Introduction

In our interconnected world, have you ever stopped to think about the incredible journey a single product takes to reach your hands? From the raw materials harvested in a distant country to the complex manufacturing processes, the intricate shipping logistics, and the final placement on a store shelf or delivery to your doorstep—it's a symphony of precision and coordination. At the heart of this global orchestra is the Supply Chain Planner, the strategic mind ensuring every note is played on time and in tune. If you are a methodical thinker, a natural problem-solver, and someone who thrives on bringing order to chaos, a career as a Supply Chain Planner could be an incredibly rewarding and lucrative path.

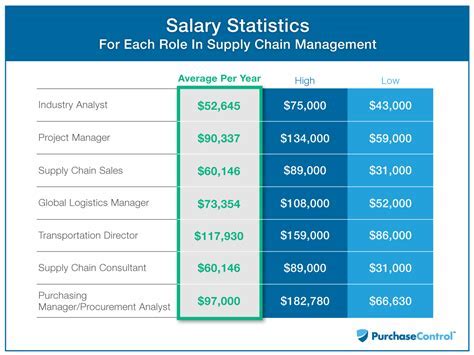

This role is more than just managing spreadsheets; it's about being the strategic backbone of a company's operations, directly impacting its profitability and customer satisfaction. The demand for skilled planners is high, and the financial rewards reflect that importance. A supply chain planner salary typically starts strong and offers a clear trajectory to a six-figure income for experienced professionals. The national median salary hovers around $77,000, with senior planners and managers often earning well over $100,000 per year.

I vividly remember the early days of the 2020 pandemic when store shelves were suddenly bare. It wasn't a failure of production but a shocking, real-time illustration of supply chain disruption. In that moment, the immense and often invisible importance of supply chain planners became crystal clear; they are the unsung heroes who keep the wheels of commerce turning, even in a crisis. This guide is designed to be your comprehensive roadmap, drawing on years of career analysis and industry data to illuminate the path to success and a top-tier salary in this vital profession.

---

### Table of Contents

- [What Does a Supply Chain Planner Do?](#what-they-do)

- [Average Supply Chain Planner Salary: A Deep Dive](#salary-deep-dive)

- [Key Factors That Influence Salary](#key-factors)

- [Job Outlook and Career Growth](#job-outlook)

- [How to Get Started in This Career](#get-started)

- [Conclusion](#conclusion)

---

What Does a Supply Chain Planner Do?

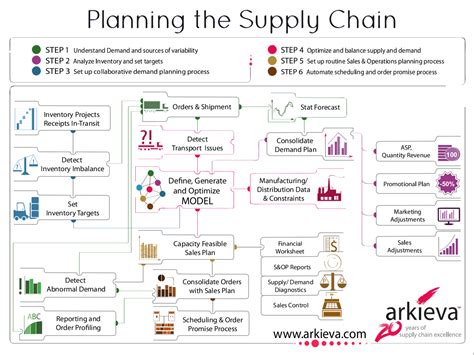

A Supply Chain Planner is the strategic coordinator responsible for ensuring a seamless and efficient flow of goods, from sourcing raw materials to delivering the final product to the customer. They are the analytical hub of the supply chain, using data to forecast future demand, manage inventory levels, and coordinate with various departments—including procurement, manufacturing, logistics, and sales—to meet that demand profitability. Think of them as the architects of a product's journey, designing a blueprint that balances cost, speed, and quality.

Their primary goal is to prevent the two most costly problems in business: stockouts (losing sales due to no inventory) and overstocking (tying up capital in excess inventory). This requires a delicate balance of analytical prowess, communication skills, and strategic foresight. They are constantly asking and answering critical questions:

- How much product will we need in the next quarter? The next year?

- Based on that forecast, how much raw material do we need to order and when?

- What is the most efficient production schedule to meet demand without creating bottlenecks?

- Where should we store our inventory to minimize shipping times and costs?

- How can we react to unexpected disruptions, like a delayed shipment or a sudden spike in customer orders?

Core Responsibilities and Daily Tasks:

- Demand Forecasting: Analyzing historical sales data, market trends, and seasonal influences to predict future customer demand.

- Inventory Management: Developing strategies to maintain optimal inventory levels, implementing systems like Just-In-Time (JIT) or safety stock policies.

- Supply Planning & Procurement: Collaborating with procurement teams to ensure a timely supply of raw materials and components from vendors.

- Production Scheduling: Working with manufacturing plants to create production plans that align with demand forecasts and material availability.

- Logistics Coordination: Liaising with warehousing and transportation teams to ensure products are stored and moved efficiently.

