for-you)

---

Have you ever looked at a towering skyscraper, a massive bridge spanning a river, or a complex network of pipelines and wondered about the hidden forces holding it all together? The answer, in many cases, is the humble weld. But a weld is only as strong as its quality, and ensuring that quality is the critical responsibility of a Welding Inspector. This is a career not just of technical skill, but of profound trust and responsibility, safeguarding lives and billion-dollar assets. If you're searching for a profession that combines hands-on work with deep technical knowledge and offers significant financial rewards, understanding the salary for a welding inspector is your first step.

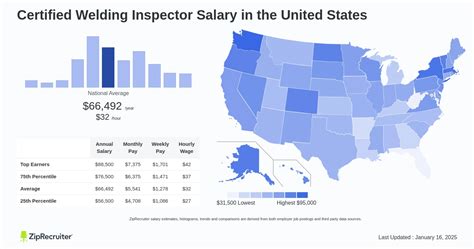

The financial potential in this field is substantial. While entry-level positions offer a solid starting wage, a Certified Welding Inspector (CWI) can expect a national average salary in the range of $65,000 to $85,000 per year. With specialized skills and experience, top-tier inspectors in high-demand sectors can easily command salaries well over $120,000, and sometimes approaching $200,000 with overtime and specialized contracts.

I remember standing on a partially completed overpass project years ago, watching a CWI meticulously work her way along a massive steel girder. With her gauges, mirrors, and deep knowledge of metallurgy and codes, she was the final arbiter of safety, the person whose signature meant this structure was sound enough for thousands of vehicles to cross it daily. It was a powerful reminder that this isn't just a job; it's a vital role in the fabric of our modern world.

This guide is designed to be your definitive resource for a career as a Welding Inspector. We will delve deep into salary data, explore the factors that drive compensation, analyze the long-term job outlook, and provide a clear, actionable roadmap for you to start your journey.

What Does a Welding Inspector Do?

At its core, a Welding Inspector is a quality assurance professional. They are the expert guardians who ensure that welds on everything from structural steel beams and high-pressure pipelines to aerospace components and nuclear reactors are performed correctly and meet stringent safety and quality standards. Their work is a blend of scientific analysis, technical expertise, and meticulous documentation.

The responsibilities go far beyond simply looking at a finished weld. A comprehensive inspection process involves activities before, during, and after the welding takes place.

Core Roles and Responsibilities:

- Code and Blueprint Interpretation: Before a single arc is struck, the inspector must thoroughly understand the project's blueprints, specifications, and the governing codes and standards (e.g., AWS D1.1 for structural steel, API 1104 for pipelines, or ASME Section IX for boilers and pressure vessels). They ensure that the planned welding procedures are appropriate for the materials and application.

- Procedure and Welder Qualification: Inspectors verify that the Welding Procedure Specification (WPS) is correct and has been properly qualified. They also conduct or witness welder performance qualification tests to ensure that the individuals performing the work have the necessary skill to produce a sound weld according to that procedure.

- In-Process Inspection: This is a critical and active part of the job. The inspector monitors the welding as it happens, checking for correct parameters like voltage and amperage, proper preheat and interpass temperatures, correct use of filler metals, and appropriate travel speed and technique.

- Visual Inspection (VT): The most common task is the visual examination of finished welds. Using tools like flashlights, magnifying glasses, and specialized gauges (fillet weld gauges, undercut gauges), the inspector looks for surface-level discontinuities such as cracks, porosity, undercut, overlap, and incorrect weld size or profile.

- Nondestructive Testing (NDT): Welding inspectors are often trained and certified in various NDT methods to find defects that aren't visible on the surface. These methods can include:

- Magnetic Particle Testing (MT): For detecting surface and near-surface flaws in ferromagnetic materials.

- Liquid Penetrant Testing (PT): For finding surface-breaking defects in non-porous materials.

- Ultrasonic Testing (UT): Using sound waves to detect internal flaws.

- Radiographic Testing (RT): Using X-rays or gamma rays to create an image of the weld's internal structure.