- Performance Analysis (KPIs): Tracking key performance indicators such as inventory turns, order fill rates, forecast accuracy, and on-time delivery to identify areas for improvement.

- Stakeholder Communication: Serving as the central point of communication between sales, marketing, finance, and operations to ensure everyone is aligned with the supply plan.

---

### A Day in the Life of a Supply Chain Planner

To make this more concrete, here's a glimpse into a typical day for a planner at a mid-sized consumer goods company:

- 9:00 AM: Arrive and review overnight sales data and inventory reports. Check for any critical alerts from the Enterprise Resource Planning (ERP) system, such as a potential stockout for a high-demand product.

- 10:00 AM: Attend the weekly Sales & Operations Planning (S&OP) meeting. Present the latest demand forecast and discuss upcoming promotions with the sales and marketing teams. Adjust the forecast based on their feedback.

- 11:30 AM: Analyze the impact of the revised forecast on inventory. Realize a key component from an overseas supplier needs to be expedited. Email the supplier and copy the logistics team to explore air freight options versus sea freight.

- 1:00 PM: Lunch break.

- 2:00 PM: Deep-dive into data analysis for the quarterly forecast review. Use advanced Excel functions and a data visualization tool like Tableau to identify trends that weren't immediately obvious.

- 3:30 PM: Conference call with the production scheduler at the manufacturing plant. Discuss the updated plan and confirm they have the capacity and materials to increase production for a product that's selling faster than expected.

- 4:30 PM: Respond to emails and update the master planning file with all the day's changes. Document the rationale behind the decision to expedite the component for future reference.

- 5:15 PM: Final check of critical inventory levels before heading home, feeling confident that the plan for tomorrow is solid.

This example illustrates the blend of analytical work, collaborative meetings, and proactive problem-solving that defines the role.

Average Supply Chain Planner Salary: A Deep Dive

The compensation for a Supply Chain Planner is competitive and reflects the critical nature of the role. While salaries can vary significantly based on the factors we'll explore in the next section, we can establish a strong baseline using data from trusted industry sources.

According to Salary.com, as of late 2023, the median salary for a Supply Chain Planner in the United States is $77,419. The typical range falls between $68,819 and $86,852. This represents the middle 50% of earners, meaning 25% earn less and 25% earn more.

Payscale.com reports a similar average base salary of $69,370, with a total pay range (including bonuses and profit sharing) spanning from $52,000 to $94,000 per year. Glassdoor, which aggregates user-reported data, shows an average total pay of $84,651, with a likely range between $68,000 and $106,000.

The slight variations in these numbers highlight the importance of considering multiple sources. However, the consistent theme is a robust salary with a strong potential for growth. An entry-level planner can expect to start in the $55,000 to $65,000 range, while a seasoned, senior-level planner at a major corporation can easily command a salary well into the six figures.

### Salary by Experience Level

Experience is arguably the most significant driver of salary growth in this field. As planners gain expertise, take on more complex responsibilities, and demonstrate a track record of cost savings and efficiency improvements, their value—and compensation—increases accordingly.

Here is a breakdown of typical salary expectations by career stage, compiled from Salary.com and Payscale data:

| Experience Level | Typical Title(s) | Years of Experience | Average Base Salary Range | Key Responsibilities |

| :--- | :--- | :--- | :--- | :--- |

| Entry-Level | Supply Chain Planner I, Planning Analyst, Junior Planner | 0-2 years | $58,000 - $70,000 | Data gathering, running reports, maintaining planning spreadsheets, supporting senior planners, tracking orders. |

| Mid-Career | Supply Chain Planner II, Supply Chain Planner | 3-6 years | $70,000 - $85,000 | Developing demand forecasts, managing inventory for specific product lines, coordinating with suppliers, identifying process improvements. |

| Experienced | Senior Supply Chain Planner, Lead Planner | 7-10 years | $85,000 - $105,000+ | Managing complex supply chains, leading S&OP meetings, mentoring junior planners, implementing new planning software/tools, managing high-value projects. |

| Managerial/Lead | Supply Chain Planning Manager, Director of Planning | 10+ years | $110,000 - $160,000+ | Overseeing the entire planning department, setting strategic direction, managing budgets, negotiating with key suppliers, reporting to executive leadership. |

### Beyond the Base Salary: A Look at Total Compensation

A Supply Chain Planner's earnings are not limited to their base salary. Total compensation is a critical part of the financial picture and often includes significant performance-based incentives.

- Annual Bonuses: This is a very common component. Bonuses are often tied to individual performance (e.g., forecast accuracy) and company performance (e.g., overall profitability). According to Payscale, annual bonuses for supply chain planners can range from $2,000 to $12,000 or more, often representing 5-15% of base salary.

- Profit Sharing: Some companies, particularly those with a strong employee-centric culture, offer profit sharing. This can add an additional $1,000 to $10,000 to annual earnings, directly linking the planner's success in managing costs to the company's bottom line.

- Commission: While less common for planners than for sales roles, some positions may include a commission structure tied to specific cost-saving initiatives or inventory reduction targets.

- Stock Options/RSUs: In publicly traded companies, particularly larger corporations or tech firms, stock options or Restricted Stock Units (RSUs) can be a significant part of the compensation package for more senior roles, offering long-term wealth-building potential.

- Comprehensive Benefits: Standard benefits significantly add to the total value of a job offer. These almost always include:

- Health, Dental, and Vision Insurance

- 401(k) or other retirement savings plans, often with a company match

- Paid Time Off (PTO), including vacation, sick leave, and holidays

- Life and Disability Insurance

- Tuition Reimbursement for further education or certifications, which is a particularly valuable benefit in this field.

When evaluating a job offer, it is crucial to look beyond the base salary and consider the entire compensation package to understand the full earning potential.

Key Factors That Influence a Supply Chain Planner Salary

While we've established a solid baseline, a planner's actual salary is a mosaic of several influencing factors. Understanding these variables is key to negotiating a better salary and strategically guiding your career for maximum earning potential. This is the most critical section for anyone looking to optimize their income in this field.

### ### Level of Education

Your educational background provides the foundational knowledge for a career in supply chain planning and is a primary filter for many employers.

- Bachelor’s Degree (The Standard): A bachelor's degree is the most common and generally required entry point. Degrees in Supply Chain Management or Logistics are the most direct path. However, degrees in Business Administration, Industrial Engineering, Finance, or Data Analytics are also highly valued. Having one of these relevant degrees typically qualifies you for entry-level salaries in the $60,000 - $70,000 range.

- Master’s Degree (The Accelerator): While not typically required for entry-level roles, a Master’s degree (e.g., an MS in Supply Chain Management or an MBA with a concentration in Operations/Supply Chain) can significantly accelerate your career and earning potential. It often allows you to enter at a higher level (Planner II or Senior Planner role) or fast-tracks you into management positions. Professionals with a master's degree can often command a salary premium of 10-20% over their bachelor's-only peers at the same experience level. It is particularly valuable for those aspiring to senior leadership roles like Director or VP of Supply Chain.

- Professional Certifications (The Booster): In the world of supply chain, professional certifications are highly respected and can directly translate to a higher salary. They validate your expertise and commitment to the profession. The most recognized certifications are offered by the Association for Supply Chain Management (ASCM), formerly APICS:

- Certified in Planning and Inventory Management (CPIM): This is the gold standard for planners. It demonstrates deep expertise in demand management, production planning, inventory control, and S&OP. Holding a CPIM can lead to a salary increase of 5-10% or more.

- Certified Supply Chain Professional (CSCP): This certification takes a broader, end-to-end view of the supply chain, from suppliers to end customers. It's excellent for those who want to move into roles that require coordinating across the entire supply chain.

- Certified in Logistics, Transportation and Distribution (CLTD): This focuses on the logistics side of the chain and is ideal for planners in roles with heavy transportation and warehousing elements.

Other valuable certifications include the SCPro™ from the Council of Supply Chain Management Professionals (CSCMP).

### ### Years of Experience

As highlighted in the salary table, experience is the most powerful lever for increasing your salary. The career path offers a clear and rewarding progression.

- 0-2 Years (The Foundation Stage): At this stage, you are learning the ropes. Your focus is on executing tasks, learning the company's systems (like their ERP), and proving your reliability. Your salary will be in the entry-level range, but your goal is to absorb as much knowledge as possible.

- 3-6 Years (The Contributor Stage): You've moved beyond basic tasks and are now an independent contributor. You own the forecast for a product line, manage supplier relationships, and begin to identify and suggest process improvements. This is where you see your first significant salary jumps, moving firmly into the $70,000 - $85,000 range as you prove your value.

- 7-10+ Years (The Expert & Leadership Stage): With significant experience, you become a subject matter expert. You handle the most complex products or business units, lead critical projects like implementing new software, and begin to mentor junior staff. You are a strategic partner to the business. Salaries here push past $90,000 and well into six figures. From this point, the path diverges into either a deep technical expert (Principal Planner) or a people leader (Planning Manager), both with very high earning potential.