- Documentation and Reporting: Meticulous record-keeping is non-negotiable. The inspector prepares detailed reports documenting their findings, including which welds were inspected, the results, any defects found, and the corrective actions taken. These reports become permanent legal and quality records for the project.

### A Day in the Life of a Welding Inspector

To make this tangible, let's imagine a "day in the life" of a Certified Welding Inspector named David, working on a new power plant construction project.

- 7:00 AM: David arrives at the site office. He starts his day by reviewing the "weld map" and the schedule for the day, identifying the critical high-pressure steam pipe welds that need to be inspected. He reviews the relevant WPS and the Welder Qualification Test Records (WQTRs) for the welders assigned to those joints.

- 8:30 AM: He heads out to the field. His first stop is to check the material storage area. He verifies that the correct filler metals (welding rods) are being used, that they have been stored properly to prevent moisture contamination, and that material traceability records are in order.

- 9:30 AM: David observes a welder performing a root pass on a critical pipe joint. He checks the preheat temperature with a digital thermometer, confirms the welder is using the parameters specified in the WPS, and ensures the root gap and fit-up are within tolerance.

- 11:00 AM: He moves to an area where several welds were completed the previous day. He performs a thorough visual inspection on each, measuring the weld reinforcement and checking for any surface defects. He marks two welds that require minor cosmetic grinding and one that shows signs of undercut, which will need to be re-inspected after repair.

- 1:00 PM: After lunch, David meets with the NDT crew. They are scheduled to perform Ultrasonic Testing (UT) on a series of welds he visually accepted yesterday. He observes their calibration process and reviews their preliminary findings, cross-referencing their report with his own visual inspection records.

- 3:00 PM: Back in the site office, David spends the final part of his day on documentation. He meticulously fills out his daily inspection report, detailing every weld he inspected, the results (accept/reject), any non-conformance reports (NCRs) he had to issue, and the status of previously identified issues. This report is then submitted to the Quality Manager and the client representative.

- 5:00 PM: Before leaving, he quickly plans his inspections for the next day, ensuring he is prepared to witness the critical "golden weld" that will tie the new steam line into the existing system.

This example illustrates the dynamic nature of the role—a constant shift between deep technical analysis, hands-on fieldwork, and precise administrative duties, all with the unwavering goal of ensuring safety and quality.

Average Welding Inspector Salary: A Deep Dive

The salary for a welding inspector is not a single, static number but a dynamic range influenced by a host of factors we'll explore in the next section. However, by analyzing data from reputable sources, we can build a clear picture of the earning potential at various career stages.

It's important to distinguish between a general "inspector" and a Certified Welding Inspector (CWI). The CWI designation, awarded by the American Welding Society (AWS), is the industry's gold standard and has a significant positive impact on salary. The data below primarily reflects the earnings for certified professionals.

National Average Salary and Typical Range

Across the United States, the average base salary for a Certified Welding Inspector typically falls between $68,000 and $80,000 per year.

- Salary.com, as of November 2023, places the median salary for a Welding Inspector I at $62,683, but notes the range for a more experienced CWI (Welding Inspector III) climbs to a median of $95,339. The typical range for all inspectors on their platform spans from approximately $55,000 to $108,000.

- Payscale.com reports an average salary for a Certified Welding Inspector (CWI) of $71,154 per year, with a common range of $52,000 to $104,000.

- Glassdoor lists the estimated total pay for a Welding Inspector in the US at $75,565 per year, which includes a base salary of around $65,717 and additional pay like bonuses and profit sharing.

The key takeaway is that while a starting salary might be in the $55k-$60k range, a six-figure income is a very achievable goal for experienced and well-qualified inspectors.

### Salary Brackets by Experience Level

Experience is arguably the single most powerful driver of salary growth in this field. As inspectors gain exposure to more complex projects, codes, and NDT methods, their value to employers skyrockets.

| Experience Level | Typical Years of Experience | Typical Annual Salary Range (Base) | Key Characteristics & Responsibilities |

| :--- | :--- | :--- | :--- |

| Entry-Level Welding Inspector (CAWI or new CWI) | 0-3 years | $52,000 - $65,000 | Often holds an Associate CWI (CAWI) certification. Works under the supervision of a senior CWI. Focuses on visual inspection, basic documentation, and learning codes. |

| Mid-Career Certified Welding Inspector (CWI) | 3-10 years | $65,000 - $90,000 | Holds a full CWI certification. Works independently on standard projects (structural steel, manufacturing). May hold one or two additional NDT certifications (e.g., MT, PT). |

| Senior Certified Welding Inspector (SCWI) | 10+ years | $90,000 - $125,000+ | Often holds a Senior CWI (SCWI) certification. Manages teams of inspectors, develops inspection test plans (ITPs), and acts as the final authority on complex projects. Holds multiple advanced certifications (e.g., API, advanced UT). |

| Specialist/Consultant Inspector | 15+ years | $120,000 - $200,000+ | An expert in a specific, high-demand industry like nuclear, aerospace, or subsea welding. Often works on a contract basis, commanding high daily rates. May be involved in failure analysis and litigation support. |

*Note: These salary ranges are estimates and can vary significantly based on the other factors discussed below.*

### Deconstructing Your Compensation Package

A welding inspector's income is often more than just their base salary. The total compensation package can significantly increase your take-home pay, especially in field-based roles.

- Base Salary: The guaranteed annual pay you receive. This forms the foundation of your compensation.

- Overtime (OT): This is a huge factor. Many inspection jobs, especially on large construction projects, pipelines, or during plant shutdowns ("turnarounds"), require work beyond the standard 40-hour week. This work is typically paid at 1.5x the hourly rate (and sometimes 2x for Sundays or holidays), which can dramatically boost annual earnings. It's not uncommon for an inspector with a $70,000 base salary to earn over $100,000 in a year with significant overtime.

- Per Diem: For inspectors who travel, a per diem is a daily allowance to cover living expenses like meals, lodging, and incidentals. This is typically non-taxed income and can add a significant amount ($100-$150+ per day) to your earnings while on the road.

- Bonuses: Annual or project-based bonuses are common, especially in the private sector. These are often tied to project completion, safety performance, and company profitability.

- Profit Sharing: Some companies offer profit-sharing plans, where a portion of the company's profits is distributed among employees.

- Benefits: A strong benefits package is a key part of compensation. This includes health, dental, and vision insurance; a 401(k) retirement plan with employer matching; paid time off (PTO); and allowances for protective equipment (PPE) and professional development (e.g., paying for recertification fees).

When evaluating a job offer, it's crucial to look at the entire compensation package—a role with a slightly lower base salary but guaranteed overtime and a generous per diem could result in much higher overall earnings than a strictly 40-hour office-based role.

Key Factors That Influence a Welding Inspector's Salary

While the national averages provide a useful benchmark, your personal earning potential will be determined by a specific set of variables. Mastering these factors is the key to maximizing your income throughout your career. This section is the most critical part of understanding the real-world salary for a welding inspector.

### 1. Certifications: The Cornerstone of Your Value

In the world of welding inspection, certifications aren't just a suggestion—they are the primary determinant of your employability and salary. They are the objective proof of your knowledge and expertise.

- AWS Certified Welding Inspector (CWI): This is the single most important certification you can achieve. The CWI exam is a rigorous, three-part test covering welding fundamentals, practical hands-on inspection, and code book navigation. Simply obtaining your CWI can increase your salary potential by 20-40% compared to a non-certified inspector. Employers actively seek out CWIs, and many job postings list it as a mandatory requirement.

- AWS Senior Certified Welding Inspector (SCWI): For experienced CWIs (minimum 6 years post-CWI), the SCWI is the next level. It demonstrates a superior level of expertise in welding quality management, procedure development, and personnel supervision. SCWIs are qualified for leadership roles, and their salaries reflect this, often commanding $15,000 to $25,000 more per year than a CWI with similar experience.

- API Certifications (American Petroleum Institute): For inspectors in the oil and gas industry, API certifications are co-equal in importance to the CWI. Holding these in addition to a CWI can make you an extremely valuable and high-earning candidate. Key certifications include:

- API 510: Pressure Vessel Inspector

- API 570: Piping Inspector

- API 653: Above-Ground Storage Tank Inspector

An inspector holding a CWI plus two or three API certifications is often called a "combo inspector" and is in constant demand for pipeline and refinery work, where salaries are among the highest in the field.