### ### Geographic Location

Where you work matters—a lot. Salaries for supply chain planners vary dramatically based on the cost of living and the concentration of relevant industries (e.g., manufacturing, logistics hubs, major ports, corporate headquarters).

Here's a look at how location can impact salary, with data informed by BLS and salary aggregator reports on metropolitan areas:

High-Paying States and Metropolitan Areas:

- California: Particularly in areas like San Jose-Sunnyvale-Santa Clara (Silicon Valley) and the Los Angeles-Long Beach-Anaheim area. The combination of tech hardware companies, massive ports, and a high cost of living drives salaries up. Planners here can earn 15-25% above the national average.

- New Jersey: Situated in the heart of the Northeast corridor with major port facilities (Port Newark-Elizabeth), a massive pharmaceutical industry, and proximity to New York City, New Jersey is a top-paying state. Salaries are often 10-20% higher than the average.

- Texas: Major hubs like Houston (oil & gas, Port of Houston) and Dallas-Fort Worth (major distribution and corporate hub) offer strong salaries, often 5-15% above the national average, combined with a lower cost of living than the coastal states.

- Washington: The Seattle-Tacoma-Bellevue area, home to giants like Amazon and Boeing, has a high demand for skilled planners, pushing salaries above the national norm.

Average and Lower-Paying Areas:

- Salaries tend to be closer to or slightly below the national average in many parts of the Midwest and Southeast, outside of major metropolitan hubs like Chicago or Atlanta.

- Rural areas with less industrial or commercial activity will naturally offer lower salaries, but this is always offset by a significantly lower cost of living.

When considering a job, always use a cost-of-living calculator to understand the true value of a salary offer in a specific location. A $80,000 salary in Houston, TX might give you more disposable income than a $95,000 salary in San Jose, CA.

### ### Company Type & Size

The type of company you work for has a major influence on your compensation and work environment.

- Large Corporations (e.g., Fortune 500): Companies like Procter & Gamble, Johnson & Johnson, Apple, or General Motors typically offer the highest salaries and most comprehensive benefits packages. They have complex global supply chains, requiring sophisticated planning and top talent. The work is often more structured, with clearly defined roles and career paths. Expect salaries at the top end of the ranges discussed.

- Mid-Sized Companies: These companies offer a great balance. Salaries are still very competitive, often close to those at larger corporations. The work environment may offer more visibility and the opportunity to have a broader impact, as you might wear more hats than in a strictly siloed role at a giant firm.

- Startups & Small Businesses: Base salaries at startups may be lower than at established corporations. However, they can be offset by equity or stock options, which carry high potential rewards if the company succeeds. The work is often fast-paced and less structured, offering incredible learning experiences but potentially less job security and work-life balance.

- Third-Party Logistics (3PL) Providers: Companies like C.H. Robinson or DHL Supply Chain hire many planners. Salaries are competitive, and they offer fantastic experience working with a wide variety of clients and industries.

- Government & Non-Profit: Roles with government agencies (like the Department of Defense) or large non-profits (like humanitarian aid organizations) may offer lower base salaries than the private sector. However, they often compensate with exceptional job security, excellent benefits, and a strong sense of mission.

### ### Area of Specialization

Within the "Supply Chain Planner" title, there are various specializations. Developing expertise in a high-demand niche can significantly increase your value. The prompt asked about IT, marketing, and finance, which can be interpreted as how a planner's skills intersect with these functions.

- Demand Planner: This is a very common specialization. These planners work closely with sales and marketing to create the most accurate forecasts possible. A Demand Planner with strong statistical modeling skills and experience with advanced planning software (e.g., Kinaxis, Blue Yonder) is highly valuable.

- Supply Planner / Material Planner: This role focuses on the inbound side—ensuring raw materials and components are available to meet the production plan. A Supply Planner with strong negotiation skills and deep knowledge of global sourcing can save a company millions.

- Production Planner: This planner works on the factory floor, creating detailed production schedules to maximize efficiency and throughput. Expertise in lean manufacturing and Six Sigma principles is highly prized here.

- Planner with a Technical/IT Focus: This is a planner who is also a "power user" or subject matter expert for ERP systems (SAP, Oracle) or advanced planning systems. They might help with system implementation, create custom reports using SQL, or build dashboards in Tableau or Power BI. This blend of supply chain knowledge and technical skill is rare and commands a premium salary.

- Planner with a Finance Focus: This planner excels at the financial implications of supply chain decisions. They can build models to show the P&L impact of holding more inventory, the ROI of investing in a new warehouse, or the total landed cost of sourcing from different countries. This skill set makes them a vital partner to the finance department and positions them well for leadership roles.