- ASNT NDT Certifications (American Society for Nondestructive Testing): While a CWI focuses on the overall weld quality and code compliance, ASNT certifications validate your skill in specific NDT methods. An ASNT Level II certification in methods like UT, MT, PT, or RT is highly desirable. An ASNT Level III is the highest level, qualifying you to develop NDT procedures and train and certify other technicians. An inspector with a CWI and ASNT Level II/III certifications, particularly in advanced methods, is a top-tier earner.

- Specialized Certifications: Other valuable credentials include AWS Certified Welding Educator (CWE) for those interested in training, or certifications from other bodies like the International Code Council (ICC) for structural steel and bolting inspection.

### 2. Industry and Area of Specialization

Where you apply your inspection skills has a massive impact on your paycheck. Some industries pay a significant premium due to the critical nature of the work, the harsh environments, or the level of regulation.

| Industry/Specialization | Typical Salary Potential (Experienced CWI) | Why It Pays More/Less |

| :--- | :--- | :--- |

| Oil & Gas (Upstream/Midstream) | $95,000 - $150,000+ | High-risk, high-reward. Involves pipelines, offshore platforms, and refineries. Often requires extensive travel, long hours (high overtime), and work in harsh conditions. API certifications are essential. |

| Nuclear Power | $110,000 - $180,000+ | The highest-paying sector due to extreme safety and quality requirements. Requires extensive background checks, rigorous documentation, and specialized knowledge of nuclear codes (ASME NQA-1). |

| Aerospace & Defense | $90,000 - $140,000+ | Zero-failure tolerance for aircraft and military hardware. Requires expertise in exotic alloys and advanced welding processes. Work is precise and highly regulated. |

| Power Generation (Non-Nuclear) | $80,000 - $120,000 | Involves high-pressure/high-temperature piping and components in fossil fuel or renewable energy plants. Significant earning potential during plant shutdowns/turnarounds. |

| Heavy Structural (Bridges, Stadiums) | $70,000 - $100,000 | Critical public infrastructure projects with stringent code requirements (AWS D1.5 Bridge Welding Code). Often involves government contracts and union-scale wages. |

| Manufacturing & Fabrication | $65,000 - $90,000 | More stable, often shop-based work. Can range from heavy equipment manufacturing to custom job shops. Pay is generally more standard, with less overtime potential than field-based roles. |

### 3. Geographic Location

Your salary can fluctuate significantly depending on where you live and work. This variation is driven by industry concentration, cost of living, and regional demand for skilled inspectors.

Top-Paying States and Regions:

- Alaska & North Dakota: Driven by the oil and gas industry, these states often offer the highest wages to compensate for remote locations and harsh climates.

- Texas & Louisiana: The heart of the US petrochemical industry. Cities like Houston are hubs for inspection companies, and the sheer volume of pipeline, refinery, and offshore work creates high demand and competitive salaries.

- California & Washington: Strong presence of aerospace, defense, and high-tech manufacturing, along with major infrastructure projects, leads to high wages, though this is offset by a higher cost of living.

- Northeast (e.g., New York, New Jersey): Major infrastructure projects, pharmaceutical plant construction, and proximity to shipping ports drive demand.

Lower-Paying Regions:

- The Southeast (excluding the Gulf Coast): While there is manufacturing, the overall concentration of high-paying industries is lower, and the cost of living is generally less, leading to more modest average salaries.

- The Midwest (non-industrial areas): States with economies less focused on heavy industry or energy production will naturally have fewer high-paying inspection opportunities.

Here's a sample comparison based on aggregated data:

- Houston, TX: An experienced CWI might earn 15-25% above the national average.

- Bakersfield, CA: Strong oil and agricultural industry presence could push salaries 10-20% above average.

- A smaller city in the Midwest or Southeast: Salaries might be 5-15% below the national average, but the lower cost of living could make it financially attractive.

### 4. Years of Experience

As highlighted in the salary table, experience is a linear driver of income. But it's not just about time served; it's about the *quality* of that experience.

- 0-3 Years (The Foundation): Your primary goal is learning. You'll work under supervision, absorb as much knowledge about different codes and processes as possible, and focus on passing your CWI exam.

- 3-10 Years (The Professional): You are a trusted, independent inspector. You begin to specialize, take on more complex projects, and perhaps lead smaller inspection teams. This is where you'll see the most significant salary jumps.

- 10+ Years (The Expert): You are a leader and problem-solver. You are the go-to person for the toughest inspection challenges, procedure development, and client management. You may transition into roles like Quality Manager, Chief Inspector, or a highly-paid independent consultant. Your salary is now based less on market rates and more on the unique value and expertise you bring.

### 5. In-Demand Skills (Technical & Soft)

Beyond core certifications, specific skills can make you a more versatile and valuable inspector, directly impacting your salary.

High-Value Technical Skills:

- Advanced NDT: Proficiency in Phased Array Ultrasonic Testing (PAUT) and Time of Flight Diffraction (TOFD) is a massive differentiator. These advanced UT techniques are increasingly required for critical weld inspection, and technicians skilled in them are scarce and highly paid.

- Robotics & Automated Welding Inspection: As automation increases, inspectors who understand the process and can verify the quality of automated/robotic welds are becoming essential.

- Metallurgy and Failure Analysis: A deep understanding of why welds fail, how different materials behave, and the ability to conduct a root cause analysis makes you an invaluable asset, especially in consulting or senior roles.

- Code Mastery: Being a "code guru" in multiple, complex standards (e.g., being able to navigate AWS, API, and ASME codes with ease) sets you apart.

Crucial Soft Skills:

- Communication & Report Writing: Your ability to clearly and concisely communicate your findings, both verbally to site supervisors and in detailed written reports for clients and engineers, is paramount. Poor communication can lead to costly mistakes.

- Attention to Detail: This is the bedrock of inspection. A missed detail could be the difference between a safe structure and a catastrophic failure.

- Integrity and Professionalism: As an inspector, your word is your bond. You must have the fortitude to make unpopular calls (like rejecting a weld) based on codes and standards, even under pressure. This reputation for integrity is priceless.

### 6. Company Type and Size

The type of organization you work for also influences your compensation structure.

- Large Corporations (e.g., Oil Majors, EPC Firms): Tend to offer higher base salaries, excellent benefits, 401(k) matching, and structured career progression. The work is often stable.

- Third-Party Inspection Agencies: This is a very common career path. Your salary might be slightly lower than at a large corporation, but the opportunity for varied assignments, extensive travel, and massive overtime potential is high.

- Small Fabrication Shops: May offer lower base salaries but can provide a great learning environment and potentially more flexibility or profit-sharing incentives.

- Union Membership: In some regions, particularly for structural steel inspection, working as a union inspector can provide excellent wages, defined benefits (pensions), and strong job protections.

- Independent Contractor ("Pipeline Rider"): This offers the highest earning potential, with day rates ranging from $600 to over $1,000 per day plus per diem. However, you are responsible for your own insurance, taxes, retirement, and finding your next contract. This path is best for highly experienced and well-connected senior inspectors.

Job Outlook and Career Growth for Welding Inspectors

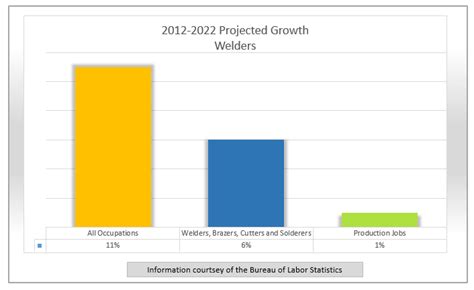

Investing time and money into a career path requires a clear understanding of its future viability. For welding inspectors, the outlook is robust, driven by fundamental needs of our society and evolving technological landscapes.

Job Growth Projections

The U.S. Bureau of Labor Statistics (BLS) groups welding inspectors under the broader category of "Inspectors, Testers, Sorters, Samplers, and Weighers." In its 2022-2032 projections, the BLS provides a stable outlook for this group. While the overall growth rate may seem modest, the specific demand for *skilled, certified welding inspectors* is expected to be