### ### In-Demand Skills

Beyond your degree and certifications, specific, demonstrable skills on your resume can make you stand out and justify a higher salary.

High-Value Hard Skills:

- ERP/MRP Systems: Proficiency is non-negotiable. Experience with major platforms like SAP S/4HANA (specifically modules like PP, MM) or Oracle NetSuite is the most transferable and in-demand skill.

- Advanced Planning Systems (APS): Experience with specialized software like Kinaxis, o9 Solutions, Blue Yonder, or Logility shows you can handle complex, large-scale planning.

- Advanced Microsoft Excel: You must be an expert. This means being fluent in VLOOKUP/INDEX(MATCH), PivotTables, Solver, and potentially light VBA/macro scripting.

- Data Analysis & Visualization: The ability to query databases using SQL to pull your own data is a massive advantage. Being able to then visualize that data and present insights using tools like Tableau or Power BI can set you apart as a strategic analyst, not just a planner.

- Statistical Forecasting: A solid understanding of statistical models (e.g., moving averages, exponential smoothing, ARIMA) is crucial for demand planning roles.

Crucial Soft Skills:

- Communication & Collaboration: You are the hub of communication. You must be able to clearly explain complex data to non-analytical audiences (like sales) and confidently negotiate timelines with production and suppliers.

- Problem-Solving: Supply chains are inherently volatile. You must be able to think on your feet, analyze a disruption, and quickly formulate and present viable solutions.

- Analytical Mindset: You must be comfortable living in the data, finding the story behind the numbers, and using quantitative evidence to make decisions.

- Attention to Detail: A single error in a planning spreadsheet can cost a company thousands or even millions of dollars. Meticulousness is a core trait of a successful planner.

By actively developing these skills, you transform yourself from a standard candidate into a high-impact professional that companies will compete for.

Job Outlook and Career Growth

For those considering this career, the future is exceptionally bright. The role of a Supply Chain Planner is becoming more critical than ever, and the employment outlook reflects this growing importance.

The U.S. Bureau of Labor Statistics (BLS) groups Supply Chain Planners under the broader category of "Logisticians." The data for this group is highly encouraging. According to the BLS's Occupational Outlook Handbook, employment of logisticians is projected to grow 28 percent from 2021 to 2031, which is much faster than the average for all occupations.

This blistering pace of growth is expected to result in about 24,500 openings for logisticians each year, on average, over the decade. This high number of openings stems from both the creation of new jobs (growth) and the need to replace workers who transfer to different occupations or exit the labor force (e.g., retirement).

Why such strong growth? Several key trends are fueling the demand:

- Globalization and Complex Supply Chains: As companies continue to source materials and sell products globally, the complexity of managing these networks increases exponentially. This requires more skilled planners to manage the moving parts.

- The Rise of E-commerce: The explosion of e-commerce has completely changed customer expectations. Consumers now expect fast, cheap (or free), and reliable delivery. This puts immense pressure on companies to have highly sophisticated inventory placement and fulfillment strategies, all driven by expert planners.

- Focus on Resilience and Risk Management: The COVID-19 pandemic and other global disruptions (e.g., geopolitical conflicts, trade disputes) served as a massive wake-up call for corporations. They realized their lean, "just-in-time" supply chains were fragile. There is now a huge emphasis on building more resilient and agile supply chains, creating a high demand for strategic planners who can model risks and develop contingency plans.

- The Data Revolution: Companies are collecting more data than ever before. They need planners who can translate this mountain of data into actionable intelligence, using advanced analytics and technology to create more accurate forecasts and efficient plans.

### Emerging Trends and Future Challenges

To thrive in the coming decade, planners must be aware of the forces shaping their profession.

- Artificial Intelligence (AI) and Machine Learning (ML): AI is no longer a futuristic concept; it's here. AI-powered planning systems can analyze vast datasets to produce forecasts that are far more accurate than what a human can do alone. The planner of the future will not be replaced by AI, but rather will work alongside it. Their role will shift from *creating* the forecast to *managing, interpreting, and validating* the AI's output, and handling the strategic exceptions the AI can't.

- Sustainability and Green Supply Chains: There is growing pressure from consumers, investors, and regulators for companies to operate more sustainably. Supply chain planners will be at the forefront of this movement, tasked with designing networks that reduce carbon footprints, minimize waste, and ensure ethical sourcing. This involves analyzing factors like transportation modes, packaging materials, and supplier sustainability ratings.

- Digitization and an "Always-On" Supply Chain: The move towards fully digitized supply chains with real-